-

Posts

256 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by Warren

-

Yes. It has been removed.

-

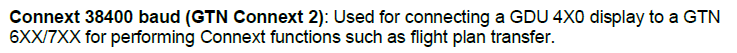

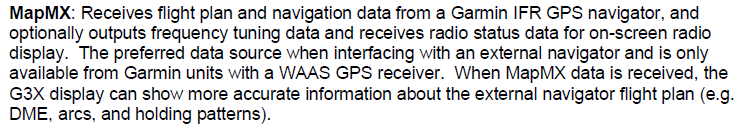

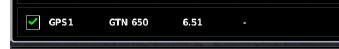

There should be two lines of communication. Here are the descriptions of the formats. The MapMX should be sending the tuning information: Also make sure in the device list on the G3X it shows that the GTN is present.

-

M20K Performance in higher altitudes - what can I expect?

Warren replied to NicoN's topic in Modern Mooney Discussion

Your fuel flow at 800' takeoff is about where it should be. I believe the critical altitude is 14 500 or 15 000 feet as a stock setup at standard temperatures. This should be the highest altitude you can still get max manifold presssure. The fuel servo references manifold pressure. As you climb, hit critical altitude and manifold pressure starts to decrease, you will see a corresponding decrease in fuel flow. For reference, I have the Merlyn upper deck pressure controller and my critical altitude is approx. 20 000 on a standard temperature day -- this upgrade is well worth it if you want to fly in the lower flight levels. -

Looking for pre-buy inspection near Greeley, CO

Warren replied to gevertex's topic in Modern Mooney Discussion

We are at KBJC. Let me know if you are still looking. Warren -

Hobbs on the K models are driven through/by the tach. The actual run rate is correlated to the engine RPM. If it quit working after an upgrade the wires were disconnected or, if the tach was removed, there needs to be a replacement signal to make it work. Many engine monitors include an hour meter and thus replace the Hobbs meter.

-

We are based at KBJC. We could try to arrange to do a prebuy in Colorado Springs for you. Rocky Mountain Aircraft Services. Send me a PM and we can talk about what exactly you want done and coordinate appropriately. Warren

-

Instrument Placement Advice for a New Panel (yet another...)

Warren replied to Seymour's topic in Avionics/Panel Discussion

I like the GPS as high as possible as viewing the screen is usually more than a quick glance. It is harder and more distracting to look at the GPS and/or make changes to flight plans, look for traffic,… when it is low. The GMC507 on the bottom works great for me. The knobs are easy to adjust and a quick glance locates them. Once you find the knob, your focus is on the G5, GI275 or other display as they are the effective display for the autopilot while making adjustments. -

Instrument Placement Advice for a New Panel (yet another...)

Warren replied to Seymour's topic in Avionics/Panel Discussion

If you buy the ADAHRS versions of the GI-275’s they meet the requirements for the six pack, including backup attitude indicator, and all the six pack gages can be removed. I would stack the GI-275’s just left of the control yoke, keep two backup gages if you want (AI and Altimeter or airspeed) to the left of the GI-275’s. Keep anything else to the right but plan to have an ipad mount that covers the gages right of the control yoke during normal operation. The ipad can easily be moved if you need/want access to the other backup gages. This would allow a full size ipad and would be great for approach plates as well as moving map purposes. -

I think you should be able to get it to VFR minimum status with a few repairs. The required instruments are pretty minimal. Whiskey compass - I have one out of a K that you can have. Vacuum hoses - need to be plugged/repaired for integrity of the vacuum system. Mic wires. At least need to do a little temporary work to get a functional radio. It can be cleaned up better in the avionics shop.

-

Is the pitot heat switch still available?

- 38 replies

-

- kt112

- slaving switch

-

(and 25 more)

Tagged with:

- kt112

- slaving switch

- auto pilot

- nose gear doors

- tach

- panel pieces and components

- cluster gauge

- ki525

- kg528

- kg102

- electric tach

- hoskins ft101

- kap150

- servos

- kr87

- ki203

- manifold pressure gauge

- rochester gauges

- ammeter

- vsi

- air speed

- oat/egt

- fuel pressure amp

- blind encoder

- whelen nav strobes

- oil pressure amp

- turn coordinator

-

Have you considered Dual G5's and only two axis GFC-500? Saves some money and you can add the trim servo later when/if you have the budget for it - not much increase when adding later vs. during the original install. You should ask them to provision/run the wires for the trim switch during the initial install if you are seriously considering this option.

-

whelen 650 install Another successful Whelen 650 strobe install

Warren replied to willerjim273's topic in Modern Mooney Discussion

The yellow wires allow the strobes to communicate/sense the other strobes and synchronize. It can be a real project to pull new wires if these weren't in your original plane. In the Mooney installs I have done, I have repurposed the ground wire from the nav or strobe light and used that for the sync wire. These grounds run back to the instrument panel and to a connector behind the engine controls. It is relatively easy to remove the ground from the mating connector and make a jumper to connect the grounds to each other. In planes with tail strobes, all three lights will have ground wires running to this point. If there is no tail strobe, you need to run a sync wire from the rear light if desired -- definitely not worth it unless you have the plane opened up for other work. -

EarthX is working through the paperwork to extend their certified Models to include Mooneys. I used my plane (M20K, 12V) for the cranking tests and capacity tests. Probably still a few more months until the FAA signs off. Removing a 32lb battery and replacing it with a 5.5lb battery will be one of the cheapest useful load increases possible.

-

Colorado - Looking at buying a Mooney, but never flown in one

Warren replied to Icebrk34's topic in General Mooney Talk

Also at metro and have a K. Happy to take you for a flight. -

Removing the diverted valve means that priming now happens through the injectors instead of nozzles in the intake. On mine it was slightly different after the removal. I found a little extra prime helped. I wait until I see fuel flow to start counting seconds of prime. Fuel pressures from the system setup should not change with the removal of the diverted valve. It is easy for a shop to check the pressures if you are suspicious.

-

Assuming you are going to a 330ES you just need to add one twisted pair for the TIS-A traffic feedback to the 430W.

-

I will take those. PM sent

-

The 330EX and 335 have different functions. GTX330ES is a mode S transponder with the extended squitter required for ADS-B out compliance as well as the TIS-A traffic input. GTX335 is ADS-B out only. GTX345 is ADS-B in and out.

-

The GNC255 only has a single ARINC output for the VOR/ILS signal. There are no ARINC inputs so it will not be possible. If you note on the GTN connections there are also RS232 connections which provide the remote control for frequency tuning on these as well. ARINC is used for NAV, GPS and Air Data.

-

The G3X only has CAN bus communication and RS232. The GAD29B acts as the interface to ARINC (429) communications.

-

The 255 has a frequency database. It needs a GPS location for reference to look up nearest frequencies. Connecting the 255 to a G3X allows the radio frequencies to be programmed directly from the touch screen.

-

This is only true if you buy an additional GI275 as a MFD. The ADI and HSI/Backup ADI cannot be configured to control a transponder per the STC.

-

The gage bezel will unscrew. It is a large diameter with almost nothing to hold on to. I suggest lining something like a channel lock with duct or fabric tape and carefully turning. Don't grab too hard and squish it out of round, obviously too loose doesn't work either. It is even harder to get it started back on when you put the panel back. Good luck.

-

FLAP RETRACTION AFTER TAKEOFF

Warren replied to DCarlton's topic in Mooney Safety & Accident Discussion

I wait for 90 knots to retract flaps. At that speed you have good control and the sink is minimal if at all. I find this takes out all the judgement, estimating,... 1. Lift off the runway and out of ground effect. 2. Positive rate - gear up. 3. 90 knots - retract flaps. -

I just bought a unit and plan to install it soon. I called their tech support and they certified the unit in a simulated environment (vacuum chamber) into the high 300's. According to their tech support, they have not experienced any issues at altitude. Their biggest issue is installers not timing the unit properly -- have to set it up at 0 degrees on the engine and get the dip switches set properly. I will report back with my experience as well.