Search the Community

Showing results for tags 'fuel'.

-

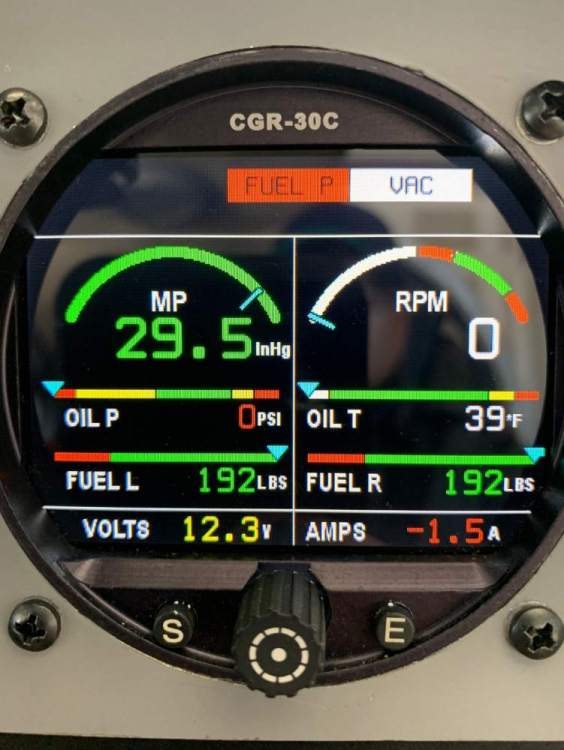

Alright Mooney group bear with me, this may get a little long winded. New Pilot and even Newer Mooney pilot. So, i just finished my 15 hours to be checked off by insurance. I now have about 20 hours in my new (to us) 1967 F model. We bought it with about 25 hours on a new engine, and just completed our first oil change as well. Lots of firsts going on here. So, I am new to complex aircraft as well. When performing our run up we normally lean the mixture to best power similar to what we did in the 172. Run up to 1800 rpm, full forward on the prop, and slowly lean until power loss catch it and give a few extra turns once the power is back. Then we pretty much haven't touched the mixture on any flight. I played with it a little the other day in cruise, lowering it until it got rough and then adding it back in until it was smooth. Our checkmate checklist says cruise around 2600 rpm on the prop, but once setting the prop you cannot use RPM as a good lean indicator correct? Plus to add to complication our fuel pressure gauge is out (so I cant just put it at the bottom of the green) which would be running it efficiently correct? (Also new avionics coming in a couple months) So the only time I have tried to lean it in flight was in a cruise the other day I leaned it until it ran rough, then twisted it back in to run smoothly. Which the POH says don't lean the power above 75% power... but at full throttle I am sure I am above that. Did I hurt the motor? How on earth do you calculate percentage of power? Then there is the throttle. I figured on a brand new engine you wouldn't want to run it at WOT all the time due to wear on a new engine. But my CFI said run it full and manage RPM and Fuel flow with the mixture and prop, but my Dad (Airforce Pilot/commercial pilot of 30 years) said he would also be worried about wear on the engine, but thoroughly admitted I probably have more experience in a civilian airplane than him at this point. Ours is also turbo normalized as well, and all I have been told about it is to keep it below 28 MP. All of this has added a ton of confusion in my mind, so I went to the internet. Specifically another post on here: Which added even more confusion. I also realize I probably sound like an idiot, but I am okay with that if it helps me figure all this out by asking the experts. So to summarize my questions: 1) Is our best mixture practice during run up correct? 2) When leaning for efficiency, can you use RPM drop with a constant speed prop, fuel pressure indication, or leaning it until its rough then adding it back in? Which is correct or are all correct and some are just better than the other. 3) Is WOT the correct way to fly? Is the POH out of date as stated in the message board above. 4) Is 2600 RPM that the checkmate suggests the best cruise setting on prop? 5) Have I hurt the engine buy leaning with full throttle in and potentially getting over 75% power setting? 6) How on earth do you correctly measure % of power? (This one is probably easy but I am missing it) 7) Does any of this change when adding in the turbo? Thanks everyone!!! I know that is a lot to follow but any response, guidance, or videos would be much appreciated. Fly safe, The FNG

-

Flying my F model today and then fuel pressure gauge isn’t working. I went to tap it and the glass on the gauge was popped free and inset in the gauge. Is there a way to fix this? Is the fuel pressure gauge required? 91.205 does not list it. Will the glass being popped out of place affect the manifold pressure gauge in the same instrument?

-

Hi, I'm a new member and new owner of a 1975 M20F. I love the plane and am just getting use to it after my complex checkout. Does anyone know of where I can get a "Dip stick" for directly measuring the amount of fuel in each tank of an M20F? If someone has one, maybe I could just get the measurements and make it with a thin piece of PVC or wood. Thanks, Larry

-

Who is worried about the future of general aviation internal combustion engine aircraft? I have concerns about what the future holds with regard to avgas burning light craft. The two biggest concerns are what will the future valuations look like if fuel prices rise dramatically and also the cost of operation. Car manufactures are pivoting to electric at a rapid pace with HUGE agendas for close to total electrification by 2030 for many. Both GM and Ford (among the other big guys ) are really rolling out the agenda. Will governments push their populations into car electrification by huge gasoline fuel prices increases with knock on effects for light aircraft? Will existing internal combustion light aircraft give way to newer electric aircraft, with an off the cliff dive of light aircraft prices as demand dries up? Interested in any informed predictions and timelines...

-

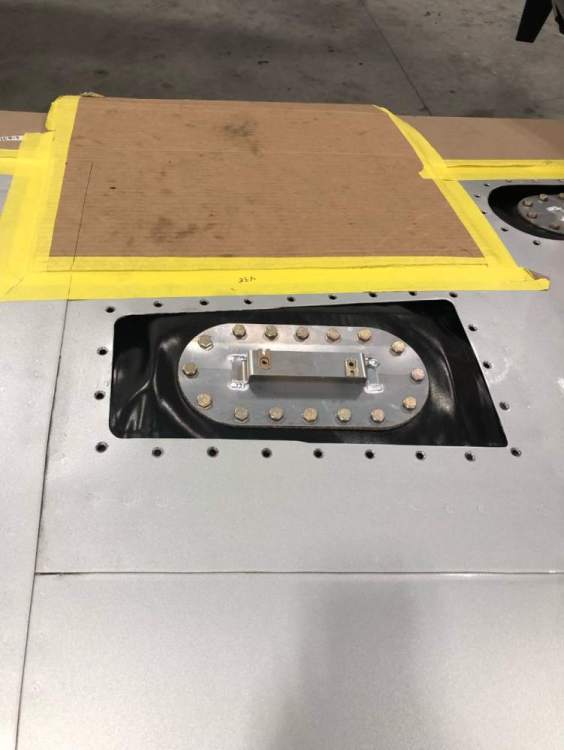

Griggs installed the B800 8-bag 64 gal system in my 1963 M20C. Went from 48 gal to 64gal ! Right at a week turn around. I’m very impressed with their skills . They did a great job!

- 16 replies

-

- 4

-

-

- o&n bladders

- mooney bladders

-

(and 5 more)

Tagged with:

-

In need of your help again! I recently bought a used fuel flow meter and I am having a difficult time trying to locate the perfect spot for the fuel transducer. I have tried to search the forums in the hope of finding that someone else had posted pictures of the install on an IO360. I could not find any (I can't find a gallon of milk in the refrigerator either) Is there a location that has worked for you?

- 14 replies

-

- fuel

- transducer

-

(and 1 more)

Tagged with:

-

My last two flights have seen some irregularities on my fuel pressure read out. The problem occurs during climb out after I have switched off the electric boost pump and no where else during the flight (I.e. I Can't recreate the issue on the ground during normal run up). Here is what happens: -Fuel pressure slowly drops once the electric pump is turned off (from 22psi all the way down to the bottom of the Green Arc ~15psi) -Once the electric pump is turned back on the pressure comes back up to about 24psi -I tried switching tanks and no luck, the issue is persistent on both sides. -Once I reach cruise altitude and pull the prop back/lean the fuel, the fuel pressure remains steady (22psi) without the electric pump on and I have no further issues My assumption is that the mechanical fuel pump is going out and can't handle the pressure requirements when I am at full throttle and prop but I would like to see what the Mooney verse had to say about this. BTW: IO-360 in a 1976 M20F

-

With the gauges on the wings and in the cockpit near zero, my M20K never takes more fuel then 50 gallons at the pump. The capacity is 76 gallons so I always land with way more fuel on board then I think. Yesterday I pushed my flight a little longer with the gauges uncomfortably reading 1 gallon and both the low fuel annunciators burning, yet the calculated landing fuel on board was 18 gallons. She took 60 gallons this time, so I guess the calculated fuel on board wins. Some uneasy flying tho. I refueled with the nose a little higher then on a completely level surface. Does that impact the amount of fuel I can add to the tanks? When refueling, the fuel gets up to those ‘anti-siphon’ doors easily. But then the topping up starts. This seems it could go on endlessly, if I just rock the wings a little back and forth. When do you guys say, this is full? I always fly with a big fuel margin, but to never use about one third of the fuel on board is silly, so I thought I’d dig in and see if it was really there. And it was. I stayed close to the airport by the way. Good to get to know the aircraft a little better again. It was a sad day for flying, last weekend we lost three young dutch glider pilots in two separate accidents. I started out flying gliders and I heard the ELT blaring on the 121.5 from the last crash, gave me the shivers. Stay safe!

-

Hi Folks, I have a couple of fuel tank access panel screws that are weeping. I know that trying to tighten them will make it worse. I am planning to reseal the screws with Permatex#3. What is the best way to remove the fuel stains? The areas are not large, but the dye is sticky and concentrated. Avgas does not seem to work great (and I dislike working with it as a solvent).

- 23 replies

-

- fuel tanks

- cleaning

-

(and 2 more)

Tagged with:

-

So...How many sample fuel for water via the sump drain during winter with ambient temps below freezing? As for me...I don't. It may seem elementary but early in my flying career in Minot, ND with temps of below -20℉ I checked the fuel via the sump only to have a small piece of ice keep the sump open draining fuel onto the ground. It was difficult to get it to stop.

-

In case any of you missed it, the weekly AOPA newsletter had an interesting piece on fighting the high cost of FBO's. I was encouraged to see that it actually called out Signature by name and mentioned some locations. AOPA battling excessive FBO fees In my day job, I see the biz jets also get hit, it isn't just about squeezing out the avgas burners. If we are realistic about the impact, Signature is more dangerous than user fees. While we can call agree that FBO's have to make money, I know we all have stories of unreasonable charges as outlined by AOPA. Signature is owned by BBA.....a UK corporation. Shame!

-

Folks, Looking for some advice regarding a weep that has developed in my left fuel tank. Appears to occur when the tank is full. weeps from the hole on the lower area of the leading edge near the wing root. Plane is based at KVGT (North Las Vegas)...recent arrival there. Searching logs to find out when the last reseal occurred. Basically looking for either a local A&P that would be willing to help me do the work to fix this or a local shop capable of taking care of the issue (prefer the prior, not the latter). Haven't noticed any fuel smells in the cabin but also don't like things that leak. Seems to only occur when tank is full. Right side does not exhibit this behavior. Regards,

-

Just purchased my 1965 M20C on Friday and had my first flight in it today (transitioning from a C172M). We went for 20 minutes in the pattern and on the second take off the fuel pressure went to 0 in/lbs and the engine started stuttering below 400'. She kept running and we continued to climb so we requested priority (we were currently cleared #2) and asked for the intersecting runway. Yes, we could have declared an emergency but there was no need since the controller was already working with us and we were continuing to climb. We made TPA so we requested the primary runway and made an uneventful landing. My second landing in her was with a hiccuping engine and was better than my first landing. You could say I was committed to that landing. She shows good fuel pressure at idle but if you run her up to over 2000rpms she reads 0 fuel pressure with or without the boost pump on and starts stumbling. I wish I'd thought to run her up on the other tank to see if there was a difference but I didn't think about that when we were testing her out after taxing back to my hangar. When I bought her on Friday my mechanic flew her to my home field for me since I bought it at a 2300' grass strip that was a little rough (my insurance requires 5 hours transition training for passengers so I decided not to fly it at all until I've finished that training). My mechanic had no problem with her, but he had her running on the right tank. The left tank was the fuller tank after I had fuel added yesterday so we used the left tank today. If we had more altitude or she had quit completely I would have switched tanks when she started stumbling, but in my mind a stumbling engine that still climbs is better than a quiet engine so I changed nothing and kept flying. The instructor (first time flying with him) was also telling me not to change anything and giving me instructions. Fuel strainer inspection/cleaning is considered Preventive Maintenance and allowed under Part 43 for an owner so I plan on taking a look at her tomorrow now that I've downloaded the parts catalog and the maintenance manual. According to the service manual a 1965 M20C has the strainer on the bottom side of the fuel selector in the nose gear wheel well. Looks like one bolt and it can be removed and inspected/cleaned according to the manual (Page 149 in the parts manual and 2-4 to 2-7 in the service manual). I'm glad we decided to do the first hour of my transition training at my home field before going anywhere else and I'm really glad that the problem didn't pop up on my mechanic while he was flying it back in between fields. It was only a 15 minute flight for him but putting it in a field would have been a bummer. When we get this sorted out I plan on requesting a VCOA for the first flight so we can stay above it in case it happens again. Am I on the right track on what probably caused this and what I should inspect first?

-

So you’re planning a flight for the next morning and realize that you have too much weight. For whatever reason you can’t take out baggage or passengers. You must offload some fuel. ( yes, you will still have plenty of reserve in this hypothetical situation ) Have you done this and what’s been your experience ? 5 gallon jugs ? Siphon hose ? Ground strap ?

-

Hello all. I had a problem with my fuel flow yesterday. ('82 M20K/231) I took off from Paso Robles, CA around 10a headed for Santa Rosa, CA. It was about 82 degrees OAT. Fuel flow was normal on take off and climb out (about 25GPH) until about 7000 feet. The fuel flow started dropping off TIT started increasing and fuel flow would only max out at about 15GPH. Leveled out at 8000 and ran it LOP. Everything was normal for LOP operations. Did some troubleshooting in the air (switched tanks, low boost pump, high boost pump) Nothing changed during LOP so felt it was OK to continue. We landed at Santa Rosa and spent some time with a mechanic on the ground. He couldn't figure out the problem either. Did a high speed taxi down the runway and fuel flow was normal. Took it up in the pattern and again everything was normal. We did fuel up before we left KPRB and I didn't sump the tanks for water. Maybe there was water in the fuel? Any other ideas?? Thanks!

-

The oil and fuel lines in my 1999 Mooney Eagle need replacement according my mechanic and Continental Tech Support. I have the rec "C" lines which are rated for 7 years. He is recommending to go to rev "D" which is teflon and is rated for 12+ years. Anyone has done this on io550? if yes, any recommendation on where to get the hoses made for the best quality and price? Driver

-

Hey all, I am looking at purchasing my first Retract, Variable Pitch prop airplane and I am looking for feedback in regards to operating cost... I live in Canada and will do a lot of Mountain Flying (Rocky Mountains) and was wondering what the true, average operating cost is for a Mooney or Similar. I've already got my insurance quote which came in at just under CAN$1700/year. Not bad considering all my 300Hr TT is in a Cessna 172..., The quote is subject to 10hr of dual instructions... I am curious on additional cost... Annual, Engine Reserve, 100hr inspections, etc... Has anyone experience in operating one out of a grass strip? Mountain Flying? I am interested in some current data, not something from 5, 10 or more years ago... Thanks in advance. Andreas

- 55 replies

-

- operating cost

- maintainance

-

(and 2 more)

Tagged with:

-

SOLD! I have 2 inboard and 2 outboard fuel senders available for sale. Removed from my Ovation2 for upgrade to Cies digital fuel senders to go with a JPI EDM-930. All were working when removed, one outboard was overhauled by Air Parts of Lock Haven a few years ago. Inboards are Mooney P/N 610242-1 (Mfg P/N 7740-118), outboards are Mooney P/N 610242-5 (Mfg P/N 7740-400). Check your parts manual to be sure, but I think these same P/Ns were used in many different model Mooney fuel tanks. Floats are in good condition with just a few minor blemishes, but they do float as they should. All include the previously used Viton mounting gaskets, but they might be of questionable value. Asking $75 each. Dave 928-710-7874 SOLD!

-

Is it advisable to you gas stabilizer in Avgas?

-

I noticed fuel smell in the cockpit last year and after removing the side panel I saw blue stains all around the fuel pick up tube. A new set of rubber gaskets were ordered from mooney and replaced. Almost one year later and after a new interior, this is what I found today...same problem with brand new gaskets. I'm curious if anyone else is having this issue and if so, how did you fix. And by the way, my tanks were resealed by week no more two years ago. And yes, my IA toqued the screws around the gasket per mooney. Thanks

-

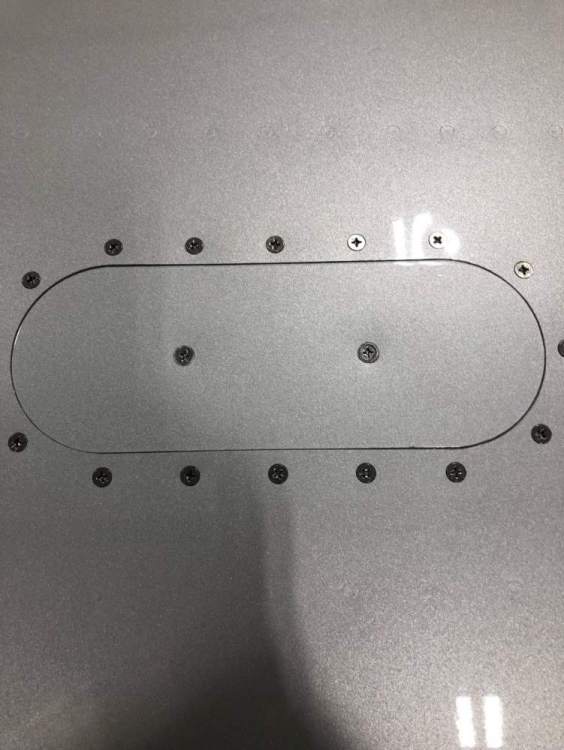

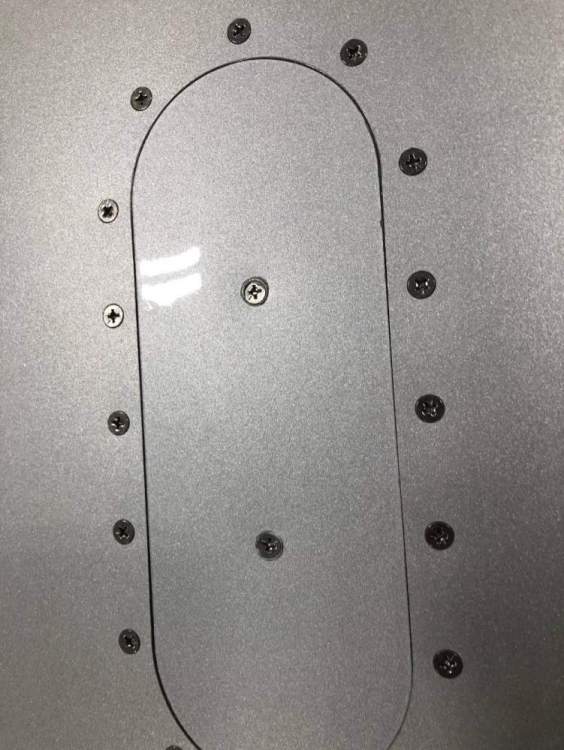

Hi all Discovered a fuel leak coming from what appear to be two screws on a lower panel. Read DMax article and what was available her and have a couple of questions. By DMax article, seems like nut plate cracks are the typical culprit in this circumstance. He says remove a screw, apply sealant to the thread and replace. Wow sounds easy. But this is a Mooney fuel tank system after all. 1) Screws are seized. I don't want to damage them and am afraid of creating new leaks on this panel if I take an impact to them. 2) the panel location is just below the filler cap, so I can get a great visual on the sealant there. Looks like a minuscule crack in the sealant along the nut plate IA is on vacation, so we'll be talking when he returns. What is the group consensus - remove panel and reseal or patch seal from inside? Seems like option 2 would be the good is better than perfect option but I'm hesitant to add layer upon layer of Proseal. Thanks as always Brad

-

Guys, I'm looking for a fuel cap for our 1978J model. Part number is 431-21A. Let me know what you have. Thanks, Douglas

-

Hi all, After several busy weeks I was finally able to fly last week and run a GAMI spread to diagnose the overheating issue of cylinder 1 on takeoff/climb. Not a massive overheating mind you (~390-400 deg) but still much higher than normal. Below are the screenshots from May this year (poor data rate but it gets the point across) and the one I took last week. You can see that the May spread was very good (about 0.2 gph). The one from last week however shows the cylinder 1 peak occurring roughly 1 gph higher than the rest of the cylinders; the other cylinders all look the same as before. To me this indicates a partial fuel blockage in either the injector itself or the feed line/distributor. I removed the injector before the flight (since I suspected this might be the issue) and everything looked clean and free. Reinstalled and flew the plane. Do y'all agree with my diagnosis? What other parts are susceptible to plugging? Since it's only this cylinder and total flow rates are normal on takeoff and cruise, I'd think it would be something downstream of (or in) the fuel distributor/spider. Should I send the injector back to GAMI to get it flow tested first before I do anything else? -Don

-

I don't have my parts manual handy,does anyone have the part number for the wing fuel drains. I have one that just started leaking so I thought I would put an order into Spruce and have one waiting when I GOT home. Thanks, Ps. I am a new 68 M20g owner. FB

-

Been flying my new (to me) 252/Encore conversion for about 3 months now, so I'm still getting used to it in many ways. But one thing that is alarming is that I smell fuel in the cockpit rather strongly on short final sometimes. It seems to happen the most and be the strongest when I close the throttle completely if I'm coming in too high, for example. It may be the attitude (fuel moving forward in the tanks?) and not related to the throttle position, but I feel like I've noticed it more often when I've been too high (darn slippery airplane!) and cut the throttle abruptly. This is rather concerning... any ideas what is going on?

.thumb.jpg.61656b3dc4768c538a94de2e99554013.jpg)