Aerodon

Supporter-

Posts

1,243 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Aerodon

-

Garmin GI 275 HSI/GMU-11 Inaccuracy

Aerodon replied to Tom 4536's topic in Avionics/Panel Discussion

If your installer was lazy and did the calibration near hangars or airplanes, I would not be surprised if this translated into a 10 degree error 'out in the open'. Aerodon -

Garmin GI 275 HSI/GMU-11 Inaccuracy

Aerodon replied to Tom 4536's topic in Avionics/Panel Discussion

I call BS. Find another installer to do both the magnetic interference test and the calibration. By definition, the calibration is the 'software' to make the corrections. (and if you can find an install manual, it's easy to do both these procedures yourself). Aerodon -

WTB: FuelScan-450 and Carb Temp for 68C

Aerodon replied to TCUDustoff's topic in Avionics / Parts Classifieds

What engine monitor do you have? You can easily add CRB to an EDM700, not to a FS450. You can add FF to a 700, advantage is that your fuel data gets recorded along with other engine instrumentation. And you are 'ready' for an EDM830 upgrade sometime. I have 450's, 700's (all flavours) and EDM800's in stock, taken in on trade for 830's and 900's. Aerodon supercub180@gmail.com -

I'm making slow progress, its hard to get the attention of a machine shop to do small jobs. Had the parts laser cut, but that shop could not do the bending. Had another shop do the joggle in the side pieces, they did a really nice job. Just waiting for them to do the centre piece. Aerodon

-

G3X / G5 / GFC 500 / GTN 650 Installation time

Aerodon replied to PT20J's topic in Avionics/Panel Discussion

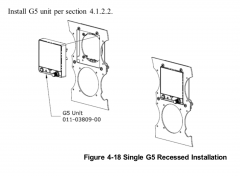

Art, with a single G5, the flush mounting holes and spacers could be placed above and below the G5, allowing for very close side by side spacing. But I would want to leave .5-.75" material between the G5 and G3x for strength. Personally, I think the GI-275 is a better way to go, even if you have a a spare G5. Aerodon -

G3X / G5 / GFC 500 / GTN 650 Installation time

Aerodon replied to PT20J's topic in Avionics/Panel Discussion

Good eye. It is indeed not vertical because the CB panel in the Mooney is not straight 9as built by the factory). We looked at it and determined it could not be adjusted, so I adjusted the panel to fit. If it were my plane, I would cut a new CB panel and mount it parallel to the rest of the panel like the later model Mooneys. Aerodon -

G3X / G5 / GFC 500 / GTN 650 Installation time

Aerodon replied to PT20J's topic in Avionics/Panel Discussion

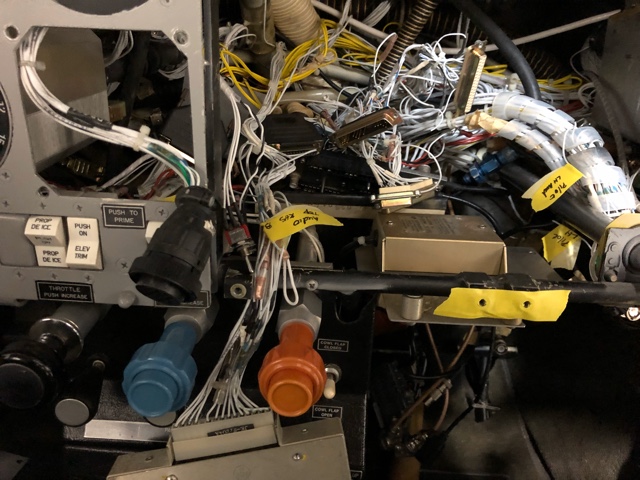

Skip, Just finishing off this M20J panel, plan to install tomorrow. Two G3x, Audio panel, GTN650, GNC255, GTX345, GFC500. This is the first 3/4 panel with radiorax that I have done. Two G5's semi flush mounted to match the G3x's along side. I have vinyl labels made, will try something with higher quality. Note the non standard gear / override switch placement as per customers request. Also 3 spare with places per customers request. I would have preferred to put the master/alternator/avionics switch there. Not the overlay panel for the old engine instruments - now contains ELT and dimmer switch - enough space for a USB outlet there too. Aerodon -

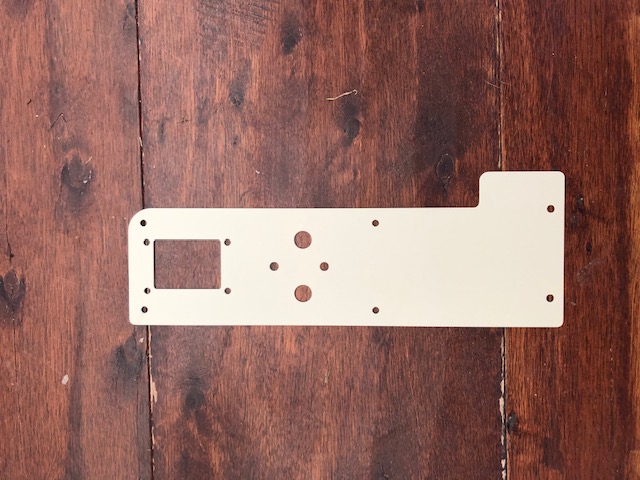

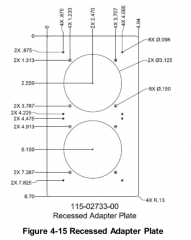

We came to the same conclusion. Here's the back of an M20J that I am working on. We've recessed the G5's by 1/4" to match the G3x. Note the radiorax rails (pointing wrong way here). Had to learn how to get my CNC machine to drill the 12 holes to align with the panel holes. Next step is to countersink and screw in place. Having fun so far, but if you've ever wondered why some places charge '000's for new panels, there is a ton of work. Aerodon

-

I have a spare TSIO360MB that could be overhauled prior to removing yours to minimize downtime? Aerodon

-

Dumb GTX330 Wiring Diagram Question

Aerodon replied to TCUDustoff's topic in Avionics/Panel Discussion

IIRC the GTX330 uses a HD (High Density) connector, so it is difficult / not possible to use 18 or 20Ga wire in the small pins. There might also be a current limit per pin. I've seen several installations where they join the two wires with a splice a few inches away from the connector. Every splice introduces a new point of failure, especially if you don't use high quality splices and crimpers. I used to like the AMP crimp splices, but my new favourite are the enviro splices. Make sure you have the proper crimper, and a small butane heat gun. https://www.edmo.com/product/D-436-0110/multi-wire-splice-red-d-436-0110 Aerodon -

I quickly looked at the chart on a 252, and it could use 50% more runway at 8000'. Think of it like this, the airplane needs to get to a certain IAS. At 8000' the TAS will be higher. Therefore the ground speed will be higher. I learned to fly at 5500' elevation, and often saw 8000' density altitudes. When I flew to sea level destinations, I could not believe how slow the landings felt, and had to pay attention and believe the airspeed indicator. Aerodon

-

From the album: M20J and M20K Panels

M20J Panel with G3x -

-

The shop that painted it was also the dealer. Now there is an Alberta dealer (the owners home province) and the plane has been pushed outside of dealer #1's hangar. I would be OK with scanned copies of previous logbooks, but it is easier to intentionally delete a page. Yes, my last experience with a dealer in Colorado was excellent - he chased down proper answers to all the questions I had, even tracking down previous owners and maintenance guys to ask about stuff. It's a hard plane to sell in Canada, there are not as many buyers that are wealthy enough, and not as many pilots as appreciative of a Mooney's capabilities. Yet given the distances and altitudes we need to fly, it should be easy. I see C172 prices going through the roof, they are being snapped up by the flying schools worldwide. So a matter of time before the more capable planes also become more valuable. Aerodon

-

It's a dealer selling it, it's currently at CYCW, and he can deliver to KBLI on a Canadian registration. You can get a broker to pre-clear the customs for a small fee, makes CBP much happier knowing that someone else has taken care and approved the import. The dealer can mask over the registration after landing and commence the de-registration process. You get a maintenance shop to do a fresh annual and get the plane ready for a DER inspector, who will issue the new CoA, one it is registered in your name. The big 'gotcha' is figuring out the point of change of ownership and change of funds. I got a little caught out last time when the escrow agent wouldn't release funds on delivery, and waited until reregistration. I was annoyed, because this was not what the sales agreement said. But it all worked out. I think the other thread said the early logbooks were missing? I have a hangar at CYCW, have seen the plane, know all the local guys, know the paint shop etc. I can help with the transaction if you want? Don

-

-

From the album: OPP Pedal Extensions

-

The second alternator hangs off the back of the engine and is driven by a belt drive off the accessory case. Then you need the second voltage regulator and all the wiring back to the circuit breaker panel. All feasible, but probably quite expensive. And I would imagine you could get it signed off as installing a factory option, the details are all in the writing diagrams and parts manuals. I have an engine that I am thinking of parting out, you could persuade me by giving me a large amount of money for the alternator, mounting brackets, accessory case (exchange) etc. Send me a PM. Aerodon

-

I've done it both ways, doing a lot of the legwork myself. 1) get someone to look at the logbooks before you commit, there are some real expensive 'gotchas'. Engine must have been overhauled by a CRS, prop overhauled within last 10 years, STC's and paperwork properly done and recorded. No '337' repairs or mods. Fire certificates of interior products. 2) the logistics seem almost impossible to me in Covid times. 3) use an escrow agent, to hold the money and release on cancelation. There is a sequence of removing the old registration, applying for cancellation, cancellation, notice to transport Canada, re-registration, ferry permit etc. Not easy. 4) in non-covid times it was easy enough arranging customs, just bring a big cheque/debit card / etc to pay the GST/HST . Right now, who nows 5) it will cost you a proper annual, rectifying deficiencies and a DER inspection or two before getting a Canadian CoA. See point 1 above, its the rectification of issues that is going to cost you. I would not buy a plane without a really good set of paperwork and with minimal modifications. Not worth the effort. Aerodon

-

Seems to me some of the posts are a bit negative. My biased view, from personal experience: 1) 252's are one of the best planes for two people to travel around in to visit lots of exciting places. 2) From 86 on, Mooney did a better job of corrosion proofing the structure 3) The engine change is with $50-70k (ask both GSX and I, we've done that). The recency of the engine change is also valuable. 50 hours on a 10 year engine overhaul is an issue. 4) As far as I know alll 252's are "encore upgradeable' 5) All 252's came with speedbrakes and decent avionics 6) Standard range is good, Monroy tanks are excellent (like fly the Atlantic without ferry tanks). 7) You will never struggle to sell a good airplane. Something with 1500 hours on an 1800 engine is going to be difficult. 8) I would say the asking price of $165k is very fair, and I think the comments made already about things to look for apply to any plane. You need to be able to accommodate $5-15k annuals, but I think you have taken a lot of risk out by having a low time engine. (who did it?) 9) Fly this 75 - 100 hours a years and in 5-10 years it is still a very saleable airplane. 10) the avionics may be dated, but the are capable and can be maintained as is. If I was in Europe and didn't have more planes than fingers I would go look. I keep trying to trade up, but I have problems with the divesting part. Aerodon

-

Wing mounted landing and taxi light installation

Aerodon replied to PT20J's topic in Modern Mooney Discussion

Yes, that's the easy part. But the IPC indicates from SN 25-1225 onwards. I had a look through the type certificate, could not find any help there. There are 'Notes' like the 'encore upgrade can be installed on serial number 1000 onwards' and 'vacuum system can be removed' if no system needs it. (you should see the debates on other types on whether is legal to remove 'required equipment' on the type certificate. I want to replace the wingtip recognition lights with midwing mounted lights so i can use the Aveo wingtips. Don -

Wing mounted landing and taxi light installation

Aerodon replied to PT20J's topic in Modern Mooney Discussion

So if the new Mooney are planning to be more supporting of old customers - I think a wing mounted landing light kit and retrofit approval would be a popular modification if it was reasonably priced? -

Where is your voltage regulator?

Aerodon replied to anthonydesmet's topic in Modern Mooney Discussion

-

Nut plates center avionics access.

Aerodon replied to Nukemzzz's topic in Vintage Mooneys (pre-J models)

I know these are quite pricey, but if you are replacing several 1/4 turn fasteners, might be time to upgrade: https://store.skybolt.com/mooney-c724.aspx I also like the 'epoxy in place' nut plates from click bond - especially useful for hard to access places or if you don't have all the tools for nut plates. Aerodon -

K Factor going from a Shadin MiniFlo to a JPI 930

Aerodon replied to LANCECASPER's topic in General Mooney Talk

I recently calibrated a gravity flow transducer in a C172. I kept records from my summer trip (42 hours) and did one correction and it has been accurate to within 0.5 to 1G (roughly 1-3% on the 'safe' side). On my trip I had one refuel that was 4G out (out of about 32G consumed), but all the rest were close. I went back to that airport on the way back and the numbers were close. I don't know what happened, I suspect a billing or fueling error (not starting from zero?), but it was a reminder to look at the refusers gauge every time, not just rely on fuel slips. And then the crazy looks when you call the truck back to squeeze another 1.8G in the tanks (4.5%). Another reminder to look. And that was with an 'easy' C172. A Mooney with long range tanks (settling issues), recessed filler caps, etc. introduces far more room for error in your calibration, so pay attention and be consistent, follow the JPI resetting procure and all will be good. Aerodon