-

Posts

1,564 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by larryb

-

Is that a missing piece of Bondo forward of the crack? Are there any logbook entries for an elevator repair? I'm not an A&P either, but I am an engineer and I would be concerned about this. Flight control surfaces are critical. I would dig deeper into this issue.

-

Actually these heaters can burn out quite easily if they do not have a good thermal contact to the heat sink (oil sump.) if the glue fails and part of the heater pad lifts then that part gets very very hot and fails. I prefer the Reiff sump heaters since they are encased in metal and use JB Weld to bond them to the sump. Larry

-

I bought a J, upgraded the panel, flew it 5 years and sold it. Then I bought a K and upgraded it's panel. So I've done it twice. My priorities were safety, reliability, and redundancy. I really don't want to be on trip and dealing with a radio failure. All of the old King radios I removed had issues, either TX or RX. I know people love them, but I just didn't want that old stuff. I don't want to keep spending $ and time repairing old radios. Finally I don't want any single failure to be an emergency. So 2 certified independent boxes that can navigate and communicate. I don't think one needs both boxes to be GPS/NAV/COM however. In the J I put a single Aspen, GTN650, and SL30. I thought that was the best bang for the buck. In the K I put 3 Aspens, and 2 GTN650's. I wanted more redundancy and capability in a more capable airplane. Now for the question you didn't ask. Do you have a single vacuum driven AI? I would bet the failure of that system has killed more pilots than any nav/com failure. I think dual certified AI's would be required in any IFR panel. Larry

-

How to fly in class B airspace after 1/1 with no adsb out

larryb replied to nels's topic in Miscellaneous Aviation Talk

So how much are you really going save in taxes if you wait till next year? Or how much investment return do you think you will miss out on? Is this really a significant number? -

Two things. Are you sure you don't mean "switch" when you say "relay." It is usually just a simple circuit of a switch and a sonalert. The Sonalert is the second thing. They often go bad, and may sound intermittent. A bad Sonalert could fool somebody into thinking the switch was bad. The Sonalert has 12v on one terminal, and the stall switch grounds the other terminal. To be sure, using a voltmeter check the voltage at the switch while exercising the switch. It should be 12v on the non-grounded terminal when the switch is open, and 0v when you activate the stall switch. If the switch checks out good the Sonalert is probably bad. Good thing they are cheap. http://www.alliedelec.com/search/productdetail.aspx?SKU=70186814

-

Back to the OP question. I don't have any specific knowledge one way or the other, but I doubt the FAA has a computer program to cross-check flights vs. pilots vs. medical status and kick out auto-violations. Certainly this sort of thing is possible. But I expect even if they did have such a program they would also need to assign people to verify the data and process the actual violation. Like many things, it is probably not a problem until it is a problem. If something happens while you are up there and an investigation is opened, we can be sure they would uncover the violation and make an issue of it. Is your new turbo airplane FIKI? If not, then it wouldn't be advisable to be on top of icy clouds in a non-TKS Mooney anyway. Imagine this, you are happy on top, with your turbo and class 3 med at FL200. Your destination is clear, but there are icy clouds 100 miles in all directions. Your JPI flashes low oil pressure. Engine is still running, but for how long? Is this an engine problem or just a broken wire? Now what are you going to do?

-

Oxygen is another factor. I took my J to FL200 one time to clear weather. That was all it could do. Proper altitude for my direction would have been FL210 but I couldn't get there. ATC let me stay at FL200 as long as I needed it. Then I took my K to FL240 one time to clear weather. That attempt was not successful, I was in the weather anyway. And I was very uncomfortable there, checking my O2 every 90 seconds or so. I was acutely aware of time of useful consciousness at that altitude. After that I decided I would generally limit myself to 18,000 and below. Since then I have not made a flight where it would have been a significant advantage to fly above 18,000. Almost all of my trips > 2 hours are at 16,000 to 17,500. Larry

-

Mine is pretty good. Coldest OAT was -30 or -40, I forget exactly, at fl240. Had a down jacket on and was pretty comfortable.

-

Either the circuit breaker switch is faulty or the switch is properly doing its job protecting you from a short due to a chafed wire.

-

If he beefs it up it is probably 3M VHB. But the dual lock is pretty sticky on its own. https://www.amazon.com/Double-HitLights-Mounting-Waterproof-Length/dp/B07TC16SZ7/ref=sr_1_2?keywords=3m+vhb&qid=1575517497&sr=8-2

-

Probably 3M dual lock. Great stuff, I use it to mount my O2D2. https://www.amazon.com/3M-Reclosable-Fastener-TB3560-Clear/dp/B007OXK1WI/ref=sr_1_1_sspa?keywords=Dual+lock&qid=1575511314&refinements=p_89%3A3M&rnid=2528832011&s=electronics&sr=1-1-spons&psc=1&smid=A1EWJ4VPL1SU6G&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUExTDdWSFFCMElKNlhTJmVuY3J5cHRlZElkPUEwNzIxMzQ5MjNZU1hRTDUzSzNVSiZlbmNyeXB0ZWRBZElkPUEwOTAxNzgzMjNRVkwxUDJQWVE1QSZ3aWRnZXROYW1lPXNwX2F0ZiZhY3Rpb249Y2xpY2tSZWRpcmVjdCZkb05vdExvZ0NsaWNrPXRydWU=

-

In addition to what others have written, get the medical first. I would get a flight review in a rental plane. It may take a long time to find and buy a plane. Why wait to get back in the air? Trading planes is expensive. Inspections, catch-up maintenance, upgrades, etc. Consider buying one that you'll be happy with in 5 years rather than just 1 year. If you truly want a 1 year plane, then don't upgrade at all. Fly it, fix what breaks, and sell it. Resist looking for a bargain plane. There are no bargains in aviation. In the long run the purchase price matters little to your total all-in bottom line cost. Buy the best quality example with the equipment that you want.

-

Sorry, no. It's pretty complicated and very little is available off the shelf. It would be a huge effort on my part just to document it. The microcontroller is on a custom designed circuit board that I had previously used for home automation. The cellular modem board is off the shelf, and the same one used in many of the cell switches out there. There is C code for the microcontroller for both the cellular communication and the heater thermostat PWM function. Then there are two pieces of server code running on a windows box. The first is a "listener" program that listens on the internet for data from the microcontroller and saves the data on the server. Then there is a web server program that creates the graphs for the browser. Those were creatd with Microsoft Visual Studio and run on a Windows IIS server on a box in my closet. But I don't think much of this is necessary. If you just want to keep the engine at a steady temperature like I do, you can leverage one of the many PID temperature controllers available on Amazon. PID is the control algorithm used. They rapidly turn on and off the heater element to achieve a very steady target temperature. The ratio of ON to OFF time is what determines the power level. I have not personally used the device below, but it is of the type I would consider. https://www.amazon.com/Inkbird-Temperature-Controllers-Thermostat-ITC-106VH/dp/B01N1ZUGUZ/ref=sr_1_1_sspa?keywords=pid+controller&qid=1575470406&sr=8-1-spons&psc=1&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUExNjZMTjk0RE1QOTBEJmVuY3J5cHRlZElkPUEwMjY1NDk0QzlLM0FQTTFWRzlXJmVuY3J5cHRlZEFkSWQ9QTAyMzM0NDE1UFM2NDlXOFBEU1gmd2lkZ2V0TmFtZT1zcF9hdGYmYWN0aW9uPWNsaWNrUmVkaXJlY3QmZG9Ob3RMb2dDbGljaz10cnVl If you don't care about temperature swings then you can use something like this. https://www.amazon.com/Farm-Innovators-TC-3-Thermostatically-Controlled/dp/B0006U2HD2/ref=sr_1_2?keywords=cube+thermostat&qid=1575471316&sr=8-2

-

Temperature rise is linear with power and is independent of the starting point. So the specific math to translate my result to a 100W bulb would be (80/700) * 100 = 11 degrees. Insulation makes a big difference. I have an old quilt draped over the cowl. Without the quilt I get half of the rise compared to with the quilt. 80 degrees rise is with the quilt. More/better insulation will give you a better result. I think you would want to get 40 degrees minimum for engine start and reasonable oil viscosity. At 20 degrees ambient 200W bulb and a quilt will get you that.

-

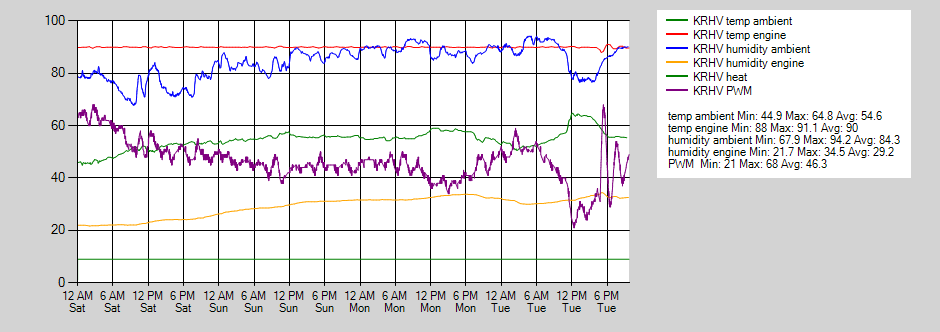

A few years ago I was frustrated by all of the opinion on this subject but lack of real data. I built a device to gather the data on my own. I've posted on this here before, so for some this is old news. I used a PIC microcontroller along with a cellular modem chip and some temperature/humidity sensors. The executive summary, in my sample of 2 engines, I found that increasing temperature leads to lower measured RH inside the engine. I also did some internet searching, finding that RH < 30% results in low corrosion and > 60% high corrosion. So my goal is 30% or less RH. Here is the theory. Corrosion is a micro-battery on the surface of the metal. The moisture combines with impurities (blow-by, acid, etc.) and creates a micro-cell which creates the corrosion. The key concept is this: If the moisture in the engine is evaporated into the air in the engine, it is not on the surface of the metal and therefore not available to cause corrosion. Water in the air is not a problem. Water on the surface of your steel engine parts is the problem. There are two possible scenarios in the engine: 1) Saturated environment. Envision a bowl half full of water with plastic wrap sealing the top of the bowl. The air is saturated, always 100% humidity, no matter what temperature. This would be bad. 2) Un-saturated environment. Envision a bowl of water with a few drops in the bottom at 33 degrees F. As the temperature warms, the water evaporates. RH goes down as temperature goes up. Because my measurements show a decreasing RH as temperature rises, I believe that there is not enough moisture in the engine to create a saturated environment. Therefore, a bit warmer is better, reducing RH and trapping the moisture harmlessly in the air and not available for corrosion. I programmed my device to maintain a steady 90 degrees F regardless of external temperature. I was looking for the lowest temperature that gives a good RH result. This is only on a sample of two engines and in two locations. I had a J model for 5 years and 2.5 years ago traded that in for K model. I have used this device both at KRHV and KTRK, both in California and not terribly humid. I have not tested this in a high humidity environment like the south. Here is a thought on the light bulb technique. I have a Reiff, 100W on 6 cylinders and 100W on the pan. With 700 watts heat I can get 80 degrees F rise over ambient at 100% power, with a cowl blanket. Simple math says a 100W light bulb would be lucky to get 15 degree rise. Hard to see how this is enough power in a cold environment. Here is the current graph. Humidity in the engine is a tad high, but look at the external humidity. We've had a week worth of constant rain here, so things are a bit soggy. PWM (Pulse Width Modulation) is the % power, averaging around 50% or so for this period. Larry

-

One more possibility is the analog voltmeter is not reading correctly. I would verify that first.

-

Is there a switch interlock on the emergency gear latch? It is on my takeoff checklist, right after takeoff trim setting.

-

Looking for streaming that says "Observe Tow Limits"

larryb replied to RobertGary1's topic in General Mooney Talk

I like the idea of a handout. But I think that SB is a bit too wordy for a busy lineman to actually read. I snipped out the pics and critical text and created this. I think I'll laminate the whole thing and attach it to the nose wheel. We do a lot of traveling to new places in our Mooney. So we need an airport and FBO big enough to provide services such as rental cars and hangar if bad weather is expected. It is hard to avoid towing in this scenario. Especially if you want the plane stored in a hangar, it is going to be towed. I always ask if they are familiar. Most are. A couple of times I have had to explain the limits however. Towinig_Limits.doc -

Looking for streaming that says "Observe Tow Limits"

larryb replied to RobertGary1's topic in General Mooney Talk

-

Looking for streaming that says "Observe Tow Limits"

larryb replied to RobertGary1's topic in General Mooney Talk

-

I have one sitting in a box available today. 24V.

-

I have had a horrible time with this part in my aircraft. It started in my first annual. I have TKS, and part of that system is a heated stall switch. The stall switch heater is so powerful it will burn out if left on while on the ground, so they use the airspeed switch to keep it on "low" on the ground and "high" in the air. There are two switch circuits on the airspeed switch, one is generally un-used unless you have TKS. My stall switch heater would not go to "high" mode. After the shop replaced it, things worked but half the time I would have to press the override button to get the gear up. The calibration was off and un-stable, and could not be suitably adjusted. My new switch went back for repair. Twice. At the next annual, my shop informs me the switch has failed again. But this time the opposite way, the gear was not "safe." If I had moved the gear switch on the ground, it would have gone up. Another new switch. Fortunately I only had to buy the first one at $1000. All the rest of them were under warranty. Next time I'll be temped to design a circuit to decode RS-232 airspeed data from my Aspen and activate a relay. Could be done for less than $100 in parts and would be much more reliable. Too bad something like that could not be "FAA certified." Larry

-

Looking for streaming that says "Observe Tow Limits"

larryb replied to RobertGary1's topic in General Mooney Talk

I printed up a card on my computer, laminated it, and attach through the front gear tube with thin wire rope and hook. I don't have a handy pic. I actually have two, one says "Dont tow, expensive damage can result." and the other says "If not familiar with towing limits, call owner at 1.xxx.xxx.xxxx." -

I've read the manual, and am planning to make the updates. FYI, the manual does discuss different settings for LOP and ROP operation. My question was more of have other folks done this and what their experience was. Thanks, Larry

-

Has anybody put effort into setting the HP constants to get an accurate %HP display? If so, are you happy with the result? In my Encore I just have the default setting so far. I show 106% on takeoff. I need to pay more attention to what it shows in both LOP and ROP cruise. Larry