All Activity

- Past hour

-

Retract Gear or Flaps First in a Go Around ?

donkaye, MCFI replied to donkaye, MCFI's topic in Modern Mooney Discussion

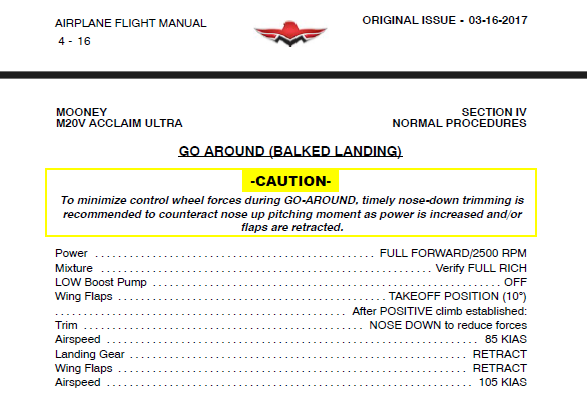

I'd like to relay one other experience that occured last Monday on a Rocket checkout. After doing all the air work and all types of takeoffs and landings, I had the student do a go around. The gear came up, then the flaps were raised too quickly before trimming down, then the trim got stuck full up. It took both hands pushing hard forward to keep control of the plane. While pushing hard on the yoke, we both finally are able to break the trim lock and return to normal flight. Of course had we not been able to break the trim lock there were other things we could have done, but the point here is that in our particular high performance airplanes, raising the flaps without significantly trimming down first could result in loss of control by less experienced pilots. Therefore, back to gear up first WHILE trimming down. When you feel a slight downward force on the yoke, only then reduce the flaps. -

PeytonM started following G3X went haywire!

-

On a flight yesterday, about 10 minutes into the flight with the GFC500 flying, climbing to and level at 7000 for about 3 minutes, my G3X generated error messages, showed chevrons to climb, A/P beeped at me, but did not disconnect. I was level at 7000. I disconnected and reconnected A/P a couple times with no change. I finally pulled the PFD CB, waited a few seconds, reset it. All good for the remaining 1 hr+ of the flight. I landed and took off, everything worked perfectly. No turbulence. Pics below.

-

- 1

-

-

Retract Gear or Flaps First in a Go Around ?

donkaye, MCFI replied to donkaye, MCFI's topic in Modern Mooney Discussion

There's no argument. Do what you want--in my opinion at your own risk. I gave my opinion that developed over 33 years and over 11,000 hours of flying Mooneys. The pitch up moment, p-factor, and torque on flap reduction is significant, especially in the long body. I don't know why the Ultra POH changed back from the Type S, but whoever made the change made a mistake in my opinion. - Today

-

Anyone have issues with defective parts in the kits or inadequate customer service? I'll post my experiences shortly. Thanks,

-

Retract Gear or Flaps First in a Go Around ?

1980Mooney replied to donkaye, MCFI's topic in Modern Mooney Discussion

After six (6) pages I hope this has been put to rest. I agree completely with @donkaye, MCFI's instructional advice. And as @PT20J says it keeps it simple (stupid..."KISS"). I was also taught that way and have been doing it from day one consistently for the past 26 years. -

that looks more like a go cart tube, than an aircraft tire tube

-

Just iron out the wrinkles and that is good for another 1000hrs.

-

Inner tube bandit struck again yesterday morning. My IA went out to go do a flying lesson in this Cherokee 180, nose tire was flat. When they pulled the tube out, it was all folded over like it had been reused two or three times.

-

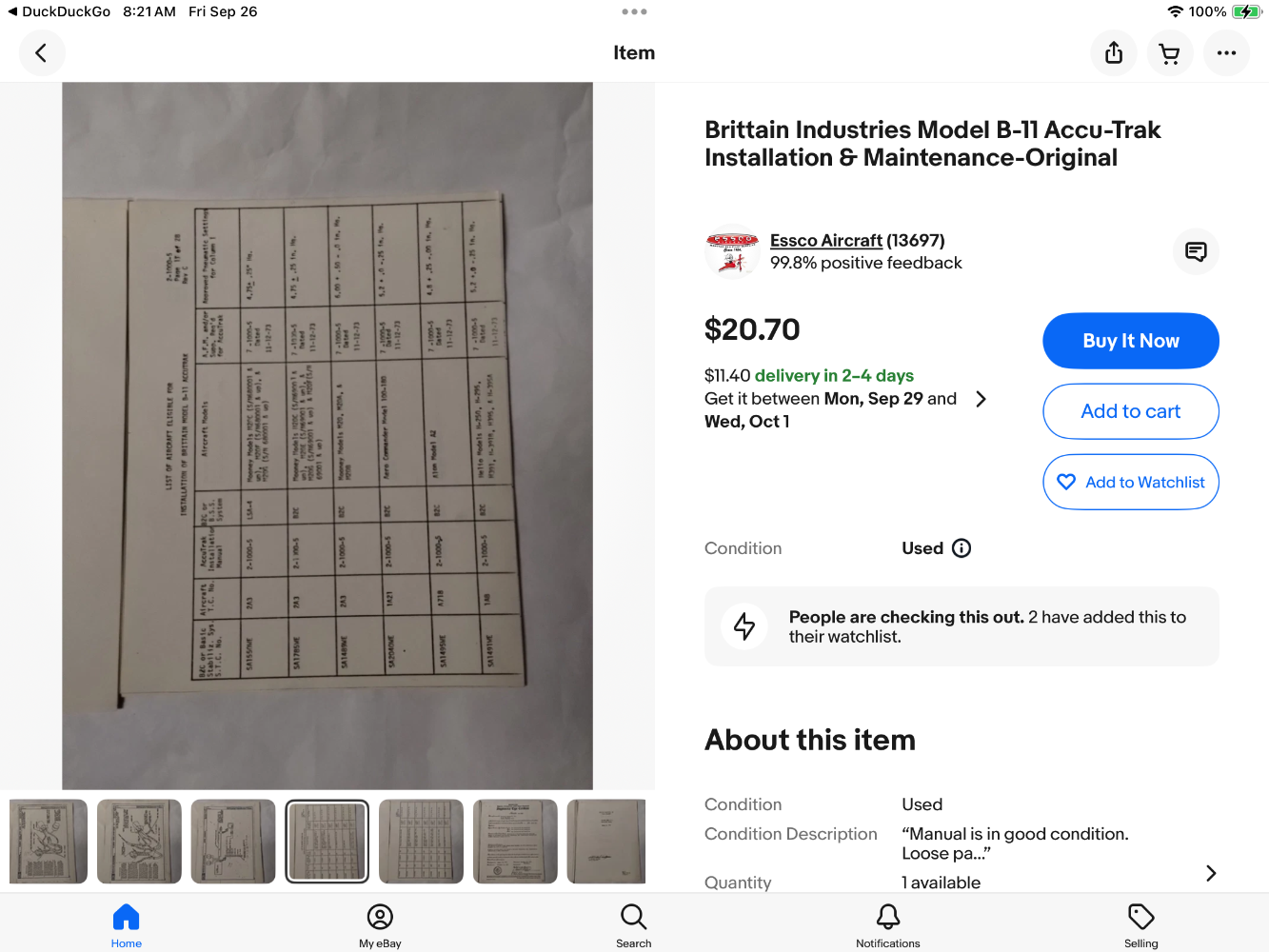

Yes. An AccuTrak can be installed, but you need additional components besides this unit shown. Look at my old threads. I installed an AccuFlite in my plane. There are two units needed. I had photos in the thread. I did majority of work myself with avionics installer down control connection and signing off. Scott (The two controllers you need are hard to find, but come up on Ebay when owners upgrade auto pilots)

-

takair started following Vintage Mooney and Brittain parts.

-

You should be able to. There is an add on STC that should still be available from Brittain. Not sure of videos, but @Kevin Westbrookshould be able to help. I built my system one piece at a time over many years. Now it is a great autopilot. It takes a little tinkering to get them set up, but once they are, they are a great autopilot,

-

Vintage Mooney and Brittain parts.

Mooney-Shiner replied to Igor_U's topic in Avionics / Parts Classifieds

I wonder if there is a way to install Accutrack II device on my 67F that has Brittain wing leveler vac system and TC100EVS Autopilot Gyro? Any videos on that? -

tav joined the community

-

M20J nose wheel collapse at KHEF

Brandt replied to Mooney in Oz's topic in Mooney Safety & Accident Discussion

Sounds like a business opportunity for FlyRPM. Just saying… -

OK that displays heading, then you probably have a KI-256 attitude indicator that supplies pitch and roll, which may need to be overhauled. @Jake@BevanAviation commented back in 2024 on this and @IvanP had him test his autopilot computer. He would be the guy I would call. I'm sure he could help you get it sorted out.

-

Retract Gear or Flaps First in a Go Around ?

midlifeflyer replied to donkaye, MCFI's topic in Modern Mooney Discussion

I think that’s what it comes down to. It’s the way I still teach it regardless of aircraft type. And my personal methodology is identical in all 30+ single types I have flown. The goal of a go-around or missed approach is the creation of a normal climb. The single biggest issue I see when I teach is rushing it instead of flying it, and I can actually see the potential for loss of control. We rarely have to do it for real, so we rarely practice it. That’s what we need to do instead if armchair it. -

Retract Gear or Flaps First in a Go Around ?

hazek replied to donkaye, MCFI's topic in Modern Mooney Discussion

I see. How would you explain them reverting back to the previous procedure for the Ultra? Seems to poke a hole in your argument. -

Retract Gear or Flaps First in a Go Around ?

donkaye, MCFI replied to donkaye, MCFI's topic in Modern Mooney Discussion

No. This.20080402_APPROACH FOR LANDING -CAUTION- The airplane must be wit.pdf20080402_APPROACH FOR LANDING -CAUTION- The airplane must be wit.pdf20080402_APPROACH FOR LANDING -CAUTION- The airplane must be wit.pdf20080402_APPROACH FOR LANDING -CAUTION- The airplane must be wit.pdf -

Retract Gear or Flaps First in a Go Around ?

hazek replied to donkaye, MCFI's topic in Modern Mooney Discussion

-

Darell Ali joined the community

-

Retract Gear or Flaps First in a Go Around ?

donkaye, MCFI replied to donkaye, MCFI's topic in Modern Mooney Discussion

There was a reason the Acclaim Type S (an Ovation with Turbocharging) changed the order in the later POHs. Review PT20J above. -

The Bendix-King KI 525A PNI

-

A buddy had one of the latches on the cowl of his Cherokee fail and he lost the top half of the cowl in the pattern. It flipped up and landed flat agains the leading edge of one of the wings for a while, and then fell off into a neighborhood, never to be seen again. He just flew it as normal, told the tower his cowl came off (the tower guy had seen it and told him about where it landed), and returned to the field without further incident. It put a dent in one of the wing tanks, which isn't too difficult to replace on a Cherokee. Took a trip to one of the BAS yards and he was back in business. It is sad when something that could be, and should be, a non-event, isn't.

- Yesterday

-

Retract Gear or Flaps First in a Go Around ?

Hank replied to donkaye, MCFI's topic in Modern Mooney Discussion

My Owners Manual doesn't mention anything other than normal and short field landings. Go arounds weren't a thing back in 1970; I just treat it like a normal takeoff. -

This happened to me a couple of weeks ago. Forgot to latch the oil door. On takeoff roll, it flipped open. Made the pattern and landed. My initial instinct was to position the plane in such a way using pitch and rudder that the wind might not rip the door hinge apart. But then a more reasonable voice came into my head and gently reminded me in a harsh way to fly the plane and not kill myself over a replaceable oil access door. I landed and taxied over near my hangar and shut down. I Decided to grab a bottle of water while I was shut down. Went to take off and on take off roll the damn thing was still open! This time I pulled the throttle at around 10ft agl and landed on the remaining runway, shut it down and closed the oil access door for real this time. -David