-

Posts

1,539 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Vance Harral

-

How to “Use” Brittain Autopilot

Vance Harral replied to Nukemzzz's topic in Vintage Mooneys (pre-J models)

Again, there are multiple Brittain systems, with multiple gyro units. The best advice in this thread is from folks stressing the importance of using the manuals for the specific system one is working with. That said, to answer your specific question, the B-5 system makes use of a Brittain TC-100-EVT turn coordinator. Here's a picture of a TC-100-EVT on Mooneyspace. Note the wiring cable with the multi-pin connector. That's the electrical connection to the B-5 control head. So yes, that particular Brittain Turn Coordinator accepts electrical control signals that control the pneumatic shuttle valve. I don't know if the B-6 system uses the TC-100-EVT or similar. But in general, the nav control unit has to have some way to "tell" the pneumatic servos to turn left/right to track a heading or course. Consequently, there has to be an electro/pneumatic interface somewhere in the system. In at least some Brittain systems - particularly the B-5 - that electro/pneumatic interface is built into the Turn Coordinator itself. It's possible other Brittain autopilot systems have a separate control valve independent of the TC, such that the TC has no electrical connection other than power/ground for gyro drive motor. I'm not intimately familiar with anything other than the B-5 system. -

How to “Use” Brittain Autopilot

Vance Harral replied to Nukemzzz's topic in Vintage Mooneys (pre-J models)

Probably not true. While there are many Brittain variants, my guess is the OP's B-6 system works very similar to our B-5. In the B-5 system, electrical turn left/turn right signals from the autopilot head are sent to the Turn Coordinator, to drive its vacuum shuttle valve left/right to induce turns for lateral navigation. So the Turn Coordinator is not "just to level the wings", but is in fact the electrical/vacuum interface between the navigational functionality in the autopilot head, and the servos which steer the airplane. -

Can a Garmin cdi work with different autopilots?

Vance Harral replied to rbridges's topic in Avionics/Panel Discussion

Yes. The GI-106A has analog left/right outputs that can be connected to the Brittain, same as any "old school" CDI. We have a Garmin GI-106A CDI hooked to our Brittain B-5 autopilot. Works quite well for tracking GPS, VOR, and LOC courses. -

The main thing you're looking for is asymmetric wear patterns on the exhaust valves. It's possible to catch these early, before the valve actually starts to leak enough to cause lower compression readings. You get to see the intake valve too, of course. But my limited understanding (not an A&P) is there's not much to look for on the intake valves other than gross damage. You can also look at the cylinder walls to see if they still have their cross-hatching, and/or if they're beginning to show any signs of abnormal wear. For pictures, see the "What to look for" section of https://blog.aopa.org/aopa/2016/12/20/scope-that-jug/

-

Simple things first: make sure the (T)ip of the 3-connector TRS plug on the Halo is making good contact with the corresponding terminal of the headset jack in your airplane. Depressing the PTT switch shorts that terminal to ground, and it could be that the exact condition of your jack is such that the Halo plug is making intermittent contact and causing noise or other issues, where other headsets make good contact (or possibly no contact at all - this can still "work" depending on how the PTT is wired to the rest of the com system). Assuming your co-pilot's headset plugs are wired with a PTT switch as well, you can try plugging the halo in over there. If it works there but not on the pilot side, it's very likely that the jack needs to be replaced, or just tweaked a little. There are all kinds of other things that could cause your problem, but this one is easy to check yourself.

-

A Car's Manual Transmission and RPM/MP Analogy

Vance Harral replied to 211º's topic in General Mooney Talk

There are a number of reasons why a constant speed prop isn't analogous to a manual gearbox transmission in a car, and I try to dissuade people from using that analogy. First, the propeller has a continuous range of pitch, not discrete pitch points. An automatic CVT transmission of the type found in certain Subarus and other modern automobiles is a little more analogous to a constant speed prop; but most drivers barely understand how automatic transmissions work to start with, much less the concept of a continuously variable transmission. Second and more importantly, in a manual gearbox vehicle, the gearshift lever sets the gear ratio directly. A constant speed propeller has no control that directly sets the propeller pitch. Rather, it is constantly and automatically "shifting" the propeller pitch to maintain a selected RPM. A helpful thing to explain to students is that if you were to safety wire the propeller control full forward such that it couldn't be moved at all, you'd still get about 90% of the benefit of the system. In fact, Cirrus SR22 Turbo 5th gen and later aircraft are designed exactly this way: they have constant speed propellers, but there is no propeller control lever, and the selected RPM is effectively hardwired at 2500 RPM. Third, the sweet spots for power and fuel efficiency in cruise on a typical car vs. a typical airplane are so different as to be almost completely unrelated. In almost all cars, you want to be in the highest gear during all cruise operations, downshifting only for unusual conditions like climbing a hill. Airplanes have more complicated and sometimes counter-intuitive RPM relationships. For one thing, selecting the highest "gear" (most coarse pitch) may result in undesirably slow cruise speeds that are not necessarily fuel efficient. Another interesting example from the cruise tables in my POH: 7500', 71% power, 10.4 GPH, and 165 MTAS cruise speed can be achieved at both 23"/2350RPM and 21"/2600RPM. There is no difference in fuel used and (AFAIK) no meaningful difference in operating temperate at these two settings. The reason to select one vs. the other has mostly to do with passenger comfort (noise and vibration), rather than any difference in speed or fuel efficiency. 2360 RPM will usually be less noisy, but may cause greater vibration and therefore passenger fatigue in certain airframes. I've spent hours across years poring over the performance tables of my airplane and thinking about how to best manage the propeller control. And after all that, I've settled on a trivial strategy: prop full forward for takeoffs, climbs, and landings (in case of go-around), full back for engine-out scenarios to minimize drag, and 2500 RPM everywhere else. Again, 90% of the benefit is the governing control system that automatically increases propeller pitch as load decreases, to maintain a constant RPM. Exactly what RPM is selected in cruise is almost an afterthought, and dramatically less important than the operation of the gearshift knob in a manual gearbox automobile. In summary, if you're trying to understand or explain how a constant speed prop works, I actually think the automobile manual transmission analogy hurts more than it helps. That's especially true in the modern era, where many automobile drivers aspiring to be pilots have never driven a manual gearbox automobile in the first place. -

Ours didn't rip in half, it just completely departed the airplane altogether (I guess it may have torn before doing so). The only thing holding it on at the time were sheet metal screws through the fairing and into the empennage skin - no nut plate or other backing. It's hard to believe the factory designed it that way, but the parts manual indicates only screws to hold that fairing on. Like you, we had a new fairing fabricated, though we had to do it at a remote airport in order to get back home. Shortly after getting home, we worked with our A&P to drill out the holes in the empennage skin slightly, and install riv-nuts to receive machine screws. Was signed off as a minor mod. I'd definitely recommend that mod to anyone else!

-

M20E Parts interchangeability?

Vance Harral replied to corn_flake's topic in Vintage Mooneys (pre-J models)

Even if the Bible (Parts Manual) says they are the same, be a little cautious. Mooneys are famously hand-built, and a part from one airplane may not exactly match another, even when they're the same make/model/year/one-serial-number-apart. There are many stories here about less-than-perfect fit of replacement parts for things like baggage doors, windows, etc. I don't know if control surfaces have the same issue, or if those parts are built to much tighter tolerances. -

This'll be my last post to this thread unless something else interesting happens. Two weeks of calendar time and 6 hours of flight time on the airplane since the last gasket was installed, with no issues. I think the problems are all licked, but will stay vigilant.

-

Suction cup bugs work OK for airspeed and altitude marks, but not heading on a DG. The bug needs to move as the DG rotates, so that it keeps marking the same heading.

-

I realize it feels like a downgrade because it's not glass, but our steam gauge vacuum DG and GI-106A have been serving us very well for the last 8 years. That said, if it were me, I'd spring for a DG with heading bug. I find not having a heading bug on our vacuum DG to be a non-trivial annoyance, and I think you'll miss it vs. the Sandel. Note that for me, this has nothing to do with autopilot functionality, I just like being able to set a manual heading reference for various reasons: when I'm assigned a vector from ATC, to visualize a runway heading or course intercept, etc. I can make do by using the #2 CDI or the heading indicator on our old Brittain autopilot to "remember" a heading, but it's not as good as a heading bug on the DG.

-

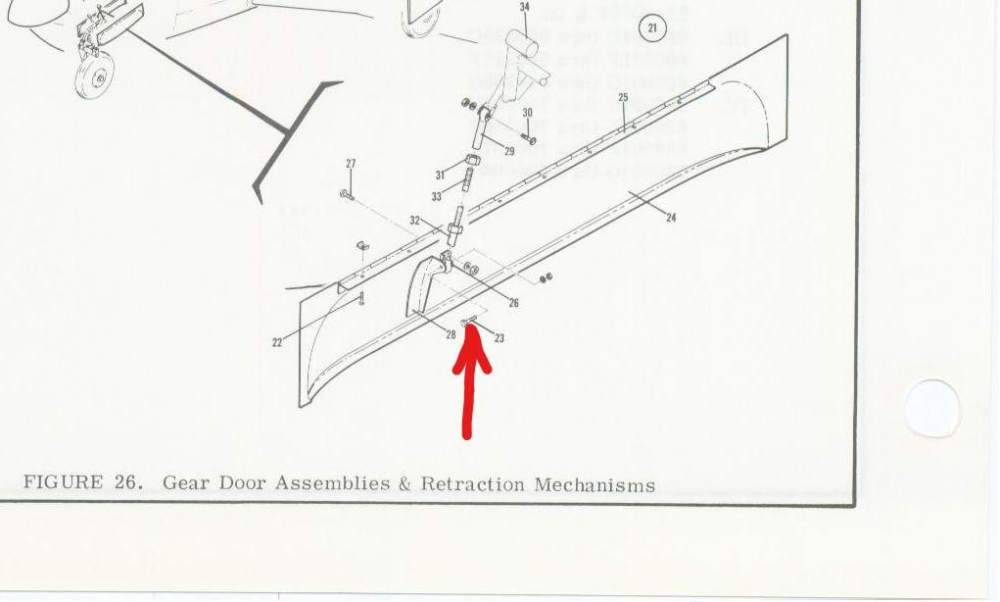

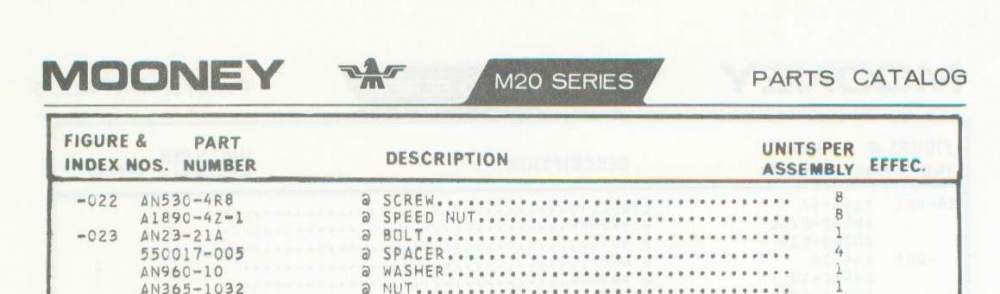

70s-era nose gear door linkage hardware

Vance Harral replied to Vance Harral's topic in Vintage Mooneys (pre-J models)

One bump of this thread, since it's the weekend, and I'm hoping a few folks might be out flying and able to snap a quick photo. -

70s-era nose gear door linkage hardware

Vance Harral replied to Vance Harral's topic in Vintage Mooneys (pre-J models)

Thanks for the data point, cferr59. I don't see any justification in the parts manual for having differently-sized spacers and two washers between the bracket and the nut. But yours is certainly no stranger than mine. I'll hazard a guess that nose gear door brackets get bent in or out a little over time, and some mechanics periodically change bolts and/or add/remove various washers during annual inspections to eliminate slop. Perhaps there is justification for this in AC43-13 as a "standard practice", but I'm not an A&P. I suppose it's even possible this sort of substitution was done at the factory, as various hand-built nose gear doors rolled off the production line - I know there are other places in my parts manual that say things like "spacers as required". -

In the midst of the fuel selector debacle described in my other thread, either myself or the adult supervisor in the shop have disconnected and reconnected the port side nose gear door linkage about a half dozen times (this makes it possible to get to the screws on the tunnel panel which must be removed to access the fuel selector, without jacking the aircraft and retracting the gear). In the midst of this, I realized the connecting hardware installed in our airplane is not what's called out in our parts manual. It's been that way for years, is functional, and I'm not particularly concerned about it, but it's a curious mystery. The aircraft is a 1976 M20F, but the parts manual is applicable to C/E/F/G models from 1968-76, and there are no model-specific notes. Wondering if other owners in this age range might comment and/or post pics. First, I quote from that bible: Figure 26, item #23: As I read this, I'd say the connecting hardware should be assembled from fore to aft as: AN23-21A bolt -> forward gear door bracket -> ( some combination/order of 4 Mooney-specific P/N spacers and the rod end) -> aft gear door bracket -> AN960-10 washer, AN365-1032 nut. What we have is decidedly different. I forgot to snap a photo yesterday, but on the starboard side ours is like: AN23-22A bolt (slightly longer than spec) -> forward gear door bracket -> thin washer -> spacer -> rod end -> spacer -> thin washer -> AN960-10 washer, AN365-1032 nut. This assembly does not meet the "rule" that you should be able to see at least one thread of the bolt extending past the nut, even in spite of the longer bolt being installed. I'm not too freaked out about it because it's very close - the end of the bolt is flush with the end of the nut. It's possible if I cranked down the nut I could see a thread, but that would take it way past torque spec and seems like a bad idea. On the port side, the assembly is similar, except instead of an AN23 bolt, there is some sort of 10-32 machine screw installed instead, with a flat screw head. One hopes it's an aircraft-grade machine screw, but who knows? Whatever it's other failings may be, it's long enough that a couple of threads extend past the AN365-1032 nut when appropriately torqued. At first I thought this whole mess might be a ham-fisted attempt to replace misplaced Mooney-specific spacers at some point in the past. If you Google that 550017-005 part number, you'll see some ebay and salvage listings with fairly silly prices (like $20 apiece). But the pictures in this eBay listing look like the spacers we have, so I think there's a good chance we have the correct equipment there. I have no idea when/why the "extra" thin washers were added our assembly, but I can tell you there is a little slop in the assembly without them. That slop could be corrected by bending the gear door bracket slightly, and if we did so, I suspect the correct-size AN23-21A bolt would receive a nut on the tail end with a thread showing. This is my tentative course of action/direction to our mechanic, but I'm not sure we want to go bending on the gear door bracket. God only knows what it would cost to fix if it cracked, and of course I'm gun-shy after the fuel selector incident. As for the machine screw, who knows where it came from? But the head on that machine screw is more svelte than a conventional AN bolt, and you always wonder about clearances inside the gear wells. Maybe I missed a Service Bulletin indicating replacement of the AN bolt with a machine screw? Anyway... all this is a long-winded way of asking other vintage Mooney owners what kind of hardware they have. Comments welcome.

-

The airplane was test flown today and nothing blew up. So far, so good. Still watching it like a hawk on a daily basis for evidence of leaks, though.

-

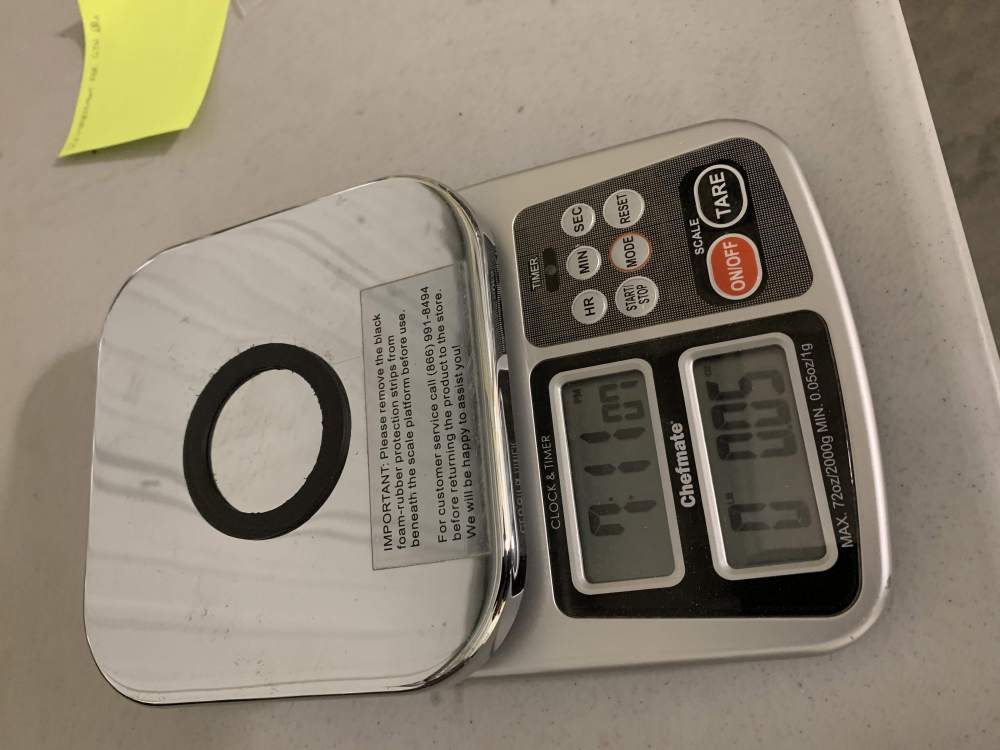

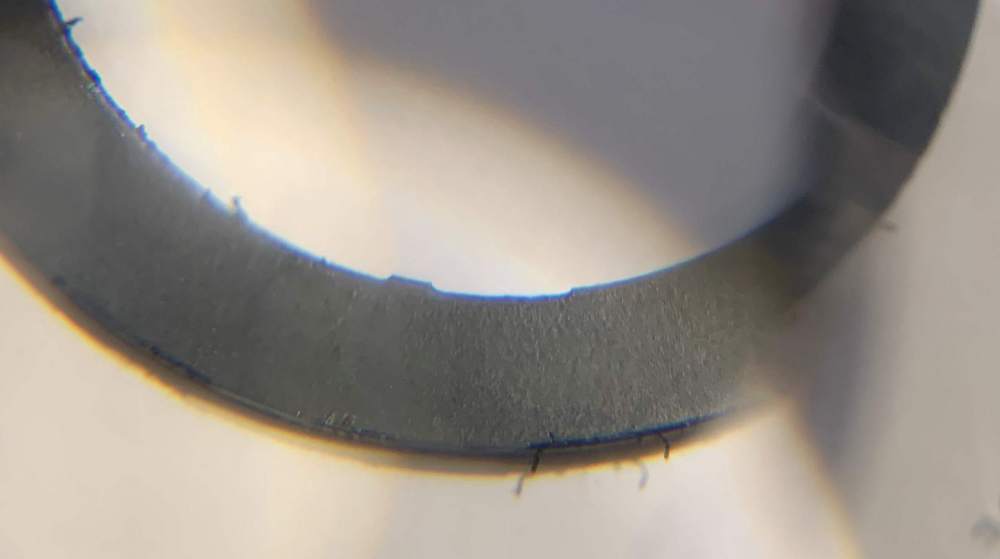

Thanks for your thoughts, Anthony. I'm with you - not feeling alarmist about it at the moment, but I'd be a lot more comfortable if the gasket hadn't changed dimensions after soaking in 100LL. Note that this wasn't exactly what I'd call a controlled study: I didn't note temperature, atmospheric pressure, humidity etc. before and after. We also didn't let the gasket sit out of the fuel for another several days to see if it returned to the original dimensions. It did weigh the same, but again, my scale isn't sensitive enough to show small variations. Mostly what I wanted to check for was any evidence of the material breaking down, and there was none of that. The preceding gasket was either cut before/during installation, or deteriorated very rapidly. Given what it looks like, the former seems more likely, but who knows? I can't cut a sample from the gasket to monitor without destroying it. We could buy another one and continue to monitor it, but that would be a different part, and it already appears there is variation between parts/lots. At some point, all you can do is verify it's not leaking on preflight, and go fly it. Barring some new development, we hope to do that this week. Coming up on 3 months now since the airplane last flew.

-

Today's update: after 3 full days soaking in 100LL, the new gasket expanded slightly, from exactly 2" O.D., to about 2 1/8" O.D. This 6% dimensional change doesn't strike me as abnormal after soaking for that long, but happy to hear any comments the group has. Thickness remains about 1/16", no noticeable change. What's most interesting is a side-by-side comparison with the "old new" gasket - the one installed by LASAR that leaked. If you take a look at the side-by-side photo, that gasket is substantially smaller at this point than the new one. We didn't measure the defective gasket when it was pulled out, so I'm not sure if it came out of the selector that size, or shrank over the last week. But the difference is enough that I continue to question whether the gasket that leaked was actually made of proper material. The next photo in the sequence shows that the new gasket, with the slight expansion after soaking, initially seemed to be a little oversize for the selector body. But after gently working it in, it seemed to lay pretty flat, so we proceeded with installation. One interesting thing to note is that the wall of the selector body interior is not 90 degrees to the exterior. It actually slopes a bit, i.e. it is actually a bit conical. This tends to cause the gasket to have a bit of a cone shape as it's worked in to place. Unsure if this is normal. The whole thing is a little wonky and I'd feel better if it went together more smoothly. But with everything worked gently in to place, the bolt that holds the bowl torqued to the low end of the 15-20 in-lb spec, and safety wire in place, it doesn't leak... at least for now. We'll let this arrangement sit a few days and have the local A&P take a second look for signoff. Hope to fly later this week if it continues to look OK.

-

I think there is a small but important misconception in the well-intentioned posts above: some of them appear to imply that a descending aircraft is always "unloaded". If that was the intent, it's not correct. An aircraft in a constant rate, level descent will experience a 1G load on the wings, same as in level flight. An aircraft in a 30/45/60 degree turn executed in a constant rate descent will experience a 1.15/1.41/2.00G load on the wings, same as in level turns. You don't "buy" anything in terms of reduced load factor just by being in a descent. If you change your rate of descent by pushing or pulling on the yoke, you do change AOA and load factor. So the instinct to "push and unload" if you're worried about a stall is a good one. Letting the nose drop in a turn so as to increase the rate of descent as the turn is executed is similarly effective. But it's the vertical acceleration that helps you, not the vertical velocity. Put another way, if you make a bad decision and snatch back on the yoke because you were startled, your odds of instantly exceeding the critical AOA and stalling are the same regardless of whether the aircraft was level, descending, or climbing when you did so. The idea that an aircraft in a constant rate descent has a lower G-loading than an aircraft in level flight, or in a climb, is a common misconception. But an aircraft with a constant bank angle and constant rate of climb or descent (including zero) experiences the same G load, regardless of its vertical velocity. The mathematical explanation is just Newtonian physics: F=MA. If the vertical acceleration (A) is zero, the net up/down force (F) is zero. Vertical velocity is not a factor in the equation. Therefore, load factor only changes when a climb or descent is initiated, not once it's established.

-

Thanks to everyone for the continued comments, and thanks especially to John for posting pics of his spare. John's spare appears to be made of anodized aluminum, as Anthony mentioned upthread. Since John says his appears to be a copy of the H&E, my thinking is that the factory switched from the cast magnesium design of the Dukes selector to the anodized aluminum design of the H&E/others at some point, perhaps for exactly the reasons being discussed in this thread. It's hard to say if John's spare could be a drop-in replacement in our aircraft without laying hands on it, but it appears to be at least roughly the correct configuration and dimensions. If no one else chimes in with specific info, I'll try to get a hold of the factory after the holiday, and see if I can get some information on the exact selector in the retrofit kit. The only reliable information I have about the retrofit kit at this point is a one-line e-mail from Stacy at the factory, who says it is p/n 940073-503, and that you order it through an MSC. Internet searches on that p/n mostly turn up bogus autogenerated "catalogs" from dubious aviation parts suppliers. But SWTA's web site does have a specific reference at http://www.swta.net/images/Retrofit_Kits.pdf, and my assumption is that's the $5K kit. Can't find any images or sub-part breakdowns, though, so no telling what the actual selector in the retrofit kit is. It also remains unclear to me what if any sheet metal work, re-routing of fuel lines, etc. might be required to use a retrofit selector. Again, the pics of John's spare look like a drop-in replacement, but I wouldn't be surprised to learn some minor tweaking is required to switch from the Dukes to the H&E style.

-

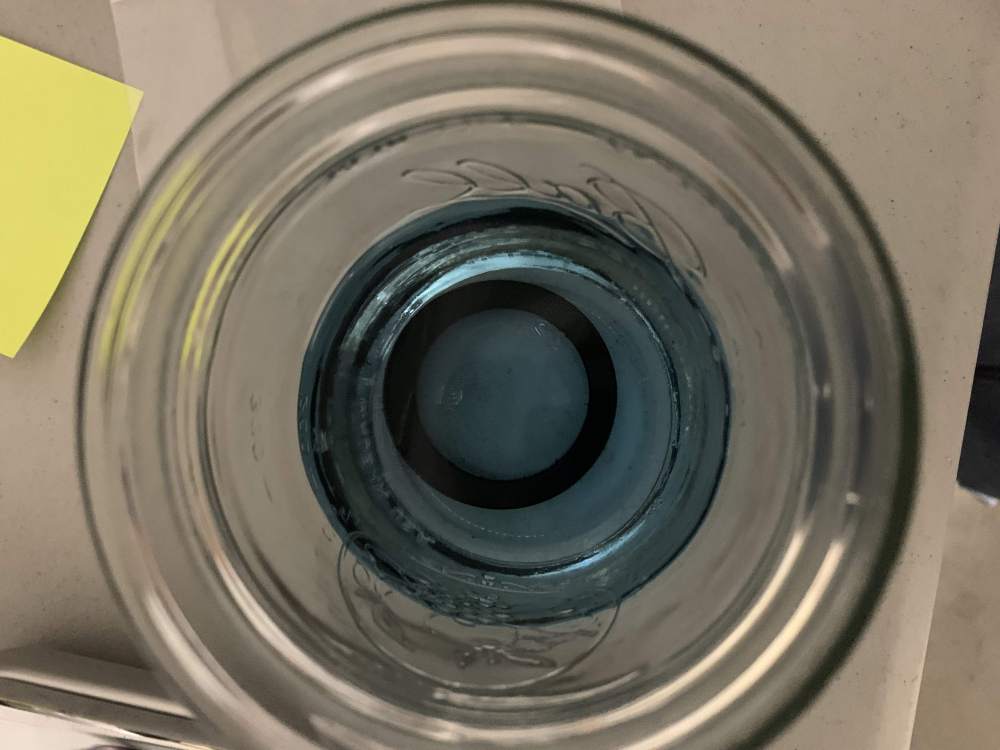

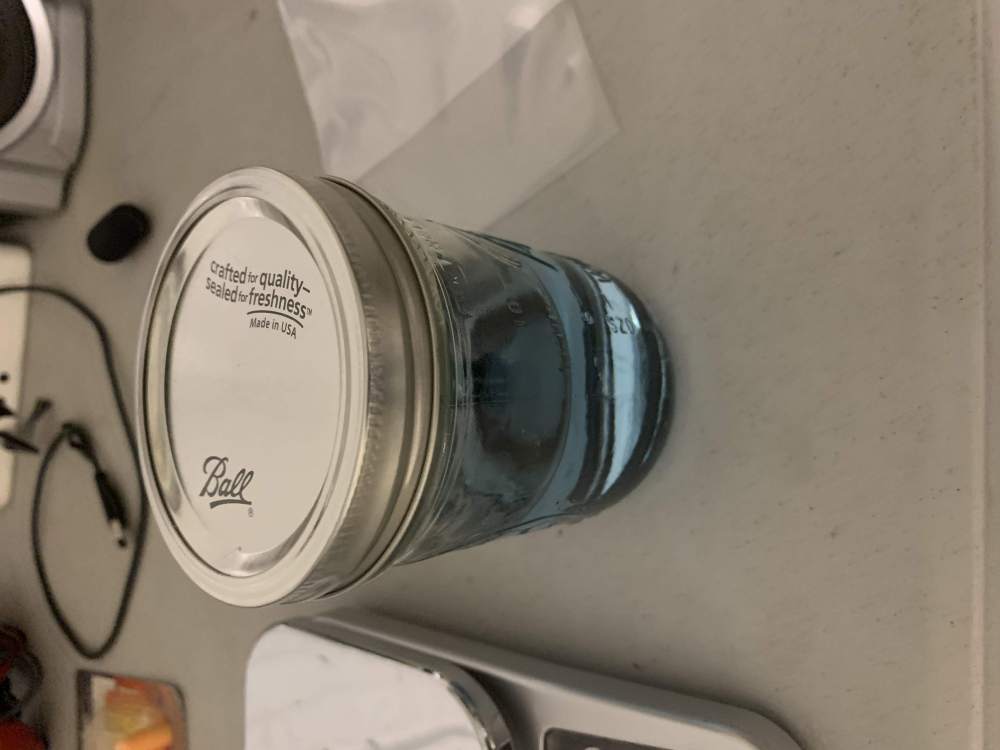

For those following the saga... Our "overnight" gasket actually took two days to arrive due to UPS delays in Louisville, but I did receive it yesterday. Out of the bag, it measures 2" O.D. by 1.5" I.D. by about 1/16" thickness. Weight is 0.05oz on my kitchen scale, but that's the limit of the scale's resolution so that's not a very reliable number. I gently tugged on the inner and outer edges all the way around and found no cuts or defects. Looking through a magnifier, you can see the material isn't what I'd call "pristine": it has some light fraying along the cut lines, and the surface is not perfectly smooth; but this is not different from anything I remember with previous good gaskets. I dropped it in a clean mason jar with about a cup of 100LL drained from our left tank (the one that didn't get emptied by the leak). Will report back here on what it looks like in a few days.

-

Garmin 430 right knob stopped working?

Vance Harral replied to AlexLev's topic in Avionics/Panel Discussion

Because the alternative is physical contacts that must scrape together as the switch slides from one position to another. The mechanical wear that results is a major long-term reliability issue. There are ways to make a physical contact knob last a long time, e.g. the knobs on a KX-155 are pretty good. But overall, the contactless solution is more reliable. A really relevant example of this is the optical encoder knob on the 430/530 series, vs. the physical contact buttons on that same unit for flip-flopping the NAV/COM frequencies. Both the knob and the flip-flop buttons are used heavily, but as these units get long in the tooth, you hear vastly more problems reported with the flip-flop buttons than the knob. If I may editorialize a bit, there's nothing "complex" about an optical encoder. It's just a little light bulb that can or can't be "seen", based on whether something is between the bulb and the detector. They are considerably simpler to design, manufacture, maintain, and service, than a physical switch or knob. The on/off signal they generate is no different than the signal associated with a mechanical switch. About the only difference between physical vs. optical switches from an interface standpoint is that in the simplest cases, the latter require 3 wires and the former only 2. But that's hardly a big jump in complexity. They do have failure modes, however - nothing is perfect. -

Garmin 430 right knob stopped working?

Vance Harral replied to AlexLev's topic in Avionics/Panel Discussion

As mentioned previously in the thread, the knobs on a Garmin 430 are optical devices, contact cleaner cannot do anything for them. The usual failure mode is the light source that shines through the windows of the rotary dial. It either burns out (total failure), has reduced output (intermittent failure), or develops a weak/intermittent connection with its power source (also intermittent failure). The fact that a previous poster "cured" their problem with contact cleaner is completely coincidental. It's likely the act of removing the outer knob flexed the rotary dial and/or circuit board enough to make a marginal light source good enough again, for a while longer. By all mean, try taking the knobs off and reinstalling them a few times, you might be similarly lucky. But R&R'ing the knobs is the salient action. Spraying contact cleaner on anything while you're doing it is no more or less effective than humming Gregorian chants. -

That's a very interesting question. I'd say it's "unlikely", but I didn't record the serial number, and probably can never say for certain - one Duke's fuel selector looks pretty much like another. I'll take a close look the next time I have it in my hands and try to recall any identifying features. But my guess is that if there was even a remote possibility our selector had been accidentally swapped for another, Dan would have already thought of it. I haven't measured, and not sure it'd be a meaningful measurement given the odd state of the gasket that was removed. But the thickness of the deteriorated gasket looks "normal" to me, about on the order of 1/16". It's comparable to the thickness of the brand new one I installed a couple of months ago, just before I broke the selector, as well as others I've R&R'd in the past.

-

Another hypothesis... the local shop drained our tanks into a portable fuel storage unit before pulling the selector to ship it to LASAR. After reinstalling the overhauled selector, they simply put the fuel from the storage unit right back in our tanks. This is a purpose built storage tank with a pump that's clearly labeled for 100LL, not some rusty bucket in the back corner. Still, if there was Jet fuel or some other contaminant in the storage unit, it may have introduced contaminants into our fuel that ate the rubber seal. This sucks.

-

I try not to be an alarmist. But I think you better call LASAR first thing tomorrow, and ask if the gasket you received was from the same batch as the one Dan used to assemble our fuel selector. If it was... or maybe even if it wasn't... I would not fly the airplane without pulling the selector bowl and inspecting the gasket. Go look at the video in my OP again, and think about what happens if your gasket lets go in the air.