-

Posts

963 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Bolter

-

Anthony, like you, bendix gear or the solenoid is my first suspicion in these cases. Upon turning the key, I can hear (and feel it when someone put their hand on it) the solenoid engage and the starter power indicator comes on the panel. I can trigger the solenoid to click in and out when pressing the ignition in and out, so I believe the switch is good. Distinctly no whirring sound of a starter motor free spinning. No Bendix gear with the Skytec NL...I think another Skytec model may use a Bendix gear. I removed top cowling, and I could reach down and turn the starter's gear freely, so it is not seized. If the shear pin gave, I think the starter motor still turns, but the gear does not. Voltage was good during the short flight to fuel. Showing 12.1 volts on the JPI which requires that the master and avionics be switched on, so there is a load just to check the voltage...not ideal but I had no handheld voltmeter with me. Does Garmin G5 show bus voltage anywhere? That would be one less set of loads to turn on when checking voltage. Never a guarantee of anything, but the battery is Concorde AGX from March, so I *expect* it is still good. Tomorrow I will be there is voltmeter and remove both cowlings. Then I can precisely check for where the voltage is, and access the starter's connectors. Anyone else have the binary failure mode for the Skytec? It was working fine, then it wasn't working at all. At least the old bendix gear starter failed over time with plenty of warning. It has been 4yrs 3mo and 400 hours since install. If it is the starter, I am very disappointed. I expected it to last much longer.

-

I probably need a referral for a shop at Arlington, WA (KAWO). I think my SkyTec starter is blown. I will make a better diagnosis tomorrow, but I expect to need a shop, as I do not think that a starter is owner serviceable, though easy to do. On the plus side, more options than getting stuck at Harvey, and better than being stuck in the Bay Area where I was going this weekend can scrubbed due to the weather. Pinging a few PNW flyers I have seen on MS: @amillet @wombat @M20C_AV8R @FlyingAg14 thanks, -dan

-

Step 1, contact your insurance agent

-

Prop governor won’t cycle on the ground but works fine in the air

Bolter replied to tigers2007's topic in General Mooney Talk

Did you review the work done on the plane during the annual? Was the prop removed or other opportunity to block an oil passage? Anything else that could have interfered with rigging the governor control cable? Real-Life Mooney Example (not my story, so no names will be given): Prop removed and a rag stuffed in the crankshaft to stop the oil from weeping out. Prop reinstalled. Rag still there. Failed the run-up and rag was found inside. -dan -

Another satisfied customer report, like the OP. I have the same setup of G5 for the HSI and KAP 150 for about a year. It has worked well, much better than the original HSI. In my case it also showed me that what I thought was a flaky AP turned out to be flaky signal from the old HSI. Installed about $6k including the G5, Magnetometer, the D to A interface to connect to the AP, and the labor.

-

Need to replace Cylinder 2 and muffler

Bolter replied to FlyBoyM20J's topic in Modern Mooney Discussion

I don't know what circumstances lead to a bent push rod, but it seems like it must be severe. I would like to understand what has happened here. Would this occur only if the valve did not open for some reason? In which case, instead of concerns about compression, you would need to check the linkage between cam and valve to see what was binding? Failed bearing/bushing of the rocker? The valve itself welded in its guide or stuck to the valve seat? The OP states that contact indications on the piston face exist. This means the exhaust valve was stuck open, correct? This should lead to a push rod flopping around, not getting caught between the cam lobe and an immovable valve. -dan -

@Chopper Dog The ebaydesc.com site was hacked in the past as part of a phishing scam. If you entered your ebay name and password from there, it gets stolen. I do not trust that link. This is the ebay.com link for anyone who prefers it: https://www.ebay.com/itm/1968-Mooney-M20F-Exec-21-Logs-Complete-Always-Hangared/323654202587?hash=item4b5b4b34db:g:FbcAAOSwqiJcM4oY

-

Beautiful Low Time 1983 M20J 201 For Sale *SOLD*

Bolter replied to Davarron's topic in Aircraft Classifieds

To someone on MS? Which city will she move to? Just curious because I remember this J at Mooney events in SoCal, when I lived in LA. -

That is even worse! You did not have the plane at all in that time, after the sale.

-

Yep. Just does not seem right if the associated tax year begins 6 months later, and I am not there to receive the supposed benefits of those tax dollars.

-

I searched old posts, and did not find something exactly like this. After many years in California, paying my taxes like a good citizen, I have moved. I moved after the 1-Jan census, so I am on the records, and required to fill out my annual assessment. The plane was moved from California to Washington in March. I have updated the FAA registration as well. Since the California tax year is July to June, I will not be there during the tax year. Can I be exempted from paying the 2019-2020 tax bill, even though I was based in California on 1-Jan when they did the census? Since I will pay a Washington fee, is this considered double taxation? Is that a something I give to California (Orange County Assessor) to exempt myself? thanks, -dan

-

I believe a QC issue at Champion. I bought 8 new plugs because I wanted a clean slate. I know these were never dropped. I sent the good and bad ones to Champion with a letter explaining the history, and that 2 plugs, 100 hours apart and so early in life is a trend, not an anomaly. Especially on an engine that had not a single other squawk in 800 hours in 8 years that I have owned it (400 hours on the engine when I got it).

-

In my case, by 270 hours, I had cracked 2 Champion fat electrode plugs (2 different cylinders at different occasions). That was end of life in terms of trusting them. Got 8 new Tempests. The condition of the uncracked and cracked Champions' electrodes was great otherwise.

-

Looking for a Garmin shop around socal? up to 400NM Ish

Bolter replied to Niko182's topic in General Mooney Talk

Did you check HIgh Desert in Lancaster (WJF) already. They are popular so it may be a long waiting list. They did all my avionics work, including ADS-B. They are a Garmin dealer and closer to you than some other locations listed here. You can take the Metrolink (which is a long trip, but better than nothing) between Lancaster and Santa Ana if you cannot get someone to ferry you. -dan -

I will be attending the Mooney Safety Foundation PPP class at Santa Maria. I will be flying down from the PNW (as of this weekend, I'm based at Harvey, S43) and wanted to know if anyone else will be attending from this area and wanted to coordinate? This is the only West Coast option for the course until 2021, I believe. -dan

-

I did the same thing departing OSH this year. Mix of distractions and non-standard operations leading to my own carelessness. Due to the long taxi on rough grass at OSH, I had the trim max back. I think my nose rose faster than @jaylw314 did in his video, so I was reacting sooner. I was correctly trimmed before the mains left the ground. Lesson (re-)learned about distractions.

-

The multiple users add variability. It is good that you are all disciplined and cooperative. I think it is essential with 3 owner-operators that you are all agreed on a standard operating procedure (SOP) for the engine. This means talking about it on the ground and sharing data and assembling a written SOP (a simple bullet list). Then you should go flying together and share the experience of ROP or LOP at several conditions, like practice IFR. 2 pilots watch the engine monitor, the other flies the plane and radios. You may need an explicit rule, such as from @kortopates 's list that starts with " when pilot workload permits", that states clearly to remain ROP until the pilot can commit the time to operate LOP with full attention to detail. tschuss, -dan

-

Columbia (O22) has a large event around Father's Day each year that has had a good Mooney presence with Mooney Ambassadors promoting it to its members. https://fathersdayflyin.org/ There is camping there all year long, so it is a good fly-in destination for a Mooney meet-up outside of the their scheduled events.

-

I have not been very active in promoting the sale of my old exhaust, and now it is a few years later and I am moving to Washington State. I don't want to haul this large box around. Final offer is FREE to anyone who wants to meet up somewhere near me in the Fullerton, CA general area. Otherwise it is going to the trash in February. PM me if you want to coordinate a pickup. thanks, -dan

-

The Modern Mooneys have batteries in the tail, so they also have a long lead to the starter. I think that your Cherokee had a current leak, major resistance somewhere or a bad starter, if it was that sensitive.

-

Adding to @Danb comment, typical airliners are at 8k foot pressure inside, and small children fly 11-12 hour intercontinental flights (usually in the seat right behind me) without ill effects or concerns of ill effects.

- 17 replies

-

- 2

-

-

- high altitude

- oxygen

-

(and 2 more)

Tagged with:

-

Specific example of prop strike leading to eventual failure. Cracks take time to propogate. This is why I think a ferry flight is safe, but the engine/crank are still a high risk to ignore for the long term. NTSB Identification: ERA10LA175 14 CFR Part 91: General Aviation Accident occurred Monday, March 15, 2010 in Hilton Head Island, SC Probable Cause Approval Date: 06/27/2011 Aircraft: SMITH EDWARD I LANCAIR IV-P, registration: N9JE Injuries: 1 Fatal, 2 Uninjured. NTSB investigators may not have traveled in support of this investigation and used data provided by various sources to prepare this aircraft accident report. **This report was modified on 8/8/13. Please see the docket for this accident to view the original report.** The pilot stated that while in cruise flight he observed the instrument panel begin to vibrate heavily and oil begin to cover the wind screen before hearing a loud "bang." The engine then lost power as oil continued to obscure the wind screen. The pilot had no forward visibility and could not maintain the airplane's altitude. He elected to make an emergency landing on a nearby beach and during the landing the airplane struck and killed a pedestrian. Examination of the airplane revealed that the propeller assembly separated from the crankshaft and was missing. The propeller assembly and propeller flange were not recovered. An examination by the NTSB Materials Laboratory of the crankshaft revealed that the aft face of the fracture contained crack arrest marks. The fracture of the crankshaft was caused by multiple-origin fatigue cracks that emanated at the aft relief radius for the propeller flange. The records for this engine and airplane do not show an entry of a propeller strike. However, multiple-origin fatigue cracks that extend nearly 50% around the circumference of the aft relief radius for the propeller flange suggest that the propeller had struck an object prior to fracture of the crankshaft. In the absence of material anomalies, the fatigue cracking appears likely to have been caused by external impact stress, such as a propeller strike. The National Transportation Safety Board determines the probable cause(s) of this accident as follows: A loss of engine power due to the failure of the crankshaft as a result of a previous propeller strike.

-

power loss on takeoff when cold M20K 231 Turbo

Bolter replied to Aspen2013's topic in General Mooney Talk

I don't know the finer details of the aircraft turbo systems, though I understand the supercharging cycle well. Is the wastegate actuator hydraulic, using pressurized engine oil? Or are they purely some simple spring and diaphragm mechanism? I would be happy with a link that describes the function of the Continental Turbo engine controls with Merlyn wastegate. Just the thoughts of a normally aspirated pilot, not an A&P :-) -

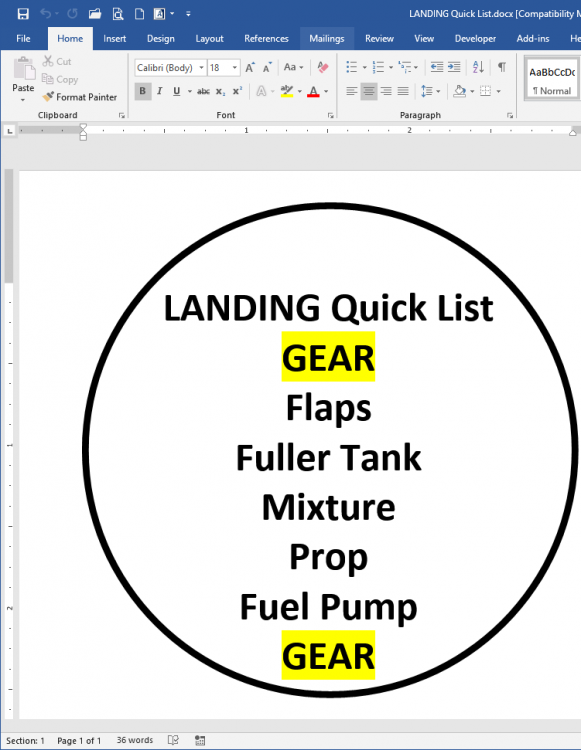

I do not have speed brakes, but since they can be deployed at any time, they may increase the opportunity of losing speed without dropping the gear. Maybe a speed brake user has a thought on that? I made this sticker and put it over a blanking plate on my panel, visually even with the AI: