-

Posts

947 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Awful_Charlie

-

I did the install in 2017 with some BizJet engineer friends and would recommend giving the job to someone who wants it and not to a friend! The kit is comprehensive and Jose was a star when we had questions, but unless you can play the double-jointed telescopic armed critter with eyes on thin stalks that see in the dark, then give it to someone else to do. And then there is the PRC which sticks to hair and skin better than sh*t to a blanket (and better than to aluminium it sometimes feels like!)

-

Cessna driver is better at keeping the nose wheel on the yellow line but it's the 747 driver that really needs to

-

Remember when you bolt a turbine on, the Vne redline reduces to Vno (what used to be the beginning of the yellow ASI segment, which then disappears) so you lose a bunch of potential speed options there. If you absolutely must have a turbine Mooney then it sort of exists in the from of a TBM

-

I followed the Lycoming instruction for running in except for oil changes, which I did at +4 and +13 hours before going to the regular 25 hour intervals. There wasn't a magic number when it was suddenly "broken in", just as I got more hours on the engine I would be a little less conservative on limits and expectations. By 40 hours I was back to using the limits I used on the old engine. (which are pretty much book, except for CHT and TIT where my limits are lower)) However, what are you expecting with "broken in" - at 1000 hours some parts/fits will still be getting sweeter and some other parts will be wearing out!

-

These mostly affect the low power regimes of an IC engine where they are predominantly quite (or very!) bad already, so there are substantial and worthwhile gains to be made when the unit spends a significant time at lower power. This contrasts so much with our GA environment where the power units are run at relatively high power for the majority of their time, to the point that in GA we are regularly seeing BSFC in the 0.35 arena for spark ignition, which is something an automotive engine can only dream of obtaining for the majority of its operating cycle. With a quick search for "BSFC map" it becomes clear we need another technology to make the next leap. Those running a NA engine up high (and thus consequently at a low power) would potentially see some advantage from long existing technology such as variable ignition timing/VVT etc., but where we are now (or where we have been for circa 80 odd years) is looking quite conclusively pretty close to as good as it gets for sustained & continuous high power output reciprocating metal based technology. My feeling is that the Atkinson will take considerably longer to determine if even the effort is worth it - if the consumption can be made to look attractive, the increased weight will have a negative impact, and the complexity and potential to induce a failure are too significant to ignore (would you carry a 50+lb device that reduces your fuel consumption for taxi and descent only, but which if it fails even when not making that saving would likely cause a catastrophic power unit failure?) https://en.wikipedia.org/wiki/Brake-specific_fuel_consumption has some figure that may be interesting (eg for gasoline engine output efficiency, Ford Ecoboot 33.5%, IO720 34.2%, Prius 36.4%) Maybe new(er) materials could resolve some of the current design constraints on reciprocating engines and gain a percentage point or two, but we really want something that gives us a massive leap, not just a minor enhancement - eg in IC engine that is twice as efficient (so 70-80%) My personal feeling is that those efforts are probably best directed to looking at alternatives to a fuel based on long dead trees and dinosaurs - and possibly even re-visiting old ideas and updating them (windmill/solar for twisting up a a rubber band?!)

-

Read this and and this and this to get started. TL;DR - do *not* use Mr Weaver or Skyferry without doing very thorough due diligence (I thought I had posted similar before, but if it's not appearing in the search then repeating it won't hurt)

-

I went factory re-man. Despite many interesting options, *none* of the rebuild offers included a new exhaust system, and adding it is a 20k+ item. On the basis that the Bravo exhaust is a weak point anyway (and I've had it welded a couple of times, and previous owners had repairs too) I felt it had to be done. I took that engine to 2200 hours, when when compression went down rapidly (exhaust valve & seat) on one cylinder. Four cylinders were original, one had been an early life warranty exchange, and I had changed one at around 1800 hours IIRC, so although I might have got some more time by replacing/repairing that cylinder, the odds were rather high that another one would go. Bonus that I wasn't expecting was that a new engine fuel pump cured the hard hot starts and very poor low speed idle/pick up in high (35C+) temperatures

-

How many copies do you need?

-

Tasteless Joke of the day.

Awful_Charlie replied to Mcstealth's topic in Miscellaneous Aviation Talk

I was on the train sitting opposite this really cute Asian girl with massive boobs last week. I kept saying to myself silently "don't get a boner, don't get a boner" when suddenly she did! -

Thanks @Chrigi Parts arrived in the post and were waiting for my return

-

Looking for tank sealer mixing tips

Awful_Charlie replied to xcrmckenna's topic in General Mooney Talk

Only a short reply as on a phone, but *dont* use extra accelerator - it will become unworkable too quickly (particularly as you have the a1/2) Use an old clean tin can to mix it with using a paddle mixer in a slow/medium speed drill. Don't scrape the tin out when applying it - this will be the unmixed stuff from the walls of the tin. The tin will be junk afterwards, but keep it until it has gone off so you can check it. Like many jobs, it is all about the preparation of the underlying materials - don't even think about scrimping on that, so mae sure you have plenty of lint-free rags and MEK before you open a panel. I used digital kitchen scales to measure the mix -

Tasteless Joke of the day.

Awful_Charlie replied to Mcstealth's topic in Miscellaneous Aviation Talk

... and then it's hilarious -

Tasteless Joke of the day.

Awful_Charlie replied to Mcstealth's topic in Miscellaneous Aviation Talk

Have another one -

Bravo Exhaust Valve Failure - Root Cause

Awful_Charlie replied to alextstone's topic in Modern Mooney Discussion

Indeed, but all valves are not the same. IIRC Lycoming exhaust valves use the sodium pellet to get more heat away from the head, whereas Conti use a straight solid (friction welded?) assembly -

My Bravo had TKS installed at delivery, but still had the electric de-ice timer and wiring installed - maybe at that time it was just always installed as standard equipment?

-

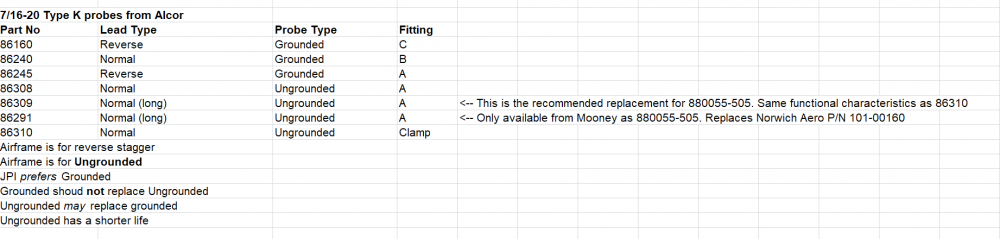

I do indeed remember the espresso - very welcome it was too! I'm not sure if the Moritz requirement is different, my notes for the Sigma-Tek are are below. One year my A&P replaced with an 86245 by mistake and it seemed to work OK, but I went back to 86309 at the next scheduled replacement (when we found the mistake!). My JPI is piggy-backed onto the ship probe (so I just have the one TIT probe). Note that the lead stagger is always inconvenient (you connect by colour, not by length) as you need the long length which don't seem to be available in reverse stagger configuration

-

Do you have a KA15 aural alerter? It can be wired in two ways, either through the intercom/panel or via a sonalert. I had a similar problem and it turned out to be the KA15 itself, but was a cheap fix (can't remember exactly how much, so probably less than 0.2AMU)

-

Tasteless Joke of the day.

Awful_Charlie replied to Mcstealth's topic in Miscellaneous Aviation Talk

-

Overhead Cabin Interior Light

Awful_Charlie replied to Scottknoll's topic in Modern Mooney Discussion

I you do that, you'll either have to accept there is no dimming available, or change the resistors (which are behind the interior trim, i.e. a git to get to!) -

Landing and Taxi lights position

Awful_Charlie replied to r0ckst4r's topic in Modern Mooney Discussion

The small (about 1.5" dia) mirrors in each light bay are intended to put a bit of taxi light in front of each wing tip - makes it easy to figure out -

I'm pretty sure if you take a couple of steps to the right and look straight down the aircraft, it will look as though both legs are canted inwards, and if you move further to the right then the starboard leg will look 'wrong' and the port leg 'correct'. It will also change if you make the wings horizontal in the picture!

-

Battery box conversion to move the batteries aft in a long body so as to be able to get rid of charlie ballast - maybe in conjunction with new battery technology too Some way to get additional heat to the interior of a Bravo and maybe other long bodies (eg a heatsink on the firewall from the oil) Glareshield dimmer and other interior light circuit 'adjustments' to go LED Lightweight air-con at a sensible price

-

I put in a new G243 and a Concorde sealed a couple of years ago. They're both dying now, not helped by me leaving the baggage light on one night and draining them both to empty. Previously I had got many more years from the G243's, which confirms a suspicion that Gill QA or manufacturing of those has gone downhill. I'll be trying a Gill sealed later in the year by the looks of it

-

TIO-540-AF1B Reman, Rebuild, or Factory New?

Awful_Charlie replied to TEX's topic in General Mooney Talk

I did the factory rebuild, principally for the new exhaust system, as this would have been enough extra on a European shop overhaul to make them more expensive, and with a slower turnaround. My original exhaust had been repaired a few times in its life, and I didn't fancy having to continually keep patching it up. I did try Ganns for a quote, but couldn't get him to answer me at all, which didn't feel great as I wondered what would happen if I had a query later - YMMV -

Carbon Monoxide Leak Finally Found

Awful_Charlie replied to alextstone's topic in Mooney Bravo Owners

It's not even that! That moulding on one side takes the external air and pushes it through the intercooler, on the heat shield side takes the heated air from the exhaust muff to the blending valve for distribution to the defroster and heater. The heat shield is protecting the moulding from the exhaust (#5 to #3 to #1) which is only 1/2" away I'm not doubting that this has fixed your CO reading, but curious as to where the CO was coming from to get in there?