1980Mooney

Verified Member-

Posts

3,477 -

Joined

-

Last visited

-

Days Won

7

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by 1980Mooney

-

Common topic....

-

I’m going to go ahead and put this BS here again

1980Mooney replied to chriscalandro's topic in General Mooney Talk

Do you have any idea why LASAR has abandoned many of their PMA'd Mooney parts? Their front end cash cost to "reverse engineer" those Mooney parts is already sunk - a one-time fixed cost. Is there some oppressive cash "holding cost" that makes it uneconomical? - insurance? legal/regulatory filings? With the frond-end work done and approved, you would think that they could price accordingly to cover any rising variable costs and still earn a return. Let's face it - if an entity like LASAR can't make a viable return on existing approved fully engineered PMA'd Mooney parts, then no-one can. Certainly seems unlikely that anyone new is going to enter this old Mooney market to pour cash and time into reverse engineering, getting it approved, tooling up and building inventory. We need to stop this dreaming. -

I’m going to go ahead and put this BS here again

1980Mooney replied to chriscalandro's topic in General Mooney Talk

Companies use layers of protection to defend their intellectual property. As stated by @PT20J there are no patents but Mooney can use the TCs, Mooney owns some STCs like the 310HP upgrade, they have confidential drawings and specs, they have confidentiality and exclusive contracts with some suppliers (i.e. - Garmin G1000 - although Garmin is capable of upgrading mid 2000 models with G1000 to Nxi, they are prohibited per contract). -

I’m going to go ahead and put this BS here again

1980Mooney replied to chriscalandro's topic in General Mooney Talk

True - some PMA'd parts suppliers are better than others.... https://www.flyingmag.com/mandatory-service-bulletin-for-superior-millennium-cylinders/ (BTW - this is a new 2022 SB - not the 2006 Superior cylinder debacle that led to bankruptcy in 2008) https://www.aviationpros.com/aircraft/news/21125014/superior-air-parts-is-paying-5-million-in-engine-lawsuit-after-deadly-2016-crash https://www.federalregister.gov/documents/2020/12/11/2020-27149/airworthiness-directives-superior-air-parts-inc-engines-and-lycoming-engines-reciprocating-engines https://www.avweb.com/ownership/detonation-concerns-behind-superiors-buyback-of-xp-400-and-xp-382-engines/ -

I’m going to go ahead and put this BS here again

1980Mooney replied to chriscalandro's topic in General Mooney Talk

In general as you get farther from the OEM there is a natural tendency for specification, quality and especially traceability to suffer. Before everyone blows yes there are great PMA'ed third party suppliers. But OPP is at the other extreme. I understand the FAA Guidelines - I am sure that they keep the "honest pilot/owners honest" (like Basic Med). And an individual may have great skill and is willing to take the risk of a problem from a part that they produced/manufactured that is installed on their own plane. But what about when they sell their plane with OPP? There will be ongoing liability to the former Owner for the OPP part. The traceability will go back to the Owner at the time of the OPP - it has to be logged in the maintenance logs. The attached FAA PowerPoint on OPP has a slide "Making Parts Why Take On That Liability?". There is liability - probably small. If a question of liability does arise, it doesn't sound like the Mooney Factory will have any desire to help you prove you produced an equivalent part to spec and material. As @GeeBee pointed out on the prior page "I asked Jonny at Mooney Max in June 2022 if he was worried PMA manufacturers were going to "pick Mooney's bones". He answered that Mooney owns the drawings and designs and no one can produce them without Mooney's approval" And Jonny, the CEO, is a lawyer so I suspect he knows exactly what he is doing re: PMA and OPP. With an OPP, a new owner of the plane does not know the skill level of the owner that made it, know if the owner had factory drawings/specs or the integrity of whoever signed off on it - it might have been just be a "paperwork" exercise. A buyer might be ok taking that risk but as time goes on these planes with OPP become more "experimental" and less "certified". Price needs to reflect that. https://www.csobeech.com/files/FAA-OwnerProducedParts-DonDodge.pdf -

I’m going to go ahead and put this BS here again

1980Mooney replied to chriscalandro's topic in General Mooney Talk

Verification by whom? Are you suggesting that the Mooney factory will be proving certified factory drawings and material specs free as well as verification? -

I’m going to go ahead and put this BS here again

1980Mooney replied to chriscalandro's topic in General Mooney Talk

Don't take this personally but if I were buying a Mooney that you or any Owner that has "a TIG welder and (thinks they) know how to use it." went the OPP route to repair, replace or remanufacture any control rod (brakes, flight surfaces or landing gear) I would deduct the cost to properly source and replace (parts and labor) those approved parts from the purchase price. I don't want to be a test pilot for someone's amateur welding ability. If I were wanting to buy amateur built parts/plane I would be going Experimental. -

Also...

-

The Toyota ones fit but are heavier than the stock Mooney - the rods are solid steel rather than tubular as in the OEM Mooney. Look at M20K Illustrated Parts Catalog - Sect. 25-00-02. There are 3 different kinds of headrests depending on serial number. But the tubular centers and diameters may be the same and interchangeable.

-

Really? Looking up country consumptions on a daily basis: Aviation gasoline is a pitifully small market....Auto Gas is about 900 times greater, Milk is about 140 times bigger, Jet A is about 100 times greater, Beer is 37 times bigger, even Orange Juice is double in size.... Canada Aviation gasoline - 47,000 gallons per day - about 3 small to medium backyard swimming pools Jet A - 2,740,000 gallons per day Automobile gasoline - 33,600,000 gallons per day USA Aviation gasoline - 412,000 gallons per day - about 27 small to medium backyard swimming pools About half a backyard swimming pool per state per day - you could fill with a measly hose during the day... Jet A - 45,200,000 gallons per day Automobile gasoline - 369,400,000 gallons per day Milk production - 57,500,000 gallons per day Beer production - 15,373,000 gallons per day Orange juice production - 874,000 gallons per day

-

"Blended by anyone"...I think you are dreaming. More "local suppliers" means more potential quality control issues for Avfuel and GAMI. They are not going to want to deal with a lot of mom and pops on start up of a nationwide distribution plan. And if there is one, even one, quality issue in the rollout and expansion because of a small/local "blender" it will be a disaster. - i.e. Chevron, Mobil, etc. I bet that Avfuel and GAMI stick with larger more reputable chemical suppliers with track records and deep pockets initially even if it means the cost is higher. What do they care if the cost is more? - they have no competition for now. At this point in their business plan, they need to grab market share as fast as possible. They need to reliably deliver perfect quality product while dominating most of the distribution and market. Then and only when (if?) Swift delivers an approved 100R - then Avfuel/GAMI can work on driving cost down with cheaper suppliers. - further undercutting Swift competitiveness.

-

Southern Cal- Can I borrow your K model seats?

1980Mooney replied to glbtrottr's topic in Modern Mooney Discussion

Geez - and I thought I had problems years ago when during a significant panel upgrade, the Avionics shop I was using was sold. The new shop owner immediately started "remodeling" before my plane was finished and misplaced my log books. I had to search the premises and luckily found them. Wish you good luck in this unfortunate situation. -

Once G100LL rolls out (as Flying says will start in California in the next 2-3 months) isn't it really "Game Over" for Swift 100R which is not yet even approved? Why would pilot/owners want to buy 2 STC's so that they can potentially run either GAMI or Swift 100UL? What airports are going to spend material capital investment on additional fuel trucks and additional tanks and pumps so that owners have the luxury of choosing between 2 different "100UL" avgas? This creates even worse manufacturing and distribution costs by splitting a relatively small market into smaller pieces. Perhaps the best that Swift can do is once Swift 100R is approved (if ever) and available then likely they will convert their 94UL distribution and the existing FBO fuel trucks, tanks and pumps to 100R - and just stop selling 94UL and just sell one grade (100R UL). Then you will might have the choice to 2 competing 100UL at some airports.

-

Type Data Sheet 2A3, Required Equipment

1980Mooney replied to 0TreeLemur's topic in General Mooney Talk

I have an M20J Illustrated Parts Catalog dated January 1989. It has an "Optional Equipment Group" and that is where the Rotating Beacon is listed (Section 110). Later IPC's that are online (1998 and 2003) don't show an "optional equipment group". Instead, the rotating beacon is with the Lights Group - Section 33 (33-40-04). It appears this light was an option and not required. My 1980 M20J never came with a rotating beacon. If it is a not required then it seems like a mechanic should be able to remove it and remove or "inop" the switch with a simple log book entry. -

Ovation Ultra Questions from a Newbie

1980Mooney replied to Canadian Gal's topic in Modern Mooney Discussion

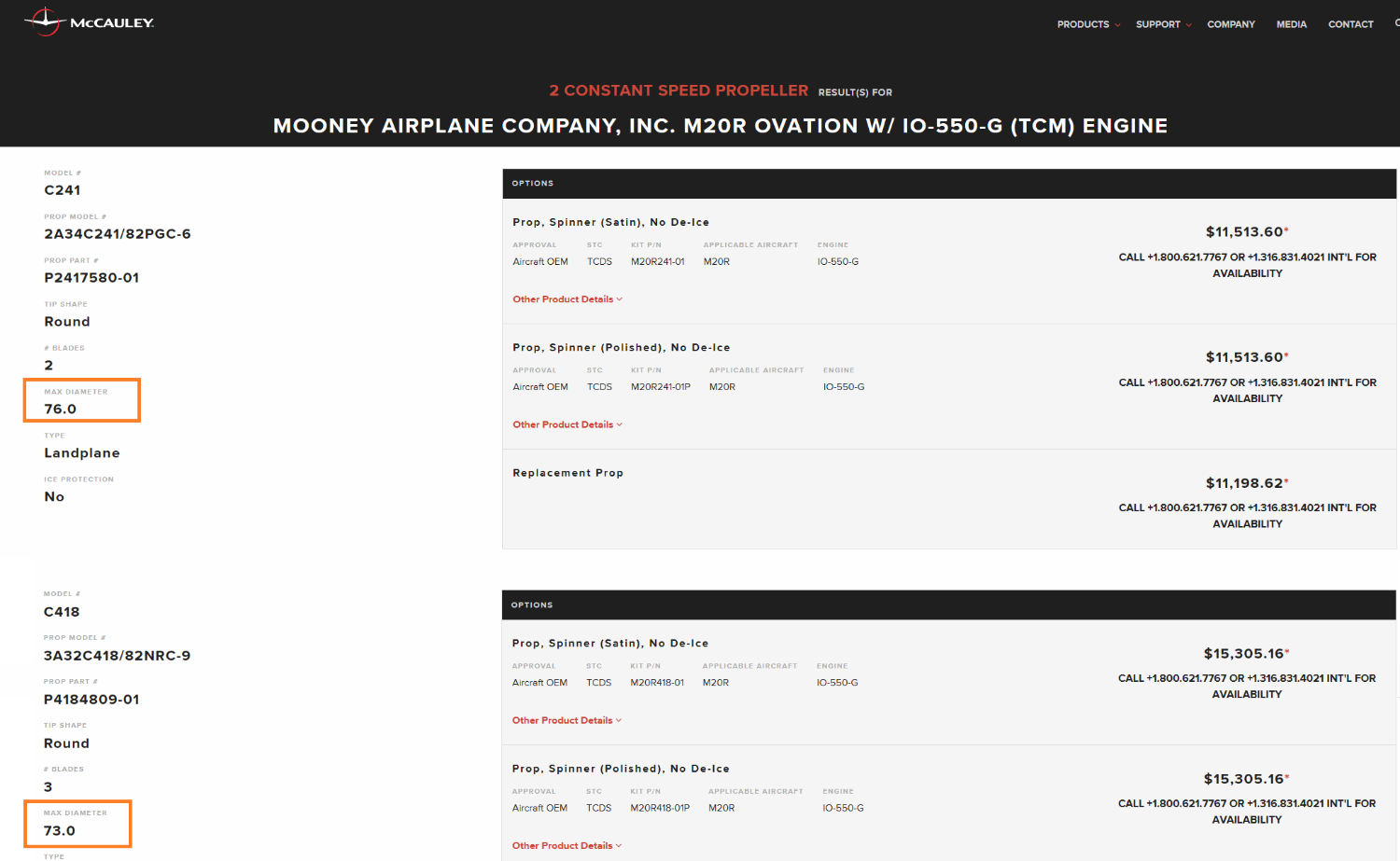

You would not have guessed it because it is not true. Since the OP is interested in the Ovation: The original Ovation had a 3 blade McCaulley - 73" The Ovation 2 came with a 2 blade McCaulley - 76" The Ovation 3 and Ultra came with a Hartzell Scimitar 3 blade - 76" These are the OEM props for the Ovation. -

How many times has your door opened in flight?

1980Mooney replied to c1tice's topic in General Mooney Talk

It has never "popped open" in flight. It was not closed properly once. One thing to watch out for however is sometimes passengers or mechanics will grab the top of the open door and lean on it or push against it when it is open for some reason. A bad gust of wind from behind the plane can wrench the door open hard too. This can flex the door and the hinges slightly (even bend the hinges some). If it is leaned upon then the top clamshell will contact before the center striker. You can probably pull the center strap getting everything flush to close the handle. But if the top is flexed outward (flexed forward when open from someone pushing/leaning against it when open or bent by a high gust of wind) then the center strike lines up but the clamshell doesn't grab the cone tip in the pic properly - sometimes right on the edge (it is spring loaded so it adjusts to what it is grabbing) - and the suction in flight pulls it open. Mooney door adjustment is an art - you have to look at any flex in the door, especially the hinges, make sure all the links and springs are lubed, make sure all your gaskets are smooth and properly placed and then adjust the cone tip length that contacts the clamshell -

Isn’t every engine certified in the STC? Once distribution starts at those airports it’s just a matter of paying for the STC. Right?

-

Exactly and you have overlooked the additional cost of litigation which continuing manufacturers and distributors of leaded gas will face. As said before leaded avgas is a boutique fuel which has to be produced in refineries. Batch runs at refineries will get smaller and economics will suffer. Quantities are too small and contamination too great to ship by pipeline - everything has to be by truck. Distribution economics will get worse and worse. There will be out-of-state litigation against those companies, still producing and distributing leaded avgas. He’s generally large corporations that won’t want the liability and hassle. And then think of the potential liability that a pilot faces if he flies a plane (with leaded Avgas in the tanks) into a state that has banned leaded Avgas. If for any reason the tanks need to be defueled by a mechanic or an airport. I bet the pilot/owner will face big hazardous waste, cleanup, cost, and potential fines.

-

Timely article in Flying online. Some new information: ”Early estimates show a March or April initial rollout focused on a limited number of airports in California. GAMI intends to utilize the existing distribution network. Avfuel and GAMI will issue a license to produce G100UL. Production and distribution will be in multiple locations based on demand.” https://www.flyingmag.com/g100ul-avgas-replacement-set-to-soon-hit-pumps/

-

That is why municipal airports and counties will make the decision to ban the sale of any fuel with TEL.

-

Possibly but Graves is also a longtime proponent of "pay as you go" user fees to fund transportation infrastructure. He has been pushing a Vehicle Mileage Tax since 2015. A General Aviation "ATC User Fee" would be the perfect bullet to fit his pistol - either by flight or by hours flown. He now has the reigns and 2 audiences that will support him - 1) It may fit the philosophy and play well with Scott Perry, Chair of the Freedom Caucus and on the Transportation Committee. Remember that he voted against the Aviation Funding Stability Act of 2021 (opposite of Graves' position). And many in the new Congress - especially the critical outlying swing votes that don't give a crap about GA, will welcome the idea of any reduced burden on FAA funding due to more direct funding by General Aviation. 2) Commercial Aviation, which I suspect will be very generous in campaign contributions, will also welcome its reduced burden of (currently near total) funding the ATC system. House Panel Advances Bill Protecting FAA Operations During Shutdowns - Government Executive (govexec.com) Roll the dice.....

-

It has been 10 years since the last fight for General Aviation ATC User Fees. Prior to that it was debated in 2005. With the coming Debt/Deficit impasse in Congress and possible (likely?) default this year spurring demands by some in Congress to reduce Gov't spending, the FAA will likely have its budget curtailed. And everytime the FAA has a budget fight, General Aviation ATC User Fees come up as a possible "solution". It seems likely to come up again. Commercial aviation sees GA Part 91 as parasites that freeload off the ATC system without pay its fair share of the cost. The average Joe sees GA as a luxury hobby. In 2012 there was a proposal for GA to pay $100 "ATC User Fee" per flight. The Senators fighting for GA in the past are gone - notably Sen, Inhofe. Will this be the "event", the year that we see the fight come back? GA supporters in Senate join fight against user fees - AOPA CHRG-112hhrg76498.pdf (govinfo.gov) Impending User Fees: GA’s Most Serious Threat | Airport Journals Are User Fees Coming? - FLYING Magazine Fight against user fees heats up — General Aviation News User Fees–Does General Aviation Already Pay “Fair Share”? | Airport Journals

-

Ovation Ultra Questions from a Newbie

1980Mooney replied to Canadian Gal's topic in Modern Mooney Discussion

If you have your heart set on an Ovation and you want to fly out of multiple grass strips and gravel then get an older model with bad paint and a high time (shorter) 3 blade prop and take off the gear doors. Flying from a home base with perfect grass which you know intimately is one thing. Flying into unknown grass is another. It is just a matter of time before you tear the plane up or get stuck. The first rut or long grass you hit with your mains will bend the leading edges of the gear doors. That big heavy Continental IO-550 puts a lot more weight on the front than the Lycoming 4's in the mid and short bodies. If you hit a rut with the nose wheel you will probably compress the nose disks during the bounce and there is a good chance of driving your prop right into the turf. And any soft ground (muck under the grass), which you will never know until you hit it, will cause your wheels to sink - you can probably power out if it is a main - but if it is the nose wheel, adding power will make the plane pull forward but the stuck nose wheel will naturally compress the disks as it slightly folds back - you will drive your prop right into the dirt. At that point make sure that your passengers or others around you are eager to help you lift the nose and push the plane back out of the rut. And gravel is no friend of a Mooney. It will just pepper your leading edges of the wings and horizontal stabilizers. And the Ovation stabilizers sit quite low to the ground. You can apply tape to the leading edges but you will still get plenty of rock damage. No point in paying for a nice paint job in that case. More than 20 years ago I was based at West Houston which had pea-gravel in the T-cover area. Just taxiing would cause damage. -

I spoke to Darwin Conrad at Rocket Engineering today. They are answering the phone and in business. They are repairing Rocket/Missile engine mounts. (509) 535-6445 (509) 991-3276 Rocket@icehouse.net