-

Posts

731 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Cody Stallings

-

1967 M20F: Prop Grease Leak?

Cody Stallings replied to PierceM20F's topic in Vintage Mooneys (pre-J models)

Looks like grease coming down the blade. May have a reseal in your near future. While having it done ask your shop to comply with SL #293 Rev 1. ghats the use of the Turbo Prop blade Orings, they tend to last forever -

No engine teardown after prop strike

Cody Stallings replied to redbaron1982's topic in General Mooney Talk

Unless your just itching to spend $11K on a new prop, I would definitely have that propeller checked out. If that’s the F7666A-2 Blade you may possibly have the material to O/H that propeller an save yourself $9500. just my thoughts -

As far as I know Hartzell only Offers a composite for 20R’s an 20TN’s an it is a great propeller, except the Price tag. MT makes a good propeller an it’s lite weight which always helps on the nose of a plane, but the lack of North American support an the fact that none of them can hold their own fluids in is a deal breaker. MT like a McCauley uses the same blade pocket design(early MT’s actually used McCauley hubs years ago) but weather it’s the type of grease or the Oring Compound MT utilizes in that Union, they are prone to leak in short order.

-

I don’t Have a Hartzell on my Rocket yet, but a STC for one sure sounds good. Your Rocket Sir just like every other Non -MT Converted planes will have a McCauley C505 CS/Feathering propeller, an it has No external pitch change provision. Have actually seen an issue like this but it wasn’t on a Mooney, Fortunately for us though it was on a Cessna 414 Chancellor New engine(reman) an O/H Propeller, High MP an Low RPM At the end of the day it ended up being the oil transfer bearing in this guys situation, there was to much clearance when the engine was assembled. With the Feathering Propeller you have what’s called a Latch or Start-Lock, this is in place to keep your propeller from going to feather at shutdown. The Latch angle is normally in the 3 to 5 degrees more aggressive that your low pitch(takeoff blade angle). So at startup your propeller has to get 3-5 degrees flatter to makes its published blade angles, which means fully compressing two giant springs that when not installed are almost as long as one of the propellers blades,(will provide some pictures below)takes a lot of pressure for this to happen. If your not able to flatten the prop out at startup that will yield a higher than normal MP followed by a lower RPM because you have to much Angle. The engine is normally sluggish to spool up an won’t get near the book RPM, but it will buildup RPM 300ft or so on the takeoff roll. The problem was found with a pressure decay test between the Governor an propeller. The Gov comes off an a block off plate is installed where air pressure is used to actuate the prop an measure how long it takes for the pressure to decay. If the decay is to much the Hydraulic system can overcome the Cwt Weight an Spring forces to acquire Low pitch. These props require a lot of pressure to actuate.

-

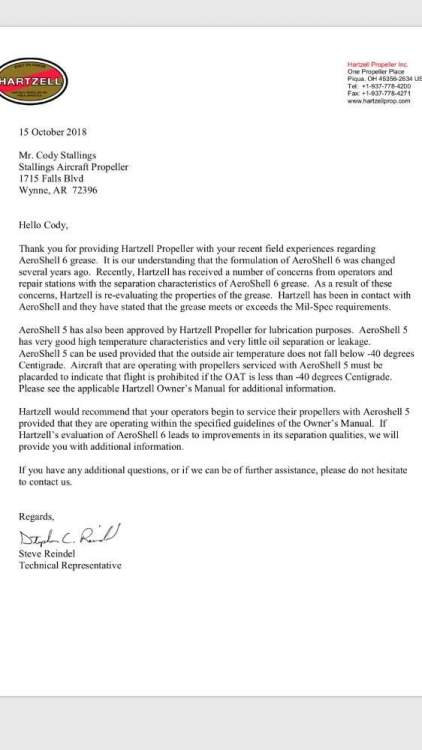

Hartzell Service Letter HC-SL-61-366

Cody Stallings replied to M20F-1968's topic in General Mooney Talk

Aeroshell #5 is a far Superior grease to #6. I see propellers torn apart everyday that have been serviced with both, an it’s a nobrainer. When the new style #6 was introduced 3-4 yrs ago our shop had to warranty 14 propellers, most of which were 4 blade King Air props because this stuff was breaking down into oil so fast the Orings wouldn’t hold it back. Jury is still out on the GN3058. It’s showing signs of being a good grease, just haven’t seen many props for maintenance yet that used it. letter from Hartzell below -

Was not aware….RIP. Was trying to crack a joke

-

Your Rocket wing has no clue what the GS readout says in the Cockpit. You Rocket drivers an your speed reports make me sick…lol.

-

Faint oil spray on cowl near spinner

Cody Stallings replied to Marvin's topic in Modern Mooney Discussion

We could reseal or IRAN that propeller in about 3-4 days this time of season -

This can get started with Vacuum Pump failure when the AI starts laying down an your on Instruments. Matter of Fact it’s almost the Textbook left turn off the Final approach course.

-

Faint oil spray on cowl near spinner

Cody Stallings replied to Marvin's topic in Modern Mooney Discussion

Hard to say where that is coming from. If it is coming from the propeller, Just be advised that the O/H is the least cost effective way to Fix it. -

I wonder if it might just be staining. You made comment you had some spent some time in IMC condition. My propeller will sometimes get some black junk that runs off the end of the ant-ice boot then trails towards the trailing edge of the blade like that. I’m a little OCD having a White propeller so it doesn’t stay on long. Its not oil or grease, but seems to be washed out of the inside of the spinner/backplate during IMC flight for long durations. Almost like brakes dust that has been liquified then slung down the blade an drys

-

Is it an oily film? Or Greasy film?

-

I don’t understand.

-

That’s correct, Both Manufacturers that produce props for Mooneys require that the propeller be Prepped an painted IAW the Manufacturers Overhaul Manual. I have even seen a few local A&P’s refuse to sign off an annual because of a polished propeller. As far as chrome plated spinners, Not a good idea. Spinners are polished or Painted. An there is no guidance published by the manufacturer showing how it should be done. Now, there are shops out there that will chrome a plastic truck stop fork an that’s great. Just not a spinner. I have seen a few that had been chromed an the prop is usually hell to balance an the stuff seems to chip an peel off rather prematurely

-

Airspeed Insurance on Just Plane Radio

Cody Stallings replied to Parker_Woodruff's topic in Miscellaneous Aviation Talk

Please, Share no pictures….lol -

I’m really Not sure to be honest, It will be cooler fall temps when I do though.

-

Looks like a big ol Top Oiled Lycoming under the hood, an there is only one McCauley propeller TC’ed for that engine. That would be the C417. BF Goodrich Sells some small containers of Conductive Cement for Boot edge dressing that works well in that area.

-

Missing paint, an if you could see all 10 blades you would notice 8 are leaking grease.

-

Pair of Cheyanne LS400 MT 5 way props. Picked these propellers up to Disassemble for export. Feel free to zoom. 450Hr TT These props turn a Max of 1591 RPMs to.

-

I have had this same issue in my shop. With the Polane paint it requires a perfect mixture of V66 Catalyst to harden properly, otherwise it will dry, just won’t harden the way it’s intended to then it blows off in sheets. Humidity also plays a part in this aswell. Polane T is a Cabinet Paint an it does really well at that job, but it lacks luster when it comes to propellers in my opinion. I see propellers that come in for routine maintenance that have had automotive grade enamels applied that is nearly impossible to media blast off, its a far superior paint for the given application.

- 33 replies

-

- 3

-

-

- prop

- prop paint

-

(and 2 more)

Tagged with:

-

That’s a strange one, prop works properly in flight, but nothing on the grd. I have always been told when replacing a component(prop or gov) the first start up afterwards to pull the propeller knob out about 1/4 travel an let the engine warm up normally. That will allow the Governor time to slowly push all of the air from the system as you wait on oil temp an CHT to come up. Then taxi to the run up area leaving propeller control in the same spot, if everything is working correctly the Governor should stop you from making 1900-2000 RPMs.

-

I think I sent you guys mixed signals. The Ham Standard Governor was on every round engine in the country. It was later purchased by Hartzell in some Fashion an labeled H-1 Im sure there is some paperwork in your logs or there is a data plate riveted to the mounting flange of the Governor that says it’s current Make an Model. This is not uncommon with manufacturers. There are several 2 blade MT composite props on Super Decathlon’s that have a McCauley C214 hub like a J model has.