-

Posts

1,264 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 47U

-

Cutting a new panel can be done relatively inexpensively, depending on how much involvement the owner provides. You can manufacture your own panel (using a template or your own custom design) and have your A&P install it as a minor mod, or install it yourself and have your A&P inspect and sign off your work. The real cost comes when you start replacing the steam gauges you have for the glass ones you want. tom

-

As panels go glass and vacuum systems are removed, could a generator be installed on the vacuum pump pad and used as the separate power source for a second E mag? Field approval, maybe? tom

-

Sure. The file is very much in 'draft' form... trying different orientations, fonts, etc... hope it helps. tom Compass_Card_20200627.docx

-

I just redid my compass card and stuck it up yesterday. I made my own in MS Word. I made it small enough to stick on the flat area above the card, about 3/4” high and 1 1/2” wide. I laminated it in clear packing tape and used foam mounting tape to stick it to the compass. I can send you the word.doc if you want and you can plug in your own numbers. I used several landscape/portrait orientations and font variations until I got something I thought would work. I should have taken a pic after I stuck it on. I usually accost my (poor) wifey with detailed pics and intricate stories on what I’m doing when sequestered at the hangar. Except yesterday I went flying. The track isn’t from yesterday, though, it’s from last week. I swung (inflight) the vertical card to the remote compass, which I had swung on the compass rose a few months ago after installation. I made a couple turns in the hold first, then flew the N - S, E - W headings, adjust to 0 error and removing half the error on the reciprocal. Then I flew the 30 degree incremental headings and wrote down the plus/minus. It actually was kinda fun. Wifey wasn’t impressed, She thought it was just going in circles. I’ll verify my inflight swing numbers on the compass rose when it’s not so hot out. tom I added a pic of the compass card installed...

-

Inspection panel come loose during flight?

47U replied to SantosDumont's topic in General Mooney Talk

Is. there a sump drain outboard of the main gear door on the F model? In the wing bay aft of the spar? Long-range tanks? tom -

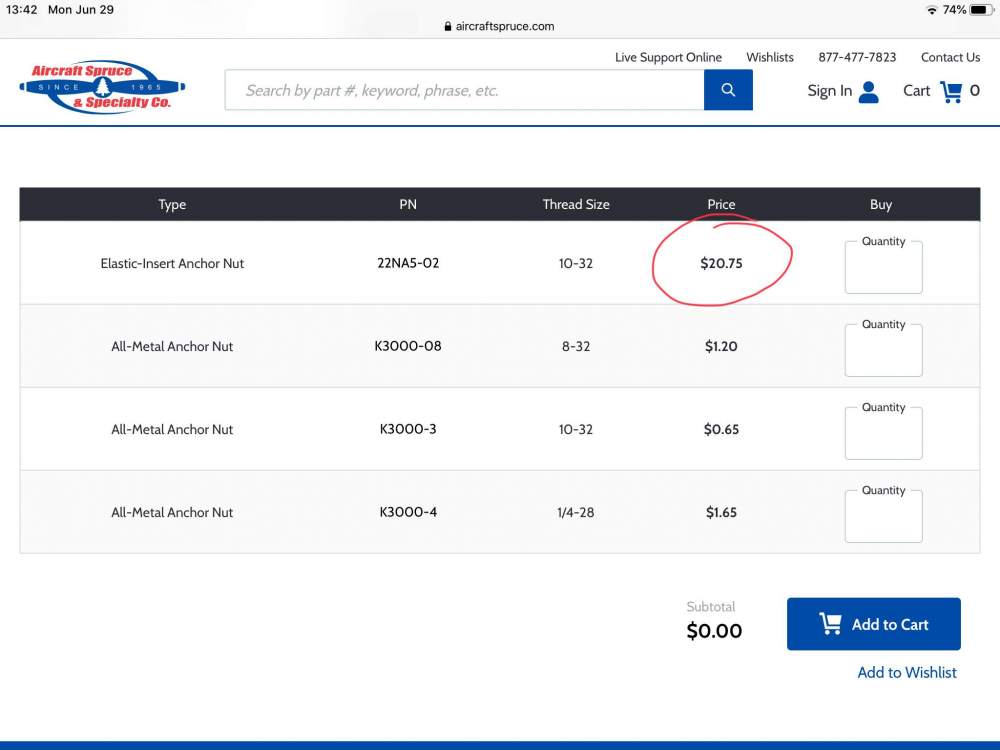

What the market will bear. Aircraft Spruce REALLY likes the plastic in their corner-style nutplates, too.

-

Is there some fuel staining at the carb/bowl split line? Precision published a couple service bulletins that may affect your carb. One is for bowl leaking/security and the other for replacement of the float. Copy the links into your browser... http://www.msacarbs.com/pdf/MSA-13.pdf https://msacarbs.com/pdf/MSA-14.pdf MSA-3 says 10 years between carb overhauls, if I remember correctly... tom

-

Are you talking just the sheet metal screws on the cowling and (some) belly panels? Or the countersunk screws on the wing oval and rectangular panels, also? The wing access panels are structural. Finding conformance data on them might prove to be a hurdle too far. I have begun painting a thin stripe of anti-seize on the machine screws before I put them back in. I’ll run them up with a ‘yankee’ screwdriver and then tighten by hand. Use a new good quality #2 apex bit when you remove the screws and 99.9% of your stripped screw problems will disappear. tom

-

Not that uncommon, apparently. I was ground running to leak/ops check an FP-5 I had just installed. It would do this on every 10th or so attempt to erect. I’ve since replaced it. IMG_0061.MOV

-

Golf Cart? Out here, it’s a Neighborhood Electric Vehicle (NEV), and they have their own lanes (except when they share with bicycles). tom

-

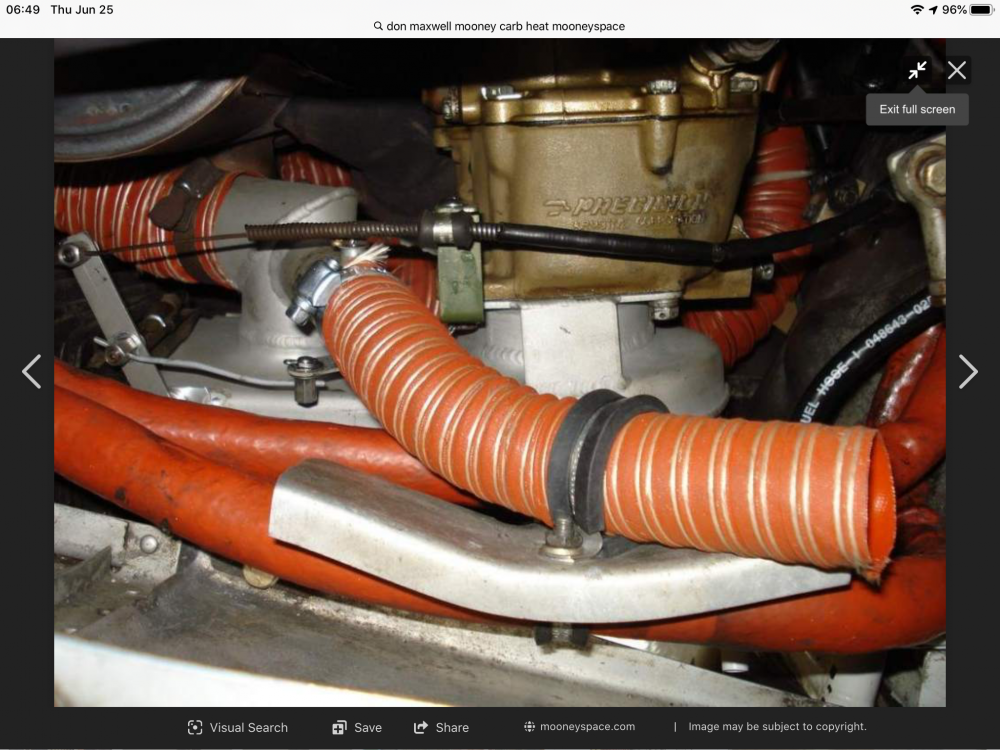

Here’s a pic from a ragedracer1977 post back last Nov showing the heat shield... Also shows pretty clearly the carb air dump scat tubing, except it’s too short. It should be long enough to exit the cowl flap. tom

-

Another plus for Aero Graphics. They sent me the flap/trim decal (x3, actually) for FREE. She said it was such a minor run and no big deal. I told her I’d be redoing more graphics in the future and Aero Graphics would get my business. I called them a few months ago when I was redoing the flap/trim indicators. I had discovered the carpet pile over the nose gear wheel well was interfering with the needle movement. Trimming the carpet pile for more clearance fixed it. While I had it all apart, I replaced the sticker.

-

The center windscreen support isn’t that difficult to remove. You’ll need to coord with your A&P though, since it’s not a side window. If you replace any hardware, use brass/non-ferrous. You might find the hardware was installed with sealant, or some clear RTV. One of the salvage yards likely has the compass mount. If you’re out west (or even if you’re not), Paul Loewen sold me a cabin door hinge very reasonably priced. He shipped it the same day I called him. https://www.loewensmooneysalvage.com/contact Phone: (707) 263-0472 Cell: (707) 272-8638 paulloewen98@gmail.com Mail: 400 Lakeview Road Lakeport, CA. 95453 Once it’s back together, my compass had a short (half inch?) piece of vacuum hose wedged between the compass housing and the center windscreen support to keep it from vibrating. It looks like yours suffered a fatigue crack and broke, just guessing. tom

-

Wing Ding - Would your shop pass it?

47U replied to glafaille's topic in Vintage Mooneys (pre-J models)

Odd that the gear door looks pristine. In my opinion, that is a wing skin waiting to be replaced. Sooner or later, the A&P (and/or IA) is going to say, “no.” There are places in TX that do that sort of work. Good sheet metal craftsmen produce artwork. Choose carefully. tom -

At the risk of spreading heresy, I’m not sure the stab trim jackscrew boot does all that much good. The concept is sound, but in application problematic. There’s not much room in there to hold the boot clear of the jackscrew so the old grease can be removed and new grease reapplied. Even with the stab trim run all the way to the stop. The result is, too many times new grease gets applied on top of old grease and no effective cleaning ever gets done. This just looks like a mess and certainly isn’t ‘clean.’ My C didn’t have a boot on it when I got it in 2008. The grease was in pretty bad shape and I suspect it hadn’t had a good cleaning for decades, even without the boot. I got all the old grease cleaned out and replied new grease and now it’s a fairly painless process every annual to clean and re-lube it. The flat panel fuselage fairings keep the cavity covered and protected from dirt and water. I think that unless you frequent unapproved strips, the boot is overkill. A good cleaning of the jackscrew once a year and clean grease applied is probably better than lots of Mooneys who have the boot and get marginal service because the access is so poor. Just say’n. tom

-

I apologize in advance for this post, I’m in a caffeine deficiency... To proceed down this rabbit hole... My private pilot and A&P mechanic certificates are the same number. An A&P cannot ‘manufacture’ parts for certified aircraft. So, if I produce a part under the owner produced part rules for my 63C (like my McFarlane throttle and prop cables), do I need to make an entry in the airframe logbook as the ‘owner/operator’ that I produced this part (conforming per blah, blah, blah) and supplied it to the A&P, then a second entry in the airframe logbook using my ‘mechanic’ certificate that I received from the owner/operator this OPP and, upon inspection, it conforms with (blah, blah, blah) to install it? I would hope the FAA wouldn’t violate me as both an owner/operator and mechanic as I made a single entry in the logbook stating these are OPPs and installed them using only my ‘mechanic‘ certificate identifier in a single logbook entry. Should I have signed it off as ‘Owner/Operator; A&P’ vs. just ‘A&P’? Or, I could request my comptroller make the OPP logbook entry since she is listed on the aircraft registration as ‘co-owner.’ Wouldn’t she just love that! tom

-

I had my main gear out and found it easier to get it apart than to get the spring/link/bolt back together. I ended up hooking a ratchet tie down strap to the spring so that the link would be free, and putting the other end of the strap around substantial structure (I don’t remember exactly what) and cinching the strap up until I got the hole in the link lined up and the bolt installed. With the gear supported in the up position by a length of 2x4, it’s soooo close, you’d think it would be easy. Not so much. I entertained using the quarters/washers method, but I’m not one to do things the easy way, so my comptroller says. tom

-

Fresh air vent door on plane top - OOC? M20E

47U replied to Skydancer2992's topic in Vintage Mooneys (pre-J models)

If your vent scoop is flush with the aircraft skin, there’s an arm inside the air box that is attached to the scoop. The arm has a retainer fitting and screw to attach the wire to the arm. There are plugs in the air box, one of them for screw driver access to loosen the screw so the wire and be removed and the new wire installed. It’s a challenge to thread the wire through the fitting, but it can be done without hacking the air box apart. I had removed the scat tubes to replace them so could ‘kinda’ see inside what I was doing. Kinda. Soak the screw with some Kroil first thing you get the plug out. If you strip the Phillips head on the screw, it could get ugly. I happened to get busy on another project, for about a month, and when I came back the screw came out like butter. Good luck! tom -

That’s a really nice looking C. REALLY nice. There’s a guy near Omaha looking for a C right now. tom

-

I’d say that replacing the empennage with a factory new (more than 50 years ago) is a proper repair and shouldn’t affect the listing price at all, similarly with the gear up 30 years ago. It’s a non issue because most vintage C’s (I’m guessing) have had a gear up. It does sound like a really nice airplane. The tie breaker between your’s and other’s on the market might come down to the paint color/scheme. That’s superficial, but often true. Someone is going to get a really nice airplane. Good luck! tom

-

Brice, I’m not following the market closely enough to make a guess on price, but regardless of the substantial engine work, TSMO is TSMO, and you’re past it. It’s going to impact the appraisal, in my opinion. Damage history? Complete logbooks? Got the FAA CD? Curious to know the story about colliding with wires and power poles back in 1967. Excerpt from the NTSB report: REMARKS- WIRES BROKEN,POWER POLES DAMAGED.PLT MADE NO REPORT AND DID NOT ACKNOWLEDGE ACDNT. If it’s all fixed up good it might not be an issue. But damage history should be disclosed and the repairs explained in detail (to the best of your knowledge), even if it’s ancient history. https://www.ntsb.gov/_layouts/ntsb.aviation/brief.aspx?ev_id=18724&key=0. My apologies if you didn’t know. tom

-

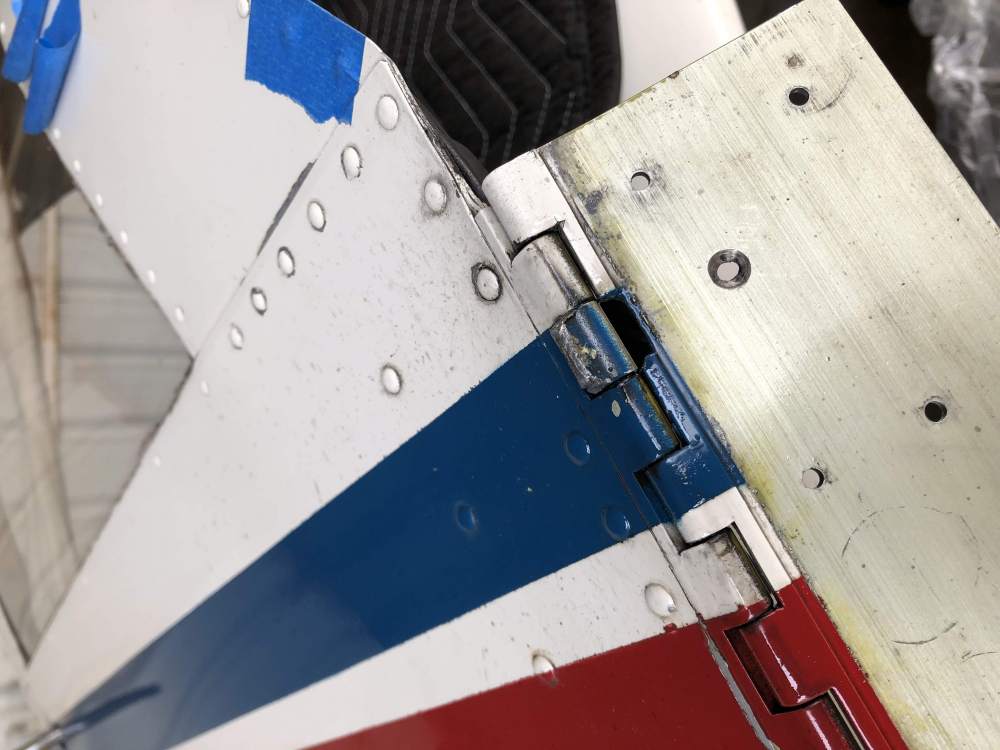

I grew up on a farm in the mid-west and Kroil was the go-to for rusted/frozen parts. But, you have to give it some time to work. How well does it work on aluminum oxide? I’m finding out. Project is to replace the cabin door hinge, ship-side half, with a broken lobe (50+ years ago). Soaked it down two days ago, yesterday the punch and ball peen hammer doesn’t move it. We’ll see if I have better luck today. I’d rather replace just the ship-side half, and not take the door all apart to replace both halves. I’ll probably have to cut the top lobe off so I can put a locking pliers on it. tom

-

What are the unexpected things in your hanger?

47U replied to flyingchump's topic in General Mooney Talk

A big piece of cardboard (or carpet remnant) to lay on while cleaning the belly. The height of even a low-profile creeper is uncomfortable steering around antennas. I’ve become fond of my mosquito fogger, during that season, and a spider web brush. tom -

How do you know you married the right woman?

47U replied to Paul_Havelka's topic in Miscellaneous Aviation Talk

Back in the day... She let me refinance our paid-off Astrovan to buy a Cherokee 160 for $7,500 (there was an M20E in the same paper for $16,500, but I knew I wouldn’t have been able to care for her like she would require). Later, she complained about making “airplane payments” and I had to come clean and tell her that if we didn’t make this payment, they would come get her car. Now a days, she really likes the Mooney. She let’s me spend about whatever I need (want), and knows where I am when I’m not at home. Of course, I let her reciprocate with her spending, within reasonable constraints... so far. tom -

Surefly + Powerflow Pirep, #4 CHT mystery in M20C

47U replied to DXB's topic in Vintage Mooneys (pre-J models)

I’ve never seen the PF installation up close... Pic taken from the PF website. The tube on the right side coming out of the muffler shroud is the cooling air exhaust? How does that work as compared to the linkage closing the exit valve on the original installation? tom