-

Posts

1,265 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 47U

-

Can you connect the lead for the SureFly to the battery terminal on your master switch relay? That works great on my C, and doesn't mucky up the battery leads with extraneous terminals. The master switch relay should always be hot, regardless of which battery you have selected for the flight (shouldn't it?).

- 82 replies

-

- 1

-

-

- ovation

- 24v system

-

(and 2 more)

Tagged with:

-

TruTrak Autopilot Pre Order's / Status Update

47U replied to Jeev's topic in Avionics/Panel Discussion

Was that the movie about the radioactive ants? Sorry, I’ve got The Deadly Mantis blocking my memory. -

I’m happy with mine. I replaced the left mag on my ‘63C, which was way past the 500 hr IRAN. Shower of sparks is history. I still need to get the dual-spline drive gear because the closest I could get was about 1.5 degrees ATDC. But, it starts and runs great. I didn’t have any unusual CHT issues before, and don’t have any now. Depending which mag you replace, consider replacing the Bendix mag switch with the STC’d rocker switch panel. There is a lag when switching from R through L to Both during mag checks, and if you’re not quick enough, expect a bang because the SureFly takes a millisecond to energize. More pronounced if you do inflight mag checks. My mag switch was shot anyway, and I didn’t have panel room for the rocker switch faceplate, so I put in a couple of mil-spec toggle switches in that dead space above the radio stack and that solved all my problems, for a fraction of the STC’d rocker switch option. I adopted (with minor changes) a schematic I got from the RV community. There’s several production aircraft that use toggle switches for the mags. After discussion with my IA I did a minor mod with a logbook entry. Other than I don’t have a ‘key’ anymore, I don’t see a downside.

-

Starter On With Master. Safety Hazard.

47U replied to ltdriser's topic in Vintage Mooneys (pre-J models)

In a previous life I was a crew chief/flight mechanic on a C-135. We were a pax hauler and based at Offutt AFB. I cannot tell you how many times I had to ‘translate’ discrepancies that the pilots had written into the aircraft forms into mx-speak post mission at the debrief table. -

Starter On With Master. Safety Hazard.

47U replied to ltdriser's topic in Vintage Mooneys (pre-J models)

I also noticed the prop twitched when letting off the key push. My old Bendix switch wouldn’t engage the starter if the key was turned all the way to the right and then pushed in. I had to sometimes turn the key slightly back to the left, while still pushed in, and then the contacts connected and the starter engaged. -

-

Thank you for making me think about this... if I understand, the theory is that there is enough fluid in the supply line to the flap pump, in excess of the volume required to fully extend the actuator. The upward-turned 45 degree fitting on the reservoir port to the flap system increases the amount of hydraulic fluid available to the flap pump. The supply line acts as its own reservoir to the flap system. Do I (finally) understand? (Picture credit to PilotCoyote...)

-

And a potential hydraulic leak in the brake system could prevent the flaps from working. Brake master cylinders, parking brake valve, plumbing/hoses, and calipers.

-

Have you checked the fluid level in the reservoir?

-

I pasted the letter into a .pdf and put it in the Engines folder in the downloads page. It’s fuzzy, but readable. We should have an airframe mx section in the downloads, along with the engines section.

-

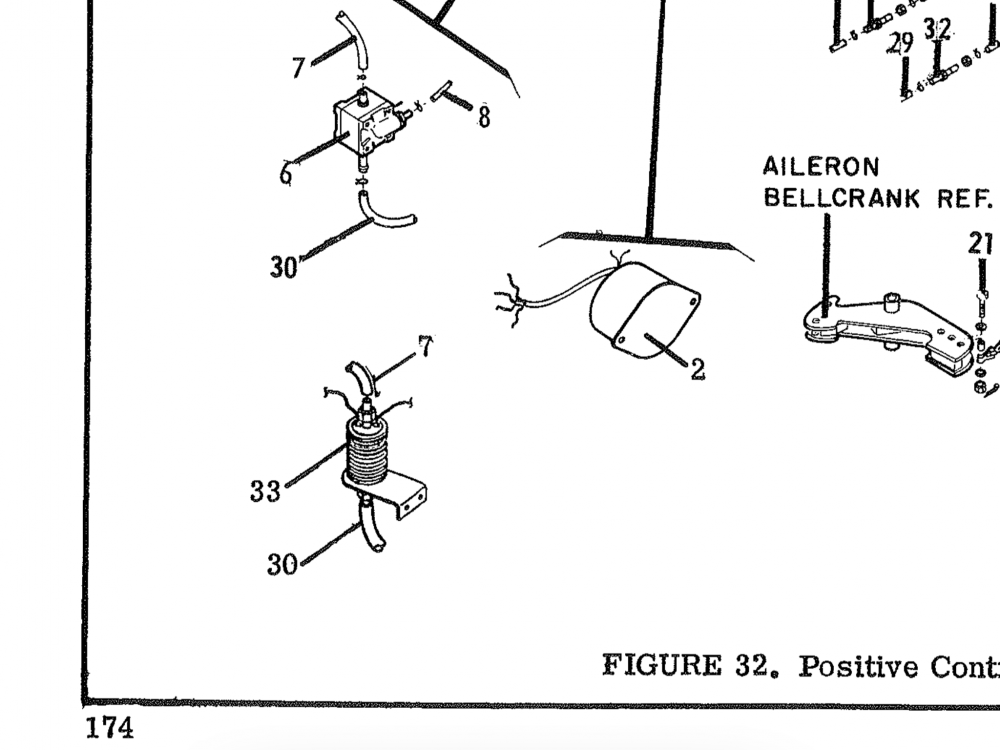

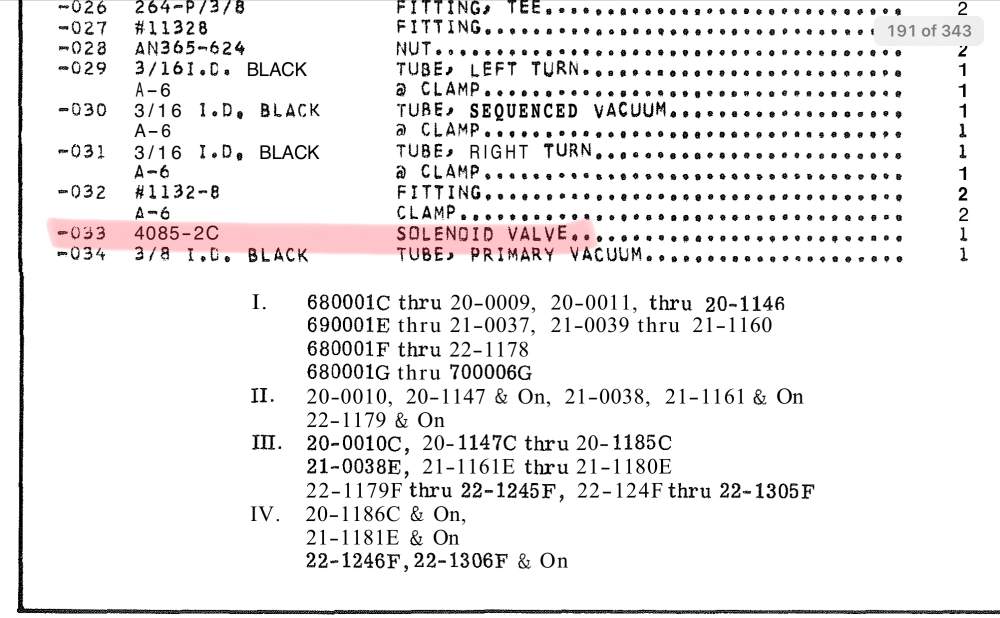

4085-20 solenoid Brittain needed now please!

47U replied to FastTex's topic in Vintage Mooneys (pre-J models)

-

@whitetheaviator This one? https://www.mooney.com/wp-content/uploads/2020/12/SBM20-152A.pdf

-

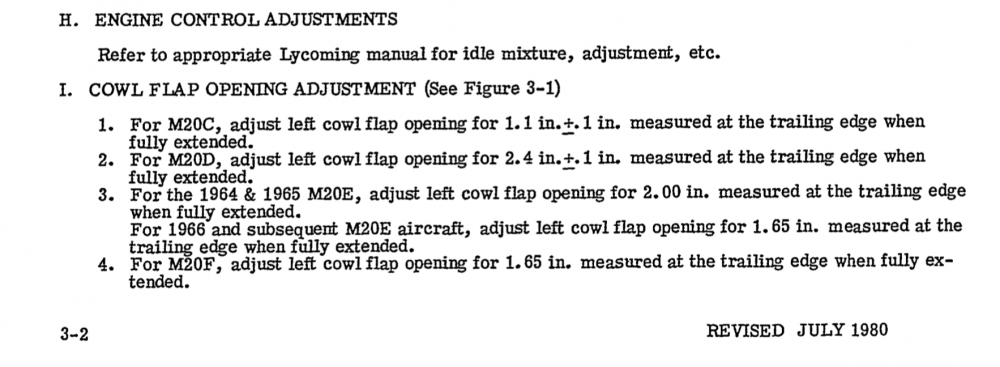

M20 D/C Cowl Flaps Open in flight

47U replied to Tcraft938's topic in Vintage Mooneys (pre-J models)

By 1970, the C had fixed cowl flaps, I think. I’m not sure if the IBP illustration for the E/F is accurate for the C/D. Someone smart here will probably know. @PilotCoyote has a C/D. My C cable attachment sticks out straight aft (edited from forward), not vertical like in the F. But, I’m not 100% sure if that’s right. Correct, the D opening is set to 2.4”. Question... is the larger opening because the fixed gear/prop D model was a little slower, so required more airflow which would be available with more cowl flap travel? What are the differences between motors in the -A1D in the C and -A2D in the D? I think it’s reasonable to adopt the C opening when converting from a D to the C. I think the addition of the spring is a bandaid and verification of the cable-to-arm attachment for security and friction lock at the knob is the place to start. -

M20 D/C Cowl Flaps Open in flight

47U replied to Tcraft938's topic in Vintage Mooneys (pre-J models)

As the below thread states, the ‘63 C cowl flaps setting is 1.1” (+- 0.1”) in the open position. I’m not sure what the thin spring is that you mention, got a picture? Shooting from the hip, it sounds like the arm is slipping on the control wire. That’s where I’d go first. -

CNC'ed Johnson Bar Lock Blocks (2nd run)

47U replied to Raptor05121's topic in Vintage Mooneys (pre-J models)

Did I miss the payment instructions? Thanks! -

-

Besides the usual Mooney used parts sources (Alan Fox, Loewen Mooney Salvage, etc.), Controller.com has a pn search feature that is sometimes handy... below is a screen shot of some of the hits on D5992... Good luck!

-

Mooney Annual at the paint shop

47U replied to Mechpilot89's topic in Vintage Mooneys (pre-J models)

Sounds logical, but I think the ‘0 degree’ reference on the flap/aileron and elevator boards is reference to the 0 degree wing / horizontal stabilizer airfoil chord. What say the experts? -

Do you have a vertical card compass? The mechanism in those have been known to eventually wear out. Generally takes years and years, though.

-

Any tricks to pulling oil screen on IO-360?

47U replied to RobertGary1's topic in General Mooney Talk

Sure enough, Skip... I didn’t read far enough. Thanks for the correction. So, the mystery of the reasoning behind food grade anti-seize continues (at least for me). Why don’t they specify a brand, like the Loctite 564? The reference for tightening the plug an additional 135 degrees past initial contact is also there, and then a CAUTION to make sure the plug is “installed tightly” (?). A new crush gasket has a lot of give, and 135 degrees doesn’t make the plug very tight (in my opinion). I do make sure the safety wire is tight, though. -

Any tricks to pulling oil screen on IO-360?

47U replied to RobertGary1's topic in General Mooney Talk

Idle minds... I can’t get through all the technical talk of the Preignition thread (you all are WAY smart!), and I can’t stomach the Sunday shows, so I’m reading Lyc SBs. Is SB 480 saying to use the Loctite 564 on the suction screen plug? Or, is it only calling for Loctite on the sump drain plug(s)? The SB states that when draining the oil, one or both sump drain plugs can be removed. The SB is specific to list individually the sump drain plug(s), suction screen plug, and the oil filter when safety wiring. The suction screen plug isn’t listed along with the sump drain plug(s) in the Loctite reference (para 5). Thoughts? -

Also, cleaning the countersink surfaces of the screw and panel really well (shiny) and waiting a few days before putting fuel back into the tank may increase your chances for success. (I apologize if I’m being Capt Obvious.)

-

Kudos for getting intimate with your Mooney. Not every wing panel needs to be removed to perform the lubrication, but you should consider pulling all the panels for a look-see. There are some steel fittings about mid-wing that develop surface rust over time, and who know what else you might find. Hopefully, you won’t have a need to put your shop vac to work.

-

I’m not surprised if George has in fact retired. He overhauled my generator some 8 years ago and looked like he was well into the retirement window back then. What a craftsman, though. I think it was a 2-day turnaround and it looked and still performs like new. The Zef VR replacing the Delco-Remy probably helps some, too.

-

Electric Landing Gear Circuit Breaker ('67 M20F)

47U replied to BWatts's topic in Vintage Mooneys (pre-J models)

Just a guess, since I have manual gear... Mooney engineers oversized the actuator for longevity and reliability. They determined that 25 amps provided enough power to run the gear and anything more than that could damage components should something jam up or perhaps a failed limit switch. Limiting the amps allows use of smaller power wiring, saving weight. There’s real engineers on MS that can give real answers. I’d like to hear what they think.