All Activity

- Past hour

-

More thread drift alert My engine rebuilder told me that it's worth the hassle of retorquing the through bolts and then everything else linking the case halves about 1000hrs into the life of the engine since the bolts do stretch a bit over time . Supposedly it reduces risk of events like this in addition to a preventing oil leaks and case fretting? Any insights on best practice on this?

-

Was Delrin the material used by Mooney? It appears it is readily available and not too terribly expensive. It looks like anyone with a lathe and halfway reasonable skills should be able to make them. Am I missing something?

-

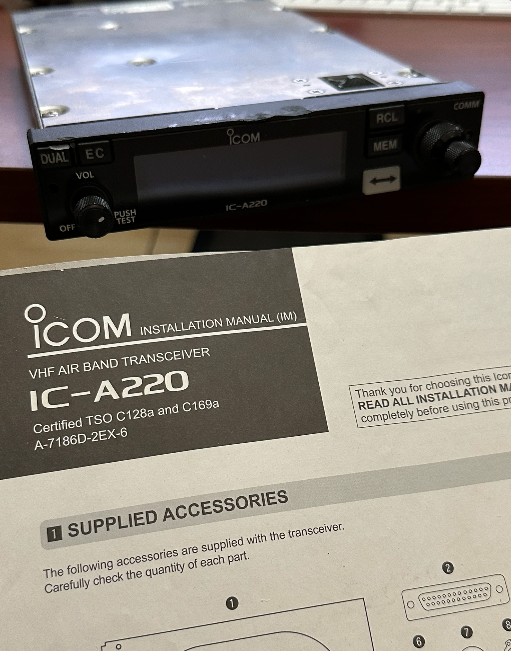

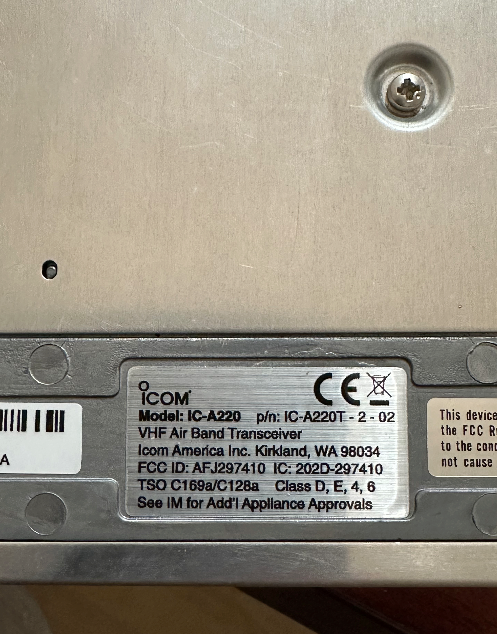

NEED A GOOD COM? iCom IC-A220T TSO Available

devyn6seven replied to devyn6seven's topic in General Mooney Talk

$1800 -

NEED A GOOD COM? iCom IC-A220T TSO Available

aviatoreb replied to devyn6seven's topic in General Mooney Talk

How much? -

DYNON SV Control Knob Available

devyn6seven replied to devyn6seven's topic in Avionics/Panel Discussion

Correct, it can be used with their autopilot, but it isn't "only" for the autopilot. -

DYNON SV Control Knob Available

N201MKTurbo replied to devyn6seven's topic in Avionics/Panel Discussion

With my limited Dynon experience, that panel isn’t for the autopilot. - Today

-

DYNON SV Control Knob Available

LANCECASPER replied to devyn6seven's topic in Avionics/Panel Discussion

How did you get a Dynon Autopilot installed in a C model? I thought they were approved for just for J & K. -

I can't keep up. First, there was no restriction, then there was a speed restriction requiring a much higher-priced plan, now there is no meaningful restriction (again). What's next?

-

kortopates started following Groton CT PPP

-

At the PPP Sent from my iPhone using Tapatalk

-

- 1

-

-

J models don't usually exceed 450 knots . . lol Edit: I was beat by a few seconds by @mhrivnak

-

See my post above. It's been gone since some time in July.

-

What about the speed restriction?

-

devyn6seven started following NEED A GOOD COM? iCom IC-A220T TSO Available and DYNON SV Control Knob Available

-

Hey all, recently redid my panel. I replaced this switch panel with the vertical one. Let me know if interested!

-

Just redid my panel and have some things becoming available. First up, the iCom IC-A220T (TSO). I replaced this radio with the Dynon SV-COM. It worked great for me, never any issues. For reference, Spruce sells it new for $2150: https://www.aircraftspruce.com/catalog/avpages/icom11-14551.php

-

I bought some from @Yetti a few years back for a previous Mooney.

-

Replacing the rollers when they were 35 years old was one of the easiest and best things I ever did. That was several years ago and I did get them from LASAR. While you are at it, consider swapping the pilot and passenger seat locations to even the wear on the frames. While you are at it, clean out the holes in the rails with a hand held drill bit. Good for another 35 years.

-

BOLO. I’ve always wanted to find an “I’ve Got PC” button which we had when PC came out in 1965. It was red, about 21/2” and I wore one like the dork nerd I was while in college.

-

safe lubricant for my main shock disks

Hank replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Yep. Eight zerk fittings on each main gear, plus the wheel bearing. -

safe lubricant for my main shock disks

Bartman replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

I would put the plane safely on jacks and have the maintenance and parts manuals on the wing. Have someone actuate the gear while you watch and listen. Locate every fitting, some are not easily seen. I don’t have my manual with me but I recall @Hank once documented all of the fitting locations. Mine has one missing and I have to use the needle on that one. Also, you may find the fitting takes grease better in a semi retracted position, and may not take grease at all sitting on the ground. Not trying to tell you what to do, and hope this helps. -

safe lubricant for my main shock disks

Derrickearly replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Maybe, but the squeak has a rubber on metal sound to it. -

Retract Gear or Flaps First in a Go Around ?

Ibra replied to donkaye, MCFI's topic in Modern Mooney Discussion

Haha, not much choice on takeoff... For landing, it has to be "power for speed" ("pitch for speed" is the only choice in gliders ), then, one day I had to "unlearn" as some airline guy wanted to see "pitch for glide" (like his coupled auto-pilote) and "power for speed" (like his auto-throttle) I the preference between Gear-Flap-Flap or Flap-Gear-Flap seems to depend on airframe specs as well as operator training background. Personally, I am all for "Gear first" in M20J, however, I used "Flaps first" twice when some examiner (who checks students on multi engine or Arrow) wanted to see Flaps, Gear, Flaps as part of "skill-test or check-ride pass standard" Are there any single engine retracts with draggy 40deg flap and under-powered engine? most ASEL with 40deg flaps seems to be fixed gear... "STOL + Complex/RG" don't mix very well (unless it's DC3: stol retract with 40deg flaps) -

From the M20C Type Certificate (Aircraft Specifiation No. 2A3, Revision 52, Dec. 9, 2010). And there you have it.

-

https://www.aircraftmagnetoservice.net It was maybe five years ago when they did the 500 hr on my right mag on my ‘63C. They identified the wrong model mag was installed (who knew?), but they worked with me to make it right.

-

Where are we supposed to be????