-

Posts

1,564 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by larryb

-

Today after fueling the plane the Shaw 531 fuel cap lever was very stiff on one side. I found I am missing the washer under the lever. Spruce has something, but it looks out of stock. For now, after lube, it's working OK, but of course I need to get a new washer. It looks like a standard washer with a wedge cut out. No idea how long it's been this way, could have been before I bought the plane. My MSC has replaced the o-rings on the cap, they should have noticed the missing washer, but... The stiffness came on suddenly, it was fine just 2 days ago. Options of course are finding the proper Shaw part. Or measuring the washer on the good side, finding a generic replacement and cutting out the wedge. Or a used one on ebay, just for the washer, I see several. If anybody has dealt with this and has insight, I would appreciate it. Larry https://www.aircraftspruce.com/catalog/appages/marshbrothers_05-22215.php?gclid=EAIaIQobChMIv7Hx3-3h5wIVbRitBh1ojgzQEAQYASABEgKuC_D_BwE

-

Today I did my 25 hour oil change and engine inspection. I found: Missing screw on heater exhaust shroud. EGT wire chafing against heater exhaust shroud. Missing washer under the lever on one Shaw fuel cap. To be honest, this was found because the lever was stiff, not due to inspection. And the biggie, very very loose clamps on #1 cylinder induction tube rubber coupler, a significant intake leak for sure.

-

It takes several days for the oil to drain back into the sump. So checking level immediately after flight will show a quart lower than the reading just before the flight. High oil temperature will lead to lower pressure due to the oil thinning. That said I do think there is a problem. I’d start with the high temp reading.

-

The one piece of advice I have is LOOK. Visually inspect everything. Spend some time on this. Look and poke at everything. In my pre-buy and annuals, there things that have been over-looked that I have seen. For example, the turbo oil line touching the hot side of the turbo. Or the oil breather line wearing a hole in my intake manifold. Wires chafing against the engine mount. It is handy to have a collection of the commonly used bolts/screws/nuts/washers from Aircraft Spruce handy so you don't have to make an order each time you find a missing screw. It's also a good idea to spray the rod ends with tri-flow more often than the annual inspection.

-

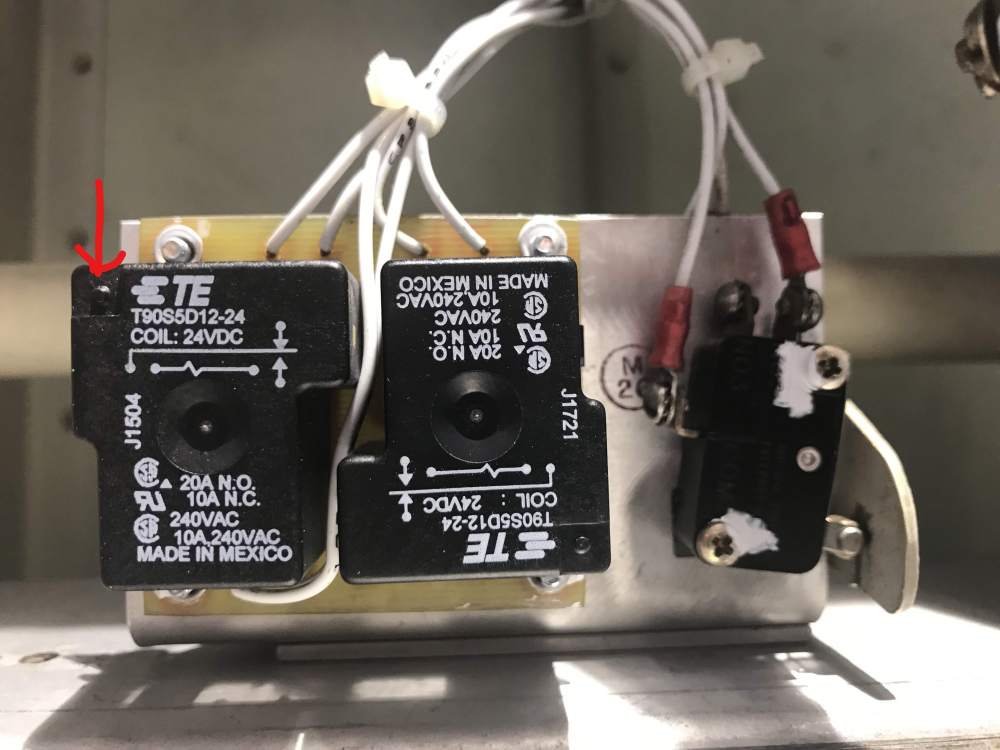

The pictures in this thread show manufacturing defects. The relays are supposed to be vented, but the vent nib has not been broken off after assembly. This can reduce the contact life 20 to 50% according to this app note. https://www.te.com/commerce/DocumentDelivery/DDEController?Action=srchrtrv&DocNm=13C9136_Venting_Sealed_Relays_AppNote&DocType=CS&DocLang=EN

-

Perry: Can you get us a picture of the failed module? I'd like to see what components are used now. I have TKS and have noticed fluid droplets behind the belly pan after a usage. I have not attributed any failures to the fluid however. Thanks, Larry

-

Perry: Last summer I made a post where I discuss design flaws in the flap relay board. This is the board in my 1997 Encore. I have no knowledge of the design in your airplane. Assuming a similar design I believe the recommendations I made regarding replacing the coil diodes with a TVS and adding a TVS across the motor leads would help. It really is a marginal design. They used a general purpose relay to switch a motor load. They used an improper design for coil suppression. They used nothing to suppress the spike from the motor. And finally, in my case at least, they failed to remove the relay vent nib. The relay used is designed to be vented but is initially sealed until soldering and cleaning is complete. Do you have any detailed photos of the relay board in your airplane? Detailed enough to see part numbers of the relays for example? Larry

-

I bought a laminator and supplies from amazon. And a paper cutter. It is surprising how handy it is.

-

Plan a day or two. Check every single function and feature. Pay special attention to audio levels and sidetone levels.

-

What’s up with that hose glued to the intake tube? My J didn’t have anything like that.

-

I have a built in tank and still use it with the O2D2. A fill lasts a year. If my plane did not come with a built in tank I would just use a portable tank. Just get the O2D2 with two 24 cuft tanks. Each tank will give you 24 hours flying time for two people. A spare tank means you won’t run out on a trip and won’t need to worry about finding somebody to fill it. Even with a portable tank you can do a clean install with tubes running behind panels and the O2D2 mounted in a convenient place.

-

It is easy to fix the cable. Disconnect both ends, pull the old one out, push the new one in with a few squirts of tri flow. Most of the time is spent in removing the pilot seat and sidewall. You could probably just lube the old cable but if going to the trouble of doing this I’d just replace the inner core with new.

-

I use 11 psi per hour for two people at 15,000 feet with a O2D2. I agree you have a leak that needs fixing.

-

Don’t forget about the others Scott ports besides the pilot. I hear they are notorious for leaking a bit. I really like that machined fitting!

-

M20R nav light won't turn off??

larryb replied to flyingcheesehead's topic in Modern Mooney Discussion

Is this a new behavior, or something that you just recently noticed? I think Carusoam is on to something mentioning the annunciator panel. That panel is powered by a number of circuits, like the ones you mention above. Depending on exactly how Mooney designed the electronics in the annunciator panel, it is possible that there is current leaking back from the circuit they use to monitor the Nav light circuit back into the nav lights and actually powering them. Remember that annunciator panel was designed before low power LED's. Just high power incandescent bulbs that would not be affected by a tiny bit of current back-flowing. With your original bulbs, the current would be there but there would be no visible effect. Another point, because the current involved is at the very bottom of what will light the lamps, it may be intermittent. It may work differently with different nav bulbs. And it may be temperature dependent. I suspect there may be nothing wrong at all. You could live with it as-is. Or you could fix it with a diode in the wire from the nav lights to the Annunciator panel. It could also be fixed with a relay in the nav light circuit. As a next step I would measure the voltage at both left and right nav lights in all 3 conditions: full on, starter CB on, and gear warn CB on. -

I had an 84 in the past and a 97 now. So never a 75. That said, your relay does not look like a factory install to me. The factory would not need to write those notes on the side and it would be mounted better. So somebody in the past made a mod. It certainly could be your problem. It will take a person very comfortable with electronics to either fix it or return it to factory spec. I may be wrong, just my guess from the pics and my own experience.

-

Every plane is slightly different, every pilot flies it slightly differently. For example, in your climb do you climb at 500 fpm or 700 fpm or 900 fpm? And of course cruise speed varies quite a bit based on how you operate your engine. So this is one area you need to determine your own numbers using your own flying preferences. For me, I have an Encore with TKS, so it's not as fast as others. You don't have to fill out every box. For climb and descent I have just one line filled out with the numbers below. For cruise, I start at 10,000 feet and go up, it uses the 10,000 foot entry for altitudes below. Climb 600 fpm, 25 GPH, 120 KIAS Cruise 10,000 ft, 150 kt, 10.5 GPH. For every 1000 feet higher I add 2 kt. Descent -500 fpm, 180 Kt, 10.5 GPH

-

Please don't take this comment the wrong way. This install would attract a lot less attention if you instruct your hanger elves to use aviation grade Tefzel wire and aviation grade wire splices. You want it to look like it belongs there, just like every other white wire. https://www.aircraftspruce.com/catalog/elpages/unshieldlwire.php?clickkey=3524

-

I never switch my tank on the ground. I figure if it worked to land from the last flight it will work for the next takeoff too. I also don’t switch much in the air. I’ll burn 10 gallons in the takeoff tank. Then I switch and burn the other one to around 5 gallons left. Then back to takeoff tank for the rest of the flight.

-

I was perfectly happy with my J for 5 years. But then I had the itch for a more capable plane, so I sold it and bought an Encore. Much more capable but much more capital cost. Operating costs are not much different however. And we all know that over the long haul operating expenses dominate the equation. This is a good time to think long hard about what you want in a plane.

-

In the reasonable future, do you want a turbocharged aircraft? Do you want FIKI? Do you want to fly higher/faster/farther? These are the things your current airplane never will do. If you want them, then best to sell the F after replacing the engine and save the avionics upgrade for the new plane. But if you don't want those things, then you may as well enjoy the new engine your F will soon have.

-

I find it helpful to have a known and detailed procedure for "keep your speed up." After having that request and not knowing exactly what the plane would do, I went out on a clear day and did some testing to determine it. I now know that it takes me 3 miles to slow from 150 to 100 on the GS. I know the sequence of tasks to perform to make it happen. I don't want to be making it up on the fly and wind up too high and fast at the end.

-

I get this most of the time if I have to do an approach to my home base. We are close to a major airport and when IFR spacing requires us to mix nicely with the jets. Yet, we still have to deal with our relatively short runway, so must be on speed. I maintain 150 kt until 5 miles from the airport. Gear up, on glideslope. At 5 miles: Deploy speed brakes. Reduce to 15" MP. Wait for gear speed, 140 kt. Deploy gear. Wait until 100 kt. Retract speed brakes. Deploy flaps. All of the above takes around 3 miles, so I'm configured for landing at 2 miles from the airport. Because of the speed brakes and the higher gear speed I can do this all on the glideslope. However, in my J I could not. Without the speed brakes I would have to level out for a bit to get down to gear speed, putting me above the glideslope. This scenario is one of the big advantages of having speed brakes. Larry

-

Well you won’t be sorry because you won’t know what you don’t know. My ADSB traffic and weather displays on the aspens and I am happy it does.

-

Speedbrakes failed after only 31 years of use

larryb replied to BobAustin's topic in Modern Mooney Discussion

I really appreciate my speed brakes, no way would I remove them. They were certainly a desire when I upgraded from my J which does not have them to my K which does. When flying an instrument approach at my home airport ATC often needs us GA types to keep our speed up to play nicely with the jets. Without speed brakes I could not do this and get down to gear speed without leveling out and going above the glideslope. Then there is the slam dunk approach or descending into an airport in a mountain valley. For my trips these are all pretty common. If you went to the electric AI you could remove the standby vac system and save your 12 lb.