Search the Community

Showing results for 'hendricks'.

-

Hendricks Engineering did my first M20E Pilot side. They did very nice work. Those panels looke great here. That lighter color is really tasteful Igor. Love it.

-

Practicality of purchasing someone's Aspen 1000?

LANCECASPER replied to AlexLev's topic in Avionics/Panel Discussion

@AlexLev I would grab the Aspen if he is offering it. The Pro 1000 is not the Max but will do fine. I probably wouldn't pay more than $1000 for it though in today's used avionics market. If you're going to pay much more plus the labor to do it then you start thinking about GI275s, which wouldn't require a new panel. It was designed to work with legacy equipment. It will work fine with your Garmin and your King. He probably has an Aspen ACU (Analog Converter Unit). If not they are very reasonable on the used market. I think you can do it for much less that what you mentioned. As far as panel, this is your chance to get the left side cleaned up and much more ifr-friendly. There is a Mr. Lyle Hendricks that used to come on here (https://store-hendricksmfg-com.3dcartstores.com/About-Us_ep_7.html). I believe he owned an C model Mooney. But he has the capability of producing a new panel much more reasonably that most other options. https://store-hendricksmfg-com.3dcartstores.com/Custom-Instrument-Panel--Engineering-Deposit_p_52.html (look at all of the pictures on that page especially the FAQ picture.) Here's a search of posts that mentioned him: https://mooneyspace.com/search/?q=hendricks&quick=1 He used to make a great Garmin GPS496 mount for the Compass post. I bought a couple of them over the years. I still use one to mount my Sensorcon CO monitor on my compass post. Another option might be @Aerodon who also does panels. If your Pathfinder autopilot works I'm not sure if that will interface, but the Aspen will handle most legacy autopilots. It should work since your Pathfinder doesn't have ALT hold and doesn't require attitude input (I think). The NAV and HDG should interface with the Aspen ACU. Normally I hate to see someone tackle a big avionics project with used equipment(since labor is the same on new and used), but this one shouldn't be that difficult if you have a shop that is open to the idea that you will be providing your own panel and Aspen. If you decide to go this route, please, for the love of all that is good, flush mount the Aspen . . lol Here comes the "while you're in there" thoughts: You might also consider this as an opportunity to do the right side as well and install a certified engine monitor that let's you get rid of the 55 year old instruments that will eventually fail. Here's an idea of what someone did, although not exactly what I would do. But it gives you an idea. https://mooneyspace.com/topic/28197-cgr-30-or-mvp-50-i-guess-install-time/#comment-475214 -

Considering engine monitor EI CGR-30

DCarlton replied to Rusty Pilot's topic in Engine Monitor Discussion

Was thinking about engaging Hendricks. Is the pilot side still mounted on shock mounts with the same tilt or is it more vertical in inset? How did you close the gap between the radio stack and the panel? Thanks. -

Considering engine monitor EI CGR-30

MMsuper21 replied to Rusty Pilot's topic in Engine Monitor Discussion

Here is the completed pic and thanks. Pilot side is Hendricks MFG, happy to share the template I used. Right side local guy. -

-

Mind me asking who made your panel (the sheet metal). I'm thinking about contacting Hendricks.

-

Way cool! You’re using a Hendrick’s manufacturing panel! Haven’t seen Mr. Hendricks in a while… He has an MS user name around here somewhere… Best regards, -a-

-

Met Brian Hendricks Mechanic? He was test flying this Acclaim out of Mexico. He was at the self-service pump yesterday and I walked up and asked if I could take a picture. Said he was a mechanic out of San Marcos and regularly flies to Kerrville on test flights. Tall and lanky guy. Thin shouldered. No wonder he likes Mooneys. seemed like a nice guy.

-

Pretty sure my yoke has vertical movement... Thanks for the info @carusoam Hendricks mfg is doing the panel for me, I should do the acrylic mock up. I do recall seeing the ADI/DG moved up on some panels. @0TreeLemur looks like you made it line up and fit somehow. Looks like its fine without the GI275. The other option is doing the AV30s or G5s half the depth and AMUs.

-

I am a start / stop again instrument student and working becoming a start again instrument student maybe. For what it's worth I think at a minimum get left side shot gun panel layout cleaned up to a standard six pack layout. I believe Lasar not sure if they still them or not, Hendricks Manufacturing http://www.HendricksMfg.com/ and others out there will sell you a left side panel. Talk to your IA first see if they are willing to assist willing to allow you to do this. I get the the shot gun panel layout for VFR flying, since I had one for many years but for instrument training you will probably save time money and little frustration in the long run. So I would suggest on getting at least the left panel to standard 6 pack layout configuration. I am sure that you could learn in the shot panel layout configuration but if you ever decide to sell or rent or fly right seat someone else plane my guess it will transition a bit easier. since it one less thing to learn. Just my opinion hope this helps, James '67C

-

There are several routes people take on this... including designing and cutting their own... There is also a resource to just buy the modern standard layout cut and ready to finish... Find Lasar... and be ready with your details and your question... Another resource that made some nice panels around here... hmmmmm... Hendricks Manufacturing? Best regards, -a-

-

I can’t get a pen or finger to work on the iPad in turbulence. The Hendricks 9G is popular with the warbird crowd. You can attach checklists with split rings on the loops to keep them handy and it’s comfortable.

- 26 replies

-

- knee boards

- flying gear

-

(and 1 more)

Tagged with:

-

Your panel looks amazing! I have been playing around with solidworks learning how to design the panel I want. Do you happen to have a file for this panel or did Hendricks do that in the background? Also between the left and middle is there a ramp down or how do the two panels fit together there? Erik

-

Hi I am looking to re-arrange my old left hand side scatter gun panel into something (relatively!) more modern. I'd love to go glass etc but for now this will do. I looked at Hendricks Manufacturing fantastic panels and was going to go that route until it appeared my hangar neighbour owns a metalwork facility and CNC machines and offered to help! I have produced the sketch using Front Panel Express and am looking to order from them and then refine it if needed using my friend's help. PDF attached, let me know what you think. I still need to re-arrange some holes etc but that's most of the design work done so far. I am going to have that panel vertical so will need to include the bend on the right hand side to accommodate the old panel layout. Anyone know what the dimensions of the side triangle are? Any advice on replacing the mounts and how to best mount the panel? Also anything to watch out when placing the magneto switch? oydfd left panel curved v1.pdf

-

How to make my switch panel look decent?

carusoam replied to bavareze's topic in Vintage Mooneys (pre-J models)

People are mostly replacing the aluminum sheet that makes up the three sections of the instrument panel... One of the coolest M20Cs just traded hands this week... it belonged to @gsxrpilot and was sold again... There are several pre-designed panels from Lasar or Hendricks... These can be updated as well... When it comes to designing panels, EAA hands out cad software to help... join EAA first... There are threads around here where people discuss their panel drawings... that is a great place to start... Then select the finish... then the graphics... There are infinitely many solutions... The aluminum is cheap... The project gets difficult because it is 3D... there is a lot going on behind the panel... Refreshing what you have is possible... expensive... and it looks like somebody else put a big decal on it... that is probably not original... Function over looks should be considered as well... Very often, people replace engine controls at the time of OH. They have been shown to not last forever... and their cost of failure can be enormous... PP thoughts only... Best regards, -a- -

There are a few resources around here from doing your own layouts to match the new equipment that is available.... Lasar has a few options... Hendricks was an MSer for a while and made some really nice pieces of metal. http://store-hendricksmfg-com.3dcartstores.com/Instrument-Panel_c_13.html Members of the EAA have used free copies of a cad software package to do panel layout work... There are many MSer panel layouts getting shared around here... The latest have Dynon square panels... in place of the old round dials.... Get your Mooney back on! Best regards, -a-

-

I did my own in a 67F, this panel came from Hendricks mfg. it cost 2.5amu or there abouts, took about 20-30 hrs...Had to remove prop and mixture cables, good excuse to replace. That prob took the most time. Sent from my iPhone using Tapatalk

-

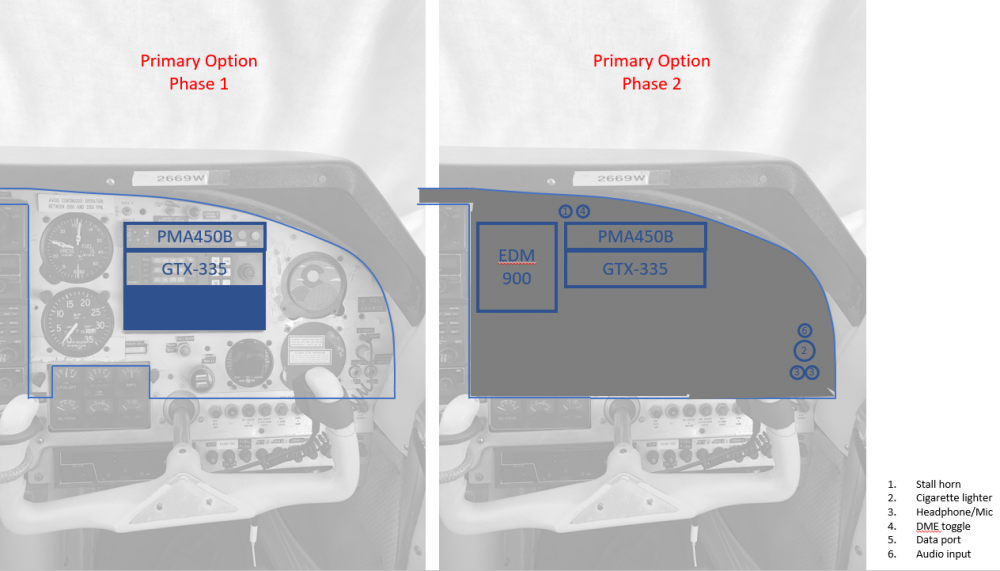

Hey guys, Looking for some advice as I embark on upgrading the copilot panel on my E. My first priority is a new audio panel and second is a primary engine monitor - assuming my first annual goes ok and I don't have to reverse course. I'm thinking of breaking this up into two phases. First phase, remove the old loran, the old CP136, and install the new audio panel. When I do that, I'll have a lot of temporary panel covers everywhere. Any tips on how to improve the looks of this until phase two starts? Is there anything a little better than a bunch of plastic covers? In phase two, I'm going to install the EDM 900 or CGR Combo, remove the Garwin cluster, the tach, the MP/FP, the Hoskins, and the 700. I think I am going to have Hendricks fabricate a new panel and get it powder-coated locally. Right now my plan is not to touch the breaker strips or anything else - maybe that's phase three. However when I do phase two, I'll have a couple gaps in the breaker strip where the Garwin cluster was, as well as in the bottom metal strip where the Hoskins was. Any ideas on how to clean that up with a short-term type solution? Other than that, does this approach seem reasonable to you guys? It's my first upgrade, first plane, all that, so any advice is welcome! Thanks.

-

Welcome aboard JD. Many have had this done... It is a bit complex depending on a couple of things... 1) what plane you have... 2) what avionics you have... Other than that, how else can we help you out? 3) Some standardized Mooney choices are available at Lasar... 4) If you search around here there was an MSer named Hendricks Manufacturing that had a couple of Mooney panels designed and made available.... Other than that... if you have a larger budget and are planning a 50amu panel update... start with your instrument shop... Best regards, -a-

-

64 M20C interior placard?

Prior owner replied to Supercop0184's topic in Vintage Mooneys (pre-J models)

I just re-traced mine with a narrow felt pen... not great looking, but okay. Hendricks makes panels and has a pic of one or both of those on their website- they make them out of aluminum. Go to bottom of the page: Hendricks -

I wanted to update my thread, here is the latest in my several month long project. here’s before/after pics. If your interested in during pics, which are not for the faint of heart, I can provide as well. Project consisted of installation of: EI cgr 30 c Garmin GMA 345 audio panel Garmin GTR 225 radio EI usb hub McFarland mix control Hendricks avionics panel Sent from my iPhone using Tapatalk

-

CGR-30 (or MVP-50, I guess) install time

carusoam replied to johncuyle's topic in Avionics/Panel Discussion

The Hendricks panel looks nice! Great location for the EI. Best regards, -a- -

CGR-30 (or MVP-50, I guess) install time

Clparker23 replied to johncuyle's topic in Avionics/Panel Discussion

I installed a CGR30c with mechanics sign off, new Hendricks avionics panel, new circuit breakers and mixture control. Took roughly 20 hrs for cgr 30c. Main thing was needing a fitting or 2 that wasn’t the anticipated size on existing equipment. Pic is on first test flight, still had a few things left to do. Sent from my iPhone using Tapatalk -

I'm aware re Hendricks. In fact, I linked to the page where he's posted his Mooney panels. The reason I'm piecemealing, as I explained, is I *don't* know what direction I'm ultimately going in. It could be Aspen + TruTrak + EDM-900, but if it's STC'd for the Mooney, it more likely will be Dynon Skyview HDX. If Garmin gets their act together, it could even be G500 + GFC500. I know I want an engine monitor more modern than the EDM-700, an autopilot with altitude preselect and approach capture (with heading, VOR/LOC/ILS tracking, and GPSS/vertical guidance; S-TEC 55X or equivalent, TruTrak + Aspen may be moving that direction...), and some sort of EFIS or, better yet, PFD. I can fly steam. I prefer to fly glass, single pilot IFR. So I'm not ready to lay out everything and start working on a grand master plan. I just want to clean up that right panel for the next year or so, while I wait for the avionics world to settle down a bit. This is mostly an overlay - it will frame the strip gauges, the tach, and the MAP/FP gauge, while holding the suction gauge and one set of circuit breakers. (Ultimately, a whole right panel will be done, with all the breakers consolidated, etc., but until I know what - if anything - I'm hanging on that right panel, doing that would be incredibly premature.)

-

Chrixx, Looks like somebody used a big piece of temperature sensitive tape to hide some minor surgery(s) of the past... temperature sensitive, meaning it shrank when it got hot... Doing it right, once isn’t so bad... repeating the work is when it gets expensive... Especially when removing and replacing the same instruments, the hours add up one amu at a time... Hendricks had an early start as an MSer. He has personal Mooney experience and a machine shop... His website includes some nice pics of actual Mooney IPs... If you know which direction you are most likely going... it may make sense to define your end product and get a panel or two cut... With an F, I think I would go with the Marauder model... then fill in the hardware as the hardware becomes available... Or an E, Bob has a pretty snazzy panel layout... Or a C, there is a really cool Swiss layout... Or an O, Steven has the panel I would start with.... GSXR, Our 252 friend in TX has the best hardware acquisition strategy... one piece at a time...from various sources... The panel sheet metal is pretty low cost if you can do the one and done routine... get new mounting hardware, select the color... Always make forward progress, not enough dough to do things twice... my own CB philosophy... really great if you have a working relationship with a mechanic... PP thoughts only, not a mechanic. Best regards, -a-