-

Posts

947 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Awful_Charlie

-

Signature publishes fees for piston airplanes - AOPA

Awful_Charlie replied to FlyWalt's topic in Miscellaneous Aviation Talk

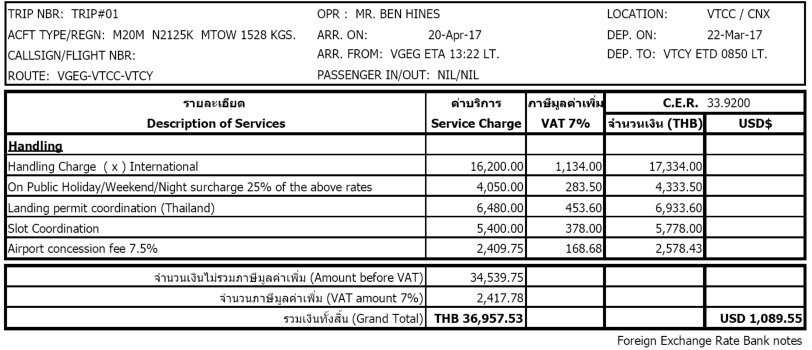

Handling is one of those things - sometime you get great and useful service, and sometimes nothing worth having, and that seems to have zero bearing on the resultant fees. I don't mind paying when I feel I get some value for services which are helpful, but it's a shame when the value feels to be poor Here's one of the more outrageous ones - a good service for sure, but the value is in the wrong ballpark! -

Maintenance and touring planning thoughts

Awful_Charlie replied to Awful_Charlie's topic in Modern Mooney Discussion

Wow - thanks everybody Prosit! No flying for a few days! Assuming it all goes ahead, I'll try to write up some notes, and always good to meet up with other like-minded people, even better when they're Mooney (and Bravo!) owners That's really generous - let's see where the plan ends up.... Nothing against museums, just the "Art appreciation" gene seems to have missed me out! Great ideas - the Grand Canyon one seems to particularly interest me for some reason. Sure it would be possible to get around the 48, but by doing that I doubt there will be time to appreciate any of it! Likewise, heading south to Texas would be great, but fear it might eat a little too much into the time available? There's going to be a transit of the east side of Canada in any case, but don't really want to spending all day, every day in the air (did that last year, got the Mooney shirt!) Another great offer - many thanks. Plan is currently something like: 1 week for France to Osh (if it overruns, then eats into time at Osh) 1 week in Osh (probably camping in the Northern 40) 2 weeks touring about, ending with leaving the aircraft at a Mooney-savvy shop Back to w*rk for a week or three, and then return 1 week "shakedown" and touring 1 week return to France (this will be early/mid Sept, so with the prevailing wind, but against the daylight. Hoping the Wx won't be too unkind!) -

Ovation recog light replacment alternatives

Awful_Charlie replied to rogerl's topic in Modern Mooney Discussion

I'm one of those that replaced burned out bulbs with the original bulb, for which the reflector has to be cut down. The bulbs cost peanuts, and after cutting them down you will have to unsolder the leads from the donor and solder them onto the new. Bulb is eg https://www.ebay.com/itm/Sylvania-ERR-25W-14V-Halogen-Projection-Lamp-Projector-Light-Bulb/111761125608?hash=item1a057b70e8:g:P4MAAOSwZVlXoR02 You can check this by removing the solver foil label on the back of the bulb. This exchange won't do anything for the lens melting issue, but my SOP is to turn them on with the strobes on entering the runway, and off on exiting the runway, and I've not had a lens issue yet -

So along with a couple of other pilot/owner friends, we're tentatively planning a pond crossing for Osh 2019. Of course, having done one somewhat risky crossing, we might as well get some extra benefit before doing the return trip. What we're all looking for is some suggested destinations, practical in somewhere around two or three weeks elapsed time (although unlikely to be continuous), but with some time at destinations rather than just fuelling and getting on the move again. General blokey/pilot things (beer, food, anything with an engine etc) are fine, art museums and the like are, ahem, probably near the bottom of the list. In addition, to me it would also make send to drop the aircraft off for a week or two with a Mooney (long body/Bravo) specialist (not necessarily an MSC) before the return trip to get a good "check up", but with enough time to have a good shake down before crossing the Atlantic back home. I guess I'm looking for someone who can do a comprehensive gear and rigging check (it all works and flies fine, so I don't think it needs adjustment, but it's good to establish a baseline). Bear in mind whilst whoever is doing this, I'll most likely have to get a return scheduled flight to Europe (although maybe I could use the time to try to get an A&P!) so the travel logistics also come into play. Still at the very early planning (costing!) stages for the moment, but I'd be grateful for suggestions of destinations and shop recommendations ('25K had a lot of maintenance done at Araphoe before the previous owner imported it, and the owner there was very helpful on the telephone whilst I was doing the pre-purchase due diligence, but as this will be a one off don't have any particular allegiance) Look forward to hearing the ideas! Ben (Off to the Munich Oktoberfest in a few hours - might be a bit slow to respond for a few days!)

-

Ah - my apologies, on reading the bumpf I see you are correct. Maybe worth giving Josef a call though, as I was only speaking about similar things yesterday and he mentioned it (I have a 150 too, but in EU land we need a second altimeter, so keeping the KEA130 and hence the KAS279B didn't raise its head)

-

You can get the altitude portion, just not the VS option - search for an APS4 from Straubing

-

Welcome fellow Bravo owner! I'm a LOP convert, and I'm also in the throes of GAMI adjustments having just changed engines (at 2200 hours, the fuel pump and exhaust system were getting tired, the final straw being the original cylinders wearing out) To take each of your questions in turn: 1) Without a data logging JPI, you've been given some options above, but I would suggest leaning very slowly, letting it settle, and then taking the readings. Might need a long cruise segment to get enough points though! (I had a long cruise segment a few weeks ago which I used too get myself in the right GAMI ballpark. Process after establishing the cruise was just to tweak the mixture out a little (say about 1/5 turn on the vernier) every minute or so - if the fuel flow doesn't settle to a value that averages out 0.1 or 0.2 lower than the previous sample then richen up and do it again! I spent 40 minutes getting down from 18 to 13GPH (easy airspace with minimal ATC interruption) 2) The readings jumping up and down up to 0.2GPH without touching anything seems to be frequent on mine. This seems to be an instrument thing (it's counting pulses, so maybe it is a pulse just in or out at the start and/or end of the measurement cycle). I have the original Shadin Miniflow and the JPI running from the same (Flowscan) sender, and the Shadin is noticeable more damped than the JPI, to the point the Shadin lags the JPI by maybe a GPH or more when leaning 3) Maybe worth getting another 10-25 hours on that cylinder - when you consider it fully run in, then that is what you are going to set up for. Remember you get so much tweaking time with GAMI for an install (a year I think) 4) Although the MP may stay the same over an altitude range, the temperatures do not (IAT is the one the engine cares about), and it is overall air density that affects the mixture. In the POH you will see the fuel flow for an MP setting varies a little with altitude, with a small temperature correction too. I would also suggest 50 LOP is the lean limit unless you are CHT limited - when you go further LOP not only is the power is dropping off but the BSFC is getting worse too. I find that at 30" 2200 I can keep everything happy at about 10 to 20 LOP When you get your data logging with a JPI sorted out, by all means choose a sample period to suit yourself, but I would suggest using the lean find option which then sets the interval to 1 second until you exit the function, and a normal reduced rate will then increase the length of flight time the unit can store.

-

That's interesting - I'd not heard that before. I've got a BJ1000AH-4L with a tube attached, do you by any chance have a reference or data sheet for it? (my google-fu didn't find one)

-

CDT is only the same as IAT when there is no intercooler - otherwise CDT is what comes out of the turbo (and goes into the intercooler), and IAT is what comes out of the intercooler (and into the engine). My elderly EDM800 has inputs for both and I have them both installed. FWIW, you can use these to track the max MP adjustment on the Bravo, where IAT is the variable that defines the max allowable MP

-

My original mechanic had me screw on firmly by hand, and then 2 flats (1/3 turn) That's worked for me on multiple aircraft over 20 years and I guess 50+ filters - never a leak yet! (and more importantly, not a problem to get them off again!)

-

Raspberry Pi, MPU9250 and Stratux? About $40, unless you want the traffic too which adds another $8 or so

-

What he really means: 10 minutes to read the instructions, broken down as - waiting 5 minutes while a woman reads them - 5 minutes nodding and going "mm - ok" while she reads the pertinent bits back

-

FoxMike is correct - it is stainless and not aluminium as I wrote earlier Lousy photo as I didn't want to disconnect hoses, so this it just easing the duct outwards to point the camera down the back - you can see it's not in the best of shape, and appears to be stuck on with RTV as well as a pop rivet or two

-

Hmm - I hope you've had that looked at in the meantime: MM Section 5.10.01 My regulator leaked (albeit on the ground too) before one of the previous overhauls but then came back fine I agree getting the professionals involved would be a good idea, but unfortunately I do slightly disagree with the pressure holding - I've got one airline extension which will hold 60PSI, but with 100PSI behind it will leak down to 60 - it's just a worn out O ring in one of the connectors (but to fix it means putting on a new connector, and it's only used for doing the tyres and that job is bottom of the pile for the moment)

-

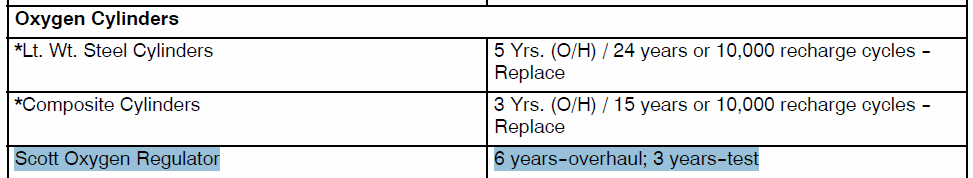

I was about to post up the data sheets for the Bravo oxygen components (cylinder, regulator, filling ports, outlet ports etc) which is probably good for other models too, but these didn't really fit with any of the existing groups so have held back. Could we maybe have a "OEM Component" area or similar?

-

As you have the altitude compensating regulator, don't forget the output depends on the altitude! If you have a leak at a seal/joint (as opposed to a hole) it may be that the leak does not manifest itself until higher pressures

-

I don't see a great variation there - I think this looks pretty normal. Here's a failing #3 exhaust valve with a 4 second sample interval (on the ground, 1000-1200RPM, so the fluctuation in the cruise would be around twice the frequency) According to the documentation, you should expect the variation to maybe be installation specific, with EGT probes further from the cylinder head showing less of a variation - however after swapping a couple of bits of exhaust with unmatched pre-drilled probe holes in the past, I have a feeling that effect may be exaggerated somewhat It only takes a few seconds to grab the data (I normally download the JPI data after the last flight of the day - the USB stick is on the keyring!) You don't need to do anything with it, but when you find a problem you have something to compare against - isolating a problem without any reference is more difficult. With a 6 pot engine, most of the options installed, a 4 second interval, the old EDM800 I have can store around 8 hours of flight - I believe the EDM x30 models have a lot more memory (although some of this will be used by the GPS options)

-

I had assumed it was standard, but maybe it got put there by a previous owner: the inside of my intercooler duct is covered by a thin sheet of aluminium

-

I just replaced mine at engine overhaul. Like Jose, it was a Rapco, and had over 1200 hours on it

-

I'm in the wrong country to make a better estimate, but my feeling is that for a 1991 with a run out engine, you're much nearer to 100 rather than 150. Deduct a bit more (say 3k for the oxygen cylinder, another 2k for the shocks, other maybe questionable required works, then I think something around the 100 mark is more on the money. With a new engine, everything up to date, I'd be surprised if this was a 200k aircraft, unless perhaps if it had new paint & interior, fully up to date and extensive avionics etc Just my 0.02

-

Built in Oxygen and firting required

Awful_Charlie replied to tls pilot's topic in Mooney Bravo Owners

I got one of these to make the connection to the aircraft I rent a big cylinder to fill from, and put together a pressure regulator, two gauges and a long bit of hose, and that lot (with a thermometer) goes on a sack trolley -

Rick shouted I've had the odd fuel pressure indication fluctuation, but normally only after levelling off in the climb - I don't get a misfire with it in flight however. It did get slightly worse as the engine got well past TBO though, to the point that taxiing with a hot engine, in high temperatures and with low fuel tank levels at low RPM that the electric pump needed the odd blip to maintain even running. From the symptoms, I also had a suspicion that the engine fuel pump might have been struggling, but then went for a factory rebuild at nearly 2200 hours (all being well, get the aircraft back tomorrow!), but even then, a change will not be conclusive on the pump. My theory (which is of course subject to many opinions) is that in the climb, you are pulling 20+ GPH through the fuel pump which gives quite a considerable cooling, The airflow is relatively low, so the back of the engine, accessory housing (where the fuel pump is bolted to) is relatively hot. At top of climb, when you then reduce power, the heat is still gradually dissipating, and if you pull the fuel flow back promptly, then the fuel cooling is substantially reduced (for me, to about half the climb burn). Hot engine (fuel pump), less fuel cooling and the fuel vaporizes on the suction side of the pump, and there is not enough time/cool bits to condense it again before it gets to the injector, hence to odd blip in pressure. SOP for me is at TOC (as the trim is winding in) to close the cowl flaps (to reduce the shock cooling, which may or may not be an OWT - your engine, you choose!) and then wait for the cooling rate on the JPI to reduce to less than 10dF/minute. This takes a minute or three during which time the back of the engine is getting a higher airflow, and the heat in the fuel pump (and the bits that feed heat to it) has reduced, aided with continuing with the high fuel flow. When the cooling rate has slowed, I then go to change the power & lean, and this work ok for me. Some things to consider: In the FLs, the air out of the injector assembly can easily exceed 60dC and this is heating up the fuel that passes through it - some components of avgas can start boiling at as little as 40dC. The engine pump is normally higher than the fuel level, so it is sucking fuel making vaporization more likely, compared with the electric pump, which will normally be below the level of fuel, hence it normally has positive pressure on its inlet.

-

second alternator in M20K -field approval

Awful_Charlie replied to flumag's topic in Modern Mooney Discussion

The Mooney part nos. on an M20M with split switch are 880052-525, with 8133K21E13T52-252 as an alternate. I might have a spare one of these at Habsheim -

Autopilot roll oscillations

Awful_Charlie replied to marooneypilot's topic in Modern Mooney Discussion

Mine wasn't as rapid as Hendrik's, but equally as annoying. Martin at Straubing found the problem quickly (IIRC one or two hours of time including removal, fix, re-install & test flight) which was two resistors out of tolerance (so less than a dollar of parts) 20160713_111922.mp4 -

Low oil pressure in 30 hour engine

Awful_Charlie replied to rocketman's topic in Mooney Bravo Owners

What figures did Lycoming get on their test cell? (printed on the yellow "Engine Test Log" sheets) AIUI the low value is 75PSI, so if yours is significantly less, then on the basis you have checked the gauges/senders, maybe you have an installation problem?