-

Posts

1,264 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 47U

-

Wiring and interior: sheet metal edge protection material

47U replied to lithium366's topic in Vintage Mooneys (pre-J models)

Nice job recognizing the potential for chafing. In a pinch, I’ve removed the cushion from an adel clamp and cut it to fit the offending sheet metal edge. RTV may work as a suitable adhesive, or Gorilla glue works pretty good (GG works on the ‘wire grommet’ material stuff, too). -

I’m the A&P and boy, has MS been a great source of information. I have a long-time relationship with an IA that I keep informed of what I’m planning as far as repairs and mx outside the norm. It’s the same trust that needs to be built between an owner and their A&P/IA. You take care of them and they’ll take care of you. The key is, no secrets, no surprises.

-

I would advocate reviewing the FAA records CD as part of a pre-purchase inspection. You never know what might be hiding there. When I reviewed the FAA records on my airplane (a couple years after purchase), I discovered a 337 documenting repairs made after a gear-up that happened in the fall of 1963 when the airplane was only 6 months out of the factory. There was no reference to the gear up in the airframe log book, nor was the 337 with the mx records. Surprise, surprise. The other thing I discovered was in the late 1960s, a 337 is referenced in the airframe log book for a propellor change. This was before propellor logbooks were the standard. The entry stated i.e., “Changed prop, see 337” with a date and signature. That 337 was NOT included in the FAA records. The blades on that prop failed spec during overhaul in the mid 1990s, so the prop was replaced with a McCauley 3-blade. But, I sure wish I had the missing 337. Who’s to say there is not other repair information on it, possibly connected to why the prop was replaced? I suspect another gear up, or perhaps a porpoise incident, and the engine logbook supports that hypothesis. I bought the airplane from my Dad in 2008. He bought it in 1973. Is a missing 337 from the 1960s a big deal some 50+ years later? I guess I’ll find out when I sell her, hopefully another 10 or 15 years down the road.

-

Help Troubleshooting Fluctuating Fuel Pressure

47U replied to Ragsf15e's topic in General Mooney Talk

Is it both fuel pressure and fuel flow that are fluctuating? Certainly check that all the fittings are tight and hard-lines inspected for corrosion and damage. How old are your fuel hoses? The fuel system in my C is nothing like your F, but I had fluctuating fuel pressure and fuel flow. In troubleshooting, I discovered the -6 hose on the inlet side of the engine driven fuel pump had failed internally. It was sucking air, but had no evidence of external leakage. The way I found it, I placed the tank selector in “OFF”, then disconnected the hose coming off the engine driven fuel pump and put a couple inches of vacuum on the system. It leaked down immediately and wouldn’t hold the vacuum. Working backwards through the system, I discovered the inlet hose to the fuel pump had failed internally. I’m not sure if this is a sound troubleshooting technique… someone will chime in, I’m sure. Be sure to use a hand-actuated vacuum pump from the local HF or auto parts store. You don’t want to run fuel fumes through an electric vacuum pump, just say’n. -

This thread goes waaaaaay back, but might be an option for you. @hammdo now owns the aircraft. I think someone else was able to fit the Mitchell gauges into the same panel space as the original Garwin cluster And this, also from waaaaaay back… (pasted in rich text format to make it readable.) tablor Basic Member 38 Location: 1T8 Reg #: 3484X Model: M20E Posted August 11, 2010 Ok, I found it. It's Aircraft Instrument Support Services (AISS) in Georgetown, TX. His name is Ralph Posey and if you call him he can give you an idea of the cost based on the instrument that needs to be repaired.

-

I think I need a breaker/switch...

47U replied to Nukemzzz's topic in Vintage Mooneys (pre-J models)

That’s a good start, checking the breaker. What’s the amp rating on the strobe? Dig back through your airframe logbook(s) and the the entry that installed the strobe should include the make and model number. Looks like a Whelen. The entry might even include what switch/breaker was installed to control it. There must be a reason they didn’t use the beacon switch/breaker on the new strobe, though. The switches do wear out, especially the higher amp ones. Or, did your Mooney originally have top and bottom rotating beacons, hence the new strobe got its own switch? -

STC for Brake Caliper Reversal on M20E

47U replied to N9240M's topic in Vintage Mooneys (pre-J models)

-

I’d say that’s a GREAT looking E model! But, admittedly, I’m partial to military influence… really nice work.

-

Try pushing the Johnson bar forward, towards the panel, as you squeeze the button with your thumb. That may help overcome some of the preload tension which holds the gear linkage over-center.

-

Crankcase Breather Tube Position for a ‘66 E

47U replied to Yourpilotincommand's topic in Vintage Mooneys (pre-J models)

Found this thread on a Bing search… -

-

Question #1 needs a fourth response… “I landed and closed it.” The top latch on my cabin door has let go shortly after rotation on rare occurrence, but I’ve never been able to get it secured in flight. Slipping, window open, vents closed, whatever. Never successful. So I stay in the pattern, land, close the door (with purposefulness) and depart again. The baggage door hasn’t been a problem. There’s an egress strap affixed on the hatrack side of the baggage door (out of the reach of back seat pax), in the unfortunate occasion I should need to pop the hatch on the ground. Therefore, I do not lock the baggage door.

-

Bob, LASAR is only 20nm NE of F72. They moved their mx to Rancho Murietta (RIU) a few years ago. Or, do you already have access to an A&P and just need the travel boards?

-

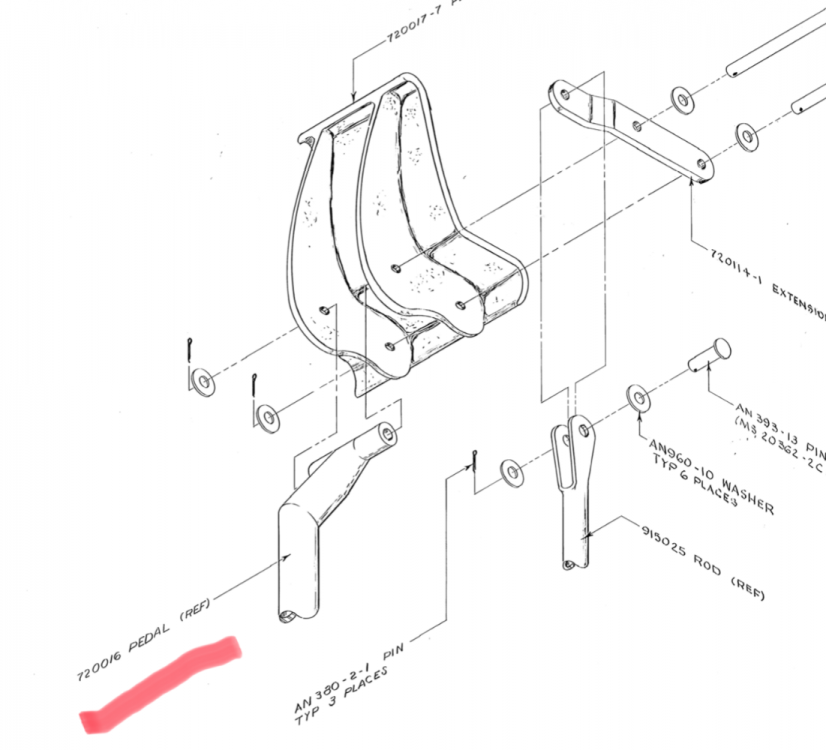

So Mooney moved the pivot point of the rudder pedal to the rear hole, where the brake rod was attached, then made an extension to attached the brake rod further aft. Is that right? And all rudder pedals are the same pn? I think I should have stayed out of this. All I wanted to do was reorient the picture. (Sorry, Boomer!)

-

I’m sorry to have added to your confusion… someone smart will be along, I’m sure. (In fact they showed up while I was typing.) Anyway, after looking again at Skip’s attachment, when Mooney incorporated the 1.5” extension to production aircraft, they changed the design of the rudder pedal(?). I always thought that extended rudder pedals had the extension hardware bolted to the rudder pedals, and that all rudder pedals were the same part number. What year/model is your Mooney? Do you have an IPB? Do the rudder pedal pn’s match the 1.5” extended rudder pedals pn in Skip’s attachment?

-

Correct, no extension. The 720016 part number is attached directly to the rudder pedal. At least that’s how I see it. I flipped your photo to the same orientation as Skip’s attachment.

-

-

7615 washer for plastic interior window trim

47U replied to cirrostratus's topic in Vintage Mooneys (pre-J models)

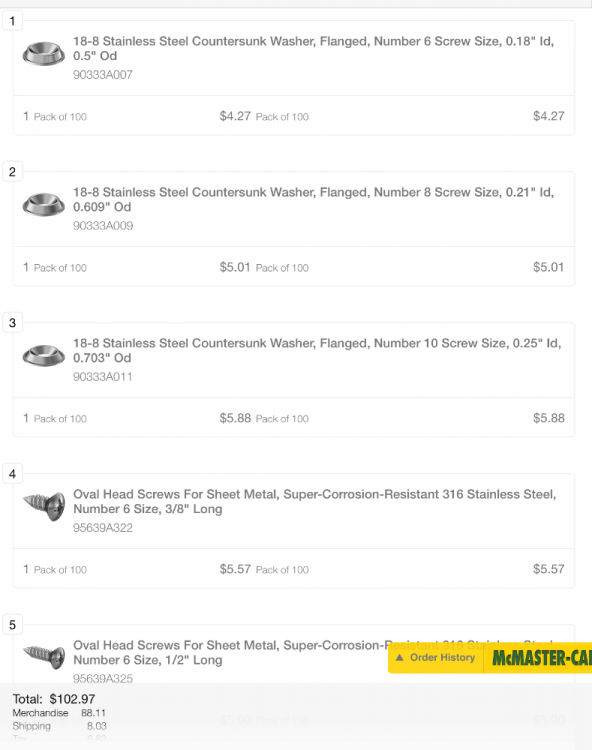

McMaster Carr has everything you need… but I went with the ‘hat’ style trim washer, which spreads out the load. If you don’t mind that it looks different. -

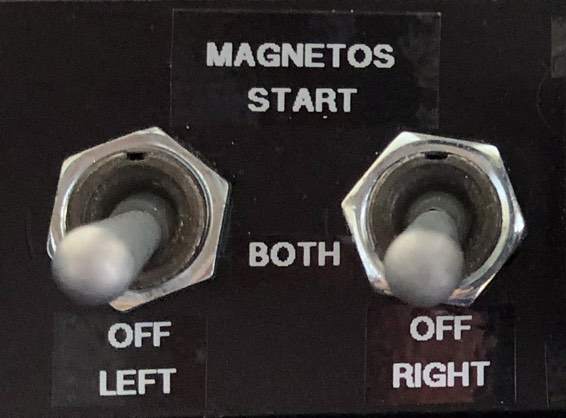

Benefit is that with the Surefly, there’s a greater chance of after-fire when doing mag checks with the traditional key switch. The Electro Air comes with an STC, so there’s also a 337 to be filled out. If you’re an aspiring CB, a couple MS toggle switches (spring loaded, DPDT) will do the same thing as the Elector Air switches. I adapted a schematic from an RV’er I found online and did it as a minor mod. Talk to your A&P/IA and see what they think.

-

I think PilotCoyote is on the right track… you have a lack of signal issue. Besides the distance not displayed, you’re also missing the groundspeed and time to station as well? The displays will go bad in time, but for both of your units to fail the same would be a long shot. Is the wire to the audio panel in place so you can listen to the station identifier? While you’re inspecting the condition of the BNC connectors, what condition is the coax?

-

-

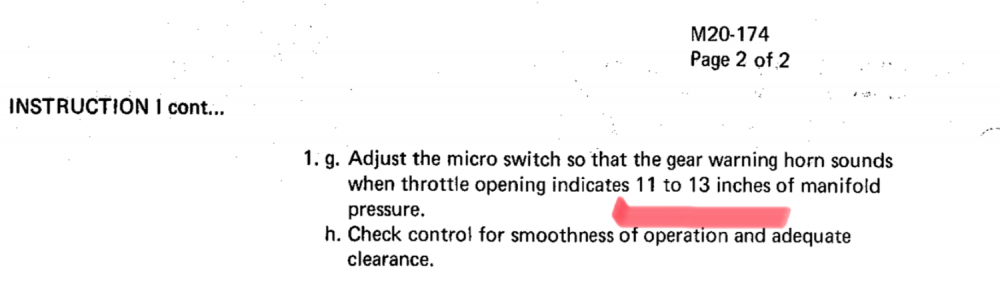

Throttle setting for gear warning

47U replied to Dream to fly's topic in Vintage Mooneys (pre-J models)

There was a SB to replace the engine controls, SB M20-174, which says 11 to 13 inches manifold pressure. I’ve seen reference in a different SB to adjust it at 3/8” from idle cutoff. If you like it at 14” no one will be the wiser. Fly on! -

I would add that if you have a vintage Mooney like mine from the early ‘60s where the CBs are of the ‘reset only’ design, it would be a good idea to upgrade. I was adding a terminal and when tightening it the housing (Bakelite?) shattered. I replaced them all with the Klixons. If you still have these, you’re due for an upgrade.

-

Service Bulletin M20-208B Never Completed

47U replied to gsoyka's topic in Vintage Mooneys (pre-J models)

It’s possible the rear spar is not cracked (M20-217). There’s a ‘64D/C that I know of that isn’t cracked. I didn’t think mine was cracked, until I pumped the flaps all the way down putting pressure on the rear spar. The crack appeared. Sabremech cut an access panel in the baggage floor and was able to install the beef up plate with out removing the baggage floor. His skills are way above average though, in my opinion. Good luck with your search.