1980Mooney

Basic Member-

Posts

3,228 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

The same could be said of the landing gear actuator "no-back spring"....Given the Mooney Factory history there I would be surprised it Mooney has anything manufactured in relatively large quantities.

-

I find them accurate and very reassuring. I have occasionally punched in the wrong amount of fuel on my fuel totalizer after refueling on a long trip and then started wondering if my panel fuel gauges or totalizer was in error. This is a great tie breaker. Also if there is ever a panel or complete power failure these gauges will still show me my fuel level.

-

Departure Emergency - Challenger Oil Filter

1980Mooney replied to alextstone's topic in Mooney Safety & Accident Discussion

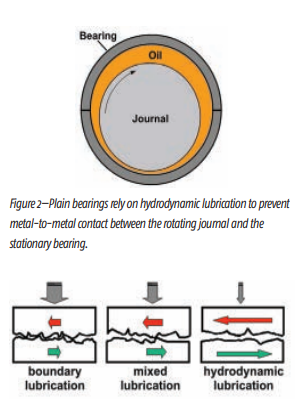

You note "I lost virtually all of the engine oil." - How much oil was remaining when you drained whatever was left? You also said " As I was rolling to the taxiway, I noted that the oil pressure had dropped to zero." Since you were focused on flairing and landing during final you probably don't know exactly when all oil pressure was lost to zero. Perhaps you have an engine monitor that records it. Residual oil film clinging to surfaces can provide a level of lubrication but I would be concerned about connecting rod bearings and the main bearings. The connecting rod bearings are downstream of the main bearings in the oil flow path and they generally go first during oil starvation. As Mike Busch pointes out when you lose hydrodynamic lubrication (with zero oil pressure like you experienced) you get metal to metal contact. You may have little wear and damage or you may have considerable depending on how long, engine speed and load (i.e. temperature and bearing pressures as well as bearing condition at time - "smoothness") Also you mentioned that you experience a loss in MP with no change in engine control. Would that be caused by the turbo.? The attached article by Aviation Safety says that turbo systems are designed with a pressure check valve that closes upon loss of oil pressure thereby trapping some oil in the turbocharger bearings and avoiding rapid disintegration while at 20,000 - 80,000 RPM. "Hot side failures in turbine wheels-again, theyre rare-are likely to take the shaft and bearings out, meaning the engine will puke much of its oil but should retain enough to run for quite some time. Thats because turbocharger oil systems are equipped with pressure-controlled check valves that close when engine oil pressure drops below a prescribed value" EAA_2014-03_not-so-plain-bearings.pdf (savvyaviation.com) Busted Boost - Aviation Safety (aviationsafetymagazine.com) Mike Busch notes: Plain bearings rely on hydrodynamic lubrication to prevent metal-to-metal contact between the rotating journal and the stationary bearing. (See Figure 2.) Pressurized oil is pumped continuously into the gap between the journal and the bearing. This gap is only about 0.002 inch wide—about the thickness of a human hair. Rotation of the journal within the bearing, together with the viscosity of the oil, creates a dynamic wedge of high-pressure oil that keeps the parts separated. So long as the bearing gets adequate oil pressure and the journal rotates rapidly enough, there is no metal-to-metal contact and therefore no wear on either the bearing or the journal. Does this mean that plain bearings can last forever? Actually yes, provided the engine is run continuously (as it might be in a test cell) with an uninterrupted oil supply and uninterrupted journal rotation. Unfortunately, that’s not what happens in the real world. We start up our engines, run them for an hour or three while we’re flying from point A to point B, and then shut them down. It’s mainly those pesky startups and shutdowns that limit the useful life of plain bearings. When we first crank the engine, there’s no oil pressure and the crankshaft cranking speed is pathetically slow. The conditions for hydrodynamic lubrication simply do not exist. Consequently, there is metal-to-metal contact between the journal and the bearing, and wear is inevitable. This startup wear is mitigated in several ways: The mating journal and bearing surfaces are polished as smooth as possible. The bearing surface is made of a material that has low sliding friction against the steel journal. Anti-wear additives in the oil react with the metal to form a thin protective film on the surfaces that further reduces friction through a phenomenon known as “boundary lubrication.” (See Figure 3.) Figure 3 -

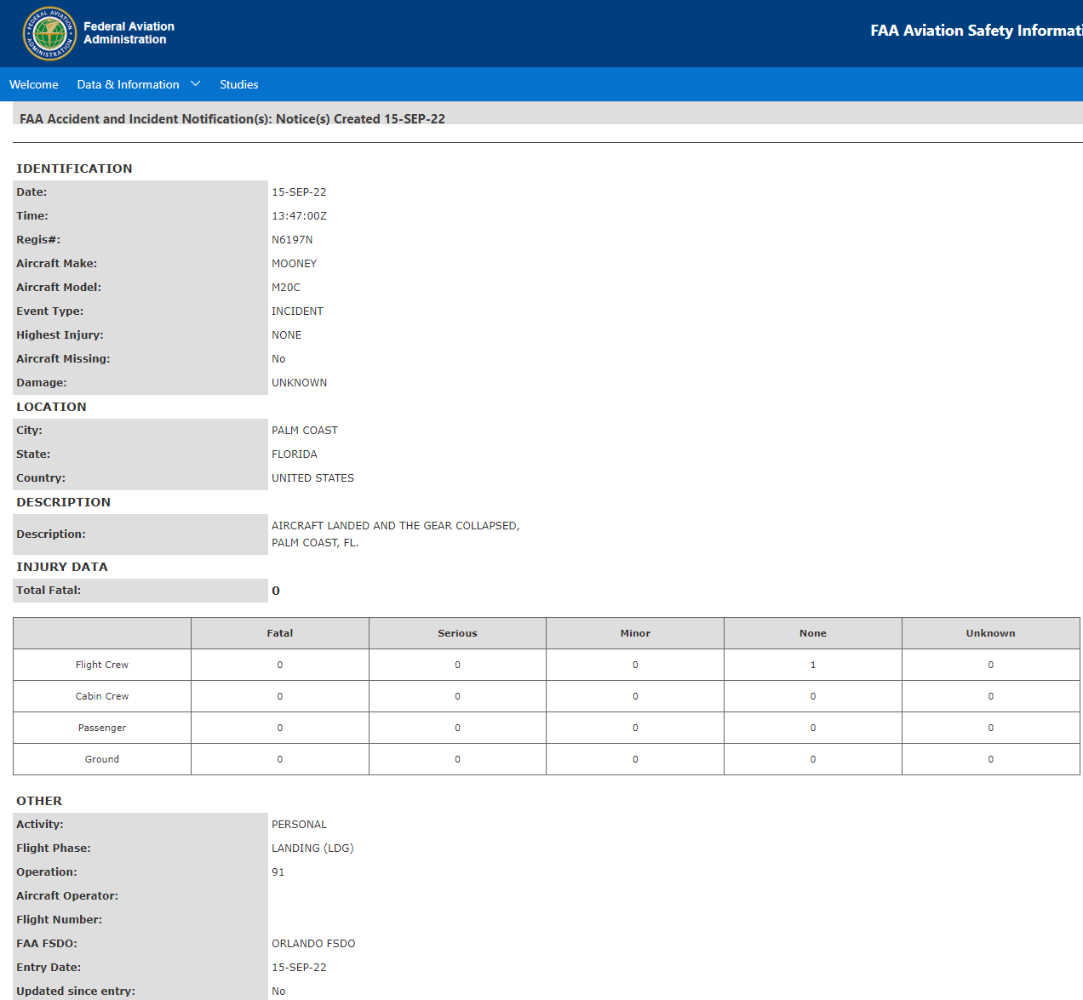

Gear up at Flagler FIN Florida.

1980Mooney replied to Jim Peace's topic in Mooney Safety & Accident Discussion

A 1969 M20C, N6917N at Flagler Exec - Palm Coast, FL. The FAA Preliminary Incident report transposed the N number - they said N6197N which is a helicopter. N6917N Flight Tracking and History - FlightAware ADS-B Exchange - tracking 13747 aircraft (adsbexchange.com)- 1 reply

-

- 1

-

-

One Piece Belly Mod W&B Change?

1980Mooney replied to Yooper Rocketman's topic in Modern Mooney Discussion

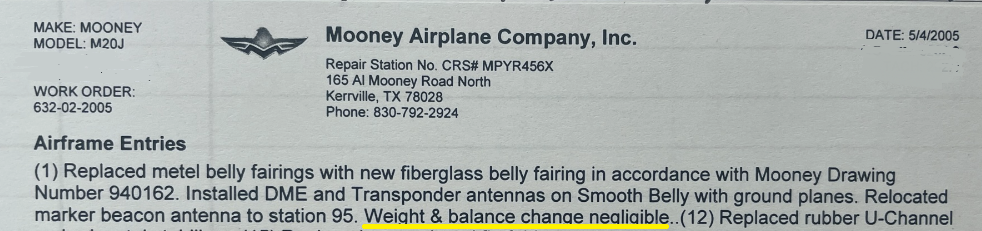

I had the one piece belly installed on my J at the Mooney Factory in 2005. They did not make a W&B entry because there was no material change. And there are only ~10 camlocks holding it on. -

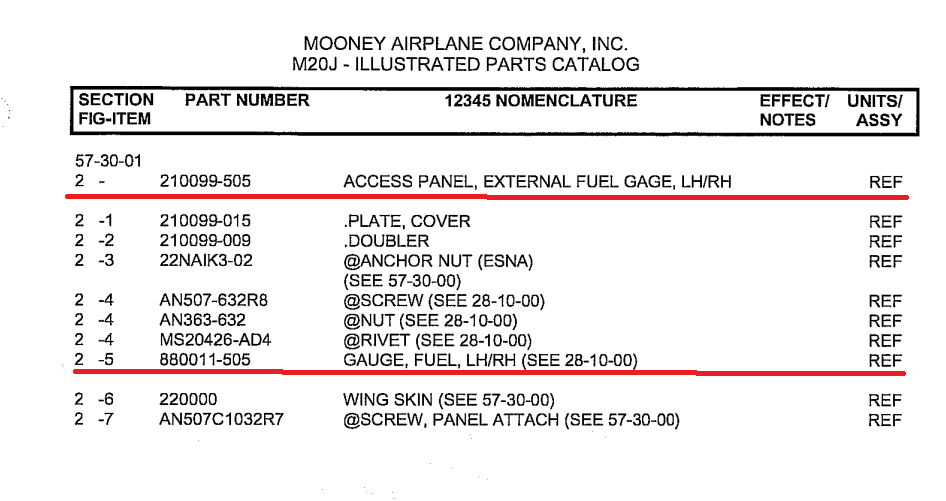

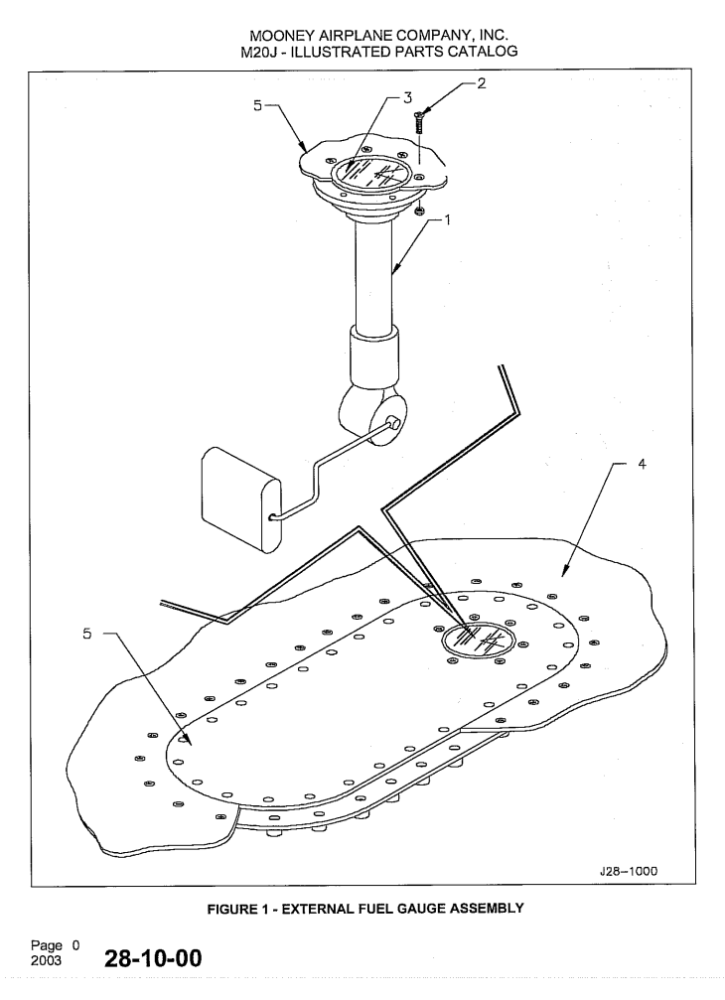

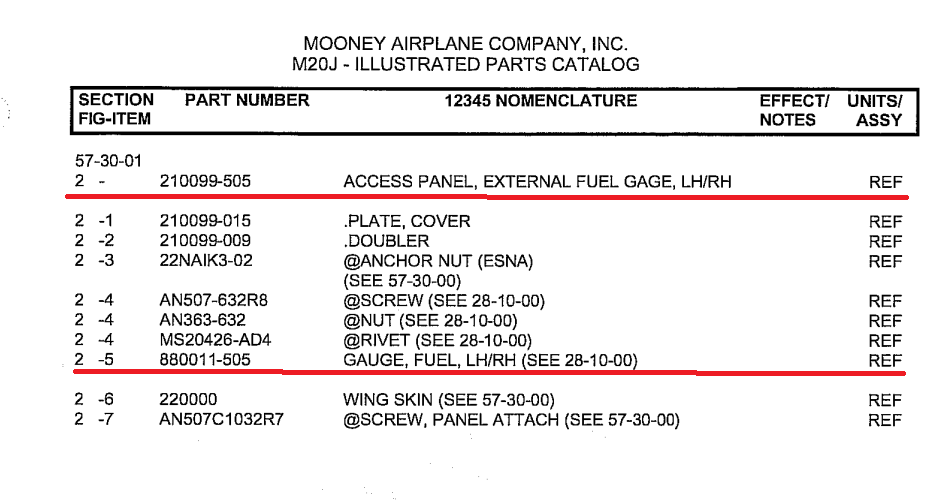

@WAFI Unfortunately that External visual fuel gauge is salvaged from a M20R - see the tag in the last pic. So it is calibrated for 44.5 gallons a side. Your N number shows that you are a M20J with 32 gallons a side. So it will read about 40% more fuel than you actually have. That doesn't seem very helpful or safe - I wonder if an AI would sign off on it. The M20J parts manual is online. It shows that you need EXTERNAL FUEL GAUGE KIT - 880011-501 — LASAR ACCESS COVER PANEL - 210099-505 — LASAR

-

While you are in there take a close look at the corrosion on the engine mounts. The wall thickness varies - I know on the Missile there are 3 different wall thicknesses. They are extremely thin. Slight corrosion can easily turn into an airworthiness issue and enginemount repair if left unaddressed. On a Rocket or Missile it is costly - both manhours to remove and cost to send and have repaired at Rocket. Expect months of downtime.

-

I think we as pilot/plane owners somehow think the scale of General Aviation is much larger than it really is. We lose sight of what a really tiny shrinking minority we are as consumers in the economy. Aviation Gasoline sales average about 413,000 gallons per day. At first thought that seems pretty large. But: The FAA has identified 3,300 airports in their 2021 Plan that are considered for Federal Funding. THAT IS ONLY 125 GALLONS PER AIRPORT PER DAY on average. That is less than 2.5 typical liquid drums (55 gal.) THAT IS EQUIVALENT TO 222 SIX-PACKS OF BEER Large filling station/convivence stores in Texas sell more beer than that every day. If you think about it on a statewide basis that is 8,260 gallons per day for each state on average That seems sizeable but the average gasoline tank truck hauls 11,600 gallons That's only 70% of one truck per day per entire state. By comparison there are 110 full tank trucks of milk per state rolling to dairies every day. If you compare it to automobile gasoline - Automobile Gasolines sales are 370,000,000 gallons per day ( that’s hundreds of Millions per day - not hundreds of thousands) That is 900 times AvGas sales. Said another way more Auto Gasoline is sold in 10 hours of one day than AvGas for an entire year. There are only about 6 refineries producing AvGas nationwide. Millner in the video said that the quantities are so small that even the refineries produce AvGas in batches. Pipelines only connect so far and then the fuel needs to be distributed in many directions. Products in pipelines are separated with pigs pushing it along. The inner pipe surfaces are not perfect and the pigs leak (bleed) along with some material clinging to the miles of pipe surface. The "intermix loss" on a small shipment is substantial. This "intermix" is a contamination which has to be trucked back to the refinery for redistillation. Pipelines make no practical or economic sense for AvGas. We are therefore stuck with the inefficiencies of truck distribution

-

Aviation fuel STC's have been around longer than most here on MS has been flying. The Petersen Fuel STC was introduced in 1983 and claims over 39,000 purchased and issued. The Swift Fuel STC was introduced in 2015. Petersen charges $1.50/HP and Swift started out at $400 but is now $100. GAMI said they will follow typical fuel STC pricing. Why all the angst, outrage and vitriol now over a measly one time maybe $300 for mid and short bodies, maybe about $450 for long bodies or maybe it will be $100. We pay more than that for virtually anything on our planes or any annual subscription for data that expires. The carping about the long established use of fuel STC's seems disingenuous. This is great day for GA. This will extend the life of our fleet. We have a superior fuel with higher energy content that will allow modern synthetic oil, higher compression, cleaner burning with less maintenance that may ultimately extend TBO. Braly/Roehl/GAMI are the classic American capitalistic success story. They are the "Davids" that persevered with their own investment and successfully did what the "Giants" (Shell, Chevron, BP, Total, FAA Coordinating Research Council ( CRC ) Unleaded Aviation Gasoline Development 1992-2007, FAA PAFI, etc.) couldn't do. They created both a technical success and successfully navigated the regulatory process. Their reward is well deserved.

-

True - Water, table salt and baking soda are toxic to humans at high enough levels... https://www.nbcnews.com/id/wbna16614865 https://www.scientificamerican.com/article/strange-but-true-drinking-too-much-water-can-kill/ https://en.wikipedia.org/wiki/Salt_poisoning

-

YES

-

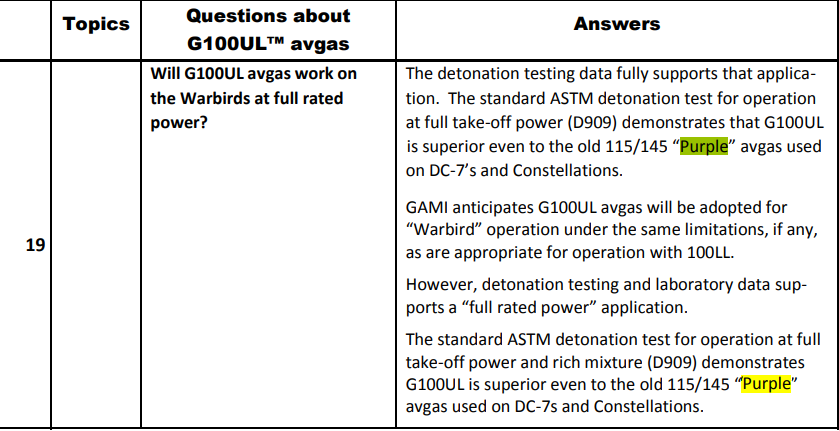

BTW - no one has highlighted that engine compression will be able to rise with the introduction of G100UL. Warbirds, that were detuned with the demise of 115/145 octane purple, will be able to go back to wartime power performance. You will be able to run the HO (10.0 to one) pistons again in the Lycoming IO-360 without fear of detonation. Synthetic oils...higher compression...no lead deposits - maybe our engines will start to enter the 21st century.

-

Let's STOP talking about free Benzene. There is no free benzene in the fuel. They are using Dimethyl and Trimethylbenzenes in these unleaded blends. Toluene (in current 100LL) is METHYLBENZENE. Xylene (in GAMI G100UL) is DIMETHYLBENZENE. Paul Millner mentions that Swift is using Trimethylbenzene to boost octane. https://www.aopa.org/news-and-media/all-news/2022/june/pilot/unleaded-avgas They are not toxic and not carcinogens. You can buy Toluene and Xylene at Home Depot or a paint store. Trimethylbenzenes are also safe Trimethylbenzenes - Acute Exposure Guideline Levels for Selected Airborne Chemicals - NCBI Bookshelf (nih.gov) 2. HUMAN TOXICITY DATA 2.1. Acute Lethality No reports of human fatalities or acute poisoning from TMB were found. 2.6. Carcinogenicity No information was found regarding the potential carcinogenicity of pure TMB in humans. None of the TMB isomers have been classified by U.S. Environmental Protection Agency or the International Agency for Research on Cancer. Let's get a grip and stop spreading false fears.

-

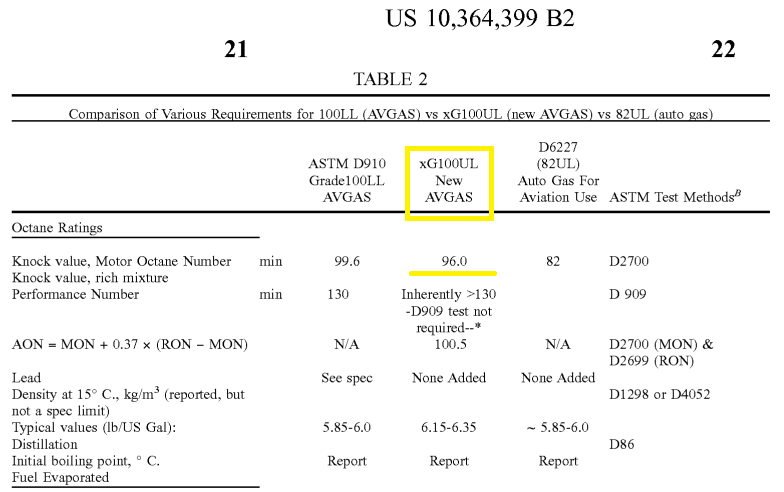

That is NOT the correct patent. That is an earlier patent by Braly in 2014. The correct patent is US 010364399B2. It was applied for in 2017 and awarded July 30, 2019 The PDF is easier to read. https://patentimages.storage.googleapis.com/44/31/62/4c121e3b946012/US10364399.pdf https://patents.google.com/patent/US10364399B2/en

-

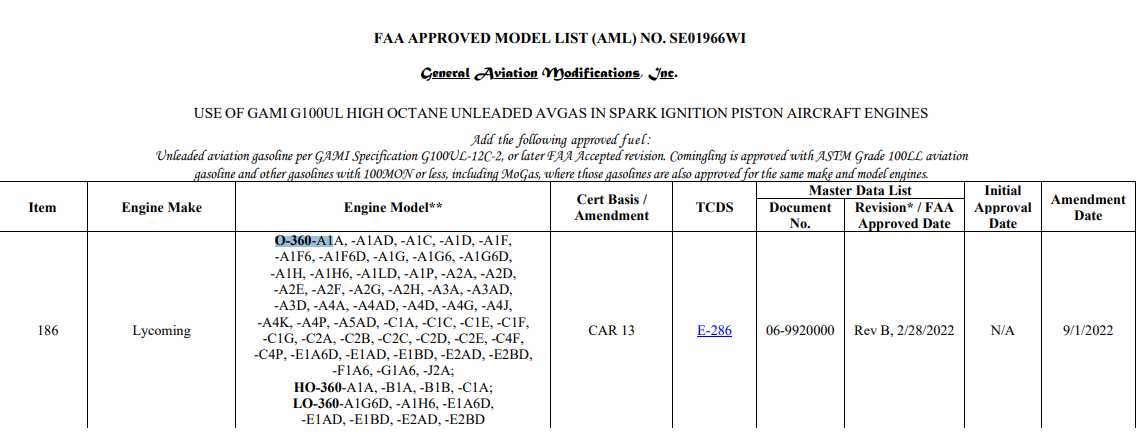

Are you getting your info from the GAMI site? There are 17 pages of engines - 244 engine "families" in total - just eyeballing it looks like 1-2 thousand engines. There are 62 variants of the O-360 listed for instance in that "family". This was also back on page 14 in this thread. You may be looking at the AML from last year (when the STC was originally approved) for only low compression engines General Aviation Modifications, Inc. (gami.com) Microsoft Word - SA01967WI_AC AML_pages (gami.com) Microsoft Word - SE01966WI_AML Amd2_pages (gami.com)

-

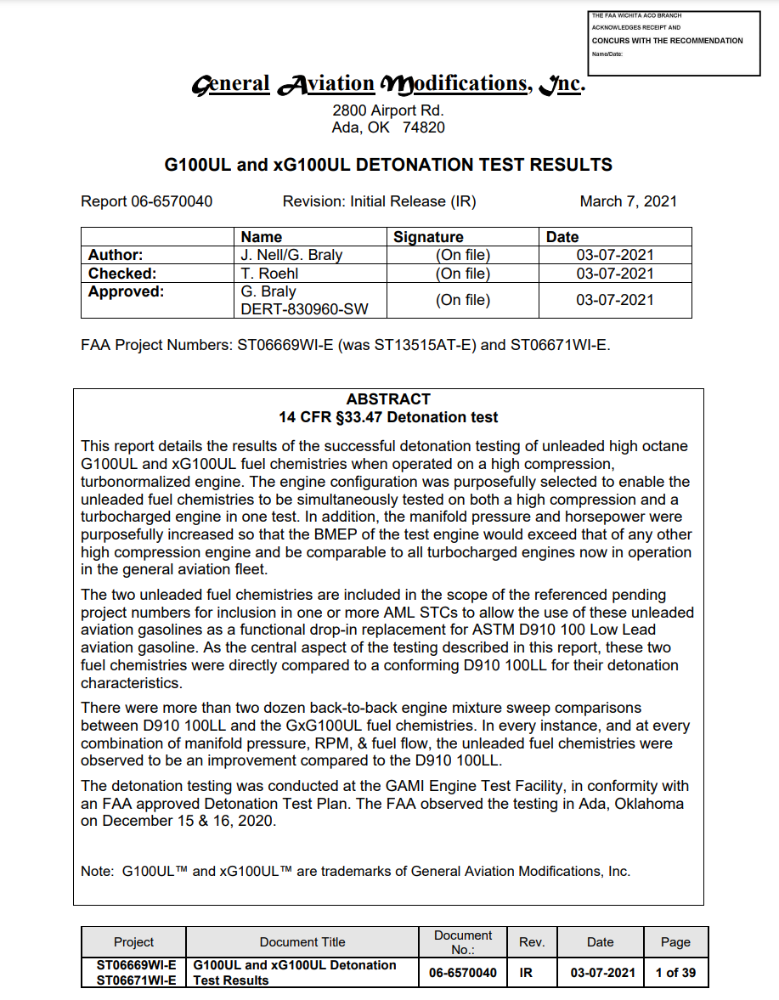

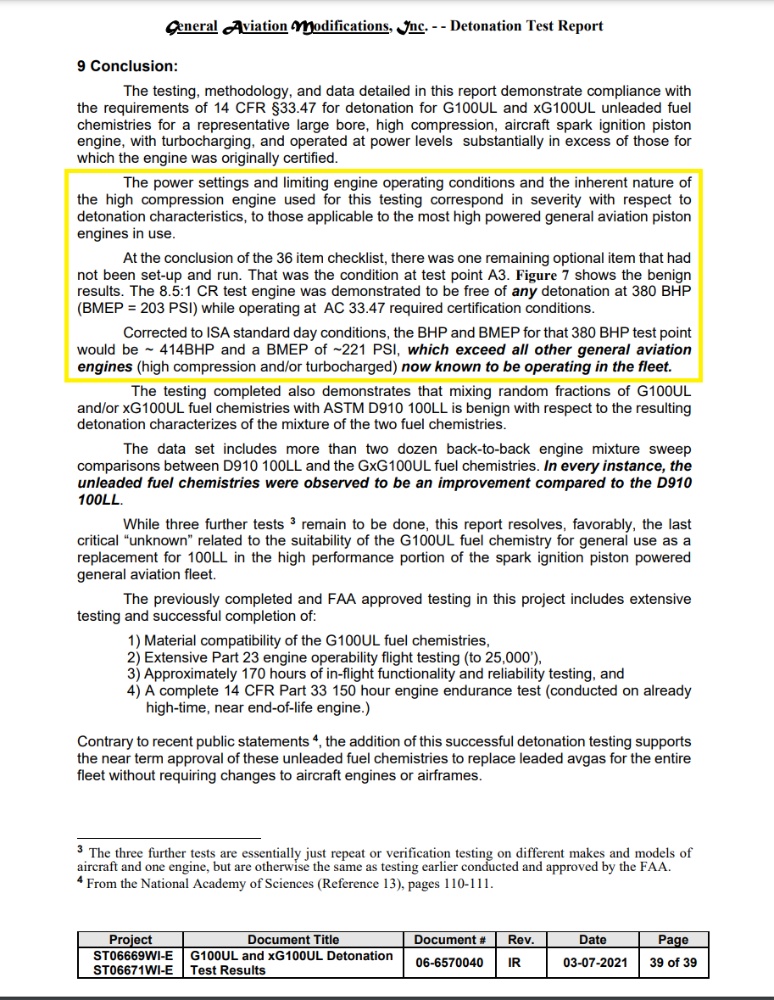

Read the Patent and read the GAMI FAQ's. Per the US Patent 10364399B2, G100UL is MON 96.0 Octane vs MON 99.6 for Grade 100LL. Per extensive testing by GAM G100UL is 150-160+ octane in the Rich Test. (https://gami.com/g100ul/Excerpts_FAA_approved_Detonation_Test_Report_March_7_2021.pdf) They ran their TCM IO-550 test engine continuously at 2550 RPM and at 33" MAP with OAT of 105 F and fuel temperatures of 110 F producing 380 HP in the Hot Day Rich tests with cylinder head temps of 431 F.

-

That is an interesting perspective. I suspect that it will make @MikeOH lose his mind as soon as he reads this.....

-

The FAA is not publishing an AML that includes every piston aircraft ever type-certified in the US > GAMI ALREADY HAS. The AML lists planes that are eligible. (Actually there are 2 AML lists - one for airframe and one for engines - see below) The original AML list last year (WHEN THE STC WAS ORIGINALLY APPROVED) was short and only included planes with low compression engines. The amended AML's now includes all engines. GAMI is the STC Holder. GAMI and only GAMI can grant you, the airplane owner, the right to use (i.e. license) the GAMI STC. If you don't pay GAMI for the STC and get the 337 you cannot legally buy G100UL. I understand that some here think they buy fuel without the STC regardless of the consequences. General Aviation Modifications, Inc. (gami.com) Microsoft Word - SA01967WI_AC AML_pages (gami.com) Microsoft Word - SE01966WI_AML Amd2_pages (gami.com)

-

It seems exceedingly simple. I don't know of anyone paying cash to fill their planes. All transactions are electronic. All it needs is a pin# or account number tied to the GAMI paid up STC and approved 337 for your Serial #/Tail #. The FBO or SelfServe will run it through when they run your credit card. It will be the same for Swift 100R (they have committed to the STC approach also). No Pin/Acct. # = No Sale. Easy peasy....

-

Given the difficulty the industry has experienced in finding an unleaded blend that works for Internal Combustion aviation engines, I suspect that there is a high level of precision required - more so than Prist. Some of the people working the fuel trucks are not the most experienced - it might be a kid working part time...and some of the self serve pumps at some small airports are in pretty sad shape. I am not going to trust either is blending "antiknock additives properly" at the truck or pump only find out that my engine is detonating on take-off with the family on board

-

While there are 2 fuels in the retail chain - one Leaded 100LL and one unleaded G100UL or Swift 100R (if it ever really gets approved) there will need to be separate tanks and delivery AFTER THE POINT TEL IS ADDED. It is a business liability issue given that municipalities and probably eventually the EPA will ban lead. Clearly GAMI has said it is compatible in your tanks and fuel lines - however there has not been a long term test. We may wake up in 5-7 years and find out that G100UL or Swift 100R is slowly dissolving the seals on our wet wings - and we will all be paying $10-15 K in the future for complete reseals while the fleet is largely grounded and backed up waiting for 3 bloody shops nationwide. Who will you be suing then? You may be saying "hey I have been using 100LL religiously for the past 5-7 years only flying to FBO's that still carry it. How did this G100UL or Swift 100R crap get into my fuel tanks??!! Are you (FBO and AvFuel distributor) telling me you shipped or filled tanks in alternate shipments with 100LL and G100UL without special handling? Without purging and decontaminating? Are you telling me that you cross contaminated the fuel supply chain out of ignorance, carelessness and laziness?"

-

OK - Let's assume $1 increase in price due to the cost of unique additives. But no one talks about the market reality of distribution - wholesale and retail AvGas sales nationwide are about 420,000/gallons per day That sounds robust but there are about 3600 FBO's nationwide That means the average FBO only sells about 116 gallons per day - that is basically two (2) 55 gallon drums I bet large convenience store/filling stations sell more beer than that every day. That means the average FBO sells about 42,000 gallons for the entire year The average FBO cannot afford to sell multiple grades of fuel - especially if one is unleaded and totally separate A separate unleaded storage tank, fuel truck, self serve tank/pump will easily cost $100,000 or more (let's say amortized $20,000/year) The incremental cost to maintain and insure a separate fuel line could easily be $20,000/year Total annual cost of about $40,000 per year vs sales of about 42,000 gallons per year A separate fuel sales line will cost the average FBO about an extra $1/gallon The average FBO will probably stick with one grade. And when they switch it will be all Unleaded Think about the wholesale distribution 420,000 gallons per day AvGas is only 8,400 gallons per day for the average ENTIRE STATE That is only about 75% of a gasoline tank truck per entire state daily. Once you start introducing Unleaded you need separate trucks - separate delivery - splitting an already small volume COSTS WILL RISE The Economies of Logistics and Scale go to crap quickly - especially in the more sparsely populated geographically large states. The Market Reality is that once Unleaded is introduced and builds some scale wholesalers will start making the decision to ship only Unleaded - they will start snipping off 100LL deliveries to small distant low volume FBO's.

-

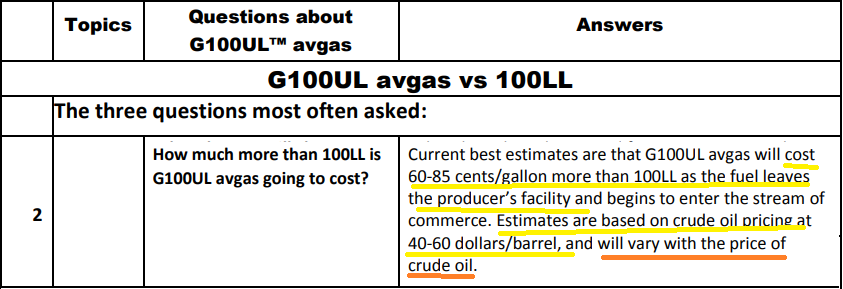

I don't understand where these comments about price at the pump come from. Braly never said the price at the pump will "be $0.65-$0.85 extra per gallon". In 2021 at AirVenture GAMI released a Q&A for G100UL . They made a statement regarding "COST" when it leaves the producers plant or facility - And he qualified that cost increase was based upon $40-60 crude oil prices. And he said the increased cost would vary with the price of crude. That was all quite dated at the time and in the rear view mirror now for the foreseeable future.. https://oac.ok.gov/sites/g/files/gmc221/f/GAMI Q and A 7 27 21 2 15 PM release.pdf "How much more than 100LL isG100UL avgas going to cost? Current best estimates are that G100UL avgas will cost 60-85 cents/gallon more than 100LL as the fuel leaves the producer’s facility and begins to enter the stream of commerce. Estimates are based on crude oil pricing at 40-60 dollars/barrel, and will vary with the price of crude oil." Note that his estimate is very dated and based upon $40-60/bbl crude oil prices. Crude has been and will be closer to $85-100/bbl. His estimate was based on a median of $50 crude. The current median is more like $92 crude. That means the increased COST to produce G100UL will be more like $1.10 - $1.56 more than the cost to produce 100LL The PRICE that G100UL sells for at the pump is a whole different thing Producers/Blenders will set a price to sell to the designated initial primary distributor, AvFuel Wholesale price will be set by AvFuel first as they distribute to FBO's Retail price to pilots/owners will be set by the FBO's Blending additives at the truck or fuel tank on the field will be a disaster. There is no quality control or testing. Many trucks and tanks at small FBO's are not especially well maintained. Letting water get into the tanks is one thing. Screwing up the additives (or not adding at all) will go undetected until your engine knocks itself to death. And I don't understand the comment about being $1 cheaper -do you mean G100UL or 94UL, In any case it appears that the additives that replace TEL are more expensive.

-

Chris D'Acosta of Swift a little over a month ago at AirVenture said: Their Unleaded 100 octane Avgas "effort is built around the STC process" Swift is building an “enriched STC process that will stand up [to scrutiny] and not get knocked down,” Currently with their UL94 fuel they note "Why does Swift Fuels insist on using the FAA’s Form 337 and FAA-authorized fuel placards for your unleaded fuel program? Yes, we do insist - Pilots know that alternations (including a change to an STC-approved fuel) requires an FAA sign-off and the application of a fuelplacard. Swift Fuels values the role of the FAA-authorized signers – typically an A&P Mechanic and in IA (Inspection Authorized mechanic) to approve the form. Other FAA-authorized signers may also certify the “alteration”. " Swift is following the same STC approach as GAMI. That is what Swift is calling the "drop-in replacement" approach. Swift has said that they currently plan to charge $100 up front for the STC. Of course this is predicated on Swift actually having a fuel that works. So now we have 2 companies following the same STC route to supply unleaded aviation fuel. No blanket approval, no implied STC - only formal STC's with signed 337's. Both require payment up front to license the STC and then the payment of ongoing royalties or mark-ups that will be hidden in the cost of every gallon. https://www.kitplanes.com/swift-fuel-drop-in-100ll-replacement-in-2023/ https://www.swiftfuelsavgas.com/faq

-

And recording artists would tell you that is a complete rip off of their unique "intellectual property" that benefits you and screws them.