Leaderboard

Popular Content

Showing content with the highest reputation on 10/31/2024 in all areas

-

They could only deny claim (in the US) if the use of the unapproved item (fuel in this case) is determined to be the cause of the failure. Now, we all know that the what's is determined to be causal in a court of law and what is actually causal in the real world are not necessarily the same thing. If you were running G100U in a new engine and the main bearings failed due to an oil blockage due to contaminants introduced during assembly or a defective oil pump, the use of G100UL would not be grounds for denying the warranty claim. They might try to make a case for it, but that's a heavy lift. I personally think this has become political and I am deeply disappointed by the public statements made by several manufacturers. If you dig deeper, you will see that none of the manufacturers give a specific definition of approved fuel. That is likely because manufacturers are not in the business of approval. They are in the business of seeking approval. However, the FAA is in the business of approval and they have approved G100UL for use in all certified, spark ignition recips, via STC. Much of what is said in the previously mentioned aircraft and engine manufacturer statements is just legal noise and has no teeth.3 points

-

Laughable? https://www.lycoming.com/publications/service-letter-no-270 Eliminating lead removes the barriers to modern synthetic oils. It will be a while before that happens, but it will. Doing away with the thick, toxic, grey film that accumulates on the belly is nearly to worth it. Being able to have my little ones help clean the belly would be worth it. I have been tested and I know that I have detectable lead levels in my system that are above average but still in the "safe range". In my youth I was careless with my handling of 100LL and aircraft parts that had been exposed to lead. I think the threat of lead to the general public from 100LL is way overstated. The real threat is to pilots, maintenance professionals and passengers that fail to take precautions or engage in risky behavior.3 points

-

I don't see a requirement for spectrographic analysis, just a visual inspection of the filter media for bronze particles.2 points

-

I was just teasing you a bit given my experience with the ingenuity of the people that populate the mountain states. I suppose I could’ve teased @Ibra about it, but it seemed more appropriate to aim at a fellow American…2 points

-

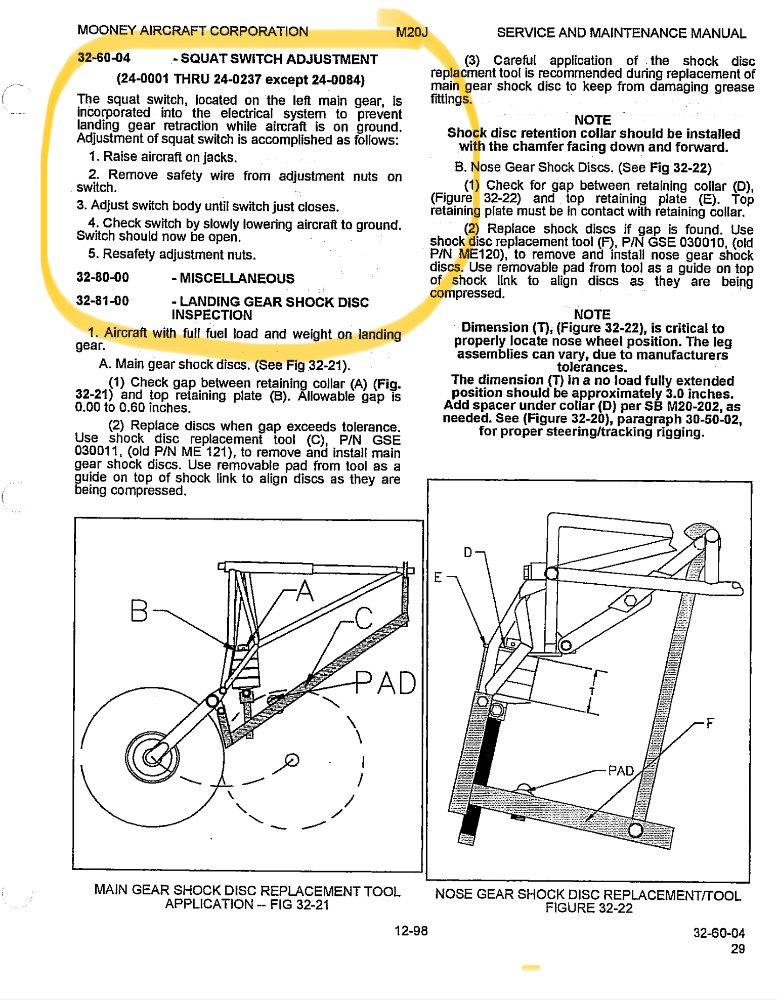

The symptoms as described do not make sense. 1. Only happens when cold 2. Motor stops before the gear is fully retracted but continues to draw current. 3. Gear CB does not trip 4. Fully retracts if gear is cycled. If it were a mechanical problem stalling the motor it should pop the breaker. When the motor stops running, it’s generally because power has been removed by a limit switch, relay or safety switch (squat or airspeed). Early M20Js have a squat switch on the left main gear. If the shock disks are good, I’d check the switch adjustment. If your airplane has a red override button next to the gear switch, you can press and hold that and if that causes the gear to retract fully it will confirm that the squat switch is the problem.2 points

-

It was finished yesterday late afternoon. I'm going test fly it this morning.2 points

-

The beta tester was just a joke, jeez. So as i have never had to purchase an STC how does one go about it. As for the other concerns i guess time will tell as real world conditions may not be the same as has been found with the limited conditions and hours accumulated by GAMI and the AOPA Beech twin. Also i have bladders and im not convinced the fuel isn’t detrimental to their health based on what happened to the beech twins tank. There was definitely an issue with the 94UL was that because of the lower octane or the lack of cushioning on the seats. Those were real concerns when the unleaded gas rolled out years ago to keep the catalytic converters on our autos from failing. Again I'm not trying to argue I'm just trying to get the truth and facts. We spend countless hours discussing all things related to the safe operation and maintenance of all aviation so please don't miss understand my concern. As for GAMI testing how many hours how many years compared to the millions that are flown in real life aviation. I wish I shared your confidence call me skeptical I’m ok with that.2 points

-

Yes, and the ones around the alternator. They need to be up into the wind, if they are down the wind just blows them open.2 points

-

I had around 200 hours on my 231 with no intercooler and no Merlyn Black Magic pressure control when I added the intercooler. I noticed immediately that temperature control was much easier. I added the Merlyn and got rid of the bootstrapping and got the higher critical altitude. In my opinion the addition of these along with a good EIS so you can see what’s going on makes the 231 much much easier to manage and improve your engine life significantly. The lower temperatures alone are justification enough in my opinion, but I am really serious about not hurting my engine.2 points

-

2 points

-

Just got this email notification: https://drs.faa.gov/browse/excelExternalWindow/FR-ADFRAWD-2024-25365-0000000000.0001?modalOpened=true Looks like mandatory oil sampling for metal (bronze) is required starting on 12/5/24 for nearly all Lycoming engines with the suspect bushing and shipped in a date range roughly from 1/30/2009 to 2/14/17. That's my read of it, others chime in if that's not accurate. Many of us probably aren't affected as that date range is well past when our engines were last apart! Pretty good news for Blackstone Labs, I would think1 point

-

@rturbett Take another look at my Lower 48 map! I finally got around to checking off UT on our way down to the PPP in Ft Worth (KAFW). Great overnight in Moab, UT just because it was someplace we wanted to stay.1 point

-

Shipping insurance baby! Don’t want to lose those coveted stickers and paperwork! (Being facetious just to be perfectly clear here)1 point

-

Not a lawyer... But I've been dealing with a few Trusts lately. Generally they are pretty straight forward, you may just need to read the Trust Document a couple of times. As for a lawyer... who created the Trust and how were you appointed? (Rhetorical question, don't give us the details in public.) But my point is, what's wrong with going to the attorney that created the Trust? Or was it done by the state?1 point

-

Good info thanks. Might gamble a bit on a used one and worst case, I'll have a cool paper weight.1 point

-

Try this link https://themooneyflyer.com/cfi.html I found a great MAPA instructor to get me current after a long layoff from flying1 point

-

Yes, licensing deals for developed technology is something I'm very familiar with. I'm also familiar with developers wanting to get paid up front, especially when it looks like their product may not be successful or gain sufficient market share to provide an ROI. BTDT, got a bunch of t-shirts. Business is hard.1 point

-

Yeah, it's not straightforward. My engine was originally built well outside the covered date ranges, but got an IRAN in 2015. I looked up the IRAN record and none of the affected parts were on the part list, and there was no indication that the bushings were touched. Seems like an NA to me.1 point

-

It's mostly an issue with engine or airframe manufacturer warranty or liability: a manufacturer may refuse engine or tank warranty if I use some fuel that is not recomanded or approved by them even if such fuel is legal from FAA point of view. For aircraft insurance, I expect to get paid after crash with an engine failure using G100UL as it's legal under STC. The product warranty/liability and the flight legallity/safety don't have to overlap. My understanding, I can't sue Lycoming for warranty or damage (real or imagined) from G100UL, in the same way that I can't sue them for my flying past TBO as I purposefully ignore their recomandation for overhaul, however, I do expect my insurance to pay if I ever crash dead stick with an engine past TBO... Take the example of uncertified or homebuilt (experimental) they can fly using G100UL without having to loop anyone in their business and they are well insured as reflected in their premiums, however, they should not ask engine manufacturers for liability or warranty, they tend to buy engines "as is" and operate "at own risk"1 point

-

1 point

-

If the positions were swapped and we were being forced to switch from G100UL to 100LL right now, the whole pilot community would be up in arms, not even counting the TEL's health effects. Lead fowling in plugs? 100LL is a non-starter! 100LL's performance per volume? 100LL is a non-starter! Can't use modern oils? 100LL is a non-starter! Sure, G100UL isn't perfect and by switching we are trading some flaws for other flaws. (I don't want my paint stained!) But overall I think G100UL is a better solution than continuing to use 100LL. Mostly because of the perception of the health effects of the TEL in airplane exhaust. And we are unlikely to ever have as much data on G100UL as we do on 100LL in terms of engine performance and longevity. Piston powered aviation has passed its peak; even if we magically switched everybody to G100UL now, there will never be as much avgas burned in the future as there has already been burned. Unless someone can state a specific testing metric and threshold that would be sufficient that we have not met, and why the current testing is insufficient, I am not going believe any arguments that 'more testing' or 'more time' is needed. I think this is just resistance to any change. https://thelogicofscience.com/2016/06/20/the-nirvana-fallacy-an-imperfect-solution-is-often-better-than-no-solution/1 point

-

Just got off the phone with George and, you are correct regarding the revenue from licensing, but he says that revenue will amount to a few pennies per gallon over a very long time, while the revenue from the STC recoups some of their 10- or 12-year investment up front. Not sure what you mean by "necessary". Everyone who provides a product or service wants to get paid.1 point

-

You'll notice that I was quoting @Ibra when I mentioned the homemade tanker. According to his profile, he's from a small (and beautiful) backwater country in Europe that I visit on occasion. Maybe that is how they refer to small tanker trucks across the pond.1 point

-

I think the lingering questions are not whether the STC covers everything, but whether it is actually a sufficient drop-in substitute. That won't be known until there is an awful lot more field data.1 point

-

They have a patent on the fuel, so it cannot be produced without a license from GAMI. STCs shouldn't be necessary to recoup their investment if the fuel is successful.1 point

-

To answer your question, yes, spar cap issues are not unusual for Mooneys that have been in salt air or other corrosive environments. It can be repaired, but whether it makes economic sense to do so or to find a replacement wing may depend on some details. I agree that the pics aren't great, and having somebody competent inspect it may be able to determine what is happening there. Can't tell much from the pic, but often a bulge like that is a bad sign.1 point

-

Yep still no BasicMed for Canada. Another lesser-known requirement is that Canada requires your N-registered airplane to equip a 406 MHz ELT. (It isn't fully mandatory for their own airplanes yet but technically any foreign aircraft needs it)1 point

-

The rear baffle looks good. AS has been mentioned the bottom ones in front don't. Can you get a picture of the underneath of the engine to see what the bottom metal intercylinder baffles look like? I see that they are there by the retainers and hooks at the top of the engine. But the "springs" that hold them together and hold them tight might need some tweaking. This is fixable. A lot of airplanes get worked on by well-meaning people that don't know all of the eccentricities of every engine and airframe they are working on. The Bravo has a lot of things specific just to this airplane. I second the idea of getting Brian Kendrick involved (brian@mooneysupport.net). I would type up everything you know in an e-mail and include pictures and let him think about it. If anyone can find the answer it's him. If you end up having him look at it and need transportation I can help.1 point

-

Mine hangs from the tubes just above the pilots right leg, above the gear cove. I have a 64, so that is open. It made it very convenient for alignment.1 point

-

I used a drill and the provided pads for all but the final step. I used a variable speed buffer for that step. They came out great. I was able to get the yellow out completely. They looked new from 5’ away. There were a few spider cracks around the screws they I glued but couldn’t hide. The ice light was a little harder bc it was recessed lower than the skins and I didn’t want to damage the finish on the lip of the painted skin so I taped and did that by hand. That one wasn’t as clear, but I got the yellow out and you couldn’t tell because the light refractor is directly below the lens.1 point

-

there is more than one thing going on, call Brian Kendrick in San Marco TX, 830 370 1190 he tends to figure things out that nobody else does, TIT probe may be burnt and read low, fuel flow transducer may read high, unlikely though that both are off at the same time, the upper deck air lines blow air into the turbo injectors, helps atomizing fuel, cant figure how lack of that air would cause high CHTs, fuel would have to blow back and leak out somewhere1 point

-

just an FYI, for the future, money has nothing to do with your inability to find an avionic shop to repair your instrument. The fact is, only an instrument repair station that has capabilities for your instrument can overhaul it. that won’t be an Avionics shop. There are many instrument repair stations around the country. Sent from my iPhone using Tapatalk1 point

-

Because it is not just the operation. If you have CAT II and CAT III in your ops specs it cascades to a whole other set of ops specs. For instance monthly autopilots checks that have to be accomplished during maintenance routines. Monthly avionics calibration checks, the airplane has to accomplish a real auto land every 30 days which means you have to track that and get your crews to do it, or you have to remove the airplane from CAT II/CAT III status until you accomplish an extended autopilot check. You have to expand your training footprint and create the simulator time on each PC to demonstrate the approaches for each and every pilot. It is not just having CAT II and CATIII capability and "use it when you need it" like having an ILS receiver in your airplane. It is a whole eco system from maintenance to training to dispatch and it is costly. An airline has to decide if the cost is worth it. SWA ultimately added it for competitive reasons. Hard to explain why every one is landing and you can't.1 point

-

I replaced mine. Great Lakes Aero made them for Mooney. They are polycarbonate (aka Lexan), not acrylic. Polycarbonate is softer and more impact and crack resistant but I find it harder to work with than acrylic. Because it is soft, it doesn't polish out as well as acrylic, but you cannot hurt anything by trying. I trimmed mine and it was a lot of work. If I were to do it again, I'd send the originals to Great Lakes and have them trim and drill them. If you drill them yourself, a step drill works best. I deleted the trim piece on mine as the later models. If you do this, drill the holes oversize and use countersink washers. No need to countersink the plastic.1 point

-

I disassembled, cleaned, lubed and reassembled mine about 15 years ago. Running like a top ever since. The adhesive on the still pliable electric tape around the motor was as sticky as new. All of the bearings were stamped made in W. Germany. It just needed to be cleaned and lubed. Brushes were hardly worn. Truly impressive build quality. They do make LED bulbs that fit your beacon. https://www.aircraftspruce.com/catalog/pnpages/13-22438.php?gad_source=1&gbraid=0AAAAADkVbL9HTtCK_TFm97Ps8cGBphzZp&gclid=EAIaIQobChMI9Z6Eo6e3iQMV3WBHAR1oXQXGEAQYBCABEgLNH_D_BwE1 point

-

hmm, you have low TIT and lots of fuel flow, the Bravo engine is very sensitive to baffle leaks, as Lance said check the metal baffles between cylinders, maybe some are missing, also check mag timing for excessive advance1 point

-

@joepilotmooney this may be a 6 month solution for your year in FL.1 point

-

I expect it is stopping on a worn spot and needs some service inside. Mine was sent to George's Electric or something close to that in CA all those years ago, but I believe they're long-gone now. If it happened to me today, I'd start with a local electric motor shop and cash to get my homemade fan motor repaired.1 point

-

Something isn't right (obviously). The motor is on if the unsafe lamp is on, and doesn't turn off until the gear is fully up. If the gear has jammed and prevented the motor from running the gear all the way up, one would expect the breaker to pop. If the breaker doesn't pop, I suspect the brushes in the motor may be getting tired and need to be replaced, or there is a potential wiring issue that is limiting the current.1 point

-

That was what they said was the problem; the longer reach on the YD servo especially, and yes it is the control cables.1 point

-

There are few market forces at work with regard to 100LL other than demand, it's mostly regulatory forces. Innospec is currently the only TEL producer in the world. If multiple refineries are able to license G100UL, then buy and blend from readily available ingredients, it should make for a more competitive market, not less.1 point

-

Actually G100UL opens up the possibility of MORE competition. GAMI does not make and sell fuel. They license the formula and right to make it. Since there is no handling of TEL, ANY refinery can make G100UL. Heck, you would get a license and a big blending tank and make it yourself. No need for dedicated blending and piping. No dedicated trucks. AVGAS already has a higher profit margin than MOGAS, so other refineries are likely to start making it.1 point

-

Wonder how much it costs to tanker the fuel from Louisiana to San Jose? Wag: .25 gallon And don't forget to add the $1 per gallon surcharge to the first 500 gallons to amortize the STC. The notion that unleaded fuel will be result in substantial savings on engine maintenance is laughable.1 point

-

The dam has burst. There is a lawsuit settlement between some eco groups and the FBO's in CA that says they have to sell unleaded when it is "commercially available". Until now the FBO Association has said that is not the case, but with the RHV delivery that will be a hard sell in a motion before a judge. G100UL will be rolling into CA literally by the truck loads. Once CA rolls, the whole obstruction program to G100UL aka "EAGLE" will collapse quickly or they will suddenly discover their leading candidate fuel "works just fine" Hang onto to your hat, the roller coaster just hit the apex.1 point

-

Because I value my time as well. Most of my flying recently has been purpose driven. Flying two to three days a week means I don’t need an excuse to get the plane out. I am not making a special trip for $50, nor would I add a stop to an existing trip for $50. I like my local FBO and I want to do business with them. I enjoy having local services available. I had to delay my trip to NC a few Saturdays back because of a leaking line to the fuel pressure gauge. I had a new line fabricated with my old fittings (local shop), installed (by me) and signed off by an IA at the FBO before 11:00am Monday morning for <$200 total. I was able to do that because I support and have relationships with the service providers on my field. Shopping all over hell and half acre to save $50 is not a big concern. I might feel differently in my retirement, but that is quite a ways off.1 point

-

Say what? I gave several examples of MUCH cheaper fuel in the Bay Area! Including one $1.24 per gallon less only 16 miles from RHV! I can't imagine why?? I have no issue flying to a nearby airport to save $50 (40 gals X $1.25); I see no reason to waste money.1 point

-

I don't buy fuel based on what the average price is! And, why would I care if Tracy is rural when the fuel is much cheaper? Less than 20 miles away it's $5.75 at PAO, or $5.49 at MRY. Fly 50 miles to O15 and it's only $4.95. In my world, $6.99 is pretty damn far from 'very competitive!' I hope they don't sell a drop of G100UL at that price. Heck, let's test how many years they can store the stuff1 point

-

You can buy one today! It is called a TBM 900. The M is for Mooney. I’ve never flown one, but I hear they are a fantastic airplane. If you did a full design study, you would end up very close to one of the three planes you mentioned.1 point

-

From what I understand, Paul Maxwell handles the avionics end of the business. Lynn Mace an A&P/IA, who used to own a Mooney Service Center himself, oversees the shop. Don Maxwell owns the business. I'm sure no shop is perfect, and no shop finds every squawk, but comparing how Jewell handled overhauls and closed down, to Maxwell Aviation who does a couple hundred Mooney annuals a year and helps many people calling for advice, free of charge, is not a fair comparison.1 point

-

yes to all, run system once a month 5-10 min, cycle all pumps, use sponge and small container with TKS fluid on dry or slow spots, squeeze the TKS fluid into the dry or slow spots to wet the intermediate membrane, tail gets much more flow per foot than wing, needs more since nose radius sharper, once it stops dripping on the hangar floor it is time to re-prime, biggest lesson learnt in 6 years of use, the system really works reliably in moderate icing conditions, lots of FBOs, however don't carry the fluid, can't be shipped air, most surprising even FBOs in Juneau AK and Fairbanks AK did not carry fluid, it pays to call ahead and when in doubt carry a jug in the trunk which also helps to wipe off frost from airplane parked outside, take belly panel off once in a while, clean up splattered fluid inside and figure a way so seal the belly panel with CS tank sealant, put on fuselage contact surfaces and put plenty of release wax on the belly panel so you can get it off again, when using system run stop watch, float in storage tank sticks sometimes, with a FIKI system leave yourself a way out, 1000 ft ceiling may be a good limit, don't use speed brakes when TKS system was used, one or both may not retract, stay away from anything that is forecast to be more than moderate icing, watch pireps continuously when in flight, draw yourself a clear line when to get out, I have seen icing in clouds at temps as low as -25 C, when in doubt below freezing the only safe spot is above or below cloud, the system is designed to allow safe passage of moderate icing layers which are typically 2000-3000 ft thick and thus take 5-6 min to pass, the system does that very well, study the AFM supplement, expect the unexpected1 point