FlyBoyM20J

Basic Member-

Posts

184 -

Joined

-

Last visited

Profile Information

-

Location

PA/NY

-

Model

1982 M20J

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

FlyBoyM20J's Achievements

-

Help identifying air duct for 1982 M20J

FlyBoyM20J replied to FlyBoyM20J's topic in Modern Mooney Discussion

Thanks Clarence! -

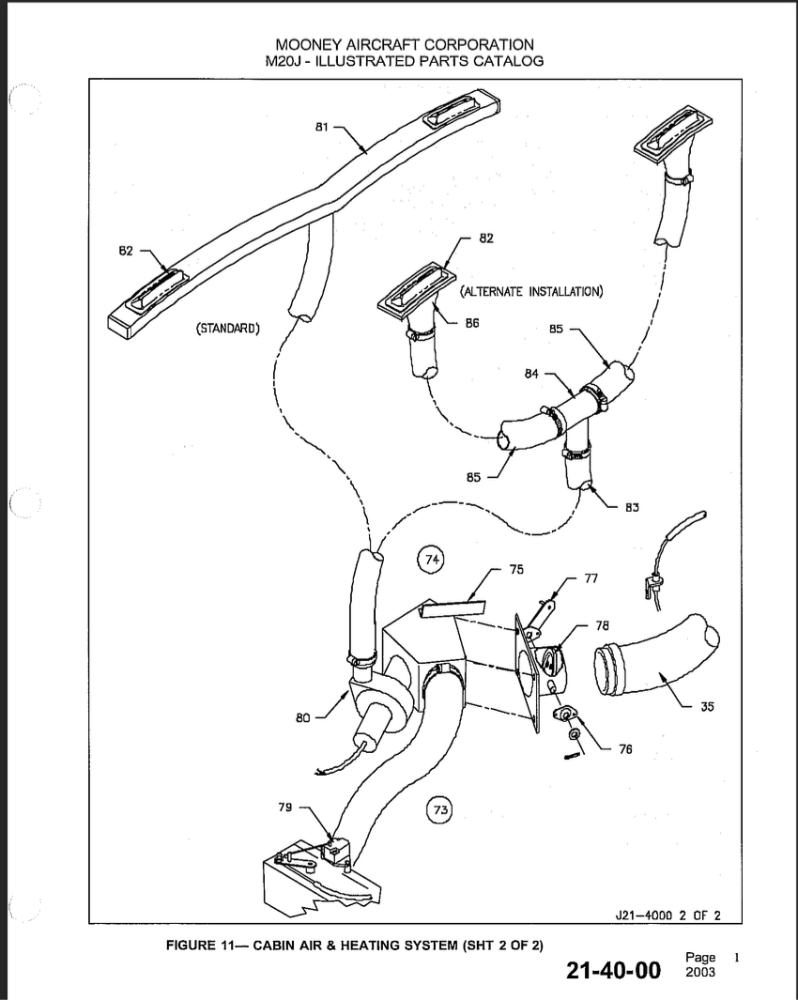

This duct is disintegrating so I didn't want to take it off to see if it has a more complete PN on it. This is co-pilot side, and the plane's SN is 24-1298. I'm not 100% sure which duct it is in the IPC diagrams (attached)...I think it must be item 35, PN 912007-503 but I'm not finding that part online easily. Has anyone had any luck replacing or repairing this duct? Thanks again, Cliff

-

All, my apologies, I got sidetracked since I was able to fly that same day once the problem was solved. It was a bad GND connector on the back of the alternator. I am reviewing everything now because this alternator needs replacing soon if not sooner. Here's the connector...doesn't look too bad, but it also looked uniformly "dusty" as if it hadn't been touched in some time. When we loosened the bolt, lots of mineralized dust fell down from between the washers, the lug, etc. We cleaned it and the other end, and that was that. Perfect charging for 2 startups on the ground and then I took off on a longer XC flight (some 6 hours in 2 legs, no issues at all). Cliff

-

1982 M20J, SN 24-1298 My alternator seems to have kicked the bucket. Intermittent lack of charging last couple of flights that corrected itself once, so I was looking for a bad FIELD connection; cleaned that and tightened it; no luck at run-up this morning. Also, should mention: the belt is in great shape. My A&P and I replaced the belt shortly after I bought this plane about 4 years ago. With engine running on ramp: HIGH/LO VOLTS annunciator is flashing, so per the POH, this is a low-voltage situation. Ammeter is discharging and JPI reports 12.5V. Toggling ALT FLD and ALT breakers and MASTER has no effect on the situation. Back in hangar, FIELD wire looks good, VR looks new (is in excellent position above copilot's left knee). I realize I need to measure the FIELD current to be sure, or at least ring out the wire, but based on the findings above, it seems like time for an alternator and I can ring out the FIELD wire when I replace that. I realize this does not rule out the VR but the visual inspection suggests all is well with VR, wires and FIELD all the way to the stud on the back of the alternator. Also, I'm not sure how a failing VR internal circuit would self-correct like a mechanical system would, or like a bad connection would. But I'm not well versed in these systems. Looking at the logbooks, this alternator (and the VR) seem to be original equipment. No mention of them in the logs. Here's the information plate: The Lycoming IPC has PN LW-14333 for alternator ALY-6420LS for IO-360-A3B6D, and Spruce lists the ALY-6520R as the correct replacement for the LW-14333. But there's also an ALY-6520RLS, below that one, at this location: https://www.aircraftspruce.com/catalog/elpages/electrosysalt1.php?clickkey=504227 Does anyone know whether I should get the ALY-6520RLS version or is the information in Spruce correct, and I should order the ALY-6520R? Thanks again, Cliff

-

Update, 3 weeks later, it is fixed! Thanks a million to Dave & Lisa at Air-Mods in NJ! Perfect fit! Flew home after the install and, if anything, there is less vibration now than at any time in the last couple of years. That said, I will have it balanced ASAP. Thanks, also, to Clarence @M20Doc, who has a part and was going out of his way to help me on his vacation a couple of weeks ago. The local mechanic where I got the plane stuck *thought* he had found a part right away so Clarence said go with my mechanic's find, but that turned out to be the wrong part. Meanwhile, Dave from AIr-Mods had had a chance to visit his Georgia location and brought this one back with him. Thanks, not least, go to the local mechanic but I'm not sure he wants to be on the internet so I'm leaving his name and the field location out of this post. He rocks, though. Cliff

-

The plane is a 1982 M20J, SN 24-1298. I and a safety pilot were up for some approach work yesterday when we both heard a loud noise from the engine...no real vibrations (going along at ~25.5", 2550, 160 kts TAS, 4k MSL, VMC), but the noise got louder over perhaps 20 seconds such that I and my co-pilot agreed that it was real...and I was sure I had never heard it before. It sounded like a chainsaw engine revved up and getting closer (growing louder, but constant pitch). About that time, we could both smell a whiff of smoke. I removed the hood (yeah, this was fun to figure out with that thing on right at the beginning), and there appeared to be a tiny bit of smoke coming from behind the spinner, so I immediately pulled power back, checked pressures, temperatures, JPI graphs, all good, and the noise lessened with lower RPMs. I notified ATC and diverted to the field right below us, did uneventful landing in VFR conditions, and pulled the top cowl on the ramp for a closer look. This is what we found...no other issues anywhere on the plane, no more oil on the gear doors than I'd expect for an hour of flight, etc. And a fair bit of chewed up fiberglass stuff in the intake filter and at the oil cooler. JPI engine data from this flight looks like any other recent flight. Engine unaffected, at least, in the couple of minutes that it was running between pulling back power and shutting down on the ramp. So, looks like I need a new bulkhead. Given my SN, this would be PN 680031-017. Any leads? I have already talked to Dave @ AirMods and he thinks he has one in his GA "warehouse". But that's uncertain and he's not going there for a while. Looks like I am going to need some fiberglass work, too. The top cowl got a hole punched through it (see pic) and there's one on the opposite side but it is otherwise undamaged and assembles like it always did. Bottom cowl has some minor damage. Cheers, Cliff

-

Just saw this...I don't have any fluctuations as long as I've manipulated the spade connectors on the back of the master switch recently. Meaning, every 6 months or so, I start to see the ammeter needle move slightly and so I generally take the spade connectors off the back of the 4 spade lugs, inspect, and put back on...and problem solved until a few months later. I can only assume some oxide is building up but I can never see anything. Most recently, I didn't even remove the connectors. I simply touched them and the needle stopped moving. That was a couple of months ago, so I expect I'm about due. Cliff

-

Both wing strobes suddenly no longer work

FlyBoyM20J replied to FlyBoyM20J's topic in Modern Mooney Discussion

This sounds perfect...is the STC included? Cliff -

Both wing strobes suddenly no longer work

FlyBoyM20J replied to FlyBoyM20J's topic in Modern Mooney Discussion

Thank you! I am away from my plane for a few days...back at it next week, and if I decide to stay with Xenon tubes and Hoskins, I'd be grateful for a working Hoskins unit. I'll dm you my phone number at that point...don't want to make you dig through your parts unless I'm going that route. Cliff -

Both wing strobes suddenly no longer work

FlyBoyM20J replied to FlyBoyM20J's topic in Modern Mooney Discussion

This looks perfect! I have the same wing tip extensions/fairings...Will check website, but I'm assuming that the way to wire these LEDs would be to bypass the Hoskins units in the wings...would be nice to remove them but they don't seem to cause much of a problem. Cliff -

Both wing strobes suddenly no longer work

FlyBoyM20J replied to FlyBoyM20J's topic in Modern Mooney Discussion

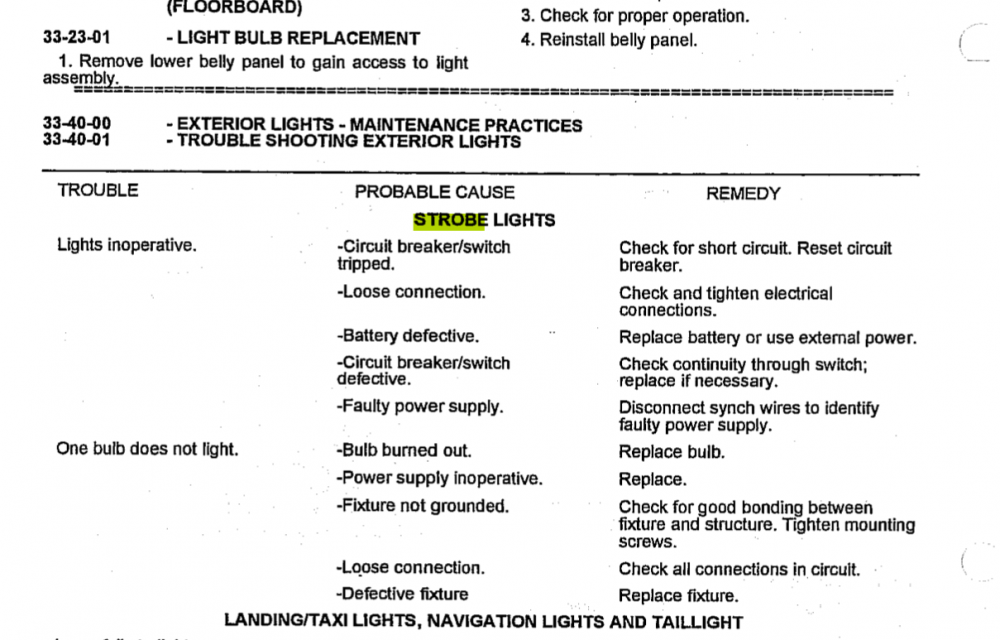

I found this, so I guess I can fix the broken PS (thanks NicoN!), but I'm leaning toward LEDs at this point... Cliff -

Both wing strobes suddenly no longer work

FlyBoyM20J replied to FlyBoyM20J's topic in Modern Mooney Discussion

Has anybody done this with Lasar wing farings? I have those on this plane.... -

Both wing strobes suddenly no longer work

FlyBoyM20J replied to FlyBoyM20J's topic in Modern Mooney Discussion

This is what is in the maintenance manual...so...likely a bad Hoskins PS that can be isolated by disconnecting SYNC as N201MKTurbo suggests?