-

Posts

1,264 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 47U

-

Hydraulic Flaps Won't Hold Pressure and Stay Down

47U replied to buckfever06's topic in Vintage Mooneys (pre-J models)

I’d suspect the retract cable needs cleaning and lubrication. Pull the belly panel and make sure the flap retract lever inputs sufficient travel to the arm on the flap pump. -

I suspect you’ve already done these things so my apologies in advance… You’re sure it’s the hose flare to the elbow fitting and not the elbow fitting pipe thread to oil cooler that’s leaking? Otherwise, a close inspection of the flare, perhaps with a magnifying glass, should be done. And proper torque (270-350 lb inches for a -08). Over torque can warp the fitting and induce a leak. And over torque of the pipe thread can crack the oil cooler case, too. Good luck.

-

What about Dan? Will parts remain in Lakeport?

-

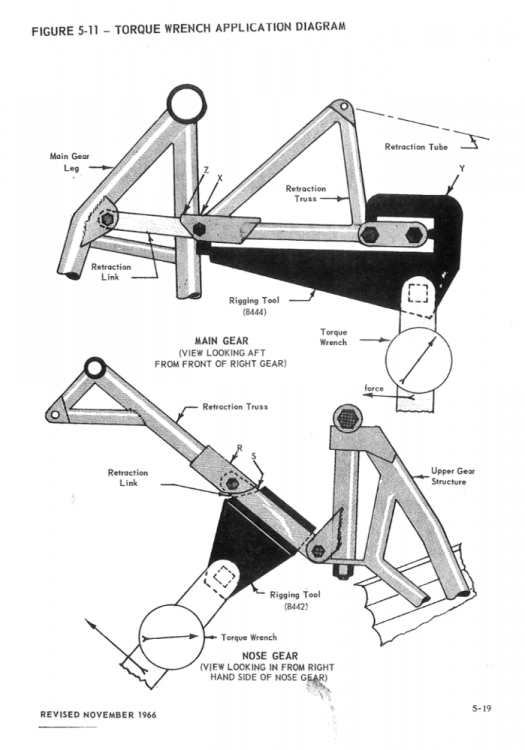

Like Boomer, I still have questions. Torque wrench extensions change to length between the handle of the torque wrench and the socket. An extension installed at 90 degrees to the handle doesn’t change the distance, so no adjustment is necessary. Whether the torque wrench is in the gear tool inline with, at 45, or 90, the distance from the handle to the socket (where the torque is input to the landing gear tool) is unchanged. The mx manual shows a picture of the torque wrench orientation in-use, which differs depending on the version of manual you’re using. The narrative(s) for setting gear preload do not address torque wrench orientation. If torque wrench orientation were critical, wouldn’t the mx manual be specific so the mechanic gets it correct? Is it relevant that the mx manual specifies using ‘a 10” nominal length torque wrench’? The illustrations show a dial-type torque wrench. I’d think it’d be problematic using anything else. Lastly, is the difference in torque readings with different torque wrench orientations (that PC refers to in his post) be due to the generally awkward nature of the activity, exacerbated by changing the orientation of the torque wrench? I have to take several readings before deciding what torque setting I’m going to call it.

-

Interesting. My MLG tool has the 45 degree offset. Using that, am I setting the torque on the high end? My first annual, my main gear torque settings were on the low side, out of spec. Is that the reason why? The figure below shows the torque wrench orientation what I would describe as perpendicular (90 degrees)… not inline. Am I confused? Is it morning?

-

Certainly the Bruce’s cover would be the Gold standard. I have a Bruces’ canopy cover and it’s great. For the tail, my solution (in comparison to Bruce’s) is crude. But, I think it’s effective enough for those RONs where I’m parked out on the ramp. Do you know anyone who can sew? I patterned it out (to fit my short rudder) in blue tape and brown paper grocery sacks, albeit with trial and error, but I think the end result is effective enough to discourage bird’s nesting. I used some Sunbrella material from an old patio umbrella. Bonus, it matches my spinner, cowl inlet, and pitot tube covers.

-

Hence my query. The light doesn’t look like it has a ‘press-to-test’ function. So, hopefully, FB Boomer is able to find the documentation on the system. Given the (visible) age of the detectors, I might try putting a heat gun on each detector and see if it will close the circuit. Perhaps if the documentation is found it will provide guidance for continued air worthiness.

-

I’m curious if the “TEST” switch checks the light only? Or does it test the continuity of the detectors themselves?

-

I’ll try my Lock and Lube next summer. To release the zerk, unscrew the end of the grease fitting from its body and the pawls will get loose. Yeah, it’s a pain to do it that way, but it keeps from breaking the zerks.

-

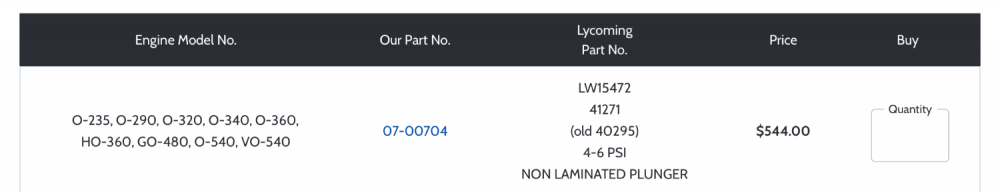

PN 40295 is an old number. See excerpt from the AS website. LW-15472 is the correct Lyc pn for the O-360-A1D fuel pump. I verified it in the Lyc parts catalog, PC-106. I had trouble getting the AN flared fittings orientation right without under/over torquing. You might need to install them before the pump is installed because of clearance issues with the prop governor. Be sure to use the proper thread lube. The straight-thread adapter fittings (2 each, Lyc pn 75505) that screw into the pump should also get new o-rings, pn MS29512-6. How old are your fuel hoses? The inlet hose can suck air with no evidence of an external leak. This might be a good time to swap them out. This isn’t necessarily a fun job, at least when the engine is installed. Pulling the battery box was essential, at least for me. If the pump arm isn’t installed correctly under the actuating rod in the engine, internal engine damage can occur. Good luck.

-

If you have an engine monitor, does it have individual limits you can set to alert you when you’ve hit the target MP? Either an annunciator light on the panel or an audible alarm in the headset, or both? EI sells a voice annunciator box that connects to their engine monitors, and some others if it drives a horn or a light when the preset value is exceeded.

-

Here?

-

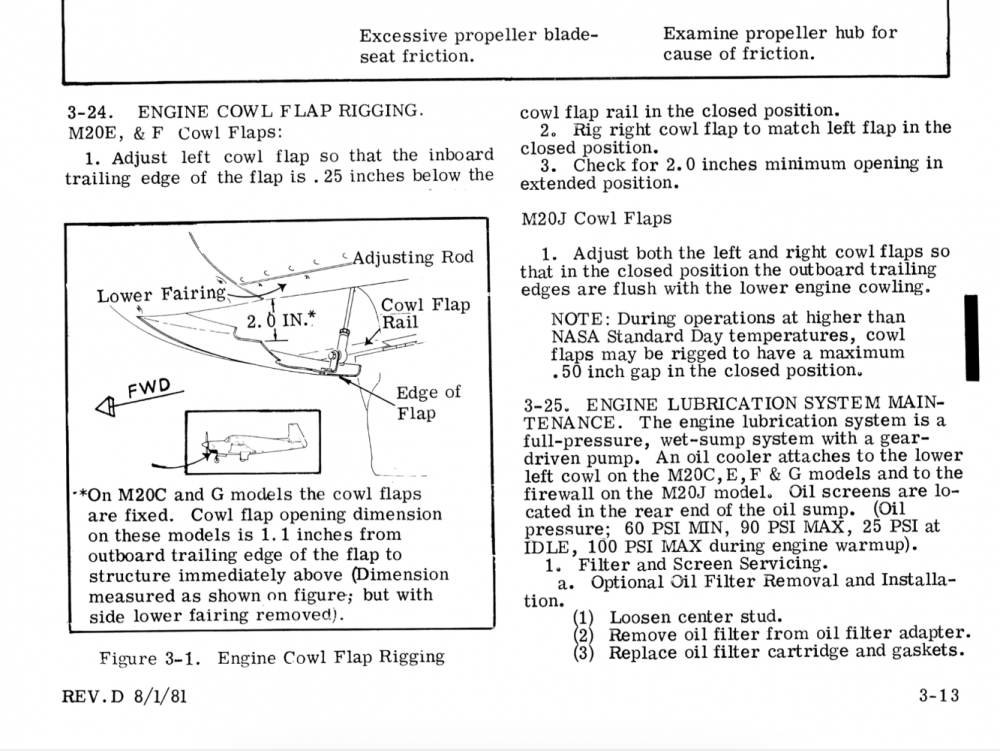

You are correct. My redline is also 500F. I have an annunciator on my panel set for 400, and start taking steps to cool down if it illuminates. To complete these mods, what are you using for approved data? I don’t see an issue with the battery relocation, but the oil cooler relocation is more problematic (in my mind). Isn’t the oil cooler mod only applicable to the IO-360 engines? Does the ‘68C have a doghouse? If so, you’d have to convert to an open-top baffle system? (Showing my lack of knowledge on model year evolution…) Changing to adjustable cowl flaps might not help you because the ‘open’ position is the same 1.1” measurement that the fixed cowl flaps uses. When I got my C, the cowl flaps were adjusted to be open a lot wider than that, way outside the mx manual spec. Maybe a wild thought… remove the left cowl flap altogether, go test fly, and see it the #4 CHT improves. If it does improve, perhaps the oil cooler plenum could be ducted to a set of louvers in the cheek cowl… like a intercooler setup? (Just brainstorming here…) That could probably be done as a minor mod, with concurrence of your A&P/IA, of course.

-

How terrible is it? CHT redline on my ‘63C is 450. In the climb I try to keep CHTs below 400 (as advised by Mike Busch, since revised to 410 I think I read). #4 cylinder is also my hottest. I reduce my climb rate and get the speed up to 120-130 to keep CHTs under control. I have a friend with a G that runs 20-30 degrees hotter (chrome cylinders) than I do in the climb. He just lives with it. Have you looked at your inter-cylinder baffles between (underneath) #2 and #4? Baffle tie-rods are in place? If your exhaust system is stock, I’m not sure if an exhaust plenum on the oil cooler will fit without interference with the #2 exhaust stack. Do you have a PowerFlow installed? More power, more heat? Are your cowl flaps adjusted per the book?

-

https://www.controller.com/parts/search?PartNumber=RG-35 AXC&SearchType=Start @jghyde Good luck…

-

I think that the wing tanks Al designed were removable from the wood wing (which was a work of art all by itself). In all fairness, integral fuel tanks were the standard when Mooney adopted the all-metal wing and is still the standard today. The fuel sealant the military used had a formulation change back in the mid ‘90s and became much more reliable. I’m guessing that the experience level of the person stripping/sealing/resealing integral tanks is the major variable as to the longevity of the repair. Even so, if someone desires bladders, that’s their choice. If you need more range, converting to bladders can get you the total fuel on board presumably quicker than the integral option. Keep in mind however, wings with bladders installed should have a corrosion inspection at some interval, depending on your location and hangar status. Until the Monroy STC is available again, I’d think Griggs would generate some sales by designing a hybrid system by adding their bladders to the wing bays adjacent to, and plumbed into, the integral fuel tanks. If your sealant is in good shape, you can keep the factory design and gain additional fuel by installing bladders with only a partial weight penalty as opposed to going with a complete bladder installation. As I soldier on with my 48 gallons total fuel onboard.

-

Help Troubleshooting Fluctuating Fuel Pressure

47U replied to Ragsf15e's topic in General Mooney Talk

In the IPB, I counted 12 threaded fittings between the selector valve and the engine driven fuel pump inlet. Lot’s of opportunity to suck air. I think you said your FP fluctuations started in the middle of a flight? How old is the hose from the firewall to the engine driven fuel pump? Stratoflex PN 111F417-6S-0184 (18.5” long). With age and vibration, a hose under suction can fail internally and never leak externally. From the firewall backwards to the tank selector valve the fuel system appears to be all hard lines. I would think less prone to leaking, unless there’s hidden chaffing or corrosion on a section of tube. -

-

Crew chiefs are “Knuckle-draggers.” Avionics techs are “Grinners.” If you maintain sensors (contractor or otherwise), you’re a “Super-grinner.” As told to me by an A-10 crew chief.

-

lasar/ mcfarlane throttle cable rigging

47U replied to jamesm's topic in Vintage Mooneys (pre-J models)

See archive screen shot below… thanks -a-! I replaced my MP aluminum line from the firewall to the gauge after the line was broken during some panel work. I didn’t notice any weep hole… maybe the line was not original. I guess I need to order me up a .023” drill bit. My question is, what affect does the weep hole have on MP gauge reading? Is insignificant? Or, is calibration of the MP pressure gauge compensated for a small amount of air entering through the weep hole, therefore slightly lowering the MP reading at the gauge. If the gauge is in fact compensated, and I’m setting MP without the weep hole, aren’t I indicating a higher MP than I would be if I had the weep hole, i.e., I’m running less power than I think I am as indicated on the MP gauge? No wonder I’m slower than my Mooney friends… -

lasar/ mcfarlane throttle cable rigging

47U replied to jamesm's topic in Vintage Mooneys (pre-J models)

Precision Hose Technologies makes -2 hose assemblies. https://www.aircrafthose.com/ Aircraft Spruce sells -2 AN hose fittings and hose. Your A&P/IA might be willing to make a hose up for you. You should research to find out if the calibrated weep hole -a- references is applicable to your model/serial number. -

25 hrs, and four(ish) months. My typical flight is less than 2 hrs. If I’m on a long cross country, I’ll extend the hours until I get home. I cut the filter and pull the sump screen every time. I had an engine shop tell me that even more important is to get a paint filter (that goes over the top of your pail) from Home Depot and screen the oil as it drains. I also use a clean pail and inspect the bottom for shiny stuff after I dump the oil into my haz waste transport can.