Leaderboard

Popular Content

Showing content with the highest reputation on 02/22/2025 in all areas

-

Consider for a moment that there is no right and wrong. There is only Alive and Dead. Fly like that.4 points

-

It will save our children from horrible death by lead poisoning. The minuscule amount of lead that 100LL puts into the air poses an existential threat to the entire world and, therefore, we must push for elimination of 10LL any cost and sacrifice our freedoms at the altar of environuts . Or so they would like you to belive.3 points

-

3 points

-

Should I drift the thread by telling my engine fire story? Of course not.....but I will Senior year in high school and know-it-all buddy stuck the distributor back in the engine of his '57 Chevy without timing it. "Doesn't matter", he said. Of course it didn't start, so he rustled around the garage and found a can of ether that his father kept for euthanizing rats (don't ask) and dumps a slug down the air horn. Didn't replace the air cleaner, of course. Get's in and cranks up. I was just turning dusk and it was BEAUTIFUL!3 points

-

So the guy I know who used to work for AeroGuard knows both people in the Cessna. He said they said that the Lancair passed them overhead, their prop hit the tail and flipped the Lancair inverted. He indicated this all happened at about 200 AGL. That would be horrible to watch.2 points

-

In college I commuted by bicycle everywhere for 3 years. I didn’t own a car and worked full time while in school. I rode several hundred miles a week. This was all a topic of debate when my fellow riders would complain about cars. I was hit three times in those three years, fortunately never serious, only one of them even caused a fall. I learned very quickly that your “right of way” doesn’t do much for you under the car. you must be vigilant and defensive at all times because people just do not see you. this is the same attitude I have at uncontrolled fields. I don’t think there are many out there intentionally trying to break rules or put people at risk, but you better just expect it, because lack of intent doesn’t make it any less dangerous.2 points

-

Owner of the museum where I used to volunteer couldn't get the left engine on the B-25 started. Primed the hell out of it leaving a big puddle on the ground. Of course it backfired (well, actually afterfired) on the next attempt and lit off the fuel. Fortunately he got it started and blew out the fire just as the fire guard was running with the fire extinguisher. Ross, I think I'd just inspect everything closely -- too many variables to predict what damage might occur.2 points

-

2 points

-

For those that don't regularly partake in FAASafety or FAASTeam Wings seminars, I noticed that some Eagle representatives are presenting at one tomorrow (Saturday Feb 22nd). "Join us for A VIRTUAL cup of coffee, a donut, and a LIVE WEBINAR as representatives of EAGLE, an initiative consisting of the aviation and petroleum industries, and other interested parties, all working toward the transition to lead-free aviation fuels (UL AvGas) for piston-engine aircraft by the end of 2030 without compromising the safety or economic health of the general aviation industry. The speakers will explain the “big picture” from developing and authorizing a UL AvGas replacement to its distribution, storage and sale at airports. They will also provide the most current status of the three replacement UL AvGas that are at various stages of development, testing, distribution and sale. Aviation safety will be discussed, and is central to the content of this presentation." Details here: https://www.faasafety.gov/SPANS/event_details.aspx?eid=134442&%26caller%3d%2fWINGS%2fpub%2faccreditedactivities%2factivitySearch.aspx2 points

-

It is hard to imagine why someone would delay on the runway. I was taught at an uncontrolled field that you don't take the runway until you are ready to take off. If nothing else you have a much better view of what's going on at the hold short line than you do on the runway.2 points

-

There are rules, and then there is etiquette and common sense. They all affect safety, and at an uncontrolled filed are all equally important. not simply because of what is right or wrong, but because of the stakes, and the fact that one or both simply may not be aware of the hazard created by the lack of observance of any of the three. simply looking at the rules, without context and respect for the situation may win a legal argument, but that doesn’t make it right, and you know it, it seems you just want to antagonize for the sake of conflict. If everyone exercised all three things at uncontrolled fields these things would likely never happen. When I was doing my first solo, I was in the pattern, making my calls. A plane came out of nowhere, not talking, flew parallel, over took me then in short final dove beneath and in front of me and landed, making me go around. he was lower, so technically he had the right of way. But was it the right thing to do? I suppose you would say yes, but no one in my situation would ever agree. As long as people like you take that attitude things will never change.2 points

-

I'm sending out some feelers wherever I can! I am back in the market and hoping to be in the air by the spring/summer. I'm located in CT, USA and this is what I am looking for: M20E, F, or magically a J model. Insurance is going to limit me to under $100k, and closer to $80k would be a lot better. Wants: Something that has been flying and not sitting, engine under 1500hr. Paint that'll at least last me another few years. An autopilot with alt hold (like STEC20, Century III, etc.) Mechanically sound Must be open to having a prebuy done I am an absolute sucker for 201 windscreens and fancy cowls.... I would rather have a plane in great mechanical condition that could use a little interior and avionics loving than the reverse. Please feel free to post or DM if you are thinking of selling or have any hot leads!1 point

-

The March 2025 AOPA Pilot magazine got me thinking: I wonder why it seems so hard to understand how our wings produce lift? Bernoulli? Newton? Both? Neither? It's not as hard as we make it, but it is not intuitive and trying to make it match our intuition seems to me to be what trips up those that try to explain it in simple terms. Consider Bernoulli. Yes, the air flowing over the top of the wing speeds up and produces a lower pressure. But why does it speed up? It is NOT because the air above the wing is funneled through some sort of half venturi. This is easily shown by the fact that a flat sheet will generate lift at a positive angle of attack, but, since there is no camber, there is no half venturi. Consider Newton. Lift is not created by downwash. Downwash creates drag. Downwash is due to the tip vortices of finite span wings. 2D airfoils generate lift but have no downwash. Ground effect reduces downwash with the effect that drag decreases and lift increases. If downwash was responsible for lift, lift would decrease as we neared the ground and our Mooneys wouldn't float so much. There are two problems that impede our understanding of lift. The first is that many of the drawings of streamlines flowing past an airfoil are incorrectly drawn. An airplane wing actually affects the airflow at a considerable distance ahead, above, below and behind the wing. The second problem is that we are used to simple systems that have discernable cause and effect. But fluid dynamics isn't like that. If the air speeds up, is it because the pressure changed? Or, does the pressure change because the air speeds up? What is really happening is that the wing presents an obstacle that the air must go around. And, there are laws of nature that the air must obey in so doing. The air must change direction to get out of the way. Air has mass so changing its direction requires a force. Force on a fluid such as air is a pressure. So, as the air flows around the wing there will be pressure gradients. And pressure gradients cause the air to speed up or slow down. It's not correct to say that the pressure causes the direction and speed changes or that the direction and speed changes cause the pressure changes because all three parameters are part of one system.1 point

-

1 point

-

That is a pet peeve of mine; not clearly announcing your intentions. Always say "Full Stop", "Low Pass", or "Touch and Go" when you make any/all of your pattern position calls.1 point

-

He also said the Cessna was doing touch and gos. So if this is true, it looks like the Lancair is way more at fault here. Who would overtake an airplane doing touch and gos doing a low pass. That is nuts.1 point

-

Yeah all of our dealers kept trying to say that what they could sell was a 400 gl airplane, thinking of course 20% less capacity = 20% less cost. But that wasn’t the case the money saved in fiberglass in the hopper was trivial, money difference between a -15 (680 HP) Pratt and a -34 (750 HP) wasn’t much, a Hartzell three blade is a Hartzell 3 blade cost wise, batteries, Starter / Generator, airframe, wings, landing gear etc are the same, there just isn’t any real savings. But you could get a Factory overhauled Walter 750 HP for about half the cost of a Pratt, the Avia prop was less, the Starter / Generator came with the engine etc. Now the Walter wasn’t as powerful as a Pratt, but I was going to derate it to 680 HP as it could make that, leave the airconditioner off as well as lights etc and a 400 gl airplane became viable, then GE bought Walter and killed that plan, but GE was building a “New” Walter making much more power, no hot end insp, no fuel nozzles to clean and several other things and they were wanting to get this new engine in new aircraft of course so we became their launch customer. I think GE General Aviation died on the vine, nobody else jumped on the engine, they designed and built a new engine with 3D printed parts and 21st Century GE aero technology etc for the Cessna Denali. But where is the Denali? Pratt also began giving sweet heart deals to manufacturers to block GE too, but our current owner was too arrogant and stupid to listen. Point I’m making is I don’t see the price point changing. I believe the street price of a Pratt -34 is about $500,000, OEM was about $350,000 back then, but then you buy prop, prop governor, starter / generator, even engine mounts are thousands, so an OEM ends up with half a mil in the engine, so I’d guess you would need a million five to turn a profit for a non pressurized four place? You know I wouldn’t be surprised if a Turboprop isn’t as expensive as a Williams Turbofan, and who wouldn’t want a Jet over a Turboprop? Transition wise a Turboprop is much easier than a piston to manage, especially a Turbo, if FADEC there really isn’t anything to manage. You have to be stupid to hurt a Pratt, they start so easily you have to be stupid to hot start one. But yeah, money is the problem, and a 680 HP Pratt airplane just isn’t much cheaper than a larger higher HP one, Everything is the same, same Avionics etc, just bigger airframe. A TBM is likely about as small as a Turbine makes sense, and a Bonanza is about as big as a single engine piston makes sense. Now if a 500 SHP turbine cost half as much as a 1,000 SHP one did, then you could do it.1 point

-

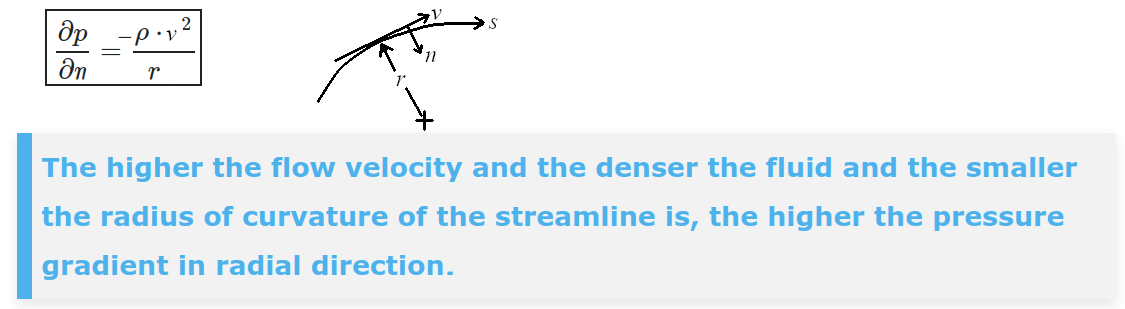

One of my favorite views of lift generation in action. Streaklines in a wind tunnel at an angle of attack near stall. Newton's second law F=ma written perpendicular to the streamlines does a better job of describing the physics that produces lift better than any other equation. It clearly shows that streamline curvature produces a pressure gradient in the direction opposite of the radius of curvature. The minus sign indicates that the pressure decreases in the direction pointing towards the center of curvature, the n direction on the figure. The wind tunnel observation also shows why our stall detectors are placed where they are.1 point

-

I would say that's how ours were. Until they weren't. Maybe they retracted a bit slower. They however also started to come down immediately and hydrolocked after a little over 4 strokes. We however found it quite challenging to fine adjust the retraction speed as simply tightening the lock nut already impacts the speed.1 point

-

1 point

-

My attitude is that if you're NEEDING best glide speed, you're better off just learning/picking a/sticking with a "best glide speed" and putting your focus on where you will put down. In my case, that's 90mph. Sure, it may be more optimal at some other speed, but that advantage is small, whereas picking where you're putting down and how you manage the final approach to that spot is way more important than the maybe 500 - 1000 ft in distance you might gain by optimizing best glide. Said another way, your brain is gonna be all kinds of busy, so pick a speed and focus on all the other stuff like maintaining attitude, looking for obstructions, shutting off fuel, making a last radio call and shutting off electrics and popping the door and maybe making a gear up/gear down decision. And if all that works out well, you'll likely end up too high at the end and need to slip her in to land at your chosen best/optimal spot. YMMV.1 point

-

Yeah, I got a 1" ratchet box end wrench. I can't get a torque wrench on the filter on the A3B6. I figured out that torqueing a rubber gasket doesn't make a lot of sense anyway and 3/4 turn seems to do it. Never had a leak on the cars or airplanes. Wobbly extensions are useful. The only socket I've had to turn down is the half inch for the Lycoming exhaust nuts.1 point

-

Cool! Never seen those before. I have a Craftsman set I got back when they were still good, with 1/4, 3/8 and 1/2" drives and a boatload of sockets, but I've still had to periodically add adapters, reducers, universal joints, extensions, etc. I bought a canvas roll of wrenches from the back of a truck at an Elk's Lodge sale about ten years ago, must have cost about $10. It runs from 1/4" to 1-1/4", and the one I use from it the most is the 1".1 point

-

I manage to squeeze this lil' guy in: https://www.amazon.com/Capri-Tools-Stubby-Impact-Socket/dp/B097Z9CB3L?th=11 point

-

@PT20J I got you beat on the car story. It was a 1973 Ford F-250, during the first gas shortage My Father had saddle bag fuel tanks put on it because we were building a beach house in Fl and you could buy gas only on odd or even days based on your tag number and we couldn’t get home without the extra tanks, it had a fuel selector valve. Well he would run it out of course, switch tanks and grind the starter until it started, second starter I put on it I put a Holley electric fuel pump on it connected to the ignition, told him turn the key on and when the pump quit rattling, crank it, which worked fine, no more burning up the starter. A few years later the truck got older and became a Farm truck, it wasn’t maintained very well and I guess the oil bath air filter must have gotten dirty because one of the men had removed it who knows when. One day it backfired, carb caught fire, but I knew we were in trouble when I heard the pump start rattling and instantly we had a BIG fire, pump kept running until there wasn’t much left of the truck. I think it quit when the battery melted. Bad thing was it was parked real close to the house but I was able to drag it away with the tractor before it caught the house on fire.1 point

-

In A&P school we were running our C340 and the #1 engine caught fire, pretty significantly. Flames were coming out of the vents on top of the cowl, and burning fuel was flowing out the cowl flaps. We got it shut down and it took a little while and a couple attempts to put it out, but we got it out. Somebody in the previous class that was supposed to prep it (our class was just running it), left the fuel line fitting through the baffling to the wet fuel pressure gauge very loose, so basically it was fuel burning from there around the top of the engine, around the accessory case, etc. We cleaned it up and there was very, very little damage to anything. There were essentially no repairs required. I was surprised, but it was only fuel burning and the fire didn't get big enough to get hot enough to damage anything else. I'm sure if we hadn't shut it down promptly and put it out right away, it would have been much worse. That's my only personal experience with such a thing, but I think in general the usual inspection criteria apply regarding integrity of parts, etc. Fiberglass pieces will be suspect if they've discolored or no longer pass a tap test, and if something like that is questionable it'd be a good idea to look for a materials expert (e.g., the airplane builder, the supplier of the fiberglass system, etc.).1 point

-

If you replace screws, reference the IPC and order the correct lengths. Many of the kits you can buy don't have the right length screws. If they are too long, in most places it just means it takes longer to remove inspection panels. But, there are a few places where the wrong length screw will interfere with something and a couple of places where the wrong length screw will damage control tubes and too long screws in the fuel tank access panels are a common cause of leaks.1 point

-

Harbor Freight or garage sales or auctions. Buy sockets, and wrenches for cheap because you will need to use a hand grinder to cut off, grind down, heat with torch and bend in odd angles. Keep a drawer in your tool box for all the modified tools you accumulate. Saves a ton of time having a tool that is bent just right or has half the end ground off so you can get it on. Duct tape or painter's blue tape over a boxed end wrench to keep the nut from falling in to never land. EXTRA long 24" or 36" screw drivers and multiple socket set extensions are really handy. Remember, buy cheap and many so you can make them work. Sure cuts down on time and frustration. Also, replace Phillip screws that are removed several times a year. They get rounded out a little and then all of a sudden, you are spending two hours trying to get it out. Eazy outs are also needed once in a while (this would be an exception to buying cheap - buy good ones). Also, flexible scopes that pair to your cell phone for getting a good view where you can't see. Beats a mirror on a stick. Amazon has a lot of cheap ones that would have been very expensive 10 years ago. -mark1 point

-

Yep. But most inexpensive sets, like I keep in the plane, are 3/8" drive. Then1/4" drive sets are generally smaller size, with shorter ratchet handles. Wrenches are still required, there is no room for a socket, much less the ratchet handle, on the oil filter.1 point

-

1 point

-

A 3/8” 1/4 inch drive will disassemble 90% of a Mooney. Next in line is the 7/16. Beyond that, you will need the rest of the sizes.1 point

-

I just keep a normal set, what? 1/4 - 3/4, in my toolbox. You'll likely need some wrenches, again a standard set works for most things, but a 1" fits the oil filter. I buy unusual tools when I need them, as there are more tools available than will fit in my hangar. Screwdriver set, ratcheting screwdriver, pliers, channel locks, needle nose, dikes, wire stripper, torque wrench and spark plug socket. That'll do most of what you need. And safety wire pliers.1 point

-

Seems to me that calling and discussing an issue is perfectly good etiquette. The flight school is free to disagree and say why what they did was perfectly acceptable. Seems like a lot of our problems are a lack of communication and therefore additional communication would be helpful.1 point

-

1 point

-

Here is what I have found out. We looked at some other long bodies and they all have much more clearance between the fairing and the tail than my airplane. On the order of 1/4 inch or more. It appears someone some time ago put a washer between the fairing and the riv-nut to create clearance. The washers are not in the IPC. I don't know if this was a factory adjustment to some poorly fitted fairings or not. I checked the parts bag for the faring this time and those washers were missing. So whoever removed the fairing last time, did not put the washers back where they belong creating the interference. There have been multiple facilities that have worked back there the past year since I last installed the fairing in November of 2022 so I don't know "who dun it". After consultation with numerous Mooney experts including Robert at Lasar, Joe Cole et al and calling in a DER it has been determined the skin is not structural. It can be patched and the DER is coming up with a drawing for the repair. It will require re-fitting or re-manufacturing of the fairings to make it work, but there will be more clearance this time. If you have the curl type fairing, check your clearance. Thanks for all your input.1 point

-

We have an agreement in place: If she has a third kid, I get to upgrade to a six place airplane.1 point

-

Who fed you that line of BS? There is absolutely ZERO pressure to do anything unsafe in a commercial jet airliner. Of course, as professional pilots, you want to “complete the mission” but never, ever by compromising safety to do so. Never once in my entire command experience, have I ever felt the slightest bit of pressure to do something unsafe, never mind because I might cost the airline some extra money. Airlines look at diversions and delays as a normal cost to doing business. They, like everyone, understand that it’s a lot cheaper to divert a flight than it is to settle lawsuits and cover a hull loss.1 point

-

1 point

-

It could also be a stuck limit switch or relay. Put the plane on jacks and check the ops on the ground. The airspeed switch is probably not the cause here unless you are retracting the gear at higher speed as well. If the gear retracted at your ususal take off airspeed, the airspeed switch is probably fine.1 point

-

I had a conversation with Mooney engineering a few years ago about a patch to an elevator Their emphatic comment was? "We do not approve of any patches to flight controls." Finding a LEGAL way to patch it will be your hurdle. I once looked at that very rudder trim system and wondered how one would ever get the rudder into correct balance when installed. Having balanced a few Mooney rudders I'm still wondering, considering the big tab at the full aft end I don't think its possible. JMO Using a TM 55 as @sabrenech says above has interesting possibilities If it was me I'd just replace the rudder and be done with it. Better resale also! Buyers don't like patches1 point

-

1 point

-

Military structural repair manuals such as TM 55-405-4 are approved data and contain repairs on corrugated skin flight controls. I used a TM55 manual along with AC 43.13 for a repair to a Piper rudder years ago. It’s a fun conversation with the young FAA inspectors when they see the reference. David1 point

-

Out of curiosity have you looked at how the dipstick compares to after an oil change and adding a quart at a time? Seems like the utility in the dipstick is how well it compares to the amount of oil.1 point

-

Two different Fedex instructors (they also train regular CA pilots) taught me to trim for full down elevator and that is your best glide for the operating conditions at the time of your engine failure. Also, the FedEX company philosophy is "TLAR" - "Than Looks About Right". In their analysis a pilots absolute adherence to perfect scenario (eg. holding course tracking perfectly in IFR), leads to more pilot errors.0 points

-

1980 Mooney - It's too bad that after all the work to modernize the manufacturing process, that the company couldn't survive.0 points

.thumb.jpg.ae084ff98f2eda1b3f595ed45b9592c9.jpg)