-

Posts

1,416 -

Joined

-

Last visited

-

Days Won

3

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Vance Harral

-

Not really a Mooney-specific question, but no luck on another board, and we've got lots of IFR experts here. Note that while the certified navigator in our airplane happens to be a Garmin GTN-650, this is a general question, possibly with different answers depending on different equipment. For various reasons - often "historical" - certain instrument flight procedures are not based on a specific course over the ground. The obvious examples are timed holds and "remain within XX NM" procedure turns. I learned to fly IFR without an IFR-certified GPS, so I'm comfortable flying these segments old-school: by reference to headings and timed legs. I confess I generally ignore the CDI on the outbound leg and through the turns of such holds/PTs, as I'd do navigating purely by ground-based systems. I just verify when intercepting the inbound course that the GPS sequences to the appropriate flight plan segment, and that the CDI guidance looks reasonable. But I'm vaguely aware the navigator paints a magenta line on the moving map for the turns and outbound leg of holds/PT, and that the CDI is indicating "something" while you're flying them. My original understanding was that a CDI in GPS mode would simply depict lateral displacement from the inbound course throughout timed holds/PTs, just as VLOC guidance with a ground-based transmitter would depict angular deviation, and I'm pretty sure I've observed that behavior in at least some cases. But complicating the matter is that holds and HILPTs on GPS approaches are defined by a specific course over the ground, and the navigator could theoretically provide guidance all the way around the hold, much as it does when flying a DME arc in GPS mode. Things get even more interesting in light of stories I hear/read about autopilots with GPS roll steering automatically flying holds and procedure turns. We don't have roll steering, but in an aircraft that does, I think this can only be possible if the GPS is providing guidance throughout the entire hold/procedure turn. So... I'm sitting down with the GTN trainer this morning to fiddle with this, but my initial attempt at understanding was to read the GTN manual, and I'm not actually having any luck there. There are mentions of solid vs. segmented flight plan segments on the moving map in the Flight Plan section of the manual, but it doesn't actually seem to discuss CDI or other guidance behavior. Hoping someone more knowledgeable than me can comment here, ideally with reference to an "official" (manufacturer or FAA) document that describes how this works. Any takers?

-

Radio noise w/ small voltage fluctuations

Vance Harral replied to J0nathan225's topic in Vintage Mooneys (pre-J models)

Multiple people in the thread are interested, but in my case the aircraft is a 1976 M20F and our alternator is a Hartzell/Prestolite ALY-8520. Regarding the paperwork, we enjoy a good relationship with our A&P, who frequently allows us to perform our own repairs under his supervision and sign them off. I'm not sure that courtesy will apply to disassembling electrical equipment and working on the internal components, however. While there is plenty of debate about what kind of work requires a Repair Station Certificate, the only opinion that matters in our particular case is our mechanic's. If he is unwilling to sign off on letting us do the work ourselves, the cost and hassle of finding someone who will would almost certainly exceed the savings of replacing internal components vs. buying a whole new alternator. -

Radio noise w/ small voltage fluctuations

Vance Harral replied to J0nathan225's topic in Vintage Mooneys (pre-J models)

Meaning that replacing these parts requires disassembling the alternator case? I understand it's certainly possible to do so, but it changes the nature of the repair with respect to paperwork. -

Radio noise w/ small voltage fluctuations

Vance Harral replied to J0nathan225's topic in Vintage Mooneys (pre-J models)

Anybody have pictures of the diode bridge? We have a similar problem with alternator noise we're going to try to solve at our upcoming annual. Baseline idea was to just buy a new alternator, but I'd be happy to replace/repair a capacitor and/or diode bridge instead, if it's practical. But I can't locate any replaceable components on our alternator, at least not that I can see in-situ with a quick look. I'm only generally aware that "old school" alternators have external electrical components that can be replaced. I understand the principles, but have never actually worked on the guts of an alternator, or seen one worked on. If you talk about this sort of thing in the context of any automobile built in the last 30+ years, you get roll-eyes and an explanation that alternators aren't built that way any more - all you can do is replace the whole unit. -

Tie down ring stripped

Vance Harral replied to Ross Woodley's topic in Vintage Mooneys (pre-J models)

I'm sure @PT20J is correct that the galvanic corrosion concerns are negligible. But for what it's worth, stainless steel is a little further away from Aluminum on the galvanic corrosion chart than mild and chromium steel, and therefore technically more susceptible to the galvanic corrosion problem, not less: https://www.albanycountyfasteners.com/blog/2017/09/15/stainless-steel-and-aluminum/ My understanding is the "stainlessness" of stainless steel refers only to its resistance to iron oxide corrosion from water and/or most air. It's not necessarily better protected than non-stainless steel from adjacent metals or other non-atmospheric elements. That said, I'm not a materials expert and maybe I'm off base here. Happy to be educated by people with a better understanding. -

Tie down ring stripped

Vance Harral replied to Ross Woodley's topic in Vintage Mooneys (pre-J models)

It's obvious from some reading that steel helicoils are inserted into aluminum structures all the time. But isn't this a galvanic corrosion risk? -

Tie down ring stripped

Vance Harral replied to Ross Woodley's topic in Vintage Mooneys (pre-J models)

At the rate those shock disks are inflating every year, I'm not so sure. When we bought our airplane 16 years ago, those things were about $70 apiece. Latest price is about double that, see https://www.skygeek.com/j11968-14.html. So a full replacement of all 11 disks in 2020 dollars is over $1500 just for the parts. Throw in a few hours of labor and the specialty tools you're supposed to use for the job, and you're looking at a $2K expense every 5-10 years depending on your model and climate. I'm a Mooney fan, obviously, but if there were an STC to install oleo struts I'd certainly consider it. The idea of storing your airplane on the jacks strikes me as only about 90% of a joke. -

Tie down ring stripped

Vance Harral replied to Ross Woodley's topic in Vintage Mooneys (pre-J models)

I don't have much experience with helicoils. What holds the helicoil in place? A quick web search suggests it's either the snapped-off edge of the tang (seems very weak), or that you can "glue" it in with thread locker. This might not be an issue with bolts that are installed once in a blue moon, but if you're R&R'ing tie down rings every time you need to jack the airplane, you want the helicoil to stay firmly in place through lots of cycles. -

Tie down ring stripped

Vance Harral replied to Ross Woodley's topic in Vintage Mooneys (pre-J models)

Hmm... after a little research, looks like these are serious chore to remove, and require a special tool to re-install. I can see why they're great fasteners for this sort of application, but obviously not designed for R&R: Nerd video showing super high-tech installation: https://www.youtube.com/watch?v=W62ZJzePjAk Redneck video showing removal: https://www.youtube.com/watch?v=pP4aoLa2eJk -

Tie down ring stripped

Vance Harral replied to Ross Woodley's topic in Vintage Mooneys (pre-J models)

Sure, but the rip-out force should be somewhere around the lift force generated by winds at about stall speed. Any less and the tie-downs aren't really helping the way they're supposed to. Any more and there are some corner cases where you want them to break away because it results in minimal damage. I agree those corner cases do not include gale force winds that flip the airplane upside down. Your point that the corner cases shouldn't include a tie-down mistake either is fair. -

Tie down ring stripped

Vance Harral replied to Ross Woodley's topic in Vintage Mooneys (pre-J models)

That's an interesting point about the nut solution causing spar damage in the event of a mistake. Tie-downs should be robust enough to hold the airplane in place in "moderately high" winds, but not so robust as to bend the spar. -

Tie down ring stripped

Vance Harral replied to Ross Woodley's topic in Vintage Mooneys (pre-J models)

Out of curiosity, has anyone here ever tried to replace this bracket? Looks like it's attached with pull rivets. Can you get to both sides of the spar with drills and rivet pullers to safely R&R in situ, or is this something that's simply not practical without removing the wing skin (which is a non-starter)? -

Tie down ring stripped

Vance Harral replied to Ross Woodley's topic in Vintage Mooneys (pre-J models)

Thanks to everyone for the additional detail, especially @Clarence for the photo and @Shiny moose for expounding on the helicoil solution. As I mentioned, we already have the LASAR tie-down ring/jack point combo, which eliminates the issue with R&R'ing a nut every time we need to jack the aircraft. I'm going to venture out to the airport this weekend, pull the appropriate inspection panel, and verify the tail of the bolt extends up far enough through the bracket for the nut solution. It occurs to me this morning that the nut solution is easily undone if we change our minds about a fix. To be clear, whatever fix we choose will be done at our upcoming annual, under appropriate A&P supervision. Thanks again! -

Tie down ring stripped

Vance Harral replied to Ross Woodley's topic in Vintage Mooneys (pre-J models)

I'm resurrecting this thread to try to better understand the options for a fix, as we've discovered the threads on one of our tie-downs is shot. I'm not having much luck with detail in the parts manual, and it will be a couple of days before I can get out to the hangar and actually look at the airplane. First, can anyone explain what structure the original tie down rings thread into? Is it the spar? A bracket attached to the spar (which could be replaced)? Something else? Second, did the original structure from the factory contain a helicoil? It's unclear to me if the comments from @Hank about installing a helicoil refer to replacing a helicoil that's part of the original design, or drilling/tapping/installing a new helicoil that isn't part of the original structure. My preference would be to fix this problem by keeping the original design and structure, but obviously that's not practical if it involves replacing the spar. If we can replace a bracket and/or helicoil that would be nice. If not, I agree the @Yetti solution seems practical. Note that we actually already have the LASAR combination jack points and tie down rings, maybe the fix is as simple as installing a nut on the back side. -

You don't need a high-end articulating arm or mirror attachment to get a good view of intake and exhaust valves. Just buy one of the cheapie cameras, bend the end of the arm around 180 degrees so it's pointing backwards (actually, you want about 175 degrees, to get the best view), and insert the whole thing through the spark plug hole. The hole is plenty large enough to allow this. If you're paranoid you can safety wire the camera end against the cable, but I quit doing that a while back and haven't had any problems. Images are great, see below. There is a slight chance than bending the arm all the way around like this will damage the wiring inside the arm. But that hasn't been the case for me, and even if it did, so what? At $25 for the whole gizmo, it's a low risk.

-

Positive Control not so Positive Right Now

Vance Harral replied to MBDiagMan's topic in Vintage Mooneys (pre-J models)

Before you implicate the boots and go through difficult gyrations to test them, remove the port side interior carpet panel in the baggage compartment and have a look at the PC lines behind them. It will only take a few minutes. The first leak we diagnosed in our PC system when we bought our airplane 16 years ago, was that the prior owner had driven one of the screws for the port side baggage compartment carpet panel directly into one of the PC lines! In our airplane, the offending screw is positioned directly over where the lines run. We repaired the line and left the screw out of the carpet panel on reassembly, as the remaining screws were more than sufficient to hold the panel. -

The actuator in your M20G should arguably be inspected in accordance with Mooney Service Bulletin M20-190B, see https://cdn2.hubspot.net/hubfs/4147179/technical_documents/service_bulletins/sbm20-190B.pdf. While that SB does not specifically call out the ITT LA11C2115 actuator, it does call out the ITT LA11C2110, and there is no practical difference between these two ITT actuators. The SB requires 100 hour grease intervals and 200 hour inspection intervals. Some people argue that installing 40:1 gears per Mooney SB M20-112 should increase the inspection interval to 500 hours. But for whatever reason, Mooney themselves have not seen fit to revise M20-190B. Don Maxwell has some commentary on this at http://donmaxwell.com/dukes-itt-landing-gear-actuator-401-ratio-gears-si-m20-112/ If you're looking for data points about what others' do, we remove the actuator and perform the inspection of the internal gears every other annual, which is a little less than 200 hours for our partnership We do this even though we've performed SI M20-112 to put 40:1 gears in our ITT actuator. Any A&P can perform the inspetion. You can do it yourself, with appropriate A&P supervision. The chief risk in performing the inspection, IMO, is the removal and re-installation of the emergency manual gear extension cable that is necessary when removing the actuator for inspection. The mechanism that engages this cable has to be "rigged" (positioned) correctly, and this is a somewhat delicate operation. Too far in one direction and it will not engage when the lever in the cabin is moved to the engage position, rendering the emergency extension mechanism useless. Too far in the other direction and the cable stays engaged even when the lever in the cabin is in the disengage position, leading to the emergency extension crank spinning when you electrically raise/lower the gear. So whether you do the work yourself or have an A&P do it, make sure a full suite of emergency extension tests is performed after reinstalling the actuator, so as to ensure the emergency extension engagement mechanism is correctly rigged. Every time we perform the inspection, I wonder if it's wouldn't actually be less risky to do it less often than the SB calls out, for fear of mis-rigging the emergency extension cable. The SB is not legally binding, of course, so it's not "illegal" to do it every 3rd or 4th or 5th annual. But for better or worse, we keep doing it every other annual. Pay no attention to the comments in this thread about "no back" clutch springs. Your ITT actuator has no such component, it was introduced in later model actuators. The brushes in the actuator motor do wear out, but there is no specific prescribed interval for disassembling the motor and inspecting the brushes. We replaced ours when our actuator failed the M20-190B inspection about 10 years ago. We sent the actuator to LASAR who installed the 40:1 gears, and they farmed out the brush replacement to some third-party shop (I don't recall if it was George's or Aeromotors or someone else). It just seemed like a good idea at the time, since we were effectively overhauling the actuator. One reason I don't worry a whole lot about the brushes is, I consider failure of the electric motor to be kind of a non-event, provided the emergency extension mechanism is properly rigged. All the bad news stories I'm aware of involving electric gear - including one in the history of our aircraft with a prior owner - involve a failure of the emergency extension mechanism after the electric motor fails. Accordingly, we're actually a lot more paranoid about inspecting and testing the emergency extension system than we are about the motor itself.

-

Replacing aileron control horns

Vance Harral replied to Vance Harral's topic in Vintage Mooneys (pre-J models)

Excellent point, I'll take a closer look next time I'm at the hangar. -

Replacing aileron control horns

Vance Harral replied to Vance Harral's topic in Vintage Mooneys (pre-J models)

Yeah, Beegles is nationally known. We're fortunate to be just 20 minutes away by Mooney, or about 45 minutes by car in a pinch. The initial appointment this Friday is just for them to take a quick look and discuss options. When it's time to do the actual work, we may take the whole airplane there, or just drive the aileron over. -

Replacing aileron control horns

Vance Harral replied to Vance Harral's topic in Vintage Mooneys (pre-J models)

Thanks to everyone for the replies. We have an appointment with Beegles in Greeley this Friday to take a look and give us an estimate on the job. I'm hoping they'll be able to get a bucking bar in the aileron and refasten the skin with conventional rivets, rather than Cherry Max. Not because I personally think Cherry Max rivets are "bad" in any functional way, but just because they'll cosmetically look out of place. I confess I'm concerned this is going to get pretty expensive - probably involves checking balance on the aileron after repair, etc. But we want it repaired the right way. -

Replacing aileron control horns

Vance Harral replied to Vance Harral's topic in Vintage Mooneys (pre-J models)

That is likely the reason why this control horn is worn in the first place - the bolt holding the rod end was not tightenened, and the bolt was allowed to work in the hole rather than the rod end working as it should. We'll be sure to tighten the rod end bolt properly on re-installation. But we're not comfortable with just cranking the rod end bolt down on the existing horn with washers, and assuming it will stay tight enough not to wiggle. It might be possible to ream the existing horn and insert a bushing, but the no-apologies fix is to replace the horn with the new part. -

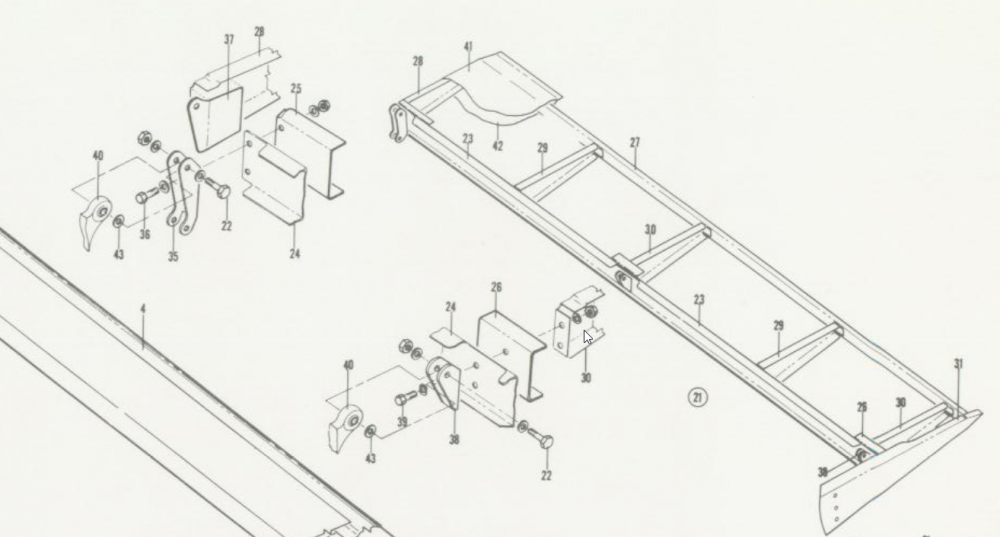

At our annual earlier this year, our mechanic flagged the left side aileron control horn as having enough slop to warrant concern (part #35 in the attached picture from the parts manual). The aircraft is a 1976 M20F, but I think all models have this same hardware. The problem is that the lower holes - the ones which capture the aileron control rod end - are a bit hollowed out, and this allows the aileron to wiggle even when the yoke is held firm. The obvious concern is flutter. We were able to obtain a replacement part from Mooney shortly before the factory hiatus, but we're running into trouble installing it. The bolts which fasten the horn to the aileron spar cannot be turned from the bolt head side, because the flanges of the horn actually capture the head and prevent it from turning. The only way to remove the fastener is to completely remove the nut from the "back" side (i.e. from inside the aileron). The aileron spar does have access holes, and it's possible to get a wrench on the nut. But with a conventional wrench, you can only turn the nut about 1/8th of a revolution before having to remove and re-seat the wrench. As you can imagine, this is a painfully slow process. After fiddling with it for over an hour, the mechanic only manged to turn the nut about 1 full rotation, and he essentially gave up (said it wasn't cost effective to keep doing things that way). He suggested it may be necessary to drill out some of the rivets on the aileron skin, and peel back enough of the skin to get reasonable access to the nut. If that's the only viable fix, we can go that route, but it seems like a major deal to partially (or fully) de-skin the aileron. Anyone ever made this repair and know of a trick?

-

Gear Down annunciation in J

Vance Harral replied to midlifeflyer's topic in Modern Mooney Discussion

While there are always corner cases, it would be rare for only one wheel to have a problem. It would be vanishingly rare - impossible I'd argue - for one wheel to have a problem you could actually do something about in flight except make a normal landing on a normal runway and hope for the best. The Arrow and other aircraft like it have three indicators because their hydraulic gear systems are arguably three independent mechanisms, each of which could fail independent of others. Yes, one wheel can "hang" in those systems, and you might jar it loose with some positive G maneuvers, etc. Not so in a Mooney. If you're really concerned about it and think it would change your piloting in a positive manner to have three indicators, suggest you just mount a camera on the tail tie-down, and look for all three gear to be down on your phone/tablet/whatever. Cheap and easy. -

Aviation Insurance Market Update

Vance Harral replied to Parker_Woodruff's topic in General Mooney Talk

It's part of some - but not all - CFI policies. It sometimes goes by different names, e.g. "negligent instruction" or "previous instruction liability". SAFE offers it as a benefit, see https://www.safepilots.org/programs/cfi-liability-insurance. The "standard" Avemco CFI policy does not include malpractice coverage, but if you purchase Avemco CFI coverage through NAFI it does. The best one-stop treatise I've seen on liability management for CFIs is at https://www.aviationattorney.com/publications/primer-aircraft-flight-instructor-liability -

Aviation Insurance Market Update

Vance Harral replied to Parker_Woodruff's topic in General Mooney Talk

Having a clear discussion about who is acting PIC when an owner pilot flies with a CFI is a great idea. But the majority of the value in that conversation regards who will direct operation of the aircraft in the event of an emergency. It has little - and in some cases zero - value in the context of everything else being discussed here. As mentioned above, the FAA/NTSB start with a basic presumption that a CFI is the acting PIC, when it comes to certificate action. My understanding of the case law is that this is only a starting presumption, and may not necessarily lead to the CFI being disciplined. So if you're looking to protect your certificate, there "might" be some value in relating a PIC agreement to the board. But the mere fact an agreement was made is not particularly protective. In many cases, both heads are actually on the table, and both parties might be disciplined. More importantly, liability lawsuits - including those initiated by an insurance company in the course of subrogation - are not subject to FAA/NTSB jurisdiction. The judge/jury is not obligated to use the FARs or NTSB case law as precedent, and almost certainly won't care about a verbal PIC agreement, especially if the details of that verbal agreement are disputed (as is often becomes the case when an incident occurs). A party attempting to deny liability might have a stronger case if there was a PIC agreement in writing, but who knows? I can easily envision a jury being convinced that The Old Gray Eagle CFI should have protected The Hapless Owner regardless of what was said or written. The point is, all this talk of agreements and rulings about who is the acting PIC, based on FARs and NTSB case law, really has very little bearing on insurance claims and liability law. Where the rubber hits the road is, flight training in piston airplanes simply doesn't pay a living wage. Never has, likely never will. Therefore, everyone who does it is either a young and low-net-worth individual instructing as a temporary gig on their way to something better, or a retired/hobbyist CFI who doesn't need the money. The latter can lay out whatever terms they want, and most of them now insist on named insured/waiver of subrogation, for all the reasons mentioned in this thread. Owners unwilling to accept those terms are welcome to stand on principle, but it restricts their pool of instructors to the young/low-net-worth set. Some of those folks are excellent instructors and I don't mean to imply otherwise. But on average, they are less experienced. They are also more likely to mis-understand the named pilot/open pilot clause on someone else's insurance, and mistakenly think they are covered, when in reality they are subject to subrogation by the owner's insurance company. Those of you in this thread who now understand the difference will have to make your own moral decisions about whether their ignorance is in any way your responsibility.