1980Mooney

Verified Member-

Posts

3,480 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 1980Mooney

-

There is another simple solution. What is being described here are shops that are overloaded with work - either because of reputation they are attracting work from greater distances, or they are short handed of qualified workers or they lack enough parts for all the planes or because the product is becoming more service prone (Continental AD, Piper wing, Mooney elevator, etc or just accelerated age deterioration of 50-60 year old planes.) Raise shop rates way up - 20%-50% Work sane shop hours so that the shop can communicate with customers. Shops be selective in the work that they accept. That way service "demand" will come into equilibrium with service "supply". Supply meeting Demand. Free Markets. Higher shop rates will drive higher mechanic wages and attract more staff. It may also attract the formation of new shops. Or plane design becomes simpler and more reliable....maybe make them out of "plastic" with fixed gear....?! Isn't that how "Captialism" is supposed to work?.....

-

Among other things the Mooney airframe is proven the be extremely labor intensive. The only way to make that go away is a clean sheet design. The 1963 289 AC Cobra was a great car - like Mooney designed in the slide rule era. However design and manufacturing technologies have moved on and the "body on frame" (just like Mooney fuselage) no longer makes sense. GM figured that out with the clean sheet design of the C4 Corvette in 1983.

-

This sounds like “If I can’t find an A&P that I like, then I am going to buy and operate my own”….

-

Perhaps you didn't read @redbaron1982 PIREP from last Thursday regarding the same shop. The MSC in the Northeast missed the corrosion - he sent it to Longview for repair. They have been working on it 10 months. It sounds like communication is an ongoing issue. "Still waiting on the plane, the shop that is currently working on it email me 2 weeks ago to go and pick it up but three days after they called me to say they have flown the aircraft and it was pulling to the left and they need to check the rigging. Two weeks after that, still radio silence, so I don't know how many weeks, months or years is going to take to rig the airplane. BTW: I'm starting to truly believe that GA industry is totally broken. I'm not talking about parts availability or things that are hard to fix, but customer service is a disaster, my two experience so far, one of which is with a highly renowned shop for Mooneys, is crappy in regards of customer service. Total lack of communication, and I'm not talking about daily communication, I'm talking about not answering emails or not giving an estimate on when a job is going to be finished or even started after they have had my aircraft for 10 months now. My point is that it doesn't cost money to fix customer service, it's just replying an email, having a schedule for the shop and giving precise information."

-

You are too quick to dismiss potential manufacturing anomalies, experimental or Certified. Two planes manufactured at the same time exhibited the same cracks. Yes they are used for training but the wings should not and usually don't fail. A small change in manufacturing could have led to a weaker spar. And unfortunately, as they say on Beechtalk, all the holes in the swiss cheese lined up disastrously. As pointed out in the Piper Owner Society presentation of the NTSB findings: "Crack development is a function of many factors, including design of the structure, how severely the aircraft is flown, and manufacturing processes. " Furthermore "Inspection of another airplane in the same fleet of the accident airplane (manufactured at a similar time and operated in a similar training mission) was also found to have cracking in the wing spar." Per the European forums: "It (the Piper spar) really is an odd design that demands perfection in production and fit. What holds it together is not the bolts, but friction due to the torque of the bolts. The typical way to design this is to assure all the forces go through one single bolt, one at the upper and one at the lower, or a series of bolts all taking equal load, either pure shear or pure tension. The bolt itself is OK, but not the structure around it because that structure is designed with friction in mind. With a perfect fit, the right amount of torque, no corrosion, it probably will be OK and will last for ever. But too much torque will insert too much stress on the structure around the bolt. Too little torque will weaken the friction between the members so too much load is applied to the bolt and the structure around it. A less than perfect fit will weaken it considerably, which could be problematic when changing a wing for instance, unless this is done 100% correct. Also, the condition and fit of the aft spar matters." Just like the many cylinders, crankshaft and camshaft AD's we have seen, and now the latest Continental FUp, manufactures over time seem to lose their "best practices." perhaps due to turnover of staff. It is possible something (or someone) on the assembly line changed. Although the NTSB did not highlight it, I bet the attorneys for the families of the deceased will be all over it. And BTW - the cracking was in a hidden area not visible to maintenance personnel. How many times have you removed your wing spars to check for hidden corrosion or cracks?

-

This sounds like a manufacturing issue. Embry Riddle has outstanding maintenance. I don't follow your comment. Hangar Talk - Wing comes off a PA28 during a checkride with an examiner (and wing spar structure discussion) (euroga.org) NTSB Issues Final Report on 2018 Daytona Beach Accident - FLYING Magazine "The 10-year old aircraft was used only for flight training at Embry-Riddle Aeronautical University and had accumulated approximately 7,600 hours of flight time. “A review of the operator’s airframe discrepancy log for the life of the airplane and flight crew safety reporting system for the 24 months preceding the accident found some reported flap extension overspeed, gear extension overspeed, and hard landing events. In each case, the events resulted in airframe examinations during which no defects were noted by maintenance personnel. Interviews with flight instructors did not yield any safety of flight issues or critical airframe or loading exceedances caused by pilot operation that would be expected to precipitate cracking.” Piper published a service bulletin in 1987 for a wing spar inspection on the PA-28 series that would not have taken effect on this airplane until it had accumulated almost another 23,000 flight hours."

-

This would be a hypothetical, newly minted private pilot that trained in Cirrus at a flight school and has the means to buy a brand new SR22T.

-

@Parker_Woodruff What is the current “approximate” cost to insure a $1 million+ Cirrus SR22T? For a low time non instrument rated pilot and for an experienced instrument rated pilot?! Could it approach $20k smooth (liability plus Hull) for the experienced pilot? Or is it closer to $10-15 K? And can a low time non-instrument rated pilot even get insurance for that model?

-

I disagree. The average person, with a family, job or any sort of commitment, will need “to burn the candle at both ends” to build an experimental plane. I have a very high skill level but I know I make mistakes when fatigued. I am not interested in buying someone else’s FUp’s

-

Unlikely. I bet they don’t need to pay to advertise. I bet spouses are their best advocates- “If I am going to own 1/2 of this plane, then it Will Have A Parachute”. And “what do you mean we can’t fill the seats in a Mooney? - we can in a Cirrus!” After all they are sold out for a year or two.

-

Oh and @hais stipulated that the entire plane with engine and avionics (and parachute?!) needs to cost $80k in total. Garmin needs to give away their equipment.

-

But @hais did say 300 kts.

-

The simple answer is NO. 1 million new pilots will not go through the grief of being instrument rated and the recurrent training to being proficient /current in a pressurized turboprop. Oh and remaining drug free. They will be killing innocent people in droves.

-

I think we need a turbine for 300 kts…call P&W

-

For $80k?! Alchemy? Perpetual motion engines?! Ok.

-

Well you are partially right. Mooney is selling what they want regardless of what the broader market wants. Cirrus is selling what the broader market wants. That is why Cirrus sells over 500 SEP per year and why Mooney is no longer selling aircraft. YES -There are a few that value and want what Mooney has to offer. Just like the 3 that value and purchased a new G36 Bonanza this year. But Mooney isn’t selling hundreds of other planes per year like Cessna such that they could spread/share the manufacturing costs on a few marginally profitable planes. Mooney would just lose more cash cost per plane.

-

Spot on. The idea that an ever more expensive “GA” plane can attract an ever more wealthy customer base is delusional. As if a slightly cheaper, smaller Epic E1000 or TBM 960 will attract a “cost conscious “ multimillionaire is a joke. As you go higher in wealth, this “target market “ can more afford to hire a charter - Netjets, etc. They can enjoy the flight with a drink. How many wealthy really want to stay current in a pressurized turboprop? Get real. BTW - if they have actually created wealth their lawyers will be advising them and their family to NOT PILOT A PLANE. And if they inherited it they may be happy taking the risk - but more likely want to enjoy the flight with a drink….

-

The number of students in flight schools is increasing because they want to fly for airlines – not own an airplane. They are reading about the salaries, and the big raises that the pilots at the majors are getting. They want to fly the new commercial iron that basically flies itself - so they can just sit in front of the computer screens monitoring the magenta line.

-

I would say that the trust was effectively gone in October 2021 when it became known that behind the scenes and “trust talk” they had been peddling the company for sale again. It showed up on BizQuest, the business broker of last chance – the craigslist of business brokers. https://flyer.co.uk/mooney-aircraft-company-up-for-sale/

-

Don Maxwell has been reported to be part of the U.S. Financial ownership group. Perhaps someone should ask him - about the other 20% owner, presumably Meijing, and the status of all the announced plans to redesign landing gear, increase MGW, and upgrade the G1000 among other things.

-

The ownership is a bit of a mystery. On 1 September 2020, Jonny Pollack announced to several aviation publications that 80% of the company was taken over by a new ownership group under US Financial, LLC. Apparently Meijing Group still owns 20%. Little is known about US Financial, based in Wyoming. I would assume that Meijing converted much of their reported $200 mil. investment into debt which they hold over the owners. It is understandable why they have no cash and are unable to build inventory. I am surprised that no-one had pressed Jonny at MooneyMax regarding the 20% and Meijing. Based upon the “Legendary Aircraft Business For Sale” PowerPoint that we saw floated in Oct. 2021, (BizQuest - which failed) I suspect that US Financial invested no money in Mooney and their plan was to flip the company getting both them and Meijing out. “A consortium of pilots and owners has taken over Mooney International after taking an 80% stake in the company formerly owned and controlled by Chinese interests.” https://www.australianflying.com.au/latest/pilots-and-owners-buy-out-mooney-international https://saflyer.com/mooney-changes-ownership/amp/ https://opencorporates.com/companies/us_wy/2020-000916521

-

I was following your plight which you posted in the Bravo Forum. There is a topic here somewhere showing the parts in the wing sight gauge. Can't find it now. The panel can be installed (rotated 180 degrees) with the gauge outboard or inboard. It should be inboard so it is easiest to read from inside the cockpit. Seems like a rookie mistake for the shop to install one inboard and one outboard. (and to not remember how it was when you delivered it to them) Were they accurate before you took the plane to WetWingologists? They should pay your local shop to fix their screwup and get the gauges installed correctly. VISUAL FUEL INDICATOR KIT - 940043-503 — LASAR ACCESS COVER PANEL - 210099-505 — LASAR

-

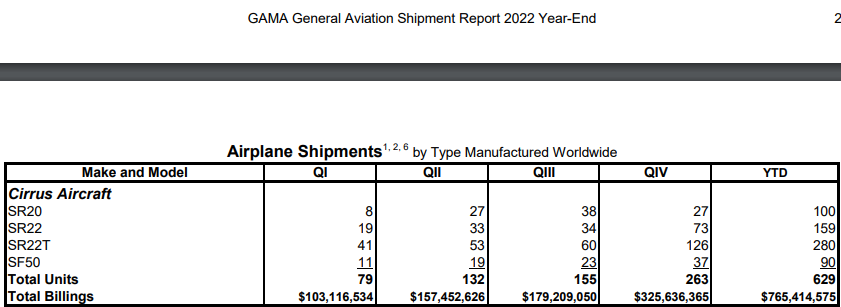

In 24 years they have sold about 9,000 SEP planes. That averages 375/year. Last year they sold 539 SEP - they are growing and accelerating. People here have reported that Cirrus has a large order backlog - more than a year or two. There are 248 Cirrus SEP for sale on Controller (less than Piper SEP or Cessna SEP BTW) - that isn't even 3% of the Cirrus fleet. It doesn't seem excessive.

-

Good point. Cirrus, along with Diamond, Piper and Cessna, have proven that you don't need retractable gear to train professional pilots. Apparently, they want fixed gear - less cost, less weight, more robust and less insurance. Everyone talks about Mooney needing to "do something different" than they are currently yet most lose their mind at the suggestion of any change.

-

That wasn't the issue - the issue is a clean sheet pressurized carbon fiber design. Just look at Cessna. They announced the start of "new clean sheet Denali" in 2015. Late last year they announced that they delayed certification yet again another year into 2023. Cessna, an established manufacturer of pressurized "aluminum" airplanes with all the technology and resources in aviation is taking at least 8 years. "First announced in 2015 by Textron Aviation as the Cessna Denali and Model 220 at the EAA AirVenture Oshkosh, the Beechcraft Denali features a completely new design to compete with single-engine turboprops (SETP) including the with Pilatus PC-12 and Daher-Socata TBM." Beechcraft Denali Certification Extended by a Year | Business Aviation News: Aviation International News (ainonline.com)