Search the Community

Showing results for tags 'cht'.

-

Slow day in the vintage Mooney world so here's another esoteric topic - moving cowl flaps - specifically they disappeared one plane before mine -SN 680002 - rolled off the line. I don't know if they ever came back on the C or if any other planes lack them. Can anyone enlighten us? Also, has anyone ever made their fixed cowl flaps movable? Was it worthwhile from a CHT perspective? If so I imagine it's a cheaper project than the top overhaul it might prevent.

- 16 replies

-

What kind of CHT, EGT's and Cruise speeds do yall get up at elevation? What RPM setting do you use? Mooney Zoom's with a tail wind and LOP - 8.6GPH SAD HEADWIND ----------------------------------------------------------------------------------------------------

- 21 replies

-

- cruise speed

- speed

-

(and 3 more)

Tagged with:

-

Quick question vintage Mooney officianado's, I've put roughly 35 hours on my new to me 67 M20F since taking ownership and finally was able to download the EDM 700 data. The engine is a Lyc remanufactured IO-360-A1A installed in Feb of this year by prior owners. Normal cowl but it does have the lower cowl cover. I'm seeing a consistent temp split between my #2 (hottest) and #1 (coolest) cylinder of ~70-80 deg F. (attached pic of data from one flight). Engine now running Aeroshell 100+...max fuel flow indicated during takeoff ~15-16 gph She runs smooth, during runup with the JPI Norm mode, all appears to respond as expected. Figured I'd ask if there is a 'normal' or expected temp differential between hottest and coldest cylinder...thoughts ?

- 13 replies

-

Mooney M20F, Lycoming IO360-A1A I thought would put this out there for some advice & feedback. Recently I had my mechanic examine my engine and he mentioned pooling of oil and possible cylinder glazing. Cylinder glazing is a condition that occurs where oil film left on the bore "glazes" to a hard coating and can prevent optimal sealing of ring to bore. The oil here is the result of cylinder head temperatures, CHT'S, not getting hot enough to burn this oil film and. thus prevent the glazing. Optimally, he says, the CHT'S should run about 360-380 F. My engine is seeing a range of 300-320 deg F with an OAT of around 34 F. This is with cowl flaps completely closed all the way, they are closed and flush with the rest of the cowling. All cylinders are running about within 10-15 degrees of each other & measured by JPI930 engine monitor. Of course, my goal is to get these temps into the suggested range. Just wondering if anyone is running into the same issue? what temps do you typically see? Has anyone found a way for the cowl flaps to create more flow restriction? has anyone done anything with engine baffling as to affect the cooling of the engine? Thanks for any feedback. 04/19/2018 -- ADDITIONAL INFORMATION: Thanks for everyone's feedback! what a great resource! I thought I would share what led to the inspection of the cylinders and a give a clarification of the above statements. On a couple of occasions, a ramp guy took notice of a puff of white smoke when taxiing up the ramp. Curiously, I mounted a go pro camera and focused it on the exhaust to try and observe it myself and of course, it never showed up. Recently, I pulled the cowl to check a few items and noticed oil coming out between the exhaust manifold and tube flange at cylinder#4. I immediately sent it in for service and it ended up being a bad valve guide. With all that said, cylinder#4 has undergone a rebuild and will require break-in, hence, the recommended higher CHT's. After clarification and reading all the great comments, this is why he mentioned the glazing and the importance of running higher CHT's. My fault on the interpretation. Fortunately, I do not have any cylinder glazing as all cylinders. were checked at this time. For those that asked, oil consumption has been in the normal range. I have 2 years of history (about 400hrs worth) and it ranges from 0.10 to 0.15 qt/hr. This looks to be well below even what Lycoming says is normal. I found this formula in their manual Normal Oil Consumption (Qt/hr) =(0.006 * BHP * 4) / 7.4. At a BHP of 0.59, this equates to 0.19 qt / hr. Compressions are all good ranging from 77 to 80. One question I do have for all of you, When do you typically add oil? Do you wait til it gets down below the 6qt mark, or, do you add it when it is hovering just above around the 6qt mark? I have been doing to latter. I have heard that these engines typically find their happy spot and then do not vary much. I may be adding too early as it may stabilize at 6qt. Any thoughts here appreciated.

-

Hello all. Over the last 4 or 5 months, I have noticed my CHT's have been steadily rising and the spread from the hottest to the coolest is increasing as well. (Used to be 30 degrees, now it varies between 35 & 40) It is to the point where I can't fully close the cowl flaps. This hasn't been an issue for the last 250+ hours on the plane over the past year and a half. This is when I started running LOP. I have an M20K/231. Inner-cooler and 'automatic' wastegate & GAMI injectors. I took the first picture this morning while flying from Phoenix to San Diego. LOP, 12k, Cowl flaps in tow (Fully closed and CHT's go over 400) The second pic is almost a year ago to date. LOP, Cowl flaps closed, not sure altitude but probably pretty close to 12k. I know It was running about 45 degrees more LOP a year ago, but the CHT's are much cooler with the cowl flaps closed than they are now. What could/would have changed over the last year? (Compression check 2 weeks ago showed about same as annual in Nov. Any help would be appreciated!

-

Hi all, I am a proud new owner of a 1980 M20K 231. A bit more than I need, but I hope to grow into it. I have been reading this forum as a guest for a while and have just signed up to hopefully get some answers from some experienced and willing people. Keep in mind, I am very green. This is my first airplane and although I started flying over 10 years ago I have only been licensed for a couple years. So still learning lots, and trying to read as much as I can. Just a quick run through: I have the TSIO-LB360. It is at about 1000 hours SMOH and was taken apart in 2013 due to a prop strike but I don't believe anything was replaced. It has the Merlyn Wastegate, an intercooler, an EDM700 engine monitor and GAMI injectors. I also have a Shadin Fuel Flow indicator. First question should be a fairly quick and easy one. I flew with some passengers for a couple of hours. Arriving at my destination I had to overshoot the first approach and when I selected the gear up, it wouldn't go up. After cycling it a couple of times with no response I checked the circuit breakers and noticed the "Gear Act" breaker popped. I tried resetting it, and it popped again immediately. Luckily I am old enough to know not to keep trying like I would have in my younger days :-P My rear passenger noticed that the safety latch (metal cover) was open on the emergency gear release so the handle was exposed. I guess one of the rear passengers knocked it with their foot. I closed it, then reset the breaker and everything was back to normal. I assume that they are interlocked? I have done a couple flights since and there have been no issues. Everything functions normally. I can only assume that was the only cause and I don't have anything to be concerned about? Input? Next question should be reasonably simple as well. When I bought the plane the gear warning horn did not work. We had the manifold pressure all the way back (at altitude) and were not getting anything. Before we finalized the deal, the mechanic adjusted it based on some throttle position/manifold pressure readings which we took during the flight and he fixed it perfectly. It would come on at exactly 14.9" of MP. Except that later in the flight it came on slightly less than normal cruise power settings. It would go off eventually if the throttle was moved in and out, and sometimes if I wiggled it side to side gently or twisted the knob (it is not a vernier) it would also go away, but not always. This is somewhere in the 20-26" range so just below normal cruise I guess. I notice it on descents or in the circuit more than anything. Is this an easy fix? I was told that a Mooney expert from Tri City Aero in Kitchener Ontario frequents this forum and may be able to give me some input. I am just in Burlington and plan to give him a call soon to start our potentially long and expensive relationship The last question I have relating to LOP operations may spark more debate (given all that seems to be out there on the topic which has been beaten to death) and probably has no simple answer but I am just looking for a bit of input, not something complicated and I will do some more research myself. Just trying to figure out where to start. My instructor told me to run ROP with TIT up to 1500. I have seen lots in favour of running LOP so I have experimented a bit running LOP. A couple days ago during cruise at 28" I pulled the mixture back to just under 9GPH. That's where it starts to run a bit rough. I bring it back up to about 9.5 with a TIT of around 1450-1500 or so. I have been told, and gotten into the habit of monitoring TIT closely, but have recently read an article that swears by leaning according to CHT. I do know that CHT's are even more important and have a very close relationship with ICP. Here is what happened. After only a few seconds... maybe 15-30 (I wasn't paying super close attention), my #4 cylinder CHT skyrocketed quickly. On the JPI the middle bar that separates the CHT and EGT appeared to be flashing or basically just started going up and up. Then I got the flashing indicator for that cylinder and the display stayed there and I think the temperature was in the 420 range. I panicked and enriched the mixture quickly and everything went back to normal. I thought maybe I was too lean, and tried it again paying closer attention to things, and the same thing happened. It seemed to happen in less than 10 seconds. What I am looking for from some of you experienced guys is the answers to some of these questions... Is this a sign of pre-ignition or detonation? Is this a bad fuel injector? Do you think I caused any damage in those few seconds that it ran like that? Could it be a bad sensor? Is this a result of running LOP? I can only assume so since it doesn't happen when I run ROP (about 1400-1450 TIT and 11.5-12GPH) Any input on this would be greatly appreciated since this is worrying me quite a bit. I know there is likely more to it than a simple explanation but I appreciate any information that anyone is willing to give. Thanks in advance and I hope to be able to post here and look forward to being part of this community. I just love my plane!

-

Oil pressure and CHT gauges (all stock) in my M20K are close to death and need to be swapped. I'm unable to find replacement parts by Googling. Could someone help me with the part numbers? Or even better, maybe one of you are getting a JPI upgrade and would like to sell me your old gauges? What do you think is the cheapest path to get upgraded oil pressure and CHT gauges if direct stock gauge replacement is not an option? JPI currently is not an option.. Thanks everyone for your help.

- 5 replies

-

- m20k

- engine gauges

-

(and 2 more)

Tagged with:

-

I've had my 231 about six weeks and just took it for the first trip of any significance. My first question, what cylinder is the factory CHT probe on ? 1985, serial # 25-878, the normal LB engine. My #3 CHT temperature is limiting everything I do with the airplane and I'm wondering if the factory CHT probe is there and the JPI probe for #3 is on the spark plug. In another airplane it was and the spark plug probe read 50º higher than after I placed it into the same area as the other CHT probes with a relocation kit. The other five cylinders are 45-70º cooler than #3. My TIT was running around 1450 and EGTs were in the 1300-1400 range so I seem to be plenty cool in other parameters. I have to climb at significantly reduced power and climb rate to keep #3 under 400º in climb. I was at gross, but it was cool and starting at sea level. Also, to keep the #3 below 380º in cruise I have to fly at more reduced power than I want. I haven't looked that closely at it yet but the Continental TSIO-360-LB engine is a 7.5:1 compression ratio. 65% power LOP should be exactly 10.0 GPH. I have to run 9.0 GPH to keep the temperatures under control (30", 2500 RPM, 9.0 GPH, 380 CHT). That's 59% power according to the calculations. At 9,500 ft I was getting 158 KTAS (based on the TAS dial on the factory A/S indicator which seems reasonable). Thoughts ?

-

The original CHT sending unit for M20J IO-360 isn't working and I'd like to find a working one for replacement. Does anyone know what the cost and where to get a new one or have a used one for sale?

-

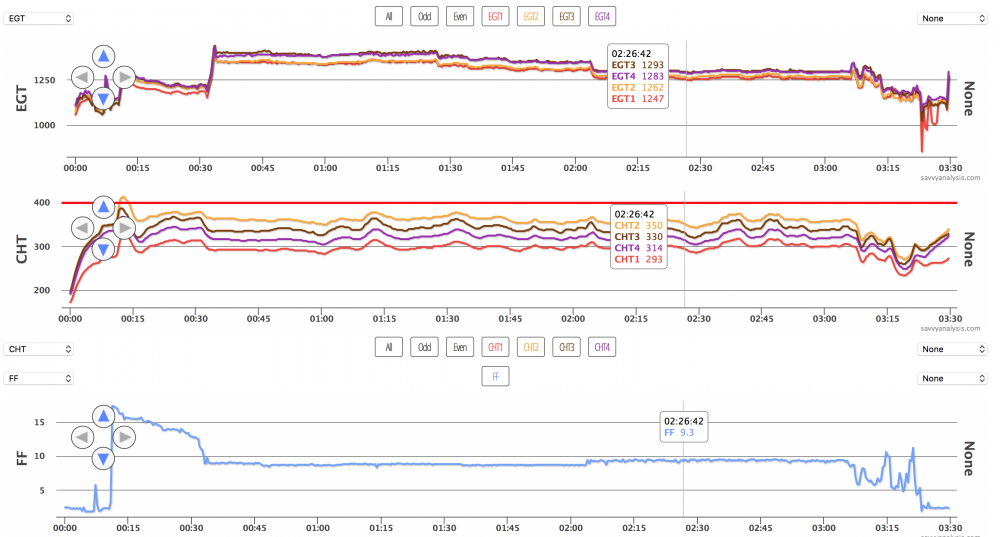

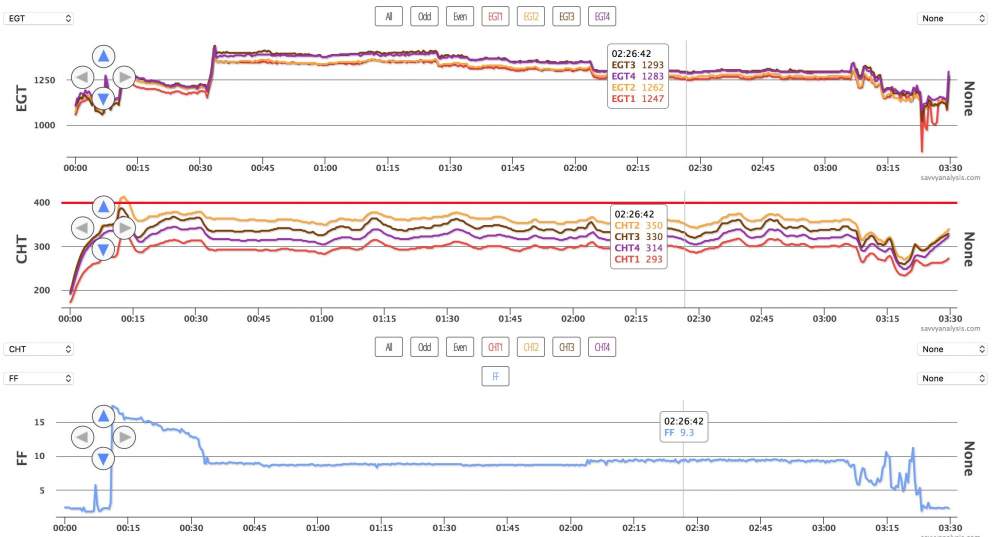

I've been on here quite a bit looking for a solution to the high CHT problem with my C. A related problem was leaning. Sometimes I couldn't get below 11 gph and EGT's were all over the place. CHT's were also all over the place with the front cylinders up to 60 degrees cooler than the rear, or specifically #4. I've been told C's just run hot. I used up a tube of RTV plugging every hole, seam, etc in the baffling. It was suggested the the carburetor might be wrong or need overhauling. I even thought I should switch the O360 out for an IO360 to be rid of the carburetor. I've experimented with all types of power settings and mixture settings. The only thing that seemed to help at all, was to reduce prop RPM as early as possible and as low as possible. And I'd never been able to close the cowl flaps without raising the CHT's too high. The solution I recently discovered is throttle position. At WOT and Full Rich mixture, everything is fine. But as the mixture is pulled back, the CHT's would go way too high, and I know the engine's not meant to be run full rich at say, 6000 ft. Solution: Prior to pulling the mixture back, pull the throttle back just until the MP needle moves 1/2", then push the throttle back in just enough to get the 1/2" back. Leave the throttle there and adjust mixture as required the rest of the flight. Now I can leave the Prop RPM high or at least around 2500 throughout the climb. CHT and EGT's are all much closer between cylinders now, and CHT's are lower across the board. I've tested this on four different 1.5 hour flights and two 4+ hour flights with excellent results. It's been said on this board before, that WOT with the O360 carburetor opens an additional port or jet dumping extra fuel. It seemed counter intuitive to me to reduce that extra fuel as a means of reducing CHT. And I'd tried pulling the throttle back just a bit, but it obviously wasn't enough. I have to pull it back enough to reduce MP and then put it back just enough to get the MP back. So now I'm speculating that the extra fuel works fine at full rich mixture, but when leaning, it's somehow messing with the distribution of fuel, and putting some cylinders too rich and others too lean. This picture is at 12,500 nicely LOP and running smooth as butter. I neglected to get a picture of the CHT/EGT screen but will do that on the next flight.

- 21 replies

-

- 2

-

-

Based on the related thread in "Modern Mooneys," I've been considering this topic but didn't want to muck up commentary on someone's big bore Continental with balanced injectors by blabbing on about my trusty but primitive carb'd Lycoming O-360. Specifically I've been musing about my EGTs and leaning technique in climbs to high DA,, or takeoffs from high DA. Though I've never actually done the latter, I might make it to Leadville one day. Because leaning to "target EGT" at WOT seems precarious to me, I decided to figure out as accurately as possible what that target value is. I looked at my JPI data from 50 flights, all of which were from near sea level and done in the colder half of the year- starting in Sept 2015 when the monitor got put in, until March this year. There was minimal variation except that two clear patterns emerged - in 70% of takeoffs, EGT on #4 was the hottest, with #3 100 degrees cooler. In the remaining 30%, #3 was the hottest, in which case #4 ran 100 degrees cooler. Peak FF was always in the 17-18gph range. Means and std. dev. for peak EGT on takeoff are shown below for the 2 patterns: Cylinder: Pattern 1 (#4 hottest): Pattern 2 (#3 hottest): 1 1260 +/- 11 1280 +/- 9 2 1296 +/- 14 1253 +/- 13 3 1321 +/- 20 1431 +/- 23 4 1427 +/- 18 1326 +/- 13 CHTs also run hotter in 3 vs 4 depending on which has the higher EGT for a given takeoff, making me think the two patterns reflect real shifts in mixture distribution, not measurement artifacts. There is no rhyme or reason to which pattern appears- it can shift on consecutive takeoffs under identical conditions on the same day. FWIW, I suspect neither #3 nor #4 is actually the leanest - #2 EGT usually but not always peaks first on leaning in cruise, and its CHT usually runs second hottest in climb (despite lower EGT), irrespective of whether 3 or 4 runs hottest (both CHT and EGT). Anyway, my only takeaway so far is that I can safely lean my hottest EGT (#3 or #4) up into the low 1400's to optimize power and improve fuel efficiency on a long climb, as long as the CHTs tolerate it. It's interesting to note that with a single probe EGT, this might have been a bad idea given the two distinct patterns of mixture distribution. Reasonable? Any other points to consider? Also, regarding high DA takeoff rolls (I have no experience), accurately tweaking the mixture to get low 1400s EGT seems precarious as heck . I have enough trouble staying on the center line, watching the ASI, checking the essential gauges, thinking about abort point, etc. in unison. It might be feasible if I used a particular high altitude field on a regular basis so could learn to set it roughly by instinct. The more complex technique to lean for high altitude takeoff has previously been covered well here.

-

This is the opposite of the typical issue. Not even sure if I want to call it a problem. My '64 E has always run cool CHTs. This is not an indication problem, as I have had it this way with two analyzers and the factory indication. Now that we are living back in CT and doing winter flying I figured I should explore it. In cruise, even at high power, and high EGT, with OAT near 0C, my CHTs are below the green (less than 300). In climb, I barely break the green. Today I climbed with the cowl flap closed and that got me 320 on the hottest. In the summer...even in the south...I might get 330, but even then 2 cylinders would be below 300. I have tried this at 100ROP, 50ROP, 25ROP, peak, and 25LOP. Does not make a huge difference. I checked cowl flap rigging today. They call for 2" full open for 64. Mine is actually closed a little from that, 1.5"... as called for later vintage Es. Oil temp is good at an average of 180. Questions: 1. Anybody else have similar situation? 2. Would this affect oil burn or break in? I have never gotten great oil consumption...5 hours/qt. this is before and after OH over 500 hours ago. My thinking is that the cylinder may not be at optimal operating temperature/shape. Would I get better consumption running slightly warmer? Thanks for any thoughts...

-

The analog CHT gauge in my M20J is reading well below (about 75 deg) what I see on my JPI engine monitor. Anyone know of a way to calibrate this instrument? The lead to the probe was shortened a little bit when the terminal at the end corroded, but it was probably a half inch, I can't imagine that would cause such an inaccurate reading. thanks in advance, Dave C

-

What's a normal CHT spread for a 1990 201? I'm seeing: 1. 291 2. 329 3. 354 4. 340 Or to put it another way, the spread is pretty consistently 50-75 degrees with #1 seeming pretty cold. They never really get hot unless you really screw up the mixture. I've replaced all 4 sensors, and their EGTs are always within about 75 degrees of each other. I'm trying to track down the source of an occasional misfire or backfire in flight. Some other issues as well, but I'll have to ask about them later.

-

I am looking for response from anyone flying a turbo or turbo-normalized aircraft. Most of the engines have a max manifold pressure based on continuous ROP max power settings. Have any of you experimented with trying to attain high horsepower numbers on the lean side of peak? I am assuming that running 80-90% HP while LOP may in some cases require MP in excess if not over redline. I know of more than a few TAT modded Bonanzas that are regularly operated at 85-90% power with excellent CHT numbers, however it does require enough MP to get to 70 to 100LOP. I would ask that those of you that use the POH recipe please refrain judging those who operate outside those parameters. I'd like to focus on engine ops and theory, so please keep the "you'll shoot your eye out" comments to a minimum unless they're accompanied by data or experience.

-

I have read a lot of post on the forums that mention swapping fuel injectors to help with EGT and GAMI spreads. I have not seen an overview of the process from ground zero. As I have read some of the threads it seems as simple as swapping the high EGT injector with the low EGT injector. As I read more it seems like there are contributing factors to EGT discrepencies such as induction leaks, probe placement, spark plugs and fine wire spark plug cables. I asking this because my plane is going in for its annual and would like idea of what questions to ask before having them swap injectors or if I need to at all. I have a 82 J with a EDM 700, FT 101 fuel flow indicator and GAMI injectors. My FT101 appears to be almost .5 GPH off indicating a higher fuel burn but I have a few result of flights I can share. Flight #1 5500 MSL, 24" MP, 2400 RPM, 9.4 GPH LOP. #1 1421 356, #2 1407 321, #3 1360 308, #4 1425 333 Flght #2 7500 MSL, WOT 22.5"MP 2500 RPM, 9.5 GPH LOP, #1 1417 352, #2 1408 326, #3 1348 290, #4 1447 343 The best I can tell so far my GAMI spread is between .2-.5, I'm still playing with it but my feeling is .3, but is that possible wth almost 90 degree difference in EGT's. The order in which the cylinders peak is #2,#3,#1,#4 After I get the EGT's figured out I'm going after the CHT's Any advice is appreciated.

-

I have a problem with the oil temp and CHT gauges. Oil temp sometimes works, sometimes doesn't. When I turn power on, both gauge needles dive to the left. When I disconnect the sender for the oil temp, it does the same thing. When I ground the sending units lead (off of the sending unit), it deflects all the way to the right. Cyl. head gauge does the same thing but when hooked up, it's dead all the time. Both the sending units show resistance. Whats up and what to check next?

-

My "J" is ready for its first annual since I bought it one year ago. My new mechanic refuses to sign it off because the original EGT has been replaced with a EI analyzer which he says is not a "primary" part. He wants me to replace it with the old original part. He also has an issue with the nav lights because the nav lights were replaced with LED lights and don't have a Form 337. So I am wondering why the last eight mechanics didn't have a problem with it? Also, the "J" I owned before this one had the same 4 cylinder EGT/CHT guage and that passed as well. I've seen the same gauge in several other Mooneys too. I would consider going back to a one cylinder engine monitor a safety issue. Why would I want to return to monitoring one cylinder when I have the EI instrument which monitors all four cylinders EGT's AND their CHT's? And I would consider the LED lights much safer than the original and hotter nav lights too. I mean is replacing a nav light really a MAJOR alteration that requires a 337? Am I the only one that thinks that these two issues are ridiculous????

-

From the album: #29-0363's album

29-0363 G1000 MFD display in cruise @ A080 -

Hello Forum, I just bought my first Mooney (a '68 M20F with J windshield, cowl closure, and other mods). What a great plane. But on the 15 hour flight back home, I noticed EGT readings I didn't understand. I was wondering if anyone on the forum had any thoughts on the issue. The plane has an Insight GEM 602 for EGT and CHT on all cylinders, plus an analog EGT meter in the panel. After engine start, EGT's and CHT's come up evenly across all four cylinders, and come up further during the runup. In climb running full rich, they remain fairly even across the board, and CHTs remain around 375F. But once I configure for cruise and lean conservatively (10% richer than book ROP fuel flow for my chosen power setting, measured with a Shadin fuel flow meter), the EGT for cylinder #3 starts acting up. It oscillates, plus or minus 50F at first, and then gradually the oscillations increase until after an hour of flight they are going from bottom to top to bottom of the EGT scale. The temperature will drop off the bottom of the scale for maybe 5 seconds, and then will shoot to the top of the scale and stay there for another 5 seconds. After 2 hours, the reading biases towards the bottom of the scale, and eventually the EGT drops off the bottom of the scale and stays there. The analog EGT meter in the panel does not quite follow the same pattern, but it's similar. It reads around 1200F through the runup, then flaps around rapidly in flight so much it is impossible to get a solid read on it. It never goes above 1200-1300F. Then it starts reading colder and colder and eventually it, too, falls to the bottom of the scale (<800F) and stays there for the remainder of the flight. I do not know which cylinder this EGT is reading. I assume it is cylinder #3. The EGTs on the other 3 cylinders are all steady and respond as expected according to the GEM. CHTs on all cylinders, including cylinder 3, are always steady in the 375F range. Cylinder #3 CHT is no different than the other cylinders. The engine otherwise seems to run like a clock. It only has about 650 hours on it SMOH (Penn Yan). The aircraft cruises at 150-155 KTAS at around 65% power and 10000', so it seems to be putting out full rated power. There are no unusual sounds or smells or rough running. Any ideas?

-

I've been messing around with running LOP and like the results as far as GPH (8.5 at 7-8k) and CHT temps ( -30 degrees) go. My question is regarding my EGT's. While running 100 degrees ROP the highest and lowest are on average only 10 degrees apart. LOP they are 80-90 degrees apart and overall about 75-100 degrees hotter with the hottest being in the mid to high 1400's. Is this consistent with running LOP vs ROP? Engine runs smooth, although it did feel a little weird pull back so much the first few times.

.thumb.jpg.ed6aafa91f819cec0d83fd72d0471094.jpg)