-

Posts

730 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Cody Stallings

-

Now is a Great Time to Self Quarantine

Cody Stallings replied to GeeBee's topic in General Mooney Talk

Hell of an idea. Think I will put your recommendation into Motion in the Morning -

Love of flying in the Time of Coronavirus

Cody Stallings replied to ilovecornfields's topic in Miscellaneous Aviation Talk

- 163 replies

-

- 18

-

-

-

-

Oh Wow, I thought you had an Issue. That’s really no issues at all. File it out an move on with life.

-

In the hands of a green horn, probably wanna use a machinist file an take your time. Have it balanced when your done, your Oil Transfer bearing will thank you

-

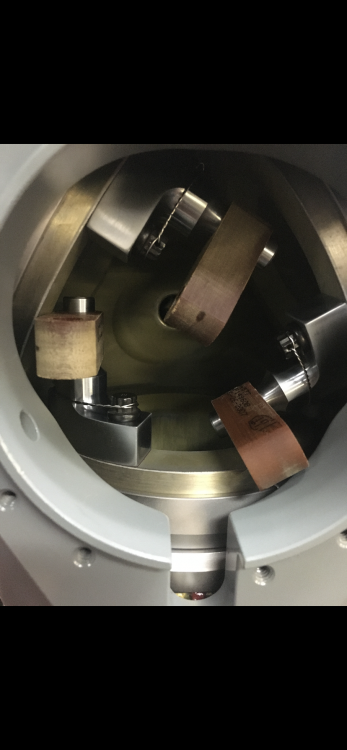

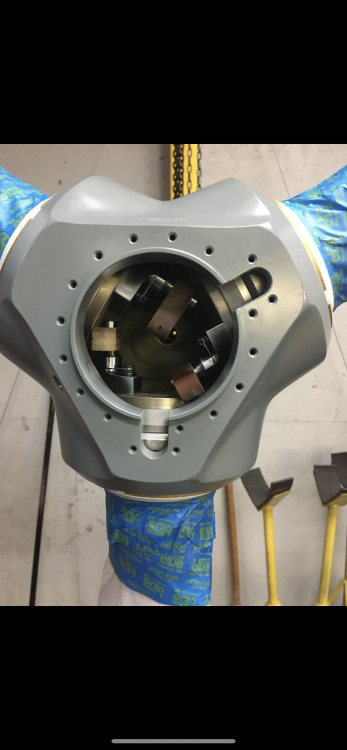

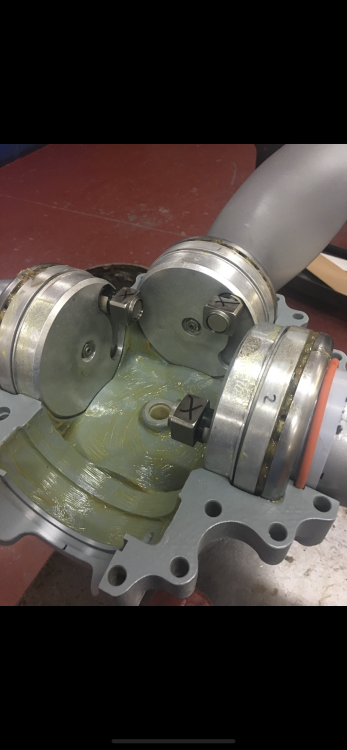

Well I hate to say it, but my propeller looked the same on the inside after 15yrs. It’s not really neglect that your seeing on the part of the pilot, it’s neglect from the guy that built that propeller. The C505 propeller is a grease lubricated propeller vs the Red Dye oil filled variant, so it uses a very limited about of grease on the blade thrust bearings. Thats really the only place inside the hub you put grease other that some on the feathering spring. That leaves all the other steel components nice an clean for the technician to assembly the propeller without a rag to wipe his hands off, but it leaves the propeller Parts vulnerable to corrosion. You can use this method of assembly with an oil filled propeller cause when it’s built it will be filled with SAE 30 Weigh Red Oil. But it never works with a greased propeller. In my shop my guys get greasy, an we use a lot of towels. We use acid brushes to paint a film of grease all over the inside of the hub, an it’s steel parts. Then the bearings are packed an the propeller is assembled. Yes it’s time consuming, Yes it’s nasty work, But it has to be done. Without that step the outcome is all to predictable. The 500 Series propeller is a breathing propeller. Meaning outsIde air(very slight amount) enters the hub when the propeller actuates. It’s not sealed like the oil-filled version. Once moisture lays on the steel components, it’s rusts. A film of grease painted on said parts will ensure this doesn’t happen.

-

A good day ends badly in El Paso

Cody Stallings replied to jcovington's topic in General Mooney Talk

Give me a shout sometime. Shop# 870-208-8882 Cell# 870-208-5198 -

A good day ends badly in El Paso

Cody Stallings replied to jcovington's topic in General Mooney Talk

I would be willing to venture a guess that your propeller was lubed with AeroShell #6. The way it looks in the spinner just screams broken down grease. Does your Logbook entry state why type of grease was used in the propeller? -

A good day ends badly in El Paso

Cody Stallings replied to jcovington's topic in General Mooney Talk

-

What do you fly if not your Mooney?

Cody Stallings replied to Oldguy's topic in Miscellaneous Aviation Talk

Wait a Second, people who own Mooneys fly Other planes? Its Mooney For me, Anything else is just uncivilized!!!! -

Propeller RPM control issues

Cody Stallings replied to Flybeech21's topic in Vintage Mooneys (pre-J models)

Negative. Need to pay close attention to the Prop Gov in this situation. Putting grease in the propeller doesn’t have anything to do with it not maintaining RPM. The Grease just Lubricates the Thrust Bearings. Bout 18/19in is where my F model gov would go off line. At that point the prop will be pushing the engine. If you push the power to 20/22in( somewhere in that area) you should get a very noticeable rpm reduction an be able to hear the Gov load the propeller with pitch. I would be very curious to know if you have a Hartzell H-1 Gov. This same thing happened to me. Propeller control full out would only pull it down to 2550 Rpms. Turns out the Gov was internally bypassing the oil that was needed at the prop. Keep a close eye on this issue. “Down shifting” to Granny Low isn’t a good idea at 140Knts -

Need More information. Depends what is being done to the propeller, an what this said tolerance issue is on the blade.

-

Memphis Area M20 Drivers?

Cody Stallings replied to bradhescock's topic in Vintage Mooneys (pre-J models)

I’m to the west of ya about 30 miles at DRP. Have a K Model you could eyeball if ya wanted too. -

Strange (to me) departure procedure

Cody Stallings replied to DonMuncy's topic in Miscellaneous Aviation Talk

I had the same issue few months ago at Fayetteville Drake Field(FYV). Was assigned the Razorback 1 Departure by the Tower while taxi out. As you did I was digging through the G device looking for it with no luck. Was just a turn from 160(Rwy heading) to 180 an climb to 4K. BTW!! That departure is the only way The Razorbacks can be Mistaken for #1 -

Not a lot, but I have been know you dabble a bit.

-

Seeking cool weather pilots

Cody Stallings replied to BrettKS's topic in Miscellaneous Aviation Talk

I would have been suffering from instant RedAss syndrome!!!! -

I think the 252 was certified to FL270. Its only Certified to 240 now with the conversion.

-

-

Seeking cool weather pilots

Cody Stallings replied to BrettKS's topic in Miscellaneous Aviation Talk

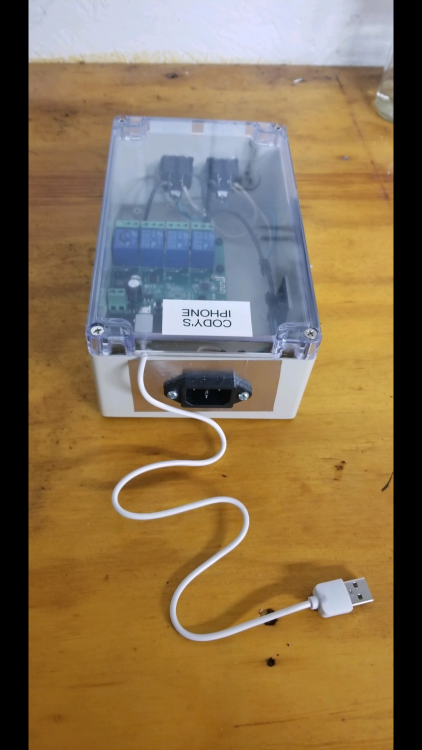

Yes it’s what’s referred to as a HotSpot so I’m told. Little black box from Verizon with a digital screen to show status an password. I understand your concerns for testing, but it has had a lot of actual real world testing an has worked flawlessly. Reason I go this route is: There are a few hanger neighbors that link up to this thing got various reason, an I also use it for monitoring the well-being of my assets. We have some airport commissioners that have demanded they have spare keys to all hangers, an they have been witnessed going in hangers at night to “check on peoples planes”. Not anymore!! -

Seeking cool weather pilots

Cody Stallings replied to BrettKS's topic in Miscellaneous Aviation Talk

Something like this? Have it in my hanger today Run engine heater an small space heater under belly to keep things un-Frozen in the cabin. With a Wifi hotspot an app on your phone, have total control of turning things On/Off in my hanger from anywhere. This switch box is homemade by May hanger neighbor. He has a little less than $80 invested an a few hours of his time. Its a very nice luxury to have, no 8 mile drives to the airport to plug in the night before. Also, Via the cell app I can select a certain Channel(120v plug) to activate at a pre-determined time, an cutoff the same way. -

What is your static full throttle RPM?

Cody Stallings replied to corn_flake's topic in Vintage Mooneys (pre-J models)

If the propeller has to much Low-Pitch that will have to be adjusted in a Repairstation. Figuring out there pitch setting on the plane will be a real pain in the Butt. That number comes from your engine/plane/blade design, engineers much smarter than me come up with those angles. Has it been making RPM in the past? Or has it been lacking? -

What is your static full throttle RPM?

Cody Stallings replied to corn_flake's topic in Vintage Mooneys (pre-J models)

The 13.9 degrees is a Engine/Airframe thing put in motion by the manufacturer. At 13.5 you may have a surging issue as the RPM comes up to fast then the Gov kicks in. At 14.4 it will never make it to RPM on the roll, however will make RPM in the air. Any Chance you maybe running a little rich on the grd? McCauley propellers usually don’t suffer from this issue the way Hartzell does. -

Gonna go ahead an get the King Size Popcorn warming up. The S*** is about to get deep.

-

Check to see if your blades are Snug(not tight). If they feel good or like other Props on your ramp you should be fine. I would say it’s probably not going to be your propeller. A propeller that out of balance will shake at all RPMs with a change in Frequency, an the amplitude will fall slightly with RPM. Calendar TBO should not apply to Part: 91 in my opinion. 5/6 Year TBO on a propeller with a 2000hr TBO. Most fly in the 100hr a Year range. So 600hrs an it time to O/H?... Head Scratcher!!! If you just wanna do something to your propeller. Re-Seal it. The Orings are what will go bad first, while the propeller is apart the Repairstation will be looking for any Safety of Flight issues. You will get more of your propeller back that way. My 2 cents

-

WTB: Hartzell or McCauley 3 blade IO-520BB Engine

Cody Stallings replied to Frank B.'s topic in Avionics / Parts Classifieds

No problem Frank.