Aerodon

Supporter-

Posts

1,318 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Aerodon

-

lean function on EDM 800 quit working

Aerodon replied to RCBass's topic in Engine Monitor Discussion

The lean function needs to see all cylinders rising so that it can determine a peak. If one cylinders keeps dropping off the get-go, then its already peaked. Go check your fuel flow setup, maybe they changed something at the annual? Timing? Aerodon -

M20K Electrical Schematics 1 Left SN 25-0172 to 0246

Aerodon replied to Aerodon's topic in Avionics / Parts Classifieds

I still have the ones in bold above. Supercub180@gmail.com -

I have one for you, Aerodon supercub180@gmail.com

-

Need help troubleshooting CDI glideslope

Aerodon replied to Seth1001's topic in Avionics/Panel Discussion

You say you have a KN-57 - as far as I remember the KX170 series had this as a remote box for the ILS, and I don't see if you have tried or checked this out? You Aerodon -

I have a TSIO360MB core that I've started taking apart. The case and crank are the same, I could get these overhauled and you could use these to rebuild your broken engine? I'm sure regulations by country vary. But if you had a mid or low time engine, you could replace these parts and a cylinder, and continue where you left off. I've seen this done with a 200 hour engine, but obviously at some point it becomes worth overhauling. Aerodon

-

IO360TSIO-GB after Continental SB - starting procedure

Aerodon replied to NicoN's topic in Modern Mooney Discussion

Seems to me your guy did not do the whole conversion. Check to see if you have the drain valves with the 'dot' on one of the faces. My guess is if you have one of the old style, the fuel will drain out immediately. The new one will 'dam' the fuel until it is used in the starting, and overflow if you over prime. BTW, the small hole does not go through on mine, I have mixed answers on whether it should or not. I found the new priming system better than the old - it is more logical to prime every cylinder than one place in the manifold. My engine starts first time within a few cranks. Don -

From the album: OPP Pedal Extensions

-

I've delivered a plane for an inspection before, I don't think I would do it again. And I wouldn't expect the seller to deliver a plane off the airfield either. If I can' find someone there to go do it and if that shortens the list of available planes, then so be it. Aerodon

-

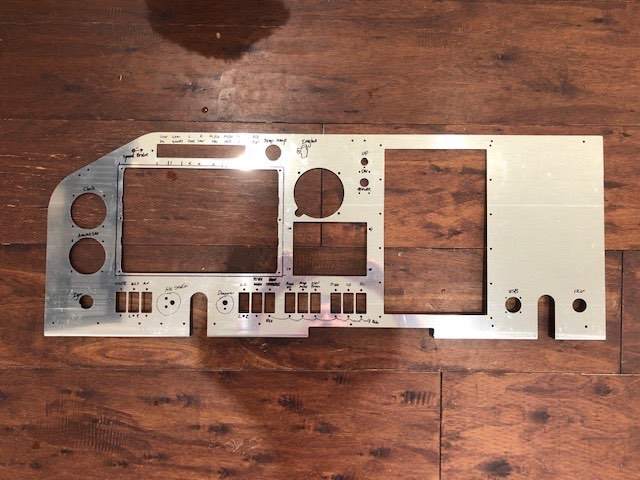

The 'standard' M20J/K panels were built in multiple pieces. Ignition / Pilots side, radio stack 1 Radio stack 2 and circuit breaker. Mooney used numerous CPC connectors so they are easily removed and replaced. Later model Mooneys used a 2 piece (3/4 & 1/4) - this is the arrangement that I prefer because you can sort out all the circuit breakers first and install the panel later. The M20J/K radio mounts are 'flimsy' to say the least, and after they have been drilled a few times, they have to be replaced. I have used 'radiorax' several times - Mooney is not on the Radiorax 'AML' so you have to work with the installer to get them approved. They sell a slimline version that will allow two full radio stacks in the existing space. If you have a new 3/4 panel made, it can pick up all the old mounting points on the airframe, and the Radiorax are a far more robust way of attaching the trays to the panel and airframe. Here is a 3/4 panel I made with 2 x G3X's. You can't tell, but the radio stack moved about a 1/4" over. You could move it further, but then you have to think of what the 'bump' in the panel and glareshiled will look like. I have managed to find an older M20K glareshield without a bump, that will help clean up the 'look'. The more you stay with the standard Mooney layout and construction, the easier it is to get it signed out. I would not move the gear selector or gear override light very much. I think it is hard to have 2 G3X's and two radio stacks - give some though to remote transponders, audio panels etc. - it can fit in one stack. Aerodon

-

I looked at pictures of a 252, and there seems to be a support bracket for the KFC150 autopilot servo along the seam. Aerodon

-

An annoying fault with my low fuel annunciator

Aerodon replied to aviatoreb's topic in Modern Mooney Discussion

Erik, I recall reading that the low fuel is calibrated in the annunciator unit. All the other annunciators are on / off, but the lo fuel needs to be set. If it's drifting, I would start with the annunciator. I'll browse through the maintenance manual sometime and see if I can find the reference. Aerodon -

I am told that all 'mechanical' diversions are reported to the FAA and that someone looks over the list and decides whether to follow up or not. I would imagine that all emergencies are too, or anything that generates an incident report. So I work on the assumption that it is going to happen. So, with any incident, it is reasonable to enquire about the airplane and its recent maintenance history. Even the pilot, was he qualified to fly, insurance etc. No different to a traffic stop, rules might be different in different states. And then was the problem properly fixed before the next flight. In Canada it is well defined, a pilot is allowed to perform the following elementary work. (17) removal and replacement of fuses, light bulbs and reflectors; (21) opening and closing of non-structural access panels; This would allow me to remove the one piece belly panel and replace a bulb. Then sign the journey log and I am done. But jiggling the wire to get it working again is not covered, and I am not qualified as a pilot to do that repair. And the bulb needs to be purchased through an approved supplier. On the M20K the floor bulb and annunciator light are in parallel. The POH shows that the gear position indicator is required for VFR flight. I would argue that the position indicator was working and at least 1 of the two lights was working. I would also argue that a flashlight could be used to check the position indicator. I do not know the FAA rules as well. But I suspect 'jiggling the wire' is not an approved repair, and if you did no logbook entry and flew, you have created an issue for yourself. Fessing up on the internet has created a paper trail, make no mistake the FAA reads through these blogs. I suspect and hope that it all turns out well for you. Personally, I think a tower fly by is a dumb thing to do. Know your airplane, listen to the gear going down, feel the clunk etc. Know your systems, if you have a second annunciator and it is working, there was no need to say anything to the tower. And if you 'alert the tower', don't be surprised if they escalate to a full emergency whether you declare or not. They don't need much of an excuse, and there's no upside on waiting until you do a wheels up or worse before calling the equipment. And the lesson to all of us, if you've opened the can of worms, make sure you do everything right afterwards. More than one plane has crashed after the owner has done some enroute repairs. And more than one jet has crashed because of landing light bulbs not working. Aerodon

-

Hidden Damage, Looking for Repair Options

Aerodon replied to AerostarDriver's topic in Vintage Mooneys (pre-J models)

I had Aveo wingtips installed, and I could not see into the first bay in the wing. I realize that there are various wingtips, but unless they went looking with a borescope I doubt they would have found it from the inside. On the outside, it would look like a bit of body filler on some hangar rash. It was a pretty sh1tty repair, but I wouldn't put too much on Dmax. If I bought plane like that and the previous owner did that repair, I would not be happy. Just fix it and move on, it's not a perfect world. Aerodon -

Aah, now I think I understand how the spring steel wire was attached to the post for the flap indicator. Just wrapped around? But there is a hole in the post, either for a cotter pin to hold the 'coil on' or maybe tuck the end of the wire in? Aerodon

-

Upgrading a 252 to the Encore's engine

Aerodon replied to Parker_Woodruff's topic in Modern Mooney Discussion

That might be correct for a 25-20XX serial number, but for a 25-1XXX conversion you need to change the lower gear legs, brakes, gear doors, master cylinders (& bell cranks too). Aerodon -

The nosegear collapsed on this airplane during its off field landing, so don't get your hopes up. Aerodon

-

If you can measure accurately, I can easily cut a filler plate for you. For a really good long term solution I cut one panel to fit behind your instrument panel and another piece to fit exactly in the hole. Then flush river the two together and paint. Drawing and cutting at the same time allows the rivet holes to match and be on a precise layout. Not all the 1/2 ATI holes are exactly the same. The KAS297 and KI572 look the same but are different. One of those aircraft spruce [plastic covers should work. But bite the bullet and do a full panel redo - this is my latest creation for a 252. This will be a template for final test fitting and tweaking the design. I'm thinking of dumping the annunciator panel and using some of the fancy square Eaton annunciators. The EDM900 annunciator will give a red or amber 'check engine' light that will draw your attention to the EDM900 for Hi/Lo volts, Low fuel, etc. Still need gear up, gear unsafe, alt air, I can do without 'starter engaged'. Aerodon

-

Labor Hours To Install a PMA350B

Aerodon replied to GeneralT001's topic in Avionics/Panel Discussion

Just wondering what you are trying to achieve? Are you still doing your glass panel update, wait until then? An older PMA7000 will be a better plug and play with the KMA24, it would not be too hard to remove the separate intercom. But all this might get you is stereo audio and a couple of music inputs. And a bit of panel space. Aerodon -

HAIS, Is your plane still at CYCW - just order a new battery from Firkus or Chief's and get someone there to change it for you? And get the best Concorde you can find and look after it properly (battery minders etc.) and it will last 10 years. Aerodon

-

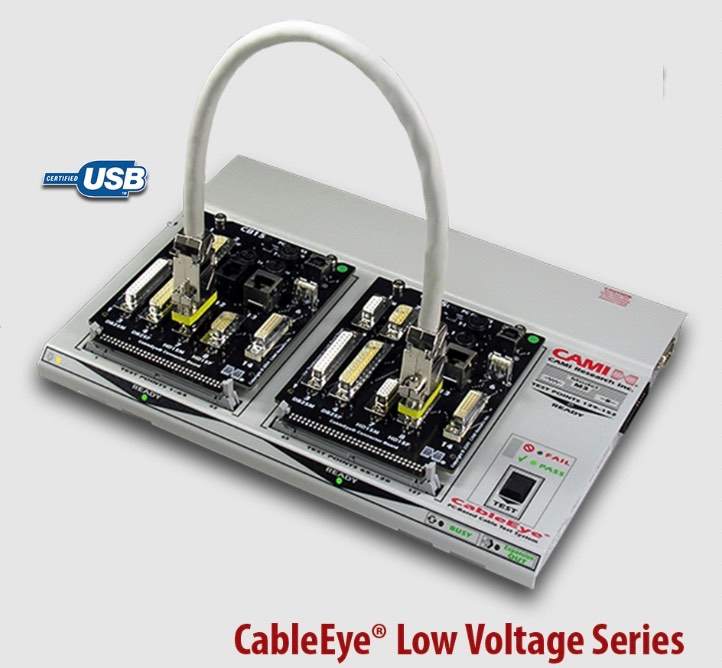

I have one of these cable testers with a total of 4 expansion slots, 12 different boards and more than 20 cables that can plug into just about every aviation connector in the plane. Even the Garmin 78 pin HD connectors, Winchester connectors (Bendix King) etc. If it is a loose wire, one of the tester cables has 10 mini clips. It tests every pin against every other pin and can generate a useable wiring diagram and a pin to pin list in seconds. This is a really excellent way of generating 'as-built' wiring diagrams testing against a known configuration for pass/fail and also trouble shooting existing installations. Aerodon

-

KCOE Cd'a ID Gear up??

Aerodon replied to Dick Denenny's topic in Mooney Safety & Accident Discussion

There are gear ups for other reasons. Broken no back spring for one. Something snagged on a gear. Broken hardware etc. -

I have made several of these for Mooney / Piper. Wide enough straddle the hole in the wing rib, tilted 7 degrees, predrilled for GMU11. Send me an email, supercub180@gmail.com if you need one. Aerodon

-

Rear driven alternator parts looks like the starter drive is part of the upgrade, this would get quite expensive.

-

That was well installed, fuse on the input side (or is that a connector?), then circuit breaker on both the oullets. The fuse on the input side should be really near the battery or the busbar that supplies it - should not be too difficult to trace? Get your voltmeter out, maybe the converter has failed? Aerodon