-

Posts

242 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Jsavage3

-

The Garmin guys at Oshkosh were very deliberate in saying the new 275 has fixed all the G3X backup issues. Personally, I just like the look of the 275 better. The useful battery time is an interesting topic. I’ll be looking forward to finding out more about that comparison.

-

I’m having the G3X installed now and was planning on the G5 backup however several talks with Garmin at Oshkosh has caused me to lean heavily towards the 275 as a backup instead. Has anyone else heard of this idea or followed thru with it?

-

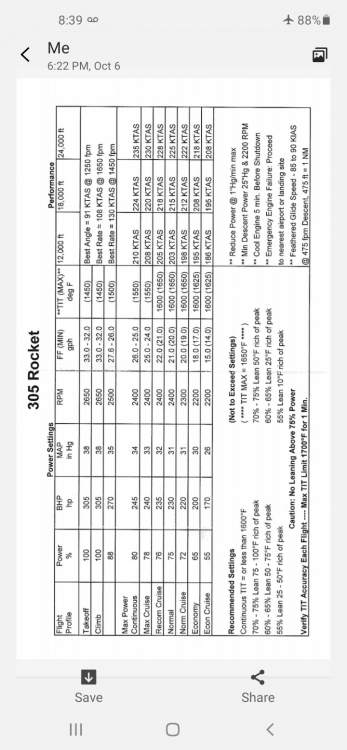

Hello M20K Drivers, I just spoke with the folks at Rocket Engineering in Spokane about the idea of them doing more Rocket Conversions to our existing K model fleet. I was told that if he had 20 airplanes lined up wanting the conversions then he'd likely do it, but it would take that many before his costs would be justifiable as doing onesy-twosy just wasn't cost effective for him to open up that option again. So, I ask, is there any K model drivers who might be facing an O/H soon who would be interested in converting their K to a Rocket? I have an 87' 252 now Encore that I'd love to see have more muscle under the hood. So, I am one. Are there any others? If we come up with a list of 20 K model drivers who would be interested in this idea, I believe Rocket Engineering would take our deposits and start up the conversions again. Anybody else?? Besides the nay sayers. 186 KTAS at 55% power ROP on 14 to 15 gph at 12,000 feet is a real eye opener...and then you've got all kinds of go faster options from there.

- 59 replies

-

- 3

-

-

- rocket

- rocket_engineering

-

(and 1 more)

Tagged with:

-

I had a similar issue, so I had the A/I overhauled, only to learn about Garmin's new GI-275 a few weeks later. Hindsight, I'd have gone GI-275 all the way!!! It interfaces with my KFC-150 plus I could eliminated my entire vacuum system. When my freshly O/H'd A/I burps, it's outta there!

-

1978J Nosegear truss turning radius stop tab broken

Jsavage3 replied to wiseng's topic in Modern Mooney Discussion

Several years ago, a friend of mine told me his story about his J nose truss getting dented because of an FBO employee exceeding the limits while tugging it around. He was without his Mooney for over a year (no parts) and got wrapped up in a legal battle with the FBO over cost of repairs. What a headache from every angle. Moral to the story? I let no one move my Mooney by tug...by hand with tow bar only. Yes, some FBOs roll their eyes. I don’t really care... So, for your situation, if it were me, I’d ferry it my MSC and let them fix it properly and, hopefully, the FBO would pick up the tab. -

I'm planning on flying in for lunch with my wife and two sons...looking forward to meeting you all finally!!

-

I can do Jan 12th and anything northern AL would be my preference...+1 for CMD. It’ll be great to finally meet everyone!

-

Yep, I had this happen on my 252 about 6 months after I bought it. A limit switch failed (smashed flat like a pancake) and then the motor shaft sheared. I had the motor O/H’d by the manufacturer and I replaced all the limit switches too. Works like a champ now, but...I made two small red dots (lady’s nail polish) on the indicator, one at the upper limit and the other at the lower limit, positioned just right such that if I return the switch to its center (off) position abeam the appropriate red dot then a limit switch doesn’t get touched or almost touched...I.e. I become the limit switch and the actual limit switch is there to back me up... Works great, lasts long time! Good luck with your repair and I hope you’re able to get it fixed once and for all.

-

-

Yes, works great! It was a “wife, buy this for me for Christmas” present. She smiles every time she sees me using it... +1 for Tempest

-

It’s a $40 tool but it works great...it’s a Tempest Easy Drain AA473 Oil Filter Drain Tool sold by Aircraft Spruce (Part # 12-02248). I’ve used it for my last two oil changes and have literally not spilled a drop. While the quick drain on the reservoir is draining thru its 3-foot piece of tubing, I strap this tool to the filter (as low as possible), screw in the plunger, fasten another 3-foot piece of tubing (provided) to this tool then back the plunger out and go to lunch while the oil drains. Once done, I remove the tool and put a piece of tape across the hole in the filter before I use an oil filter wrench to loosen the old filter. No mess , no headache, money well spent IMHO.

-

It's been years ago, but this thread brings it back for me, unfortunately. A nice fellow who enjoyed family time at his hangar had his beautiful lab get into his Bonanza's prop. Killed the dog nearly instantly...got it in the neck. Everyone at the airport was sick at heart. That poor family, to say the least, they quit coming out to the airport... I have to say I would certainly vote for pets to be restrained when anywhere near operating aircraft.

-

Welcome back and thanks for caring enough to save a Mooney! A lot of folks might have considered it too much trouble and just discarded her...our Mooneys can’t be replaced. Blue skies!!!

-

I have a 252, but it’s certainly close enough to be relevant. Before, I always climbed out with everything fire walled (36” MP, 2700 RPM and mixture rich for 23 GPH) all the way up. Recently I’ve started climbing as the POH calls for, which is 32” MP and 2500 RPM with mixture still full rich...this profile gives me just under 17 GPH...all the way up. What I’m seeing is more fuel on board at TOC and the time-to-climb penalty is essentially negligible. This cruise climb profile costs me 100 FPM, but I’m still climbing at the same 120 KIAS that I always have. Seems like a good trade off to me...IMHO that is. For vertical speeds, I see the following at 120 KIAS: Max power climb (23 GPH)...800-1000 FPM (cold vs hot weather) Cruise power climb (17 GPH)...700-900 FPM I wish to point out that I climb at 120 KIAS no matter what I do with the power...whether I max climb or cruise climb. I do pay close attention to my CHTs in the climb, but they always stay very cool...around 330-350...maybe 350-380 in the summer time...and that’s with my cowl flap in the trail position. These vertical speeds are dialed into the A/P, so these numbers are pretty accurate b/c it holds them alot steadier than I can...

-

I'll make a pitch for the 252. First, I've always used my Mooney's as a four-person family hauler. I live in Ohio and we often travel to Florida, the Bahamas, Iowa, Wisconsin and have been as far west as Seattle, WA. We had an 86' J model for 5 years after which the anemic climb performance above 10K caused us to "need" a turbo. For two years now, we've had a stock 87' 252...210-hp Continental, two-blade McCauley, no TKS, no VGs, etc...just clean & fast. For climb performance...in the summer, I set 800 fpm (900-1000 fpm in the winter) with the autopilot's vertical speed and that holds 120 KIAS all the way up with cowl flap in trail. This config keeps my climb CHTs around 330 degrees F in the winter and about 350 in the summer. I don't touch a thing all the way up. It's a beautiful thing! For cruise...I use the MAPA Mooney Manual's "Key Number" concept (53 for 75%, 49 for 65% and 45 for 55%) for setting cruise power initially, but then refine it with the POH (sun visor numbers) each time. In cruise, I lean based on TIT, not EGT, and I'm a 50 ROP TIT guy. I see 175-178 KTAS at 11-12,000' where I often cruise using 75% (key # 53...28" MP, 2500 RPM and 13 GPH)...my TIT usually settles between 1500 and 1550 degrees F. This is where I usually fly it. Although 1650 is the TIT red line, I use 1600 as my red line; my CHTs always run cool (just under 350) and my oil runs too cool sometimes (~150-160). Same power (53) and fuel flow (13) gives me 190+ KTAS in the high teens to low 20s. If I'm trying to extend my range, I'll set 65% (key # 49...24" MP, 2500 RPM and 11 GPH) for 170 KTAS. If I'm taking someone on a local sight-seeing ride, I pull it back to 55% (key # 45...23", 2200 RPM and 9.5 GPH) for about 130 KIAS... I've been as high as FL210 and saw 192 KTAS while there. When I switched from cannula to mask, I was immediately reminded of how demanding an environment it is above 20K...the pulse ox showed it coming back, but s-l-o-w-l-y. For descent...I plan the TOD for 500 fpm (300 if I have a headwind), set the desired vertical speed in the AP and sit back without touching anything...I typically pick up 15-20 knots in the descent. If it start getting bumpy, I'll pull it back to not less than 20" MP and fan the boards if needed to slow down. Now, useful load...the 252's only "weakness," if you want to call it that. We have two sons, ages 9 and 11 years old...they are growing fast. They day may come when I'll need that extra 230# of UL...and it's nice to know I have that option. But, let's face it, once kids hit 18 years old or so, the days of the family of four traveling together get few and far between. Then it's grand kids...who start out small...just like our two sons did. The UL so far has not limited us in our travels. Even now, I can put all four of us, 80# of bags and 4 hours + reserves (65% numbers) of fuel on board...that's a pretty get-up-n-go machine! It works out especially well since I like to keep everyone smiling by keeping the leg lengths down to about 3 hours or less. My wife's smiles are certainly worth a "fuel" stop. The UL has not been a weakness for us. We've been very happy with our decision. We really liked the J (and still do), but we love the 252! Good luck with your quest!

-

M20K Pre-Buy Questions and Shop Recommendation (NC, KEQY)

Jsavage3 replied to agoessling's topic in Modern Mooney Discussion

Often a PPI turns into an annual inspection, much to the new owner's benefit. Since an annual causes a shop to actually sign it off as airworthy (no signature req'd for a PPI), said shop has a lot more skin in the game; hence, they're much more motivated to do a thorough inspection. As far as where? I'd suggest getting the inspection done at a Mooney Service Center (MSC). I've never had any dealings with this shop, but Foothills Regional (KMRN) is a MSC and their phone # is 828-757-0099. Good luck!! -

I have a stock 1987 252...210-hp Continental, two-blade McCauley, no TKS, no VGs, etc. I use the MAPA Mooney Manual's "Key Number" concept (53 for 75%, 49 for 65% and 45 for 55%) for setting cruise power initially, but then refine it with the POH (sun visor numbers) each time. In cruise, I lean based on TIT, not EGT, and I'm a 50 ROP TIT guy. I see 175-178 KTAS at 11-12,000' where I often cruise using 75% (key # 53...28", 2500 RPM and 13 GPH)...this is where I usually fly it. Although 1650 is the TIT red line, I use 1600 as my red line; my CHTs always run cool (just under 350) and my oil runs too cool sometimes (~150-160). Same power (53) and fuel flow (13) gives me 190+ KTAS in the high teens to low 20s. If I'm trying to extend my range, I'll set 65% (key # 49...24”, 2500 RPM and 11 GPH) for 170 KTAS. If I'm taking someone on a local sight-seeing ride, I pull it back to 55% (key # 45...23", 2200 RPM and 9.5 GPH) for about 130 KIAS... This is a fast bird combined with excellent efficiency...the Mooney guys got it right! The operational capabilities now available above and beyond what the J allowed is what really makes it a sweet deal for me. We had a J model for 5 years before getting this 252. Though we loved the J (and still do), we're VERY happy we made the switch.

-

Steingar, it took courage to share your story and you've earned my respect for that fact alone! I've been into the Parr airport many times and Bob Norman was my mechanic for quite some time (and yes, he's a great mechanic!). I completely agree, the Parr airport is challenging, especially in a Mooney! At 3,100 feet, obstacles on the east end, very narrow with a fairly significant hump in the middle...well, it's do-able, but it's a handfull for sure! I commend you for sharing your story and in so doing helping us all perhaps avoid a similar situation...because let's face it, it can happen to any of us! Blue skies to you and yours!

- 89 replies

-

+1 for Phillips XC 20W50 plus Camguard...used it in my previous J and now in my 252...

-

I've heard nothing from TCM, but here's an article by Mike Busch regarding the use of Camguard in turbo Continentals. Seems to sum it up nicely, IMHO. J Mike Busch from the Savvy Aviator does some Q&A Bob Klee: I was under the impression we could not use Camguard in Turbo engines? This from their website: “Turbocharged engine acceptance pending”, so is it our call if we use it or not? I’ve researched this quite extensively (including with my Principal Maintenance Inspector at the FSDO who oversees my IA activities). There is no such thing as an FAA-approved oil additive. ASL Camguard has been “accepted” by the FAA Engine & Propeller Directorate for normally aspirated engines. What that “acceptance” means is that the FAA wrote ASL a letter saying that they are persuaded that Camguard “does no harm” when used in normally aspirated engines. ASL has requested such “acceptance” from the FAA Engine & Propeller Directorate for turbocharged engines, but the FAA has indicated that they will require ALT to submit the results of endurance tests that ASL anticipates will take them at least two years to complete. Thus, do not expect FAA type acceptance any time soon. There is no regulatory requirement that an oil additive be FAA “accepted.” People have been using Marvel Mystery Oil in aircraft engines for five decades (at least) and I’ve yet to hear of one of them being busted. I actually used a little in one of my engines years ago (the statute of limitations has run) when I detected some valve lifter clatter. The lifter clatter cleared up. NOTE: This is NOT an endorsement of MMO!!! I do not use it and do not recommend it except in abnormal circumstances. The issue of TCM acceptance is a totally different matter. TCM specifically does not accept ANY aftermarket oil additive, even those that have been FAA accepted. In fact, TCM states that the use of any aftermarket lubricants may void TCM’s warranty. The reference is TCM SIL99-2B. In fact, however, I am unaware that TCM has ever denied warranty coverage based on the use of any aviation oil additive, and it’s clear from the wording of SIL99-2B that TCM is primarily concerned about the use of automotive products in aircraft engines. Bottom line: I have written extensively and spoken publically about my own experience using Camguard in the turbocharged engines of my own airplane. I have done this quite high-profile under FAA scrutiny and I have received no push-back from anyone in the FAA. I have discussed this issue face-to-face with my FAA PMI, who told me that while he’s not exactly thrilled about my public endorsement of Camguard in the context of turbocharged engines, he knows of no regulatory issues that would make such use problematic. As for TCM, their stance against the use of aftermarket additives applies to all additives and all engines equally. In theory, TCM could deny warranty coverage on the basis of the use of any aftermarket additive in any TCM engine, whether normally aspirated or turbocharged. In practice, I have never heard of a single instance in which they did so. The language is SIL99-2B is clearly CYA boilerplate. With respect to Camguard, the issue is moot anyway because TCM does not offer any warranty for engines in SR22 Turbos (Cirrus provides the warranty for those engines). SIL99-2B has a lot of problems. For example, I have been using Aeroshell W100 in all my TCM piston engines for well over 4 decades. If you look at the list of approved aircraft oils in SIL99-2B, you’ll observe that Aeroshell W100 is NOT on the list! (Aeroshell W100 Plus is on the list, but the non-Plus variety that I have always used is not on the list.) However, SIL99-2B also says: Lubricating oils qualified for use in Teledyne Continental Motors engines are required to meet SAE (Society of Automotive Engineers) specifications. SAE specification J 1899 (formerly MIL-L-22851) is the approval for aircraft piston engine ashless-dispersant oil. SAE specification J 1966 (formerly MIL-L-6082E) is the approval for aircraft piston engine non-dispersant mineral oil. Aeroshell W100 meets SAE J 1899 and MIL-L-22851 (says so right on the bottle). Just use whatever oil and additives you think best (as long as they’re intended for use in piston aircraft engines), and don’t worry about the FAA or TCM. There is no oil police. My recommendation is to use either Aeroshell W100 single-grade or Phillips X/C 20W-50 multigrade and to add at least 5% ASL Camguard (1 pint per 10 quarts) at each oil change. (A little extra Camguard doesn’t hurt, and a 10% concentration is recommended as a “pickling oil” if the aircraft will be idle for a significant length of time.) For our Savvy clients, we recommend W100 with Camguard as our first choice unless the airplane is likely to encounter unpreheated cold-starts in sub-freezing OATs, in which case we recommend Phillips 20W-50 with Camguard. We have several Cirrus clients who had lousy looking oil analysis reports and cleaned up nicely after a couple of oil changes with Camguard. I have seen the same thing occur in at least a dozen engines in non-Cirrus aircraft (Bonanzas, Centurions and twin Cessnas) as well. I have documented my own oil analysis results from my own airplane in considerable detail in several aviation magazines. I am personally persuaded that the stuff works quite well and has no adverse side effects. (If I wasn’t , I sure wouldn’t be using it in my own engines, which are now approaching 200% of TBO.) I used Camguard quietly for almost two years before I started talking about it in public, because I was skeptical and wanted to see plenty of data before putting my reputation on the line. Mike Busch (A&P/IA CFIA/I/ME) 2008 National Aviation Maintenance Technician of the Year Savvy Aircraft Maintenance Management, Inc. (SAMM)

-

I think I can get used to this mooney stuff.

Jsavage3 replied to teg916's topic in General Mooney Talk

Kind Sir, in my defense, I'd like to say that I was in fact in straight & level, cruise flight with the altitude-hold auto-pilot (KFC-150) engaged. To backup my claim, if you'll notice in the bottom left corner of the picture, you will see the illuminated ALT annunciation indicating that the altitude-hold function is in fact engaged. The -146 FPM in the top left corner, which I surmise is what caused you to come to your conclusion, is actually a function of my top-of-descent (TOD) settings, i.e. when the negative FPM number hits that which I have set for my TOD, then the GTN-750 will alert me to the fact that it's time to begin my descent. I usually use either 300 or 500 FPM for my cruise descent planning. Though 238 knots GS is surely nice and it's my personal best to date in the Mooney, there are other airplanes, to include Mooneys, that will go faster. However, those faster airplanes are usually burning substantially more fuel. My picture was taken while cruising at FL210 somewhere between Jackson Hole, WY and Valentine, NE. My power at the time would have been set at 28" MP, 2500 RPM, 13 GPH at 50 degrees ROP TIT and per my notes, 192 KTAS is what the GTN-750 computed that day for those conditions...so that's only a 46-knot tailwind. My imagination runs wild when I consider the results of easily attainable stronger tailwinds. So, I'm with Teg916 in that I am still amazed every day at just how capable our Mooney aircraft really are. I consider myself very fortunate to actually own one. Very respectfully, A happy Mooney driver -

I think I can get used to this mooney stuff.

Jsavage3 replied to teg916's topic in General Mooney Talk

-

Use soft-field takeoff & landing procedures as taught in any Private Pilot training curriculum. Works good, lasts long time...

-

300 FPM when descending with a headwind and 500 FPM down when descending with a tailwind...I don't touch the power until I start getting into the bumps, then I slow her down just a little...