All Activity

- Past hour

-

DAC International GDC31 GPSS System - AFMS/AFS

rklems replied to Falcon Man's topic in General Mooney Talk

PM me your email and I’ll send you a copy -

Rght out of the gate? Seriously???

DCarlton replied to Freddb34's topic in Vintage Mooneys (pre-J models)

I'll add one thing to consider. I landed with no power several years ago after experiencing a rough running engine about 7 miles from my airport. The engine quit making power on the downwind leg (full throttle; nothing). We landed safely but used the entire 5000 foot runway. My highly experienced mechanic who I trusted completely, did every troubleshooting step in the text book. However, we did not identify an obvious cause. After completing several successful ground runs (the engine was "running like a top"), we decided to fly together. We flew for over an hour before the engine started running violently rough. We had meandered about 10 miles from our airport. We made it back to the airport and landed again ("white as a sheet"). After that incident we overhauled the engine; I was planning it eventually anyway. The point is don't assume you've got it fixed if you have a successful ground run up and short flight. Be careful unless you've clearly identify root cause and stay alert and be careful until you've got some time on the airplane. - Today

-

Order the pouches...just use the box they come in! But on a serious note... @exM20K what are the dimensions of the sporty's pouches? They don't give dimensions on the website. But if you have an O2D2, regulator/feed tube and several cannulas in one, they must be larger than they look on the website... you mentioned ~6" diameter x how thick?

-

Whoa, enough with the high-tech consumer uni-tasker solutions here .. Full disclosure: I was one click away from a set of those little Sporty's bags.

-

Standards are typically developed before products, with as much testing as the standards participants deem necessary in order to develop the standard. The science and engineering are known well enough to do that. My understanding is that engine and airframe manufacturers participate in the ASTM standards, which can accelerate acceptance downstream. Contrast that with engine and airframe manufacturers publishing "don't use that" letters for other products.

-

It seems like any prudent manufacturer would theorize development of a fuel, test its capabilities (internal R&D), apply for specifications like ASTM and enter the certification process. Swift appears to have been developing 100R for some time, and from what I can tell, an ASTM spec takes a couple of years. So, perhaps they only applied for an ASTM spec when they felt internal R&D (i.e. testing on engines in lab) showed they had a viable fuel. And now they are going through the STC process, which appears to be iterative. My point is that I feel like they know what the fuel’s capabilities are and have previously tested it. Now they are going after the formal certification process. Michael

-

Having experienced a mechanical failure with a gear leg after several flights of 'it just needs an adjustment', all I can say is investigate this properly before flying again. Aerodon

-

LightKeeper Dave joined the community

-

This thread, like the gami thread, is getting difficult to read. We can squawk and bray all we want but the problem is simple and the blame lays in once single place. The regulatory environment is the only reason we are flying on 1930’s technology. There is no incentive for anyone to innovate when it is not possible to recover the cost of development. Either flying is a fundamental right, or it is not. So either take off the chokehold on the certification process, or admit that they are trying to kill GA in a war of attrition. The FAA has reached the inevitable destination of any bureaucracy, which is a self serving organization that could care less about its subjects, and only cares about preserving its monopoly. There is zero desire for the FAA to improve our fleet, because they do not care and their existence is secure regardless of what happens to the piston fleet. I don’t believe it’s fixable under the current disaffected fiefdom. If someone doesn’t parse our sector out of the current set of rules, piston GA will die a slow painful death. Just to be clear, I am not impugning FAA individuals that many of us have had to interface with, but they are all bound by the onerous and stupid rules that are ruining our genre.

-

Doubtful, but my boom cannula is “permanently” affixed to my headset. Outside diameter is just over 6”.

-

Rght out of the gate? Seriously???

PT20J replied to Freddb34's topic in Vintage Mooneys (pre-J models)

The fuel tank pickups are above the sumps. That’s why there is unusable fuel. It would take a lot of water in the tanks to reach the pickups in level flight. Maybe less in a steep bank. There are coarse screens on the pickups to catch big chunks. Since the mechanic looked inside the tanks (presumably with a borescope) I presume these were checked. Some aircraft require adding a fuel filter between the Dukes boost pump and the engine-driven pump per MSB20-222. -

Rght out of the gate? Seriously???

Fritz1 replied to Freddb34's topic in Vintage Mooneys (pre-J models)

Curious how this plays out, take pics of fuel pickup tube when access panel is out, think this is a 1/2" tube with holes drilled into it, takes a lot of debris to clog up, glad everybody walked away and no metal was bent -

Rght out of the gate? Seriously???

takair replied to Freddb34's topic in Vintage Mooneys (pre-J models)

Fred…will he also check the previously mentioned screens…total 3? They may be holding junk that just needs to work its way past the screens to cause more problems. It is amazing how the junk gets by and then causes problems, but I have had it happen….in fact…shortly after getting bladders installed…. -

I use 11"X6" toiletry pouches and I put one labeled in each seat back. I place them "crossed over" so the pilots is in the back of the right seat and the right seats occupant's is behind the pilot. Makes it easier to reach without turning around. I got mine from the TUMI outlet store for about 6 bucks each, but you can find them all over Amazon.

-

Rght out of the gate? Seriously???

Freddb34 replied to Freddb34's topic in Vintage Mooneys (pre-J models)

Ok, a lot to unpack here. I did go back and ask the FBO if they did checks and was told they check it each morning as part of their pre op checklist. Yes, we did sump the tanks after they filled the tanks and there was no water or abnormal specks in the sumps that I could see. The AP sumped the tanks and that's when he noted the tiny, silvery specks in the sump drains BUT he did have to sump the tanks about 6 times before he saw them. Most pilots don't sit there and sump the tanks more than 2-3 times unless they see something odd. The AP did remove the drain plugs and empty the tanks. They took photos of both tanks and found the right tank clean but there were several large chunks in the left. Chunks that wouldn't come out of the drain sump (which the logs show the seller had done). I'm not 100% sure we were on the left tank, once again, unfamiliarity with the fuel selector BUT I do know for a fact it was not in the OFF position. It was selected on A tank, just not 100% certain it was left or right. I plan to paint the top of the selector (Green towards the tank selected, Red for the tank not selected) so that I have an easy reference as to what tank I'm on. The AP is going to pull the top panel off the tank and clean out the entire tank. He's very confident that this will resolve any fuel pick up problems. -

Bryan Turner released a new dating app for pilots only but if you watch all the way, you may realize why you’re ineligible.

-

- 2

-

-

Rght out of the gate? Seriously???

Freddb34 replied to Freddb34's topic in Vintage Mooneys (pre-J models)

No, we didn't switch tanks...since this was only my second flight, it slipped past me on the "memory items" for the Mooney. Coming from Pipers and their easy access tank selector to the Mooney "floor based", we just didn't have time to make that flip. We were on the ground in about 90 seconds. Lesson learned. -

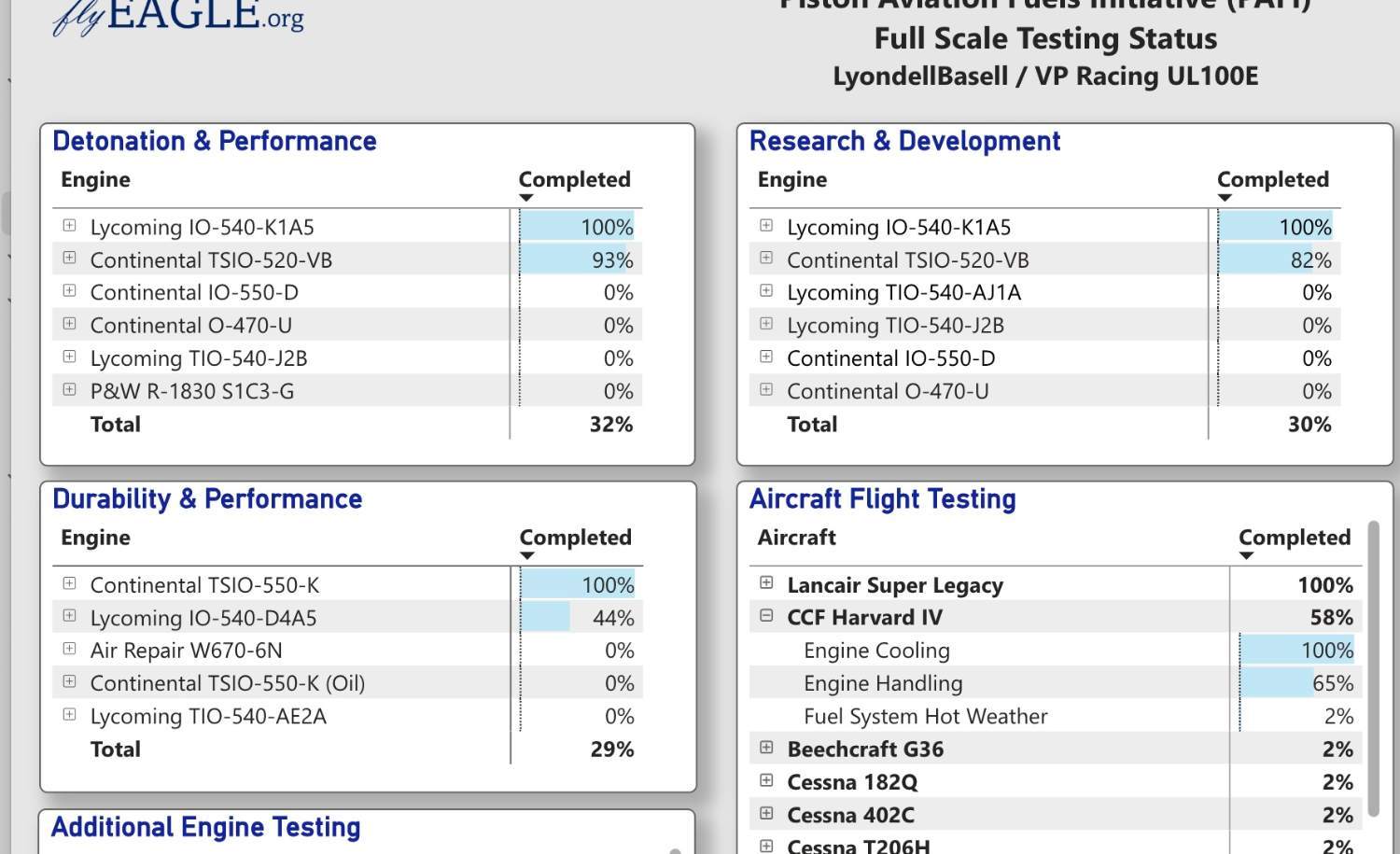

That is very useful to see. And the Conty TSIO520VB is very very similar to my TSIO520NB.

-

Rght out of the gate? Seriously???

cliffy replied to Freddb34's topic in Vintage Mooneys (pre-J models)

Most if not all FBOs selling fuel drain their tank sumps every day and log that along with checking for water in the sample. Tanks and trucks alike. One of the items the FAA does after an accident (engine failure) is go back to the last place fuel was purchased and check the logs and test the fuel farm system. Does the FBO have the tank logs that show he did the inspections? Does he do inspections? Were the sumps of the plane drained effectively before flight? Have the orings on the tank caps been checked for cracks? When were they last replaced? Have the sump plugs now been removed to drain LOTS of fuel out to check for water and not just the little fuel stick tube? USE PROPER GROUNDED FUEL BUCKETS AND NOT A PLASTIC HOME DEPOT BUCKET!!!! Static electricity is generated by falling fuel and a plastic bucket!!!! Have long power run ups been done to verify fuel feed integrity now? We have the cart before the horse here right now. -

The point is that Engine testing and Operability should be established BEFORE ASTM certification, not after. There should be NO ASTM Certification until it has been shown to the satisfaction of the engine manufacturers, the aircraft manufacturers and the FAA that a new fuel can safely power the fleet. As it stands now, ASTM for GA aviation fuel is nothing more than a standard for supply chain purposes.

-

Rght out of the gate? Seriously???

PeteMc replied to Freddb34's topic in Vintage Mooneys (pre-J models)

You weren't specific on your "troubleshooting" and I'm not sure if switching tanks was done. I'm assuming it was done, but just wanted to confirm. I would have thought the engine would have started back up in a couple of (looonnnggg) seconds had the issue been water or some other issue with the initial tank or feeder line. -

The PAFI testing might be a good comparison for looking at what engines would be used to set the bar for the certification testing and then compare to engines you might be running. This is for VP/LyondellBasell's fuel (which appears to be similar to Swifts in many respects). https://app.powerbi.com/view?r=eyJrIjoiZjg3Y2ExY2EtODY4ZC00ODA4LWEwOGQtMDAyNWJkOTViMTRmIiwidCI6IjRiYjdlYzcwLWJjOTAtNDI5Ni05NTUxLWQ4ZGY1MDg0MDllMyJ9

-

My understanding is that the fuel Swift was testing in the PAFI program during the 2018 timeframe was an entirely different composition than 100R. The PAFI program was suspended partly due to Shell and Swift's entrants at that time needing more work. So, it seems that Swift essentially started over and created 100R. 2018 article https://aviationconsumer.com/aircraft-ownership/whither-100ul-tested-fuels-fall-short/ I would surmise that Swift has tested other larger engines in their facility with 100R, but the certification process is different than lab testing. Thus, the smaller engines start first in the 'for credit' testing. Michael

-

I have an automobile trash container that hangs from the back of the right seat that I use to hold things I might need in flight. That’s where my X3 and boom cannula wind up when I’m traveling alone. My wife’s will fit in there too. i’ll find a pic or link. EDIT: Here’s the one I have https://a.co/d/6jS7TUQ

-

Rght out of the gate? Seriously???

Matthew P replied to Freddb34's topic in Vintage Mooneys (pre-J models)

we don't even know if he did a fuel sample from each tank yet, that could explain things..I'm just glad they they are ok and the aircraft is ok..