Leaderboard

Popular Content

Showing content with the highest reputation on 03/27/2024 in all areas

-

A low(ish) pattern, overshooting final, heavyweight, unexpected return, new owner, distraction from wind/noise… there are lots of things stacked against them. None of them should be fatal by themselves or even together, but they do increase the risk.3 points

-

Long delay update again. Sold the K in fall of 2019. Was going to hold off on buying a new one until summer of 2020, or later, then this thing called COVID happened. 3 months in to lock down, my wife we need our own airplane so we can travel during lock down. Well, when your wife say buy an airplane, you do one thing, right away. Took a few months but I found an Ovation I like, Serial number 0002, the first production model. Nice upgrades and fantastic, over the top new paint job. Paint job was documented on Mooneyspace, Prebuy found few things. Seller was in a hurry since he already bought a new plane so we worked it out. Timing was perfect. Airplane prices had been dropping and interest rates were dropping at the same time. Closed the deal June 2020. Coming up on 4 years, love the Ovation, love the newer everything. Annuals have been good. In hindsight, could I have gone a different route? I am wondering if I would have been better off doing the overhaul, and a full glass upgrade in the K. The cost of that would be about the difference between price of the runout K and the R I have. I know I would be upside down on the K but I would have had the plane I built for me. Anyway, love the Ovation. Comfortable, fast, quiet.2 points

-

Yup, both tanks were looked at and had some preventive sealing applied. I’m using Scheme Designers to help in developing a good layout. I should have something from them in three weeks or so.2 points

-

While the pursuit of useful load is a worthy pursuit, I see people going nuts on some things. During an "upgrade", taking out a working stormscope or strike finder to save a few pounds makes no sense to me when they are so useful if you read up on how to use them.2 points

-

(Of course you have the riveted clamp - if you look through your logs it was mandatory that the older clamps had to be replaced somewhere around 20 years ago.) Mooney says you get two documented retorques on the riveted clamp. These retorques should be logged. The part of the AD that does apply is that if you haven't exceeded the number of retorques, rather than replacing it by time in service only, it can be inspected by an IA. But only the riveted version can be used on a Bravo not the spot-welded version.2 points

-

My 2000 bravo has the riveted v band clamp does this mean the AD doesn’t apply? alan2 points

-

Not that this possibly-a-transient guy would know this, but until very recently (gone now but as recently as a couple years ago?) the TPA at SGJ was published as 800. It was definitely 800 when I did my PPL there in 2007 and it was the outlier that I used to point my students to. Guess the FAA finally changed it. Anyway, if he was a local, this wouldn’t necessarily be uncommon.2 points

-

Angelos and Paul. i have you down for a set each, as soon as I can get them done. I have just moved from one residence to another, and am absolutely snowed under for a while.2 points

-

2 points

-

Received word from my MX shop that they will fit me in prior to paint. All worked out after all. Thanks to all replies2 points

-

I guess it’s been too cold for someone to start the yearly picture thread? I flew today just to get the airplane moving again after a week of really cold temps. Yes, it’s-15C at start, but the engine and cabin were both preheated all night and were above 50f! Interestingly, it was -21C at 2500’agl, but only-14C at 10,000’!1 point

-

Guess I'm a certified CB! When my massives started to look football shaped (still ran great LOP, no fouling) I just replaced them with new Champion massives. I just couldn't justify that kind of cost difference to myself without some hard evidence; ads/marketing stuff/SGOTIs not sufficient1 point

-

I had my right eye done in January... just before my medical! Need 8500-7 form signed by ophthalmologist and bring to your AME exam. Should have done it years earlier but I could no longer pass the eye exam so I really didn't have any choice. Literally 30 minutes after the surgery I could see distance perfectly; like when I was 20! Couldn't be happier. I went with the the single focus IOL for distance.1 point

-

@Danb I had my right eye done a couple of years ago. I chose a multifocal implant and have had great success with it. Minor halos at night, but less annoying than the halos from the cataract. I chose to prioritize intermediate and far vision and that has worked out great in the cockpit. I keep a pair of glasses available but I haven't needed them yet. I did need a laser treatment to clear up some minor cloudiness about 9 months after the surgery but it was a non-event. Monovision implants will allow you to fly as soon as your ophthalmologist says you're good to go. Multifocal implants require a 3 month waiting period before you fly. Your brain needs to adjust, as Hank has described. Your post about being legally blind in one eye just popped up. That raises the risk bar, but the odds are still well in your favor. Trust your ophthalmologist to advise you on the risk/benefit analysis to determine your best course of action. That being said, I have been amazed at the capability of new technology and the relative ease of the out-patient procedure. You have my best wishes for a great outcome should you decide to proceed. Cheers, Rick1 point

-

They have supply chain issues resolved, and anticipate restarting production in 10 weeks. However, they have a 4 million can backlog. Anticipate a significant delay in fulfilling backlog. However, apparently some allocation remains available on the startup order if you order direct from the company. Sold by the case. They don’t charge your credit card until order is fulfilled.1 point

-

Luckily it occurred during landing I was already trim up, when I taxi back I generally neutralize my trim well it wouldn’t work, but the trim wheel did. The brackets holding the servos on are weak, my avionics guy works on bigger planes jets and turbo props his other encounter with an Acclaim was the roll servo also came loose, once he got home he said self any chance a different one worked loose his hunch paid off. Obviously a weak point in the system. I’ve had numerous scary encounters with auto pilot runaway trim or worse but with an STEC a/p. Gotta stay on top of the game. D1 point

-

1 point

-

Found it! https://www.amazon.com/PLASTIC-Cleaner-Protectant-Polish-13OZ/dp/B00HRXN6KE/ref=sr_1_22?adgrpid=1224856287810592&dib=eyJ2IjoiMSJ9.OcahK8l_9k6kgKU31Mm8raY_VPNIhHHle-RwAqqdcx1GavidI6Lg99CSENI0O8MKhCBD4MVj5kCg2sfaJNoLVBvOb2mP94DZ7n4z3Sjw6X3UUAec-46VipLSQilw4XkTCparCcg0HS7GKc0YIPP7caEZZmODA_nMsMuuvGQsf7yMYIQIB6HSXITv_AdMRozZjeSO7y_Dz46e69HJUBL3y4WC93pRba5tmGHKeJBGpih9UsvJe9zEBYzkGq_yOSawQCUW5dRO9JbxyeNVQACd4-MP9u7auTwcTIYeXg7o6C8.btLBCmSC-_yGqXXNTiCax-nXe04Lj6Eav7c7fVKEKxk&dib_tag=se&hvadid=76553685304290&hvbmt=be&hvdev=c&hvlocphy=90161&hvnetw=s&hvqmt=e&hvtargid=kwd-76553777653471%3Aloc-190&hydadcr=4994_13299750&keywords=plexus&qid=1711556005&sr=8-221 point

-

All of those sound like fun next birds I'm moving to the first ... turbine six seater in the form of a Jetprop.1 point

-

Yea, indeed. I did and he was very helpful. It'll be a field approval based on the STC they have for a Baron. My plane had had a wx900 between 1992 and 2015. I wonder why they removed it...1 point

-

Thanks @carusoam! @FlyLateNLife no damage history and logbooks and more photos here: https://drive.google.com/drive/folders/1OJZvbe9V0Zwhi_SLVaAmQ87F7wOYUflU?usp=drive_link Send me a PM if you're interested1 point

-

That hose that runs from your oil fill tube back to your air/oil separator needs to be replaced (left arrow below). It was once a yellow material like the one you see next to it (right arrow), but the oil "sludge" that fills up that hose affects the pressure in your cylinders and "cokes" them up which causes the compressions to go low. The Tygon (yellow) hoses should really be inspected and cleaned (and I feel replaced) every 100 hours. It's very inexpensive. The black Gates brand hose that runs from the bottom of the air/oil separator down to the pilot's side tailpipe gets clogged also and needs to be replaced or cleaned every 100 hours (https://www.mooney.com/wp-content/uploads/2020/12/SBM20-312.pdf). If the Acclaim has been maintained by someone that knows Acclaims these items will have been done regularly.1 point

-

It was definitely cleaned up and waxed when I visited to look at it. That said, the paint is original and in great shape! The leading edge might be accentuated by the TKS strips. Indeed, the engine arrangement, baffles, plumbing, etc, is very elegant. It's a lot of power and design packed into a small place. Kind of reminds me of the funny Lightning McQueen quote from cars, "I'm a precision instrument of speed and aerodynamics" which is later misquoted by his rusty old truck friend.1 point

-

1 point

-

Looks like Pencil CAD to me! Definitely a straight edge (I uses to carryna small 30-60-90 triangle in my shirt pocket) and either a compass or circle template. But it looks much better than a completely freehand sketch.1 point

-

The Same cylinder is used on the G engine as the N engine on the TSIO-550 on the Acclaim (TSIO-550-G1 and then after the heater modification it became a -G3) https://www.airpowerinc.com/658815A31 point

-

1 point

-

Somebody was looking for one yesterday… or parts of one…? see if I can find the link… -a-1 point

-

1 point

-

Angelos, Remember what does come before paint…. Any tank stripping / reseal should be considered before painting… The other thing…. We always love to critique choices of colors and layout designs around here…. Please post pics! Good luck with getting this all completed! Best regards, -a-1 point

-

1 point

-

1 point

-

1 point

-

That is not correct. The one that was all over youtube was at cruise speed and is the only one I'm aware of that departed the aircraft. Many here have reported one coming open on the t/o roll or after t/o with a normal landing to follow. From the overhead shots of this wreck, the baggage door appears to be open and attached to the plane, and the overhead shots appear to be taken before any first responders were on the scene. -dan1 point

-

Hey David I this past weekend lost my pitch trim servo, figuring I have a 3-5000 expense, I got lucky my avionics man found a loose pin on the servo plus the other pin was missing unbelievable he found the pin in the back belly of the Acclaim. He said it’s his second Mooney that had this issue, changed the captan pins good to go. At his mercy he could have said it was a bad servo and nailed me for a major repair. So many things can go wrong or occur gotta be diligent luckily I lost it landing at home airport. D1 point

-

I believe George Perry has some Hi-Rez photos of his plane that he posted on here in flight. It’s exactly as it does on the ground. If it’s low sitting in the chocks, it’s low in cruise.1 point

-

Gevertex, If you decided to get the set from Niko, let me know, and I will take "make visors" off my list of things that need to get done soon. Incidentally, the visors are pretty sturdy, and having a used set should not present any problems. The shades might get scratched some in use, but they are replaceable.1 point

-

Never thought I’d learn so much about the handling qualities of shopping carts on MooneySpace!1 point

-

@skydvrboy, no idea what his tester uses as Pass / Fail criteria, but I've always heard 5000 ohms. A simple multimeter with two probes will show you the actual resistance, then you decide if it's too high. No need for a fancy tester with lights and what not, especially if you don't know how it works.1 point

-

Yep, that's exactly what happened with my bird - so you get some extra UL above what's published if your TKS tank isn't full. Or 881 lbs. with full TKS.1 point

-

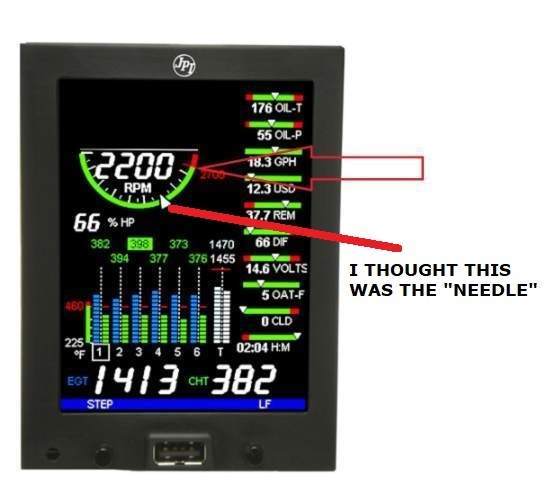

I think you are chasing your tail. First, you have a new engine, go fly it hard for a while, only concern is not to let the temps go over 400. Then check which cylinder might have a different probe location, just so you know. Then go learn all about the Gami 'spread'. Once you understand which cylinder peaks first, 2nd, 3rd, 4th and how the EGT's and CHT's follow one another (or not) you will start to understand why one cylinder is hotter than the rest. Is more likely unbalanced fuel and air rather than cooling and baffles. And then cylinders are just different, both in manufacture, location on the engine, baffling, airflow etc. I don't think you have an unreasonable spread at all. Aerodon1 point

-

I thought this was an auction for oxygen equipment and was wondering why it was so expensive.1 point

-

1 point

-

First, I have a custom car shop I have worked with building the seats to my specs. So, I can’t elaborate on specific upholstery techniques. I also did not have the time to learn all the trades required in that project. I wanted it finished by the time my new engine arrived and there was a long list of other items on the airplane that needed attention. There are a lot of details involved in the interior. I encourage you to source a local vendor as I did unless you have a lot of time on your hands. Also, taking the interior out is at least half a day and there is a bit of technique involved. Getting it back in will be a bit longer I believe. Because of the limited space inside the airplanes any seats that are reupholstered need to be copies of the seats that were removed more or less. The leather was cut using the existing ultra suede covers as a pattern. Existing foam was used where it was still good, replaced if bad and augmented with new where we wanted it stiffer or fuller. I used burn certified leather. I used the 3 layer memory foam, and “back saver” foam from Aircraft Spruce. I’m sure there are plenty of other types. It had good reviews and is already burn certified so that was good enough for me. I took advantage of the rebuild to clean, paint and lubricate the seat as well. Doing the interior yourself is totally doable and you learn a lot about your airplane as well. I highly recommend hiring out the seats and anything else that you are recovering. If you are just doing the seat foam and reusing the covers you will have to research foam types and use trial and error to get it right. It sounds like some time invested would be required but I think that is doable on your own. If you want me to quote your seats for you message me. Hope that helps.1 point

-

Sorry to hear, hope somebody makes some clamps soon, since the exhaust crack is a potentially serious issue, could you post a pic?1 point

-

I'm in the same boat (crack found in the exhaust so the v-band clamp had to come off and it already has had two re-torques) and I, along with the shop doing my annual right now, have come up empty on finding them without a crazy ridiculous lead time that renders my airplane a very expensive paperweight for much longer than it should. I'll be following if anyone comes up with anything!1 point

-

1 point

-

It's definitely time, those were made two months after man landed on the moon. They would buy those in Canada to use for hockey pucks.1 point

-

I installed a WX-1000 unit in my plane, I found it to be worth it. The unit cost 1000$ and it was about 400$ in cables and parts, I rented the crimper tools from Valentine. You could skip the bench test and install it, rteplace defective parts is cheaper than repairs or testing.1 point