Browncbr1

Basic Member-

Posts

2,336 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Browncbr1

-

You could use the blue aluminum box and about 6-8” of SCEET to a NACA or gills out the bottom of the cowl just in front of the left flap. shoot, you could just adel clamp some longer sceet to just go out the flap to at least test it. It could just articulate with the flap. Smash the tube a little flatter and adjust the flap position to account for the exit area

-

After the nearly 2 hour flight this morning, it seems the oil consumption is zero. I’ll just continue regular 65% power from here. Oil temp seems to have calmed down a little bit, CHT‘s are a little more regular, but were never hot from the beginning. Planning to cut the filter at 10 hours and switch to AD oil at 25

-

Yea, I flew again this morning. Flying around at 180 is cool, but not very fun if going in circles. I wanted to put it through another couple hours before leaving the field. Next flight I’ll do a short CC to grab some $5 fuel. It’s not fun breaking in at $7.67/gal, but at least it’s just a four cylinder.

-

One challenge I had, as it relates to the oil cooler thread, at high power, air flow over my oil cooler is minimal, it results in high oil temp and low cht temp because I have to open cowl flaps. I’ll post some jpi data soon. I’m planning to fly again this morning.

-

Ok I’ll watch oil level and fly on

-

Today I did the Lycoming SI break in flight procedure and everything seemed fine. It only went through about a half quart, which I thought would have been more… so do you guys recommend I just fly at 75% until oil consumption stops or ??? Wondering when I should be able to start flying as normal

-

Ran the engine for about 4 minutes to just do ops/leak check. I’ve gotta say, this is the smoothest running 4 cylinder I’ve ever run. Feels like a smooth 6 cylinder actually. starting oil temp was 65 and resulted in a peak of 106psi at 1100 rpm, so will definitely be preheating this oil. That is on the jpi coming from the upper oil port. The OEM gauge showed 75psi and it’s connected to the lower oil port. I guess with new engines, things are tighter, so cool oil is more of an issue. Previous engine build would go to 100psi at about 60 degrees at 1100rpm

-

Yes, definitely doing that. Also going to fill up the new oil cooler and lines, then spray some oil in cylinders and motor with the starter to confirm oil pressure reading before starting.

-

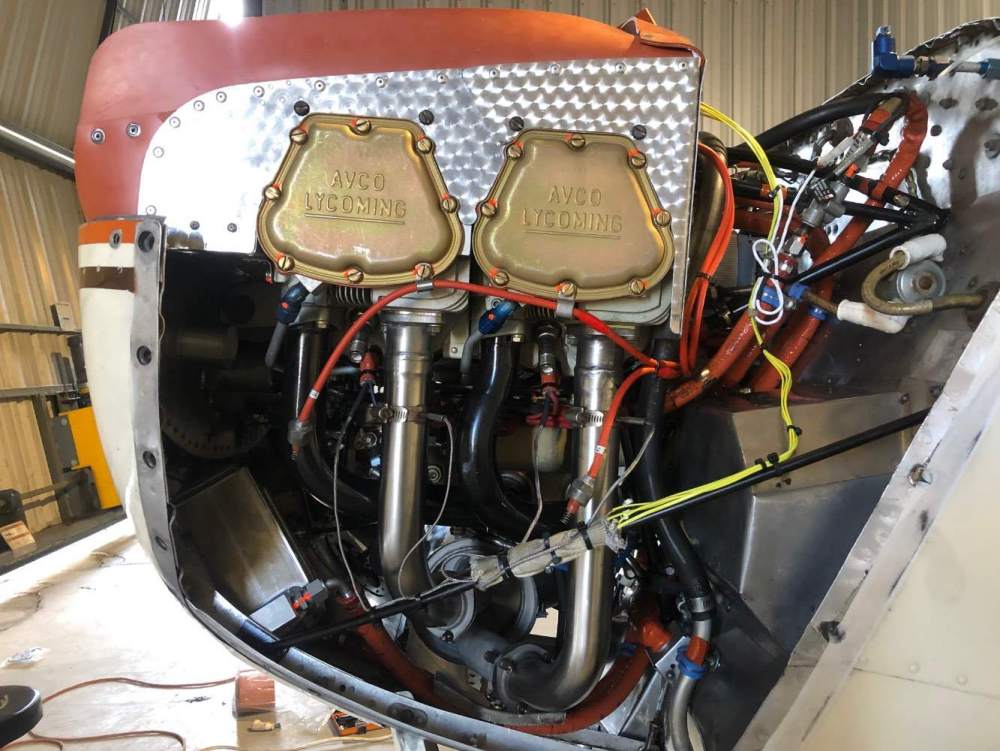

It’s just about buttoned up now. Planning to hang the prop and do a short run up installation / leak check tomorrow. I gotta say, I’m glad I put the effort in on the baffle and exhaust. I like the look. I did foul up and order the wrong exhaust hardware, so correct new exhaust hardware is on the way.

-

How do you rotate them?

-

It seems the builder did just the breakin checklist ground run that is detailed before the 2.5hr first flight. I think the time I mentioned earlier was the total time, not continuous run time.

-

Today Was mostly tedious routing and securing of fuel a electrical lines and lots of reworking to making things a little cleaner and easier to access later on down the road. Next time, the left rear baffle definitely will go on before the motor mount. That took several hours.

-

Two of the ignition lead springs are missing from my harness. Does anyone know where these are available?

-

That’s pretty much what I did with one of them.. I was able to tap it through without actually beating it through I’m afraid the other one is too tight and may damage the threads without a helping hand to reduce side load on the bolt. Hopefully will get that last bolt on tomorrow with good threads. Then torque all as per page 71

-

This is a newly rebuilt servo. This doesn’t look right??? See how it over centers?? IMG_0558.MOV

-

Went over and checked torque on several things. I found the gov oil line fittings was loose at the gov. Didn’t find anything else that was loose. Put motor mount and isolators on the engine then bolted bottom firewall attach points and swung engine up to attach uppers. Major pain to get the top bolts in through the cabin. Co-pilot side bolt is in, but still working on pilot side. Need two people. My idea of using the tiedown strap doesn’t really work because it needs to also go up a little bit. All new hardware.

-

From what I understand, it’s the combination of low power and hot cylinders that causes glazing. All I know is I’m planning a short installation and leak check run up and let it cool to ambient before starting it up to taxi out and fly. Then I’ll fly it like I stole it.

-

I read that multigrade non-AD oil is better for protecting against glazing compared to straight weight. Does anyone have any technical knowledge on the subject of breakin oil?

-

I really can’t rethink what has already been done. It’s history. He has built many engines since the 80’s. He worked at a shop for years where they had a water dyno and did as you describe. Shops that have that equipment charge about $10k more for the engine rebuild. Not everything is ideal, but it comes with a 2 year warranty and I trust him, as he’s built hundreds of engines. I’d rather not have the anxiety of trying to question history right now. I’d rather just focus on hanging it and break-in. thanks for your comments though. You’ve posted tons of valuable info all over MS for a long time. I appreciate you!

-

I spoke again to the builder. the engine oil was drained and the filter was removed and cut after the test run. The filter inspection was normal and he told me what to expect with the 10hr filter cut. it was run with the club at low power to test function and set oil pressure, etc. it was a cold day and he guarantees chts didn’t get hot enough for any glazing. He did run it up for mag checks and then full power to make sure it’s made the rated rpm for 200hp. He said that as a general rule of thumb, glazing is avoided so long as chts don’t get up about 425 for a few minutes. He and others have told me the club props put out so much wind, that cowling isn’t needed. also, that you couldn’t run it like that with a flying prop though. He also reminded me that this was not a run-in or a break-in run. He gave me a very specific procedure for the initial installation check run and let it cool back to ambient. Then details on the initial 1.5 hour break in flight.

-

Bill Wagner at SkyBoss Aviation in Tulsa

-

Yea…. Not everything has gone as expected.. I don’t know for certain how long and how hard it was really run. In the beginning, he said he would have CHT probes on every cylinder. I don’t see them in the video. Not sure

-

-

It’s basically an operations and leak checking run. Seems he also set the idle speed and mixture for the new servo as well. I still have to break it in.. yea, it’s not a dyno, and I knew that going in. I just wanted to make sure it’s running good and no leaks before shipment. I didn’t want to have to ship and install on the plane to find out if something was wrong. I don’t think the oil or filter were changed after. I understand that happens at 10hrs.

-

The engine shipped out to me on Friday. Should have it this week. Here is a video of it running on the test stand while it was warming up. He ran it at high MP for about 40 minutes. I’ll post a $ total detail break down later this week. I had to order a new oil cooler, as they said mine old one was beyond repairable. IMG_0538.MOV