-

Posts

113 -

Joined

-

Last visited

Fry's Achievements

-

182: good for people who love to take pictures of the landscape. Solid platform, if a bit slow. M20R: two classes above the 182. A travel machine, speed machine, beauty on the ramp. SR20: certainly a nice airplane, but no comparison. Weak, nasty stall characteristics, expensive regular chute repacking, optically a "yoghurt cup" (as we say in Germany).

-

Hi there, I have a GoPro Hero8, and have 3D printed my own quick-mount including a 5000mAh powerbank which allows the GoPro to run for >5 hours. I have mounted the camera to the VOR antenna at the vertical stabilizer, so the movies show my aircraft in front of the scenery, which I like very much. The quick-mount is so convenient that I now routinely record every flight (and get to judge every landing afterwards :-). So far, so good. Two concerns: * I would not be a Mooniac if I wouldn't complain about the ridiculous form factor of the GoPro, would I? That form factor imitates the form factor of a big camera which makes no sense, as it is usually mounted to something in motion (helmet, bicycle handlebars, etc) where aerodynamics is somewhat important. So, does anyone have a recommendation for another camera with a better form factor and preferably also a longer battery run-time, but comparable 4K image quality? * When flying through clouds, even the least bit of icing clogs the camera lens, rendering the movie unusable until one gets back to lower, warmer air. Before some of you jump at me for flying through "icing conditions" - I am talking about light icing of a few millimeters, hardly noticeable on the leading edge of the wings. Does anyone have an idea how to make a "deiced" lens, possibly using a slightly heated cover element)? Happy landings Fry

-

@PT20J @ArtVandelay I believe both the app and the POH are ROP. There, power is determined by airflow, which in turn is determined by RPM and MP. LOP, power is determined directly by FF - unless you are extreme LOP and thus inefficient. The reason I am using my "calculator" is simply to be more or less at that optimum point. @A64Pilot: Of course, running the engine at lower power will result in less wear PER HOUR. But when going places at a slower speed, that will use MORE HOURS, so again, I don't find it obvious that I'm being nice to the engine going slower. Plus, as pointed out before, over 4000ft or so (and I don't usually cruise below that unless it's a short flight and/or airspace restrictions above me), power is limited to 75% or so anyway. So less power, less wear. And I don't think I am running my engine "hard". Not at all. When reading Mike Bush, I understood what is destroying engines (besides corrosion when not flying) is high CHTs. My usual cruise CHTs are 300-320 at this time of the year, and only somewhat higher in summer. Of course, turbocharged engines are different. But we are talking M20J here.

-

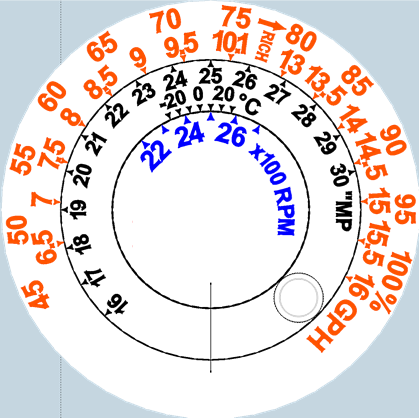

Because somebody asked how I do it: here is my self-made leaning calculator for the Lycoming IO-360. The outer ring and center are fixed, the ring with the black numbers can be turned. When flying ROP (right side of "RICH"), I use the indicated gph or MORE. When flying LOP (left side of "RICH"), I use the indicated gph or LESS. Keep in mind that 10.1 gph corresponds to 150 HP (in ideal conditions, in the IO-360 at 1:8.7 compression), thus 75% power of the IO-360. Because of that, 10.1 gph or less will NEVER put you inside the "red box", and that is the reason I don't use EGT for leaning anymore, since I am more concerned about getting optimal power than anything else. My CHTs in cruise are 300-320°F at this time of the year.

-

I wonder why (apparently) everybody agrees that wear is proportional to "piston travel", i.e. higher RPM converts to proportionally higher wear per hour. To me, this is absolutely not obvious, and I don't "buy" it. Just think about this: at the same power, lower RPM means higher torque and thus higher forces. Why should that mean less wear? I am running my engine at lower than the 2700 RPM (max. specified continuous RPM) for noise reasons. But by doing so, I get less air (at the same MP) into the engine, thus have to choose a lower FF, and I get less power. But flying is about speed (for me), so I don't want to go lower than 2600 RPM.

-

Also a J here: I am consistently using 2600 RPM. Keep in mind that this does NOT mean the propeller pitch is always the same. It varies with airspeed. But my blue lever remains at 2600 RPM. I don't believe in more wear because of (somewhat) higher RPM, but cranking down to 2500 reduces air flow and thus available air for combustion. I would even keep 2700 RPM from takeoff to landing if not for noise considerations. Quick notes on the other levers: once above 4000ft or so, power is limited to about 75 percent anyway, so I do the "big pull" to 10.1 gph (that is 75 percent) or less, and from then on don't worry about red boxes and the like, since 10.1 gph limits engine power to 75 percent in any case. (I do that "big pull" even in climb, of course with open cowl flaps, and rarely see CHTs over 360-370 even at Vy) The throttle remains wide open throughout the flight unless MP goes above 25.5 inches when descending (in that case I throttle back, since more MP will just be useless air not needed for cooling). And the mixture remains tuned to 10.1 unless MP goes below 24.4 when climbing. Below that, I use a table to find the FF optimal for complete combustion (LOP). Basically a proportional reduction, e.g. 22.7 MP corresponds to 9.4 gph, 21.0 MP corresponds to 8.7 gph, etc. Thus, somewhat surprisingly, I no longer use EGT for leaning since the above procedure keeps me out of the "red box" anyway, and my concern is simply the most efficient mixture for cooling and combustion. (That is, unless I cruise below 4000ft, which I rarely do, and in that case, simple tune to 24.4 MP and 10.1 gph). I see CHTs around 300-330 in cruise. For RPM values other than 2600. most values above need to be adjusted.

-

M20j 1996 remote oil filter setup recommendations

Fry replied to Chainfire's topic in Modern Mooney Discussion

So far I have skipped checking the oil suction screen when doing the oil changes, primarily because of the many warnings how hard it is. Is there a good instructional video somewhere on how to do this on the IO-360-A3B6D? Preferably naming all tools that one needs? (I live in a country with metric units) -

Greetings back from Fulda, Germany :-) And welcome here! (I have bought a 1995 M20J aboout one year ago, and used to fly club aircraft for ~20 years before that)

-

Ok thanks, I will ask the shop to have a look at that. My thoughts were, since manifold pressure is fine and fuel flow is fine, the obvious next thing that may influence engine power is the ignition timing... any other thoughts welcome. And BTW, it's not a major difference, I'm just not seeing the 2700 RPM on takeoff and I'm not seeing 160 KTAS at 75% power in cruise.

-

Thanks Hank! Where do I find that data plate? And if your assumption turns out to be true: I understand the SB is not mandatory, so I should be able to tell the maintenance shop to set the timing back, correct? (a quick Google lookup points me to SB 380A, but as far as I understand (still learning :-), this applies to older models than this IO-360-A3B6D on my 1995 M20J MSE. Also, looking up in the operating manual for the IO-360, I understand my engine with serial no. L-1015-51E should have mag timing 25° BTC, correct?)

-

Hello all, thanks for the discussion so far. I'm bringing this topic back up because I have a new idea. On two recent flights, I again perceived slightly lower engine power. I note that on takeoff roll the engine does not reach 2700 RPM (later in the flight, it does - so this is not due to the governor). Also, in cruise at 10k ft or so, the airplane is doing only 140 KTAS or so (well, I'm flying LOP, that _may_ contribute...). The new idea: maybe my mag timing is retarded? Add to my perceived lower power a really cool running engine. In cruise, with cowl flaps closed the CHTs, are usually around 300-330. Question to you: is there a way how I as the pilot can verify this hypothesis, without advanced equipment? According to the logs, the mags have been overhauled in late 2017 (two owners before me) and are due for another overhaul end of 2021. In the work reports of 2017, I have not found a report on checking or adjusting the mag timing. Thanks for any hints or advice. PS. The pitot static system has been checked and was/is fine.