1980Mooney

Basic Member-

Posts

3,228 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

I also bought a J model Mooney when I had only 48 hours in a C-172 and 1 1/2 months before I got my Private. I had 2 instructors and I didn't tell the first instructor/flight school that I was flying a Mooney at the same time with a different instructor. And I did have insurance. I finished my PPL and Check Ride on the C172. Then we logged my M20J flight time and continued transition training. I did not pursue my Instrument ticket immediately but that did come later. Of course that was "last century". My point is if you have the interest, time and means then go for it. You have retained a good advisor to help you find a decent Mooney. No plane you find will be perfect and you will encounter unexpected costs and repairs along the way. Many will advise you to proceed more slowly with caution. But worst case, if you change your mind and flying doesn’t work out for you, you can always sell the plane. You’ll be out the cost of training and annual fixed costs of course (hangar, annuals, insurance, Data base subscription, transponder/instrument cert, etc) but if you purchase carefully you should be able to recover most if not all of your initial capital investment plus wing repair (adjusted for amortization of engine wear). If your mission or family hauling needs change over time you can also always sell the plane or trade up. Depending upon the timing and how much you sink into the plane for upgrades such as panel, paint, interior, etc you will probably get a lot but not all of your investment capital investment back (adjusted for amortization of engine wear). I still have the same Mooney although I added a 300 HP IO-550 to it, paint and multiple panel improvements over time.

-

There is B&K at Houston Sourthwest. Houston Tank Specialties at Eagle Lake does Mooney Annuals in addition to tank work. Pearland has a couple shops -Air Professionals for instance. The problem is that if you call any today they will be booked out just as long or longer. For instance there are comments on MS that HTS is overbooked and will be longer than scheduled. Sugar Land is no better. The shop that I traditionally used lost a mechanic to KIWS and it’s short staffed – they are a Cirrus service center so they are overbooked with Cirrus which gets the priority regardless. There is another shop at Sugar Land but they are more of a Cessna shop and I don’t recommend them. The other thing is you will need a Ferry Permit to legally fly to another airport. I am sure you can get one but it will be more delay. You can call around but you may be better just waiting at West Houston. Welcome to the joys and unexpected delays and expenses of plane ownership.

-

Buying advise - would this scare you off?

1980Mooney replied to Tim-37419's topic in Modern Mooney Discussion

Sounds like a typo.. Have you actually looked at the engine logs? -

Leaking fuel tank. How much is too much?

1980Mooney replied to Bill_Pyles's topic in Modern Mooney Discussion

Here are a few threads on MS with PIREPS on Houston Tank Specialties (HTC) - Good and Bad. Tank resealing is tedious and an art. You spend the money and roll the dice.... Good From 2016 and 2021 some good comments. And not so good or bad... From 2022 - read down to @louisut he said "Unfortunately our experience has been somewhat mixed. While I think he's a meticulous A&P who knows Mooneys and does a good job, I think he might be taking in more work than he has capacity for. Our reseal job began mid-July 2021 and the reseal, annual, and replacement of two cylinders took nine months, and that's with frequent nagging towards the end. I'm not sure how long Wet Wingologists and Weep-No-More are taking, but it seems like a long time. Most recently, a leak developed in one of our tanks and so the plane is going back. While he guarantees his work with a seven year warranty, I'm hesitant to take it back based on how long it took the last time." From 2018 @M20Doc reported poor workmanship on some Monroy tank work. And not so good or bad... -

Leaking fuel tank. How much is too much?

1980Mooney replied to Bill_Pyles's topic in Modern Mooney Discussion

FWIW - I had a leak similar to yours in my left wing during Annual. This particular A&P brought in a subcontractor to work on my leaking tank which unfortunately didn't work out. The A&P declared my plane Unairworthy. They signed off on my Annual With Exceptions. I had to get a Ferry Permit to go to another A&P at a different field that knew what they were doing and successfully patched my tank. -

Advice requested on damage incident

1980Mooney replied to whiskytango's topic in General Mooney Talk

FYI. https://resources.savvyaviation.com/wp-content/uploads/articles_eaa/EAA_2014-04_ferry-permits.pdf https://pilot-protection-services.aopa.org/news/2015/september/16/a-special-flight-permit-may-mean-flying-without-insurance https://www.faa.gov/about/office_org/field_offices/fsdo/phl/local_more/media/ferry_permit.pdf -

Advice requested on damage incident

1980Mooney replied to whiskytango's topic in General Mooney Talk

Mooney’s land pretty straight gear up or nose gear collapsed. They stop really quickly. Of course it could slide off the pavement. The problem is that it will add $40-80 k in damages to the current damage. -

Advice requested on damage incident

1980Mooney replied to whiskytango's topic in General Mooney Talk

You are going to have to get the shop at KSAV involved regardless. If you are contemplating ferrying you will need an A&P to sign off the application for the ferry permit. He will need to get it on jacks. Maybe he finds no bending or cracks and you are good to go to Wet Wing or an MSC for a second opinion. Or maybe he stipulates that you fly it gear down during the ferry. You also need to inform both insurance companies if you plan to fly with a Ferry Permit. Some exclude coverage during ferry. Some cover only if notified before the ferry flight. If you choose to ferry and retract the gear and they jam while up or partially extended resulting in a belly landing or if you fly with the gear down but the nose collapses on landing the FBO insurance company may say that you caused the gear up landing damage. They will say it was your choice and not necessary - could have been repaired on field -

Icing did not overwhelm the control or flyability of Colgan 3407. Mismanagement of the aircraft by the pilots brought it down. The icing did alter Ref Speeds but the stick shaker automatically adjusted for it. "The National Transportation Safety Board determines that the probable cause of this accident was the captain’s inappropriate response to the activation of the stick shaker, which led to an aerodynamic stall from which the airplane did not recover. Contributing to the accident were (1) the flight crew’s failure to monitor airspeed in relation to the rising position of the lowspeed cue, (2) the flight crew’s failure to adhere to sterile cockpit procedures, (3) the captain’s failure to effectively manage the flight, and (4) Colgan Air’s inadequate procedures for airspeed selection and management during approaches in icing conditions."

-

Carson Speed/Altitude/Engine & Prop Settings M20K (231)

1980Mooney replied to Ethan's topic in Modern Mooney Discussion

But if you are down at low altitude (let's say 5,000) then the Carson speed is 120 - 131 ktas. Who wants to fly at that speed? Compromise is right! -

Carson Speed/Altitude/Engine & Prop Settings M20K (231)

1980Mooney replied to Ethan's topic in Modern Mooney Discussion

If you are at 5,000 ft. then you are flying 120 - 131 ktas If you are at 10,000 ft then you are flying 132-145 ktas If you are at 20,000 ft then you are flying 162 -177 ktas If you are at 25,000 ft then you are flying 189-198 ktas. Down low you will be flying like a C-172 Up high you will be WOT. -

Regardless of supply chain and Covid issues, 9 months is ridiculous. You nearly pissed away a year of hangar and insurance fixed costs, maybe databases and subscription costs not knowing when it would return. You probably are out of currency. Your insurance company may ding you for low flying hours this year. And your wing is leaking again.

-

Sign of the Times. A&Ps are not growing. They are consolidating and shrinking. And one less MSC. Flying cross country for an annual is nuts in my opinion. The additional time, cost, reduced opportunity to be involved (some may desire that ) and no chance for minor adjustments.

-

You don't have to name the shop. There is only one MSC at the airport that FlightAware shows test flights where your plane has been for the last couple months. Based on all the work you mention I suspect that you handed them a check for $75-80K+. It is sad that this is the quality of work delivered. Quite frankly you are lucky to be unscathed. A detached throttle is obviously deadly. A cracked spinner leading to detachment less so but a Bonanza with the same failure fatally crashed in 2018 because the distraction led to poor pilot decision making. Accident Beechcraft A35 Bonanza N580B, 15 Jun 2018 (aviation-safety.net) Do you now wonder what else was poorly or improperly done to your plane by these mechanics/MSC/prop shop? BTW. Who is paying for all this rework/repair?… Did you tell them to “just send the invoice to the MSC/prop Shop”?

-

Here is the same plane when it was for sale in 2015-2016. It points out that the plane has a useful load of only 882 lbs. (and since it is a late model J it is already at 2,900 Max GW.) I am surprised that GMAX isn't more transparent and lists that prominently on the summary page. After all the perspective buyer is going to figure it out eventually and there is no way to sugar coat it or make it go away. N9139Z | 1992 MOONEY M20J on Aircraft.com https://www.gmaxamericanaircraft.com/inventory/?/listing/for-sale/214133937/1992-mooney-m20j-mse-piston-single-aircraft?dlr=1&dscompanyid=6946&settingscrmid=614667 I can see that there have been a few updates on avionics (Avidyne IFD- 540 with remote transponder in place of old Garmin GNS 530W, removed CD player, 2 G-5s, moved the HSI, new Garmin GMA340 Audio Panel, ) But same autopilot and HSI driving it, same stormscope, same GNS430W, etc. The vacuum pump/instruments remain so there is no meaningful weight reduction. So if you fill the tanks (64 gal x 6 = 384 lbs) that leaves you with 498 lbs. for all people, luggage, flight bag, hat rack crap, food/drinks, and since this is turbo normalized dont forget the portable oxygen cylinder(s). etc. If the average male fully clothed is 200 lb and ave female 170 lbs then that leaves you with a whopping 128 lbs for the passengers in the back seat and luggage, flight bag, O2 cylinder, etc. Bottom line - you are not flying this plane long distance with the seats filled unless you and your family is very small. And definitely not when they grow. This is more like a 3 person plane. Maybe only 2 if you are big and taking a long trip. Alternatively, you can fill to only 30 gallons and add a person - and limit yourself to 2 hour trips with VFR reserve. Or you take no luggage and ship ahead (bus or Fedex) as someone suggested (sounds like a complete pain and likely disaster for not showing up) Aviation is a compromise - A balancing act of speed, size, useful load, ceiling and range. And EVERYBODY lies about their weight. Bring a bathroom scale sometime when loading for a revealing experience.

-

Here is a 2017 thread on the same topic

-

Mooney gear up landing. KCLM

1980Mooney replied to amillet's topic in Mooney Safety & Accident Discussion

It looks like it came down just fine in the last pic (after they lifted it). I take the comments in the Facebook post as a confirmation of pilot error. -

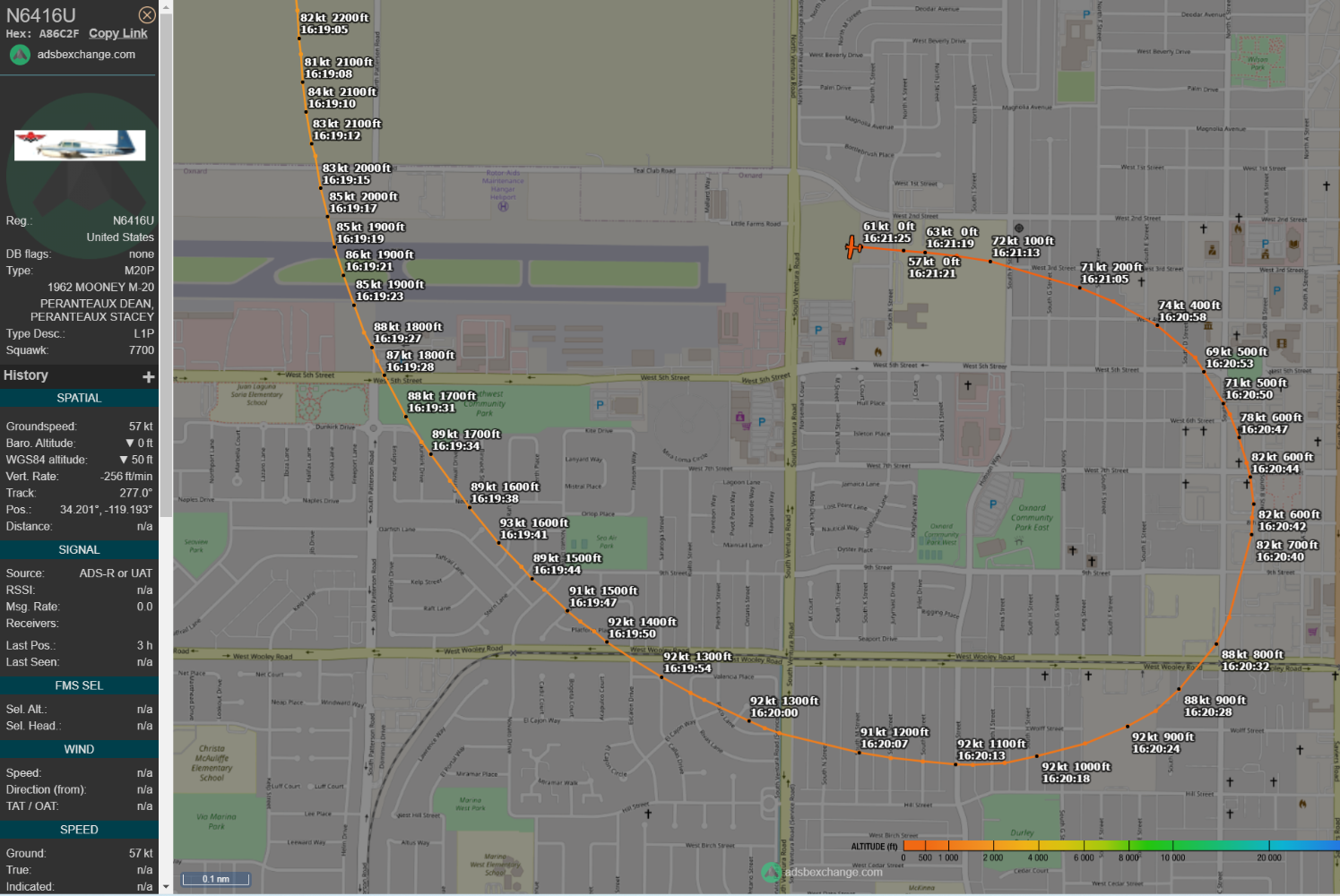

Another one... Oxnard CA

1980Mooney replied to DCarlton's topic in Mooney Safety & Accident Discussion

I think you are right. FAA ASIAS is out and it says "AIRCRAFT EXPERIENCED ENGINE ISSUES AND LANDED IN A FIELD HITTING A FENCE, OXNARD, CA." I think the FAA gets this statement from the pilot. -

Another one... Oxnard CA

1980Mooney replied to DCarlton's topic in Mooney Safety & Accident Discussion

Maybe you mean completely at idle (or "dead engine" windmilling) vs being at full wide open throttle. In between I am not sure if it is conclusive. Now here is a pic of a Cessna with the blade tips bent forward but no explanation https://www.boldmethod.com/learn-to-fly/systems/propeller-strikes/ And here is another Cessna with one blade bent forward and the other backwards! https://www.airport-data.com/aircraft/photo/000901972.html None of these prop strike/gear-up landings say "engine out" or "engine failure". And they are bent back. The throttle must have been pulled back - some perhaps all the way to idle but I suspect some some had a small amount of power in and were not windmilling like a dead engine. http://www.kathrynsreport.com/2017/12/incident-occurred-december-28-2017-at.html http://www.kathrynsreport.com/2016/06/runway-lights-could-be-returning-to.html http://www.kathrynsreport.com/2016/02/mooney-m20c-n6495u-bb-air-inc-incident.html http://www.kathrynsreport.com/2021/05/beechcraft-v35a-bonanza-n7974m-incident.html http://www.kathrynsreport.com/2017/05/committee-hears-from-general-aviation.html http://www.kathrynsreport.com/2019/02/cessna-r182-skylane-rg-n3177c-incident.html https://www.ironplanet.com/for-sale/Aircraft-1986-Beech-Bonanza-B36TC-Propeller-Plane-Saskatchewan/5857330 -

Another one... Oxnard CA

1980Mooney replied to DCarlton's topic in Mooney Safety & Accident Discussion

Very true. 5 ft is what separated a repairable, flyable plane from a pile of scrap parts. It appears the landing gear sheared off backwards when he hit the curb - punching thru the wing and bending the flaps up. Damage to prop, engine, wing and probably ripped the guts out underneath - most likely the insurance co will total it and it will feed salvage parts to the supply chain..... -

Another one... Oxnard CA

1980Mooney replied to DCarlton's topic in Mooney Safety & Accident Discussion

-

Good point that hasn’t been discussed - Oxygen. And something that you haven’t experienced in a C-172. MEF at Angel Fire is 12,700 ft. To the north it is 13,500 and to the west 13,200. You may say the regs don’t require O2 if you stay below 14,000 for 30 minutes. But sometimes the unexpected happens. And you probably want to give yourself a margin of safety over the mountain ridges. And everyone has slightly different reactions to high altitude due to health. Additionally you may find O2 reduces fatigue even when flying above 10,000 and especially at night. If you buy a K or as some suggest fly a J above 15,000 then you will definitely want oxygen. BUT you may find your pax don’t like it. Below 18,000 you can use cannulas. Above that you and pax will wear strapped on masks. If you look at ADSB or talk to some pilots, many planes that are capable of flying in the flight levels typically only fly at 12,000 feet or below. Their pax may not want to wear O2. If you are flying around TX and OK 90% of the time flying at 9-11 k is sweet and no need to go higher. Aviation is a balancing act of compromises.

-

There are 2 “max gross” on the J. The later were 2,900 lbs. Earlier were 2,740 lbs. The K was 2,900 lbs and the M20K Encore was 3,130 lbs. You need to look at each POH.

-

@William A Here is a good thread earlier in the year on real maintenance costs of Turbo vs. Non-turbo