All Activity

- Past hour

-

@midlifeflyer My bad; I confused you with another poster that has owned a size-able number of aircraft. Wish I could remember his name!

-

The reason I ask about your encoding source is that they said your mode C was intermittent. The mode C is the altitude reporting portion of your transponder signal. The transponder gets its altitude from the encoder which is a separate device.

-

- Today

-

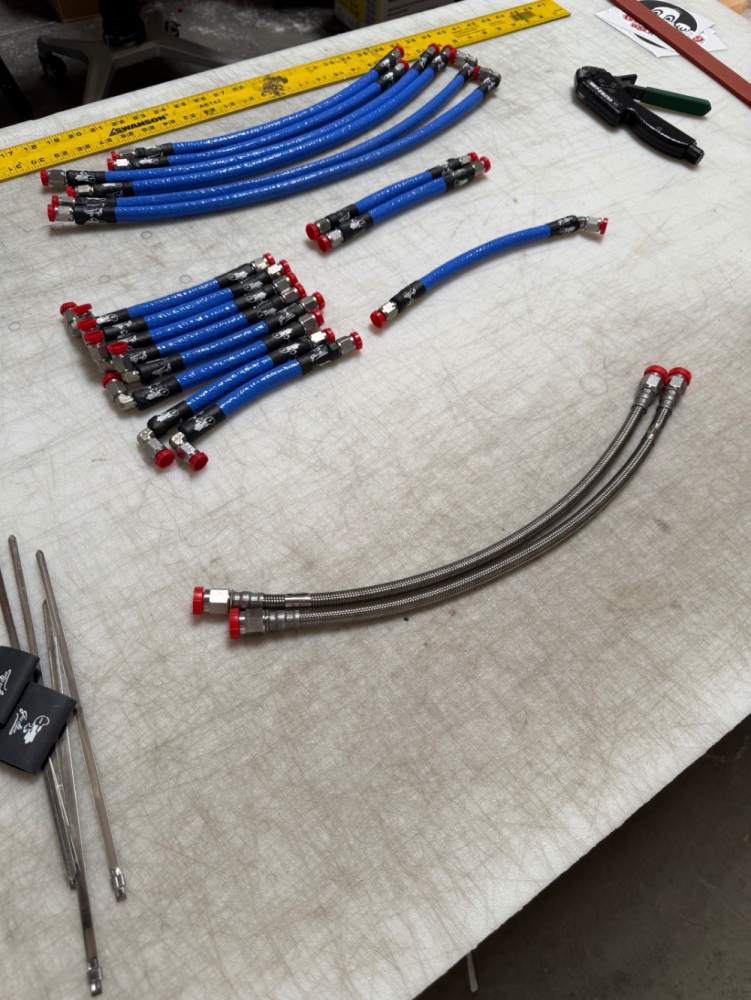

All hoses have a tso tag custom colors in firesleeve Tio541 from a B60 Duke shown 20 Assys for two engines, I did this customers hoses in 1995. we have completed the airframe to engine , next are the accumalator hoses .

-

Yes, but what’s its altitude source? I don’t think a gtn can be the altitude source? There will be some type of encoder hooked up to static air that provides it. Could be anything from an old school grey code box or a fancy little garmin one on the back of your unit. It’s where the transponder gets the pressure altitude. Strangely, the transponder needs a different box to do this for it. The transponder itself just takes care of sending out the different mode c signals, adsb, etc.

-

@DanM20C, @SkyBound, any update on Mooney Summit X???

-

I have it linked to GTN 750Xi; no flags on GTN or on LRU page. Software 8.04 in the GTX330ES, and 3.42 in the GDL88.

-

Oscar Avalle started following Landing at a new airport in El Salvador

-

The Government of El Salvador has made aviation and general aviation in particular a policy priority. As part of that effort it has repopened and opened several airports. This is a video about a flight to one of these new airports. Hope you enjoy.

-

- 2

-

-

Quoting from the Plane & Pilot article above: We do know for a fact that performance can be really bad when you have a damaged prop. A survivor of a prop strike accident told us so. A Cessna 172RG was on an instructional flight out of the Washington Memorial Airport in Marthasville, Missouri, on April 23, 2002. The private pilot was killed, and the instructor received serious injuries. During a touch-and-go, as the plane was in ground effect, the nose suddenly pitched down, and the prop hit the runway. The airplane started vibrating badly, and the flying pilot turned the plane over to the instructor, who was unable to control it. The instructor told investigators that the airplane made a sharp turn to the left and went nose down into the ground. On May 19, 2016, the propeller of a Beech D35 that was landing struck Runway 10 at the Gatlinburg-Pigeon Forge Airport in Sevierville, Tennessee. A witness said the landing gear had been up and, after the propeller blades struck the runway numerous times, the airplane skidded along until the engine speed increased and the airplane lifted off. The witness said the airplane appeared to be very unstable in ground effect, its performance dramatically deteriorated. It was observed to pitch up, roll to the left, and crash to the ground. The pilot, who was the only occupant, was killed. ******** Please don't try to "save" an already damaged airplane. Ride the slide and live to tell the tale, even if you don't fly again afterwards. How damaged is the propeller? What was damaged in the engine? Did your flaps drag down the runway, more on one wing than the other? How much power will the engine produce? What is your new propeller efficiency? You don't know. Maybe your controllable pitch propeller won't fully adjust, because the impact changed it's angle; maybe a tip broke off of one blade; maybe the crank shaft is cracked, and going for full power may break it. Land the plane and live.

-

Ragsf15e started following Transponder intermittent

-

What is it using as an altitude encoder? I had this happen with a gtx-345 and it was actually the encoder.

-

You can just buy music wire. The trick is attaching it to knob. It is crimped into the knob. On my old M20F I repaired my boost cable that had the same problem as yours. I carefully cut the crimp off of the knob shaft with a Dremel cut off wheel, not cutting the wire, then putting the wire in a vise and pulling it out of the shaft. Then carefully drilling the wire hole deeper, insert the new wire and crimp.

-

Wire routing and securing wire inside the wing

Yetti replied to Mooney-Shiner's topic in General Mooney Talk

Assuming the right wing? There should be no laying wires on the wing panel. Follow the temp sensor wire at the leading edge wing root by the door. The fiberglass ceiling wire snakes are helpful here. There is an access panel on the lower wing that is about 3 panels out. I had to run a 9 conductor wire for the Dynon. Even if you don't use the same rib hole you can still tywrap to that wire bundle to make a neat install. I would run the loose end back to the cabin. Pull the lower panel in the cabin to route wires to Comm Bay. I mounted the Magnetometer to an access panel out board of the fuel tank middle of the wing. One you can route wires to, the next one outboard could not get wires to. If I get to the plane I will identify which one. It takes a little figuring, but it works. -

The method of torquing is critical and if you are going to hang around to observe the work, this is the one thing you do not want to miss. First the torque wrench should be calibrated, most shops do this and FAA Repair stations are required, but you never know when Vern pulls out his personal wrench. You want to make sure the torque to final spec occurs in one smooth swing and of course the torquing method (wet) is complied with.

-

Wire routing and securing wire inside the wing

GeeBee replied to Mooney-Shiner's topic in General Mooney Talk

^^^^^^^This -

Wire routing and securing wire inside the wing

Mooney-Shiner replied to Mooney-Shiner's topic in General Mooney Talk

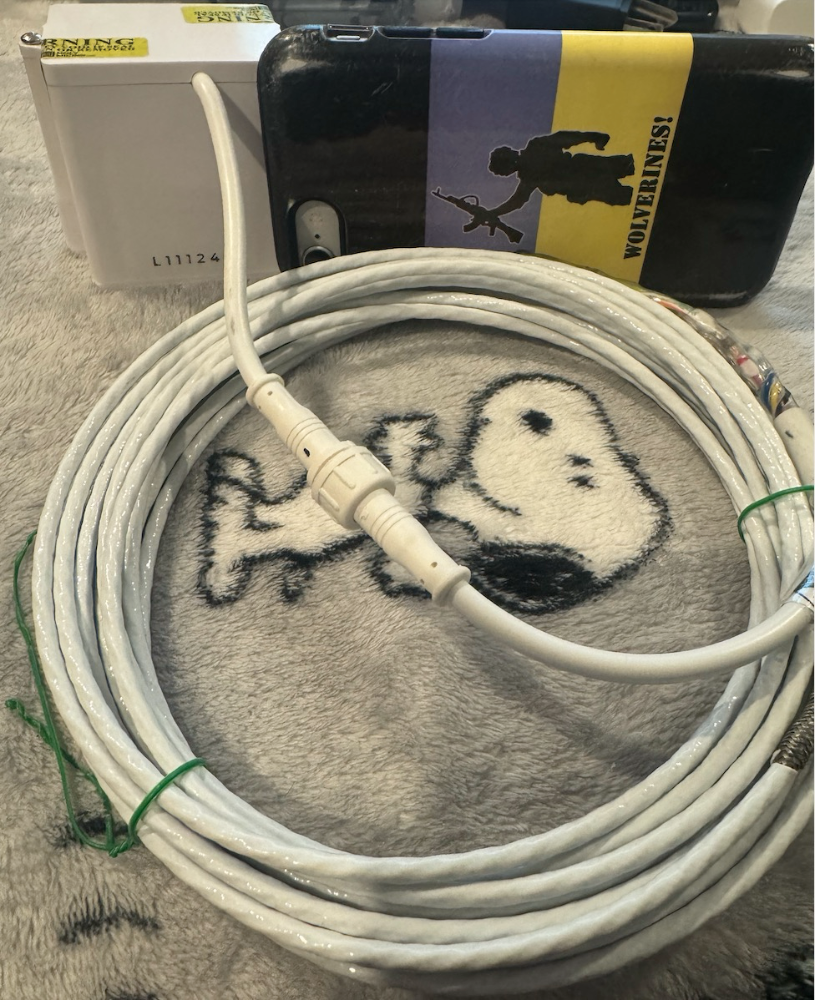

Thank you. This is the size of the wire in question. iPhone for the scale. I guess, I can wrap it with the heat shrink tubbing with spiral wrap and let it lay on the bottom of the skin of the wing to let the wrapping serve as a sacrificial material. I just would rather have a cleaner install where nothing has to be sacrificed. -

You have had some good answers already. I’ll tell you what I do on most Annuals now, but of course this is what I do, I’m not saying it’s what should be done by others, but I believe each aircraft and the conditions and frequency it’s operated and stored in should be taken into consideration. Realize my Annuals I do are for older Retired guys with Champs, Cubs and the like, not fire breathing twin turbo complex aircraft that fly in the flight levels and fly hundreds of hours a year, none fly 100. They also almost never spend a night outside or in the rain. The problem as I see it is there is an attempt to cover every aircraft flown in every environment under every condition with one yearly inspection, then add in the most conservative response is to do it and we see why wheels are pulled on aircraft that fly less than 50 hours a year and have never been rained on. The FAA relies and gives mechanics the ability to use their experience to adjust the scope of an inspection, but not the frequency. I jack up the wheel, check for radial and axial play, spin it, check for noise and smoothness, in my opinion I have inspected the bearings. Fuel injectors, comply with the AD of course, check for condition and security, leaks and if operation is normal I don’t remove them. I do clean, inspect and repack bearings if the wheels are removed like for example tire replacements. If aircraft wheels were sealed as well as automobiles are then we could not bother but they aren’t, if water ever gets to the axle for example, they need to be repacked. I do check engine oil filters / screens and we usually change the oil, but if it was changed last month and 5 hours ago I recommend we don’t. Compression test, borescope, check / adjust timing. Rarely bead blast plugs, I’m of the dig the carbon / lead out and don’t blast myself. I do check resistance. Condition and security of everything else. I do require checking of all flight and engine control ends as in every bell crank pulley etc, run a Cossosion-X soaked rag over every inch of control cables looking for meat hooks, pulleys for wear / play etc. Gascolators are just too easy not to do, and occasionally I find evidence of deteriorating fuel lines, looks like black granular bits. I think that’s often what clogs injectors (opinion) Owner does all of the manual work, cleaning, and usually if we have to pull mags etc they do so under my supervision, now not all are at the level I’m comfortable with, for those I do the technical stuff myself. For that I charge $300 and I approach Annuals as a teaching event for the owner. Not that I want or expect them to do more than they should unsupervised but I think it helps understand how things work if you took it apart and put it back together yourself. Those that own and fly twin Comanche’s, Bonanza’s and the like there are local Professional shops that usually specialize in a Type that I recommend for them.

-

And then the gear come out on the climb out.

-

I would consider this, but you have to weigh the equation's benefit/cost/time components. You already have 6 new cylinders that will get you back in the air quicker than playing whack-a-mole, which is a significant benefit too. Even if you don't send these new ones off, I would definitely send the ones you remove for rebuilding. Store them properly and you have 6 ready for the overhaul a few years down the road.

-

I watched the video from the original post. What's up with that extreme nose angle? There appears to be no rudder input, and it's got to be complete weathervane into the wind and at least 30 degrees left of center.

-

I made these decisions a long time ago. If there was a lot of runway left, I MIGHT consider adding enough power and level off just to put the gear down, but I would not go around. If not enough runway, slide it in. I also have a plan for complete gear failure, including the manual crank. A few years ago, there were threads about trying to stop the prop, and I think those discussions were about achieving the best glide range. Some members tried it and reported that it is not as easy as it sounds. I won't try to slow the airplane to stop the prop at altitude. Not worth the effort and stress. The prop might stop in the flare, but mine always stops with the blade in front of my face on the pilot side at 10 o'clock. The other blade is going to take the damage. If that happens, I won't waste my time trying to bump the starter. GUMPS out loud 3 times before landing.

-

Huh?

-

Neshi started following LPV 35 KOWD from window

-

Inexperienced pilot looking for Bravo wisdom

Raistlin replied to hazek's topic in Mooney Bravo Owners

Airfares are not crazy expensive if organized in advance (in Y, in C they are outrageous since after covid). Germany or France are most appealing due to the number of Mooney owners and the presence of the two Mooney service centers, but I can also offer up our arport in Milan (LIMB), runway 1080m/3600ft, hotel in front, three major airports to travel to. Our Aeroclub operates it, so we can figure out logistics and costs. I would love to see our apron full of Mooneys ☺️ -

Aerostar lands gear up, then takes off and flys home. https://www.military.com/video/aircraft/civilian-aircraft/plane-lands-gear-up-then-keeps-flying/4189092003001