Leaderboard

Popular Content

Showing content with the highest reputation on 04/14/2024 in all areas

-

It bothers me that most people I do transition training with aren't comfortable with crosswind landings. They are actually the most fun landings. They're relatively easy if you just think "rudder for alignment", "aileron for drift", both done simultaneously. It's the "both done simultaneously" that creates the issue for most people.3 points

-

The Story: I bought an Ovation last October that needed some attention. My son and I are going to travel in it and he is building time for a flying career. It had a new and very nice glass panel in it but everything else was well used. The airplane flew about 35 hours in the last 5 years. The paint was very oxidized, carpet old and dirty worn through and the seats looked like a frat house couch. Both wings had fuel leaks. It had been well maintained but it was tired when i bought it. I used the Winter months from then until now to refurbish the airplane. I tackled a bit more than i wanted to but my thinking was to fix everything now and fly it versus fly-it-and-fix-it etc….. So, this is what we did: Firewall forward is all new. Every line, hose and connector. Factory new IO-550. New engine isolators. Stripped and painted the engine baffles. Prop Governor Overhaul Prop Overhaul to include new internals. Compete external light conversion to Whelen (WATT) LED’s. New wingtip and taxi/ landing light lenses. New tires and tubes. New batteries (2) New O2 bottle and fill. Polished the spinner and took the dents out. 18 hours with a buffer and ceramic wax to bring the paint back to life. Complete fuel tank seal scheduled for this year. New Interior. (I started with the just carpet but I had to take the seat out to take out the carpet………and one thing led to another and i just took everything out). I also removed most of the old adhesive, cleaned every inch of the inside and added insulation and sound proofing to the interior. FIRST FLIGHT: Accomplished the first flight and first two hours of engine break-in yesterday. The new engine and prop are powerful and smooth. Everything else mostly worked as advertised. After the first hour I landed. We took the cowlings off to inspect. No leaks. We adjusted the prop governor for full take-off thrust and the gear warning horn on the throttle cable. We flew another hour and I got two more landings in since it had been awhile in GA for me. I would have added 4 more hours to the break-in except i was limited to lower altitudes and high power settings for the break-in and it was VERY windy. TAS was 176-178 on 24/24 at 3500” so I am guessing 180-185 higher. It was a rough ride. I have a fuel pump that needs overhauled so that is going out. I also have a small box in the avionics bay that controls glareshield and panel lighting that needs overhauled. Maybe one EGT probe as well. Otherwise, for the amount of work we did on the airplane……everything went well.2 points

-

Seems like you could take a clean shop vac with a fresh filter and pressurize the intake and spray all the connections with soapy water same as testing for exhaust leaks.2 points

-

I got these auto shades, they have suction cups but I don’t need them, just squeeze them into the window frame.2 points

-

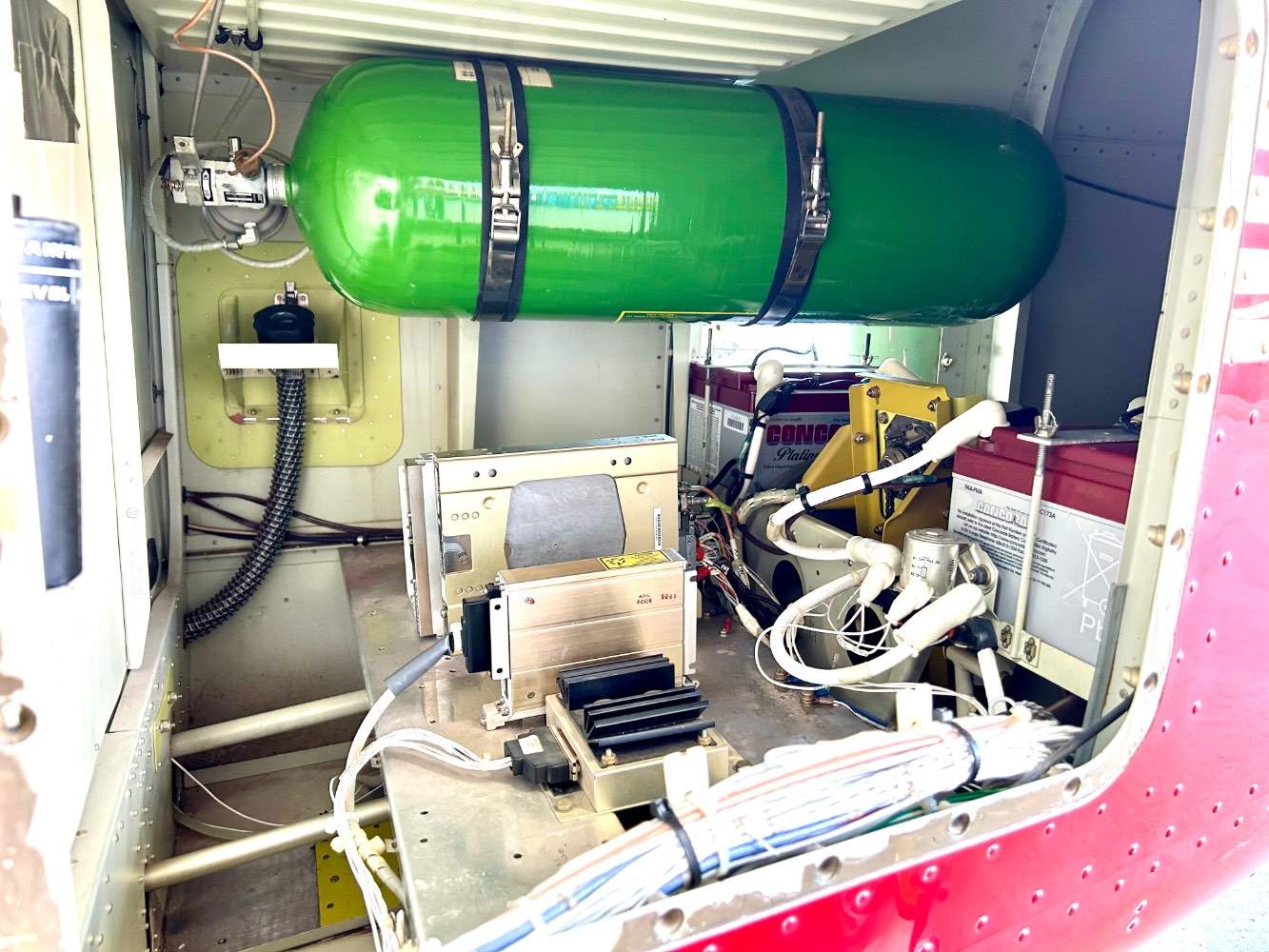

Time for me to move on from Ovation ownership to the next chapter. Aircraft is presently in San Marcos, TX. PM me to discuss. -Steve N21625 (1999/2000) Full Specification Sheet - Offered at $319,500 ENGINE/PROP No damage history – No corrosion – Hangared – One previous owner ~1300 TTAF – Complete logs since new Engine – 23 hours since factory new (test/break-in runs only) 310HP Continental IO550-N8B, 2700RPM 2200-hour TBO Iridium fine wire spark plugs installed Prop governor overhauled to new specs New 20A backup alternator New exhaust system (muffler proactively rebuilt by Acorn) New Mooney factory metal baffles New Mooney factory silicone baffle seals Real Gasket Corporation rocker cover gaskets to replace Continental factory gaskets Prop – Hartzell PHC-J3YF-1RF /F7498 (Acclaim Type-S prop STC) Inspected, lubricated & re-sealed by Jordon Propeller 3/2024 (23 hours since OH) New TKS overshoes installed AVIONICS 5. Garmin G3X Touch with synthetic vision Garmin GTN 750xi WAAS with GA 36 antenna (2nd GA 36 antenna installed, and cockpit cabled for future GTN 650Xi installation) Garmin GFC 500 autopilot (3-servo installation) Garmin G5 backup ADI Garmin GDL 69 XM weather + dedicated antenna Garmin GMA 35 audio panel Garmin GSB 15 dual USB chargers – 3.0A ports (qty. 4 – 2 in the front, 2 behind rear seats) Garmin GTX 345 panel-mount transponder Mode-S Extended Squitter (ES) ADSB In/Out TIS traffic L3 WX500 Stormscope JPI EDM930 engine monitor CIES digital fuel senders Artex ME406 ELT (antenna relocated to embedded position under vertical stabilizer) Bose/LEMO plugs at all four seat locations AIRFRAME TKS known ice-equipped (windscreen, prop, heated stall warn, ice light, 20A standby alternator) PreciseFlight speed brakes 102-gal certified usable fuel New 51-USG filler necks installed + cockpit fuel selector placard All Whelen (WAT) LED lighting: OR650E wingtip white anti-collision + NAV (ACL synced with “b.”) OR500 tail white anti-collision + position (ACL synced with “a.”) Model #908525D lower red anti-collision beacon Parmetheus Gen3 landing lights Model #78013 baggage light A508-24 wingtip trailing-edge lights Reiff TurboXP full engine heater + oil cooler heater strip option 115cf Scott 4-place oxygen system – current Kevlar bottle good for 10+ years (15-year life) Two Concorde RG24-15M batteries (#1 new in 3/2024) Landing Gear no-back spring replaced (3/2024) New Michelin tires and Airstop tubes (3/2024) New static wicks (3/2024) New landing gear shock discs (1/2024) New brake linings (1/2024) SafeFlight Stall Warning tab replaced with factory-new (3/2024) Medeco high-security locks on both main and baggage doors New GLAP wing landing and taxi light lenses installed (3/2024) Fuel cap O-rings replaced with blue fluorosilicone (replace on-condition) Paint 7/10, Interior 8.5/10 Useful Load – 1007 lbs. Redline Sidewinder tow bar and bag included with sale Fresh annual signed off by Brian Kendrick – 4/2024 Fresh 91.411 / 91.413 certs completed – 4/2024 ADDITIONAL CATCH-UP MX AND WORK PERFORMED BY BRIAN KENDRICK RECENTLY CB panel removed and electrical systems inspected Two breakers replaced with new All CB collars reinstalled to correct CBs Emergency buss operation adjusted to confirm correct operation GEAR DOWN light intensity adjusted to display correctly with all-LED lighting installation (previously an issue with nearly all Mooney aircraft having a combination of LED/non-LED lighting installed) New, tougher XPDR IDENT switch installed Low boost pump FF set to between 7 – 9 GPH Brakes down bled and reservoir refilled All charlie weights removed New paper induction air filter installed (3/2024) Added 1GPH to takeoff fuel flow Replaced oxygen control inner cable Relocated StormScope antenna to proper location at belly of aircraft Landing gear rigged and preloads set appropriately1 point

-

I came across this thread on G100UL today and thought I would pass along one conversation I had with a former colleague of mine who is a sealant expert. The chemistry is not my field, but what caught my attention is that, as mentioned previously in this thread, there remains uncertainty about the durability of existing elastomeric materials such as seals, gaskets and, especially, polysulfide fuel tank sealants, once in contact with the higher aromatic chemistry of the G100UL fuel. Until recently, I had focused on the engine performance and reliability and thought little about the fuel system impact outside the cylinders. That has changed - I'm keen to learn more about any long-term durability testing required or performed for the STC route and the FAA's broader fuel certification protocol. I figure my day is coming, but my 1985 M20J has yet to leak or weep fuel. Hoping we can get to unleaded fuel without accelerating other issues.1 point

-

I wouldn't necessarily assume you'll never use massives again, especially given the price difference between the two now.1 point

-

Saavy has an airborne induction leak test. It’s not perfect but maybe worth a try… Page 6 of this: https://resources.savvyaviation.com/wp-content/uploads/articles_eaa/EAA_2012-01_flight-test-profiles.pdf1 point

-

SLC is kind of a PIA. First, there aren’t any great /close GA fields and second, it’s really busy class B. Don’t underestimate how busy it is going in there. Now, here’s my experience… I’ve used two of the FBOs on KSLC in the SE corner. They might be pricey but are full service and nice. If you can land on the east runway, it’s pretty easy. If they say “unable”, and put you on the west, then get your A game ready for the taxi because you will definitely need it. I have used KOGD several times and both FBOs were good and not as expensive. I did find the (contract) controllers were jerks, but the fbo was good and it was pretty easy to get in/out. Maybe at @Utah20Gflyer can give you a suggestion for a good airport south of SLC? Maybe provo?1 point

-

Our navigators could do VOR VOR with just a software change. I don’t think any of them have DME receivers. From the governments standpoint, maintaining a few LORAN chains is probably cheaper than maintaining a bunch of VOR DME stations.1 point

-

If you send your prop for work, ask for an IRAN, NOT an overhaul. If you say overhaul, they will grind your blades. A few times doing that and you are buying new blades.1 point

-

I got one. The frame was too stiff and caused it to pop off and it didn’t work on the pilot’s side window because the latch for the storm window is in the way. I kept it in the plane an a trip through Texas and the heat while parked outside softened the glue and the frame slid out if position. I threw it out and used the case to keep a static cling shade in. The zipper on the case is now broken.1 point

-

I like that you said “rudder for alignment" before "aileron for drift". I hear it described the opposite way, "aileron for drift", “rudder for alignment". It may be a small difference but my tail wheel excursions have taught me that giving alignment priority helps enormously, and I use it when teaching crosswind landings in any airplane. Great satisfaction a few weeks ago when a pilot I worked on landings with last year nailed a 15-16 KT gusting crosswind at the end of a mock instrument checkride I gave him, And I absolutely agree they are the most fun.1 point

-

1 point

-

You own the aircraft we had when I was a child - N6876U. Did you know it was involved in a crash in Redding,CA? We sold the Mooney after the crash and bought a Cessna 206. I have home movies of that Mooney. I was just watching them so decided to look up the N number to see if someone currently owned it.1 point

-

1 & 2 could both be the same issue. Check the pressure screen gasket to make sure you installed the correct gasket on the pressure screen. There are 3 types of gaskets. Depends on what screen, and filter set up you have. 3. What makes you think you have an intake leak? Fuel Stains? many times the tabs for the intake tube are overtorqued and bowed. Take the tube off and file the edges down on a flat surface. Also, intake tube can hang up on the lip of the riser and not fully seat. The tube should seal on its own with no spooge . Also, the oring on the sump has two different part numbers as well. The sump can ware a grove where it won’t seal on the sump. That’s all I can think of, -Matt1 point

-

LASAR’s website for parts in stock is not always correct. Sometimes it says no stock and when you call they are in stock. Good luck1 point

-

Rolling down the runway at 100 KTS with a 40 KT crosswind doesn’t sound like a good idea to me.I like to get stopped as soon as I can in conditions like that.1 point

-

Very happy with the service. Occasionally, their serving as an intermediary slows things down. That drawback is more than mitigated by knowledge, having a second ear, troubleshooting, break down service, etc. Last year, I saved so much money on a complicated problem, after their negotiation, the service easily covers itself for over the next decade.1 point

-

While I'm a proponent of the 3° slope stabilized approach, this is the one instance when you need to come in flat and "grease" the landing on 3 wheels. That's why I say it is not for the inexperienced pilot because you have to touch down with no vertical motion and control the rate of slow down such that if you can't hold the runway, you initiate a go around immediately.1 point

-

1 point

-

Landing in gusty conditions with a strong headwind component is one thing, landing in gusty crosswind conditions with no headwind component is quite another. In the "Proficient Pilot" by Barry Schiff he discusses one method that has worked well for him in a Piper. I prefer another that I use but haven't seen published anywhere. It isn't for anyone unexperienced in large crosswinds or on short runways. Using that method I have landed in direct crosswinds in excess of 40 knots with no headwind component. It does involve flying the airplane onto the runway at speeds in excess of 100 knots and gradually slowing the plane down, with more and more aileron added into the wind. At any time if directional control is unable to be maintained, then full power can be added and a go around immediately initiated. Except for several go arounds at Oceano, L52, a 2,360 foot runway when there was a strong gusty crosswind, I have not had to go around using this technique. I went around twice and told myself that if another go around was required, it was time to go to another airport. The winds cooperated the third time and I was able to make the landing. However, never "force" a landing.1 point

-

Thanks everyone for the good advice. Nothing has changed in the panel years but iwill definitely check it on the ground with and without the engine on.1 point

-

Hats off to you! I underwent a similar project but found a local custom car outfit to do mine. The hardest part of doing the interior is contorting into the fuselage to remove and then reinstall the pieces you took out. If you can measure and use scissors and a screwdriver…….you can redo your interior. The upholstery part is real skill so if you are interested in good results, I would find a good one. Otherwise, take it slowly, take notes, take a ton of pictures, put the screw from each section into baggies and label them. Good luck.1 point

-

1 point

-

Another happy Savvy QA customer for the last 6 years. I like the data analysis and deep cohort history along with the exhaust valve monitoring. Looking forward to using the borescope service. SavvyMX is way too expensive to be a good value IMHO.1 point

-

I love my shop (Top Gun) so I have no need for the SavvyMx but I've been using the SavvyQA and have found it very useful a few times (like when I had issues away from home). I'm not sure it is worth it but the QA cost is about half the Mx cost so I've been using it for a couple of years now and will probably keep it for a little wqhile at least.1 point

-

At least on some models Mooney used a custom screw which is a pan head screw with a captive plastic washer and the screw is painted to match the washer color. I tracked down the supplier, but Mooney did not use a standard color (of course) and there is a set up charge and minimum order for for custom colors that makes it cost prohibitive. I ended up just buying #6 and #4 stainless oval head PK (sheet metal) screws and metal countersunk washers. I also painted them to match the interior by poking them through a piece of cardboard. I used some #4 pan head screws around the windows on my J. When I had the plastic out, I attached Tinnermans to the backside of all the places where Mooney just screwed the plastic panels together with PK screws. Be careful not to use overly long screws in some locations as you want to avoid the wire bundles behind the panels.1 point

-

Interesting side note. Statistically this pilot was super lucky. The fatal accident rate for the Lancair is 10X the GA average and ~ 40X that of the ubiquitous C172. That data came from the Lancair Owners and Builders Organization.1 point

-

I had a very good initial PPL flight instructor. We did a lot of practice where he let me come into the airport at different heights, speeds, directions, etc., then his instructions were "Look out the window, and make the airplane do what you want." and "Keep your aim point centered in the windshield and get your speed right, and the plane will land itself." That was all in a 172 but you can do it in a Mooney too. I am still most comfortable landing that way. I glance at the airspeed indicator but most of my focus is visual, outside. If you come in too fast you'll float, but you can feel that in the controls, and in the seat of your pants, and see it in your attitude - if you're too nose low for your flap setting, you're too fast, usually. Basically what an AOA indicator would be telling you (wish I had one). Another pilot I know and fly with learned only stabilized approaches. His CFI was an airline pilot. He does math in his head in the pattern, calculating his descent on downwind and base, checking AGL on final, compensating wind speed with altitude. Would stress me out. But to each their own. I have wondered how those pilots handle situations where a stabilized approach is not possible. Slam-dunked by ATC. Last minute pattern changes from tower. Flying the FISK arrival at Oshkosh. Landing at Gaston's. Circle to land ops. For the pilot I know, those are very stressful situations. I've encouraged him to go get some VFR practice and instruction. I think it should be taught more than it seems to be.1 point

-

Landing any airplane is a result of a stabilized approach….meaning airspeed and vertical descent rate. By 500’ (1000’ in large airplanes) your airspeed should be stabile at the approach speed for your landing weight and you should be on a 3 degree slope (obstacles permitting). Varying airspeed and/ or descent rates changes the landing picture and leads to your experimenting with every landing. Consistent control over airspeed and approach slope reduces variables and results in consistent landings. There is no substitute for a stabilized approach. Gusty winds? Add 1/2 the steady state HW and all the gusts up to 15 knots.1 point

-

As the mixture leans, approaching stoichiometric proportions the exhaust temperature gets higher. The valve returning to position, pounds the seat. The supposition is without lead as an intermediator and consequently conductor of heat at the valve to valve seat interface, erosion occurs. At lower power setting not a problem. At climb or take off power it can be a big problem, especially if the engine turns high rpms where the exhaust valve spends less time against the seat cooling. One of the reasons why when going for LOP you should be at 65% or less and do not linger in high EGT regions during lean. I.E. "Big pull".1 point

-

Years ago I was flying home and while planning my flight realized there was a 70knt tailwind at 25k, directly on my tail. Pretty hard to pass up in a plane capable.. I was alone, had the nice blue silicone mask with a microphone, so I filed for 25k and off I went. I was cruising along and I looked down in my lap and saw this little black disk. At the time the plane I was flying was an ultra with the precise flight conservers, and I thought the disk looked like the adjustment dial on the outside of the unit. After a few seconds of fiddling with it, I realized I was trying to put it back together, but it wasn’t apart…. By the grace of god I realized that what I was doing made no sense whatsoever and I engaged the vertical descent for 1400fpm and still to this day do not recall the next two or three minutes. What I do recall is being level at 8,000 ft with atc calling me asking intentions. I hit replay on the g1000 and listened to me responding to them and taking instruction. I did not sound like myself, but I was responding. I do not remember any of this… After my wits were about me again I looked down and realized my arm had gotten wrapped around the o2 hose going to my mask and had inadvertently pulled the grommet out of the front of my mask at 25,000ft. The disk was the grommet, and if one was completely cogent, would never had mistaken it for anything else. I don’t know how long it had been pulled out, or how long it took me to notice something was wrong. The flight recorder only goes back about 2.5 minutes on a constant loop, so that’s all I could listen to. I don’t know how long the entire event lasted, but I did realize how close I came to being a bad story. There is certainly more elevated risk at those altitudes, and one must be very vigilant, aware and have some routine to check yourself very regularly. I personally stay 19k or below if I am alone, and will only go to 25k with someone else and if we pick up enough time to really make a difference. This isn’t my recommendation or suggestion, it’s merely a personal minimum in my Mooney, or any non pressurized airplane. Things can deteriorate much quicker than you would like to believe… Last thought on this story… I was embarrassed by this. I felt foolish, like my arrogance and confidence led me to a bad choice that could have killed me. I finally opened up and told the story to a pilot friend of mine and he told me I should share, because perhaps someone could benefit from hearing my mistake. I sure hope it does, because I still feel foolish.1 point