1980Mooney

Basic Member-

Posts

3,337 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

I previously painted my interior gray. I left the trim, original beige. I think it looks just fine.

-

AOPA has a sample Aircraft Purchase Agreement online. It has multiple options on the language. One way is to have the Seller pay for discrepancies related to airworthiness. The alternate language states Seller is to pay for all discrepancies. Otherwise the Seller can back out and escrow is returned. It even has language that the Seller will reimburse Buyer for the cost of the pre purchase inspection if the Seller refuses to make repairs. The real point is what is a fair agreement. Personally I think there should be a “Collar” or limit on the cost to repair identified discrepancies. Every plane will have some issues. But especially with someone new to aircraft ownership, there should be a reasonable limit of things that turn up in the inspection. https://www.aopa.org/-/media/Files/PPS/AOPA-Legal-Services-Plan--Sample-Aircraft-PurchaseSales-Agreement2018-01.pdf “[ Upon completion of this inspection, Buyer shall present to the Seller any list of discrepancies compiled. The Seller shall have ________ (______) business days to review the list and to notify the Buyer of Seller's decision: (a) to pay to have the [discrepancies] [discrepancies affecting the airworthiness of the Aircraft] repaired at Seller's expense and to complete the sale; or (b) to decline to pay the costs of repairs and to terminate the Agreement. If Seller declines to pay the cost of repairs, Seller shall refund, or have refunded, the Buyer's deposit and shall reimburse the Buyer for the cost of the pre-purchase inspection].”

-

Earnest money is fully refundable under certain conditions. A prospective buyer conducts a home inspection by a third party during the “option period”. If the inspection turns up more problems and cost than anticipated the prospective buyer can back out of the purchase and the earnest money is fully returned to the prospective buyer. Your scenario would be the same - in this case the inspection by a third party turned up more issues and projected cost than the prospective buyer anticipated.

-

Nothing beats the ease and comfort of entering the 2 doors of that old Cardinal that you used to own. Also it appears all your experience is with stiff leg planes - so get ready to pay a higher insurance premium for retractable gear as well as higher maintenance costs. Below 8,000 ft a K is probably less efficient and no faster than a J. You don't need to fly in the teens when traveling from the mid-west to Texas - in New Mexico a J is fine for 2. If you are going to take advantage of a K you need to get the Instrument ticket and wear oxygen. But when flying westbound you may find that you need to fly low due to punishing headwinds up high. Additionally, although they are the same 360 cu. inch displacement, the maintenance and overhaul cost of the 6 cylinder Continental in the K will be materially more than the 4 cylinder Lycoming in the J. Mooney Versus Bonanza - Aviation Consumer Bonanza cruise speed v. Mooney Used Aircraft Guide: Mooney K-Model - Goes Fast, Sips Gas - Aviation Consumer Mooney M20K - Aviation Consumer Mooney 231/252 - Aviation Consumer Mooney M20K 231/252TSE/Encore - Aviation Consumer

-

As @EricJ says the gear motor is just a large load. Remember that the gear motor is on its own circuit breaker. If you had binding or overload in the landing gear system, it would trip that breaker first. It is just a load that is within design limits. If the plane was in annual for a while the battery may have been down a bit and was still charging. When you pulled the gear there may have been a drop in voltage momentarily. As said maybe some adjustments made the motor work harder (still within limits) but pull a bigger load than you normally see. This voltage drop can effect relays that are weak. Did any other power cut out except the radios/nav? If not I would look at your radio master relay. It could be just from sitting the relay contacts had some resistance. Cycling may resolve.

-

Per Mike Busch: "The fundamental message of SB03-3 is that the compression test is not a reliable way of assessing cylinder condition, and that the borescope inspection is much more reliable. If a jug flunks the compression test but looks good under the borescope, then the compression measurement must be considered suspect, and heroic measures should be taken to raise it before a decision is made to pull the jug." EAA_2013-07_compression-in-context.pdf (savvyaviation.com)

-

Here is an ongoing saga (one year now) of a purchase that "checked all the boxes" - ie bought from another MS member, used an MSC for prebuy, Purchase contract spelling out resolutions, etc. He talks about his Purchase Contract on page 4: The owner is still waiting for parts and has not yet flown the aircraft after owning it for one year.

-

More specific prior threads on your topic:

-

As you might suspect the purchase process is a popular subject - it is a big step, lots of variables, may be first plane, potential for disagreement and financial risk. You may or may not have already see these threads:

-

My J is the same - you either pull it up from inside or insert the wire rod on the traditional drain cup up from below. This is picture of a dissembled K gascolator .

-

I think it is an Air Mods Inc SA4080NM No longer available https://drs.faa.gov/browse/excelExternalWindow/EB2049E65E659A0885256CC2000C60A7.0001

-

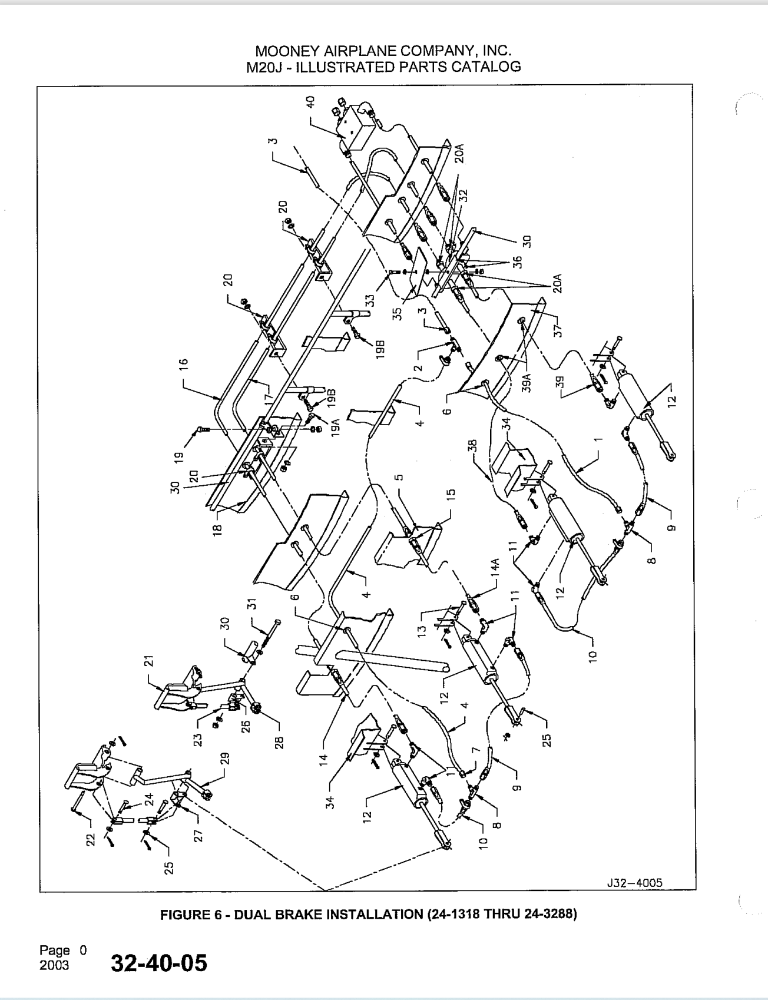

And let's not forget that @gevertex thinks he has Dual (Copilot) Brakes that don't work "Copilot rudder pedals looks exactly like pilot’s, but don’t have any effect on the brakes. Is this normal?"....That is Definitely Not Normal. Has anyone ever seen that before?

-

Given the delays that @Rotorhead is likely to encounter for the other parts that are damaged, I would say that "winter" is perfect timing.

-

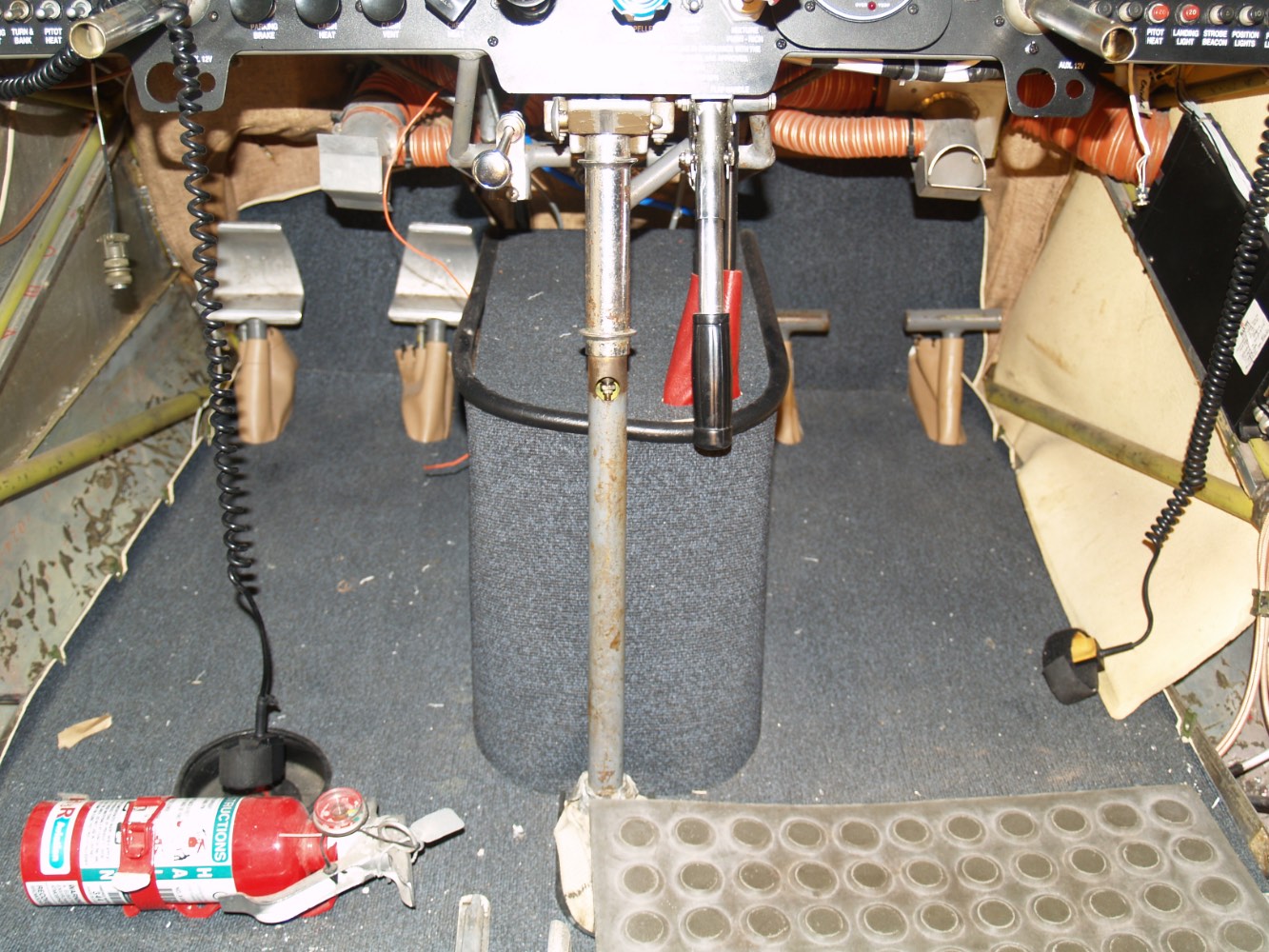

The pic on your post shows that you have serial number 24-3275. See parts diagram below. It shows the 4 cylinders better. You can download this M20J parts manual for free. See page 482. I assume your A&P has the parts manual and Service manual. I don't understand how the copilot brakes could be "INOP" unless the mechanical linkages are disconnected. Everything is in series as @M20Doc says. The fact that the Copilot brakes don't work and that the Pilot brakes stick (or are harder than a C172) sounds serious. If it were my plane I would not fly it until a competent mechanic troubleshoots it. You started this because you are worried about the brakes sticking - we may read an accident report when they "don't stick". Mooney M20J Illustrated Parts Catalog.pdf (free.fr) Mooney Service Manuel M20J Vol. 1 of 2.pdf (free.fr)

-

There are 2 master cylinders with standard brakes and 4 with dual (copilot) brakes

-

Copilot brakes are an option. The standard Mooney has copilot rudder pedals (just a bar) without the toe/heel brake pedal (see pic). If you have toe/heel pedals on the copilot side that look like the pilot side then they should be functional.

-

I think you are new here. This topic is probably not that right one to get people to answer your question. You may get a better response if you post you question to the topic below or else start a new one - specific to your plane/question. @carusoam can help guide you too.

-

Can’t find any specs but comparable dehumidifiers draw 900-1,000 watts/ hr. In humid regions with naturally leaky hangars it will run a lot. Purchase price and operating cost aside, many publicly owned hangars will not allow operation unattended.

-

Good idea as inconvenient as it sounds - if his plane is flyable. Years ago my J was undergoing an avionics upgrade when the shop changed ownership (without informing customers). The new owner couldn’t find my logs. I searched the building and found them myself. Century is probably a lot like Mooney - struggling to survive on its last legs. Everyone getting old and knowledge leaving rapidly or gone, no cash. No longer building complete systems. Same with many others - Rocket Engineering owner is in his 70’s - in business but good luck getting them to answer the phone. I had them repair my engine mount last year - and yes they lost one of the parts of the mount. They did search and found it - but untouched from the day it arrived- caused a month delay. However I am confused by your comment about 2 “pitch servos”. I have a Century 41 also with the installation manual. It indicates that there is one pitch servo and one roll servo. They serve different purposes, have different requirements and have different part numbers. I have a 14 volt J model. Neither of my servo part numbers match your servo number. What model and year Mooney do you have? @RideOrFly said in November that he had a Century 41 coming off a J soon - I think it is 14 v…. FYI

-

Right. That is half full on the standard tanks - and that is when the fuel gauges should read right.

-

Plessey/GEC actuators had their own problems wrt the "torsion spring" There was a 1992 Service Bulletin M20-92. It highlighted 2 gear failures. C:sb-si-slSISi-92.PDF (mooney.com)

-

"If you have a Plessey actuator you're good"....as long as you never need it repaired. There are no parts and no support for Plessey.

-

Do you mean the commitment made to prioritize this back in November 2020...? Maybe they are in stock - I haven't had the need to look.

-

What recourse do I have - extortionary mechanic

1980Mooney replied to goalstop's topic in General Mooney Talk

Oh geez… There are a lot of complaints about poor quality of MSC‘s here on MS. There is an ongoing saga about one MSC that missed identifying serious corrosion in a pre-buy. Just ask @redbaron1982 The MSC is only as good as its People. The factory is just trying to survive as a parts supplier and obviously provides no audit or quality control of what used to be its dealer network. -

What recourse do I have - extortionary mechanic

1980Mooney replied to goalstop's topic in General Mooney Talk

This all started with work done by a MSC per the original statement by the OP. Why not go back to them? This "mechanic" was not involved until after the work done by the MSC had prematurely failed. He may or may not be capable but he has been thrust into the middle of a problem that started with the MSC - and the "mechanic" is being blamed for it. Have you spoken to the MSC? They should have replaced all brittle tubing and disintegrating fittings. This is not their first rodeo in working on a 60 year old Mooney.