Browncbr1

Basic Member-

Posts

2,336 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Browncbr1

-

Fuel Pressure Flux or Bad JPI Sensor?

Browncbr1 replied to bhtitle's topic in Vintage Mooneys (pre-J models)

Right, I’m just talking about the expanding threads that go into the aluminum transducer housing. The jpi housing is easy to crack after just a few threads. Putting thread sealant on flare fittings would be useless. Haha -

Fuel Pressure Flux or Bad JPI Sensor?

Browncbr1 replied to bhtitle's topic in Vintage Mooneys (pre-J models)

I used permatex thread sealant on the tightening NPT fittings on my fuel flow transducer to solve mine a few years back.... then had the same issue, but less pronounced and it was solved by rebuilding the fuel selector with all new o-rings. I saw the slightest hint of dye on the FF transducer, but none on the selector. Hopefully, there is no leak coming from any of the NPT fittings on your mechanical fuel pump. it's very tight access back there. -

-

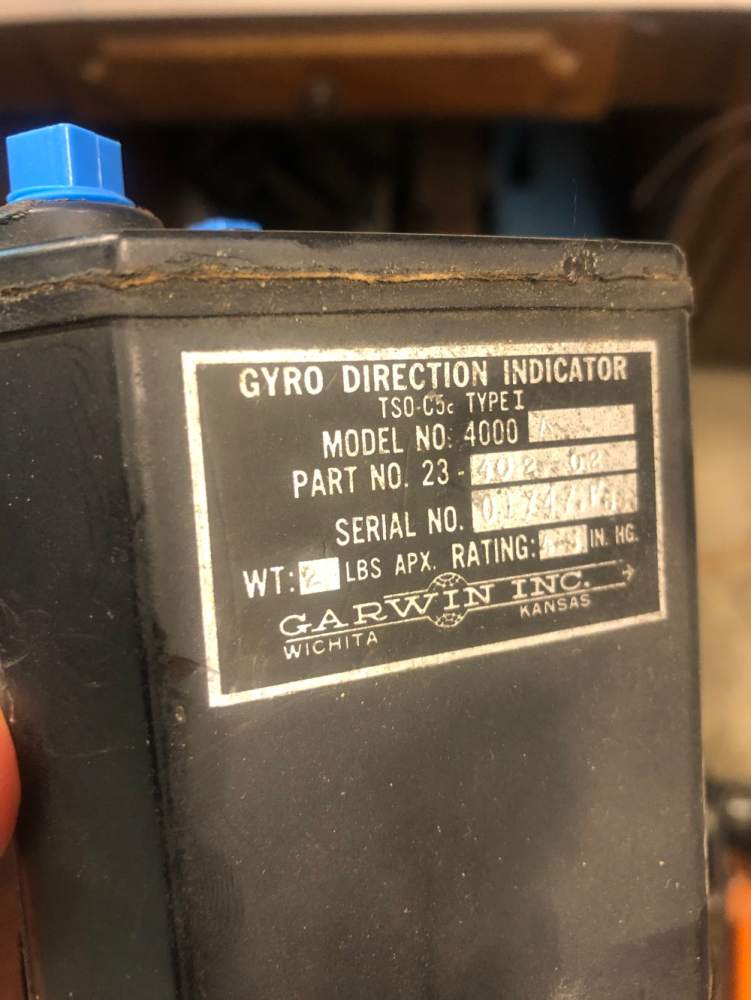

if by original, you mean the small 2 1/2" DG that came with our 67Fs, then yes, I have one on the shelf. it was working when removed. been on the shelf in dry storage since 2017 or 18 though.

-

Fuel Pressure Flux or Bad JPI Sensor?

Browncbr1 replied to bhtitle's topic in Vintage Mooneys (pre-J models)

if it does it worse the higher you fly, then air is getting into your fuel system... sometimes it's from the gascolator/valve selector. Sometimes, it's from a loose fuel line fitting. Is fuel flow unstable also? this is usually accompanied by what feels like slight roughness or missing. wobbly fuel pressure corroborated with wobbly fuel flow points to air in fuel. check for loose wire connections and/or ground on for the sensor and also check that the pins are clean and straight. clean the fuel screen on the right side of your fuel servo and also clean the gascolator and check the gasket for cracks. Do not over torque the gascolator bowl bolt!!! iirc 20in/lbs. There is a little rubber coated metal washer on that bolt that should be replaced every several years. -

You must have a special colemill baron. Fox star colemill 58 barons usually at 25 LOP 8-10k get 178-185ktas and ~13gph per side. For me to burn only 10gph per side, I’d be going along about 160kts or so. Is yours a 55 or 58? i see the video, he’s at 12k with 2200rpm to get that low fuel burn.

-

Looks like cross hatch to me. follow skips advice.

-

true, and time to climb and descent through icing is less in the baron.

-

I'd pay and extra $10k for non-fiki tks.. probably not more though because it's more things to maintain and costs a little speed. I visit NE ohio year around, but typically figure that December-March is no go season unless I plan to stay just a couple days or so. Honestly, for my 67F, I think the best value would be a just a slinger on the prop (alcohol or tks).. For that, I'd pay proportionally more than a full tks system. From my experience using alcohol props; it ends up slinging all over the plane anyway, just except for out at the wing tips. The baron I fly has alcohol props and I've never had to actually use the wing boots. So, I'd pay for a small 2 alcohol prop slinger for sure.. problem is, I don't think an stc like this exists!

-

I cobbled this together several years ago. Works well. I need space in my garage! Free to anyone picking up in Knoxville, TN.

-

Given the cost and lead time of overhaul, I’d definitely pull some cylinders to see what can be found.

-

NARCO AT 150 Putting out two Codes?

Browncbr1 replied to Ned Gravel's topic in Avionics/Panel Discussion

@Ned Gravel I’ve got one on the shelf that worked just fine when removed for upgrade. I also have a nearly new Sandia digital encoder that can go with it. Let me know by PM if needed. Craig -

Buying advise - would this scare you off?

Browncbr1 replied to Tim-37419's topic in Modern Mooney Discussion

Depending on how the engine has been operated, simple valve lapping and/or solvent flush could bring the compressions back up. for what it’s worth, my engine has the original crank and wide deck case. So, the total time is over 6000, but they were both inspected/serviced at overhaul ~70 hours ago. Cylinders can be reworked if not too far gone. New angle valve cylinders have a long back order these days. in my experience, glass panels and autopilots cost more than engine overhauls. If the engine is running ok and making good power without making metal, I wouldn’t be scared off. Just make sure you know what kind of case and lifters it has. It could be that the previous owner replaced the original engine case simple because they wanted roller tappets when they did the overhaul. Log books should tell the story. -

Con

-

I have been getting great TAS numbers.

Browncbr1 replied to Jim Peace's topic in Vintage Mooneys (pre-J models)

Usually a nicely done dynamic prop balance will increase tas 2 or 3 kts. I bought the balancing equipment for myself and friends. I got mine down to .00 - .01…. I see similar TAS as you under similar atmosphere. I’ve got an F model though. I have to plug in my CAS and OAT separately for some reason though. My GTN doesn’t automatically pull accurate data from the GAD13 for some reason. -

@Sabremech hey David, I’m quite dehydrated from drooling the past two months. Do you have any updates that might quench my thirst?

-

Watch the thumb button click into place when you push the bar into the block. Then verify by pulling down on the handle to make sure it doesn’t come unlatched. I don’t pay much attention to the light, although my light did burn out one time and it was a no brainer to look at the bar. I also unscrewed the red gear up light and put it into the gear down socket just to verify it was just the bulb before landing. consider a new block if the plane has higher total time with the original block.

-

I would adjust pressure down quite a bit to cruise at about 75psi. If I’m using 100w oil, I don’t take off until oil temp is at or above 160. With multigrade, I take off at about 140 degrees. This helps keep oil pressure at or below 100psi. also, not sure about continentals…. I think the OEM gauge takes oil pressure reading at the end of the gallery? Lycoming have two at the beginning. I may have a little bit of calibration error, but it seems the upper port on mine (hooked up to jpi) reads slightly higher at times than the lower port (OEM garwin gauge)

-

I fabricated my own out of some scrap stainless sheet. Pretty easy with a dremel. You can probably find some scrap at metal shops or maybe old thrown away exhaust shroud. Might be able to find a SS washer of appropriate size at lowes or HD that you can notch with a dremel.

-

you can run multi pole wire through each of the tubes. I have the ptt button where the PC button valve was with one two pole wire fed through one of the tubes. That would free up the other tube for trim switch wire. you could also wrap your yoke in leather, laying up the wire where the seams are, so the relief would be hidden under the seam.

-

Other devices showing true rather than magnetic?

-

Air stop tubes are def the way to go.

-

Twisted Wing - What’s the deal?

Browncbr1 replied to gwav8or's topic in Vintage Mooneys (pre-J models)

+1 -

Crazy or stupid? Oil leak revealed

Browncbr1 replied to BDPetersen's topic in Vintage Mooneys (pre-J models)

red honey flame master (iirc 3306) is pretty good for sealing leaking case halves. easy and nothing to mix and not quite as ugly as other methods.. if it doesn't solve it, it's probably because the metal wasn't completely clean or you can mix up some PRC to goop on. I also use torque seal on all hardware to easily see if anything has backed off.