-

Posts

1,449 -

Joined

-

Last visited

-

Days Won

9

cnoe last won the day on December 17 2016

cnoe had the most liked content!

Profile Information

-

Gender

Male

-

Location

Houston, Texas

-

Model

M20J

cnoe's Achievements

-

I had the (electric) fuel pump from my J (IO360-A3B6D) overhauled recently and the spec'd fuel pressure for the Dukes 1499-00-19 (14V) is: 35 GPH @ 21 PSI and 25 PSI Max. As Skip mentioned, the mechanical pump isn't field-adjustable. First thing I'd do is make sure that the hose to your transducer isn't full of liquid fuel. Also the tiny orifice into the transducer may be gunked up causing inaccuracy. Then tee'ing into the line at the transducer will tell you if it's an indication error. CNoe

-

Leaking fuel tank. How much is too much?

cnoe replied to Bill_Pyles's topic in Modern Mooney Discussion

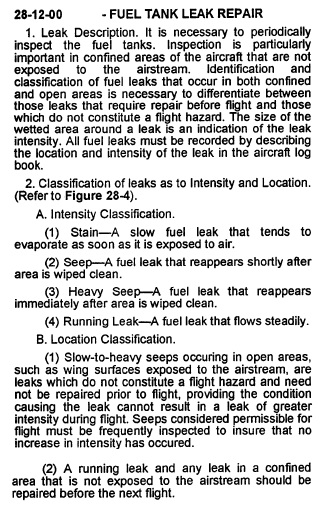

In case you don't have it, here's Mooney's guidance on the issue. I offer no other advice than to use your common sense, and keep a fire extinguisher handy. CNoe -

Correction: In spite of multiple accounts of top-coat issues from both a manufacturer and plane builders, plus assurances that the modern formulations of CS3204 are 100LL compatible without top-coating we are applying CS3600 to the repaired area to be fully compliant with Mooney Service Instructions. CNoe

-

I talked to Paul a couple of times earlier when I had a couple of seeping rivets. He was helpful offering advice on a simple home-base repair. Being in-warranty at that time he offered to fix for free at his location but that's nearly 1,000 nm from my current home base. My recent "bubbling" issues are outside the 7-year warranty period so I didn't bother calling him about that. With today's gas prices the fuel alone would have been $800+ so I opted for another local repair again. Sealants are inexpensive so the entire cost to scrape out the affected areas, clean with MEK, and reseal was around $100 + (my) labor. It's also a great learning experience. Now all the temporary sealant has been removed and the leakage is gone. I'm happy and hold no ill-will towards Paul. He did exactly as guaranteed. I had just hoped that it would have held up better long-term. CNoe

-

Joe, not to nitpick but if not already done, you may want to tighten up that jam-nut at the top of your cowl-flap adjustment rod. I can't believe Clarence didn't mention that already! CNoe

-

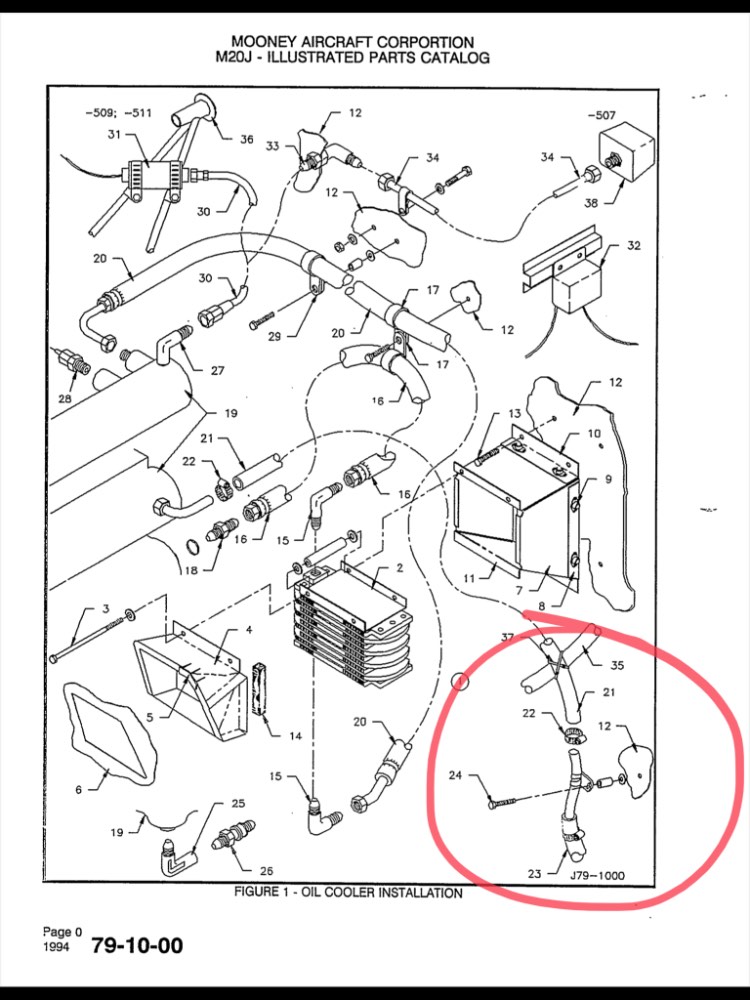

Following up… Eric’s installation has the lower bolt further inboard one hole with the adel clamps rotated opposite of mine. That would likely put the tube ~1” further towards the center which might help your clearance. I can’t state how it left the factory 40+ years ago and my manual doesn’t contain an accurate depiction but it appears either setup above would work. FWIW I too have the flat cowl flap on the port side. CNoe

-

Just another data point and a couple of observations... My J had a complete reseal at the end of 2012 by Weep No More. A couple of rivet/screws needed touched up; no big deal. 10 years in I'm experiencing some minor bubbling (poor adhesion) of the brush-coat sealant in a few locations with resultant seepage (blue stains) under the wing. For the most part the sealant is doing its job but I hoped it would last longer than 10 years. FWIW the sealant is not "brittle", it's just not adhering properly to the aluminum (poor prep?). I don't think a complete reseal is necessary at this time as the problem areas can be identified and repaired/resealed as needed. But when it's time for a do-over I'm going to be exploring bladders. The leaks can be identified (in the tanks) by taping an acrylic window over the access ports and then applying a vacuum (shop vac) to the drain or vent port. Spray a soap solution (or better yet a non-soap leak-solution) to the area showing blue staining outside the tank. The solution will appear as foam or bubbling in the tank at the exact location of the leakage. I also suggest looking for "bubbling" (while under vacuum) around the general area and taking care of all that too. Also, Edison (WetWingologists) did a reseal for us on my previous plane (M20E) several years ago and was very detail oriented. I don't have ownership in that plane anymore so I can't comment on the longevity of the repair but I haven't heard any problems from it. See pic above for an idea what the leak and bubbling looks like. CNoe

-

Your upper adel clamp may need to be rotated 180 degrees. Mine also points straight back as shown. ‘78 J. The vent hole should align properly if the tube points rearward.

-

cnoe changed their profile photo

-

Multiple bird strike event with a happy ending (except for the birds).

cnoe replied to cnoe's topic in General Mooney Talk

I thought of you right away when writing this up Mike. Condolences. It was a ~40 minute (gulf) coastal flight cruising at 4,500’ and I truly don’t know whether the strike was during climb-out, cruise, or descent. I assume they were in a small flock but didn’t see a single one. From what I’ve read this species is not native to Texas and was likely migrating between Mexico/Central America to the northern U.S. or Canada. They’re apparently a non-endangered population. CNoe -

Disclaimer: Animals were harmed in the making of this post. Graphic images are included and may not be suitable for all viewers. For the record you won't find many people with a softer heart than me when it comes to animals. My wife and I take our 100# dog on every trip we take. Just last month he surpassed 400 hours of Mooney time; I'm pretty sure the CFI who conducted my last BFR had less than 400 hours. Hell, I'd take our cat along too if I didn't value the leather seats so much. Anyway... I was making a "cheap fuel run" the other day (anybody remember cheap fuel?) and had just pushed the plane back into my t-hangar when I noticed a bloody mess on the starboard (that's "right" for you landlubbers) wing just outboard of the stall-strip. I thought to myself "that's weird; I don't remember hitting anything" as I inspected the leading edge for damage. Luckily there appeared to be virtually NO damage other than the blood/guts/feathers and perhaps a small chip in the paint. I'm not even sure about the paint damage, after all it's a plane that hasn't been painted in years. So I got out the wash bucket and got to work. In short order things were all cleaned up and I grabbed the pitot-tube cover to install when I noticed an even BIGGER mess on the leading edge of the port wing further out towards the wingtip. Yuck! Again I looked for damage and found none. Before cleaning things up I considered that it might be appropriate to file a bird-strike report with the FAA so I quickly checked the iPad for the relevant information. I was surprised to find that not only did they want a report, they also requested that bird remains be sent to the Smithsonian for positive ID. So I grabbed a ziplock bag and deposited a fair amount of the carcass for the good folks in D.C. to examine. That evening I dutifully submitted my report and prepared to ship out the poor dead bird. Later I shared pics and details with a few close friends who commented that similar to the old idiom I had "killed two birds with one Mooney". Bear in mind that these particular individuals do not make their living as stand-up comedians. By this time it was obvious to me that these birds had pretty much exploded on impact and obviously weren't vultures, pelicans, or anything else of significant size. I'm certainly a fan of the near-indestructible Mooney wing but smacking into a bird of significant size at 150 knots would surely inflict more damage than what I experienced. Additionally, nobody could believe that I'd plowed through these buggers with two direct hits on my wings without noticing a thing. Not a sound, not a bump, nothing. Truthfully I was just glad they didn't hit the windscreen 'cause even though I doubt they'd have punctured it I'm pretty sure it would have startled the crap out of me. Now the plot thickens just a little more... Two days later I arrived at the hangar with my wife and canine unit for a 3-hour flight to visit family. During the pre-flight inspection I got to the part where I peer into the cowling air-inlets at the engine and, son-of-a-bitch, there was ANOTHER bird carcass splattered on the front of cylinder #2 with feathers strewn beyond. This one had obviously passed through the propeller arc untouched (no marks were on the prop at all) and entered the cowling. I informed my wife of the situation and then began removing the top cowl while her and the pup chilled in the car. Again I found lots of bird remains with essentially no damage. There was blood and feathers on the cooling fins, injector lines (which I inspected VERY thoroughly), spark plugs, and plug wires on the left side of the engine. And the oil cooler was well covered in feathers. About a half-hour of shop-vac and cleaning-brush work had things back in order and after a quick ground-run I reinstalled the cowl and off we went. No issues. I wanted to wait until the remains were identified before I wrote this up and the results showed up a couple of days ago. So the birds were... (drumroll please)... Setophaga magnolias, aka Magnolia Warblers. In my favor they're dainty little things ranging from 6-15 grams (a half-ounce at most), so there was obviously no need to land on the Hudson. There's also little chance that Tom Hanks will be making a movie about my experience. I don't know the exact physics involved but I'm quite certain that when a 15 gram bird collides with a 1 million gram airplane traveling at 250 feet per second the result is inevitable. RIP little warblers. I'm not sure there's any moral to the story other than to say that you won't necessarily recognize that you've experienced such a strike. Also, report it; the process is easy and it's pretty cool having the bird identified. Apparently researchers gain valuable information from these reports and perhaps it will help spare a few planes and birds in the future. CNoe

-

Mooney down at KHEG (Jacksonville, FL)

cnoe replied to Hector's topic in Mooney Safety & Accident Discussion

I’m genuinely interested in hearing more about this incident. After landing was the outer handle sticking out? Does it have the plastic cover inside covering the emergency release? Was the assembly inspected or repaired by an A&P afterwards? The Service Instruction quoted doesn’t apply to the M20M so that shouldn’t be an issue. I think the odds of me putting it down in a field, lake, or stand of pines is much greater than my hatch popping open in flight since it’s been thoroughly inspected and is regularly checked. Time will tell. Still I prefer giving any first responder (not just a trained and well-equipped rescue team) easy access to my cabin in case I need help. But I understand and support others’ choice to keep it locked if that provides you more peace of mind. All good! CNoe P.S. We missed you at KOSH this year Anthony! I try to visit MS occasionally still but my piano-playing duties at the brothel take up so much of my time these days. -

Mooney down at KHEG (Jacksonville, FL)

cnoe replied to Hector's topic in Mooney Safety & Accident Discussion

My condolences go out to the family and friends of the lost souls. And I apologize for the thread drift but I felt it necessary to provide an alternative point of view on baggage doors/emergency exits. This has been discussed a great deal in the past and a fair number of us purposely leave this hatch "unlocked". I previously locked the latch religiously believing that the "lock" kept the door more secure, but I now choose to leave it unlocked so that any first-responder/rescuer will have easy access into my plane in the event of an incident in which I am incapacitated or need assistance. I have studied the latch/lock mechanism fully and the "lock" only secures the outer handle; it has absolutely no effect on the security of the latch (unless some external force is pulling on the handle). Granted there are perhaps some latches out there that were improperly installed or modified but mine is not one of them. There is an important Service Instruction (SI M20-82) that addresses this issue and I would advise owners to follow it. In fairness I will admit that in this SI Mooney "recommends" that the door be locked before flight. This document is available at https://www.mooney.com/wp-content/uploads/2020/12/SIM20-82.pdf With all due respect "locking" your baggage door in flight isn't necessarily a good or bad thing. For me the door is either fully open, or fully closed-and-latched. But it's never locked in flight. Everybody gets to choose their own SOP on that one. CNoe -

Instrument Procedures for Mexico and Canada

cnoe replied to chrisk's topic in Miscellaneous Aviation Talk

Thanks guys; you've helped me out for sure. I've got a Jepp account and previously used their NavData but never purchased their charts before. It's an easy add-on with Foreflight but the least expensive option is $259 (if buying an "annual" subscription). Calling them is a good idea but I've found a work-around. Paul, I didn't realize that Seattle Avionics had added the Mexico IFR Procedures to their subscription. I don't typically use FlyQ but with their recent new-subscriber special I was able to buy-in and get the (Mexican version) plates I was looking for. Thanks for the tip. I must also send a shout-out of thanks to another contributor who texted me the Jepp plates I was requesting which is great to have and easier to interpret. While I can't integrated them into Foreflight they're all I need to augment my GNS's guidance should I find myself in need of making an approach in IMC. I was also glad to receive the IFR departures (SIDs) in case I'm instructed to follow such (these are also among the FlyQ charts). This is my first flight into Mexico in the Mooney so I'm slightly anxious about the whole affair. Still I think I'm good-to-go and have planned things thoroughly. While paying for FBO handling is not my typical modus operandi I'm opting in for this initial trip to ease the process (and keep my wife happy). I actually got a fair quote ($250 total) from AirBusiness and visited their FBO last time I passed through that airport flying commercial. One good part is that I will clear C&I in the FBO rather than having to visit the main terminal. Amazingly, even with FBO service the Mooney trip will cost me less than 2 coach tickets on United (which isn't always the case). Still having been a regular visitor (by auto and commercial flights) to Mexico for over 40 years I intend handle my own affairs on future visits. We are indeed visiting friends in San Miguel but agree that Guanajuato is also a great destination. Flying out of Houston makes Queretaro a better destination airport for us though Leon is another option for sure. They've been trying to make the airport work out in San Miguel but it's been a battle from what I know; still it won't be an airport of entry so I'd still have to fly thru MMQT. Thanks again guys! CNoe -

Instrument Procedures for Mexico and Canada

cnoe replied to chrisk's topic in Miscellaneous Aviation Talk

I was wondering if there was any more-current info on this topic. I'm specifically looking for approach plates for MMQT. I have the Mexico enroute charts thru Foreflight and the certified NavData on my GNS530W but can't easily locate plates for the four approaches (1 runway). I'm not planning to launch with IFR approach conditions at the destination, but you know sometimes things change. None of the links on this thread seem to work any more so I'm curious if anybody has more info, or perhaps a screenshot of these four plates that I could print out. I'll contact the FBO there as well as AOPA for more help but perhaps Mooneyspace will help. Thanks guys! CNoe -

As typical Anthony makes some good points, but I figured I'd offer an anecdotal data point to the conversation... I just looked at my records and can state that my Sensorcon CO detector was put into service in February of 2017 and I've yet to see the "low battery" indicator come on. It seems obvious that the expected (CR123A) battery life (2+ years) is based on time-in-use (not calendar time). And while the sensor element may become less viable with "age", mine still reacts quickly and vigorously to any level of CO in the cockpit. To me, absolute numeric accuracy is less important than prompt gross detection while in flight. I still want the "programmable" model though and will be looking for an excuse to upgrade sometime. Hopefully my existing unit won't continue to work for ANOTHER four years. CNoe

.jpg.84045bc772bc6f4ff91335cb68175dc0.jpg)

.jpg.f3a8391ff7b0ba11985106c8cb78a148.jpg)