1980Mooney

Basic Member-

Posts

3,228 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

That raises a good question- @Mark89114 are these 430 or 430W boxes? Garmin stopped doing WAAS upgrades on GNS430 last year. If they are not WAAS units I would junk them.

-

No they are all in parallel. Planes that were originally 14 v are still 14 v and those that were 28 v are still 28 v. They just have 2 Concord Recombinant XC batteries wired simply in parallel in a box that slides all the way to the back of the tail. They give you a special board that you use temporarily to slide them because of the weight and difficulty getting back there. Ovations have 2 batteries in parallel but have a more sophisticated wiring of the batteries so if one fails the other is still at peak performance I believe. I have never had any problems with the Rocket approach If he roasted even one he needs to replace both batteries with equal strength because of the parallel wiring - he is looking at about $1000 in batteries, new regulator and labor. Probably an easy $2000 total if there are not other problems or damage.

-

Rocket Engineering, back in the day, took the airframe that you brought them (J for Missile 300 - IO550 and K for Rocket 305 -TSIO520) and essentially did a firewall forward modification. They did not gut the plane of existing 14 volt electronics/wiring if you had a pre 1986 K or a pre 1989 J. They did not touch the 14 volt vs 28 volt relays, breakers, landing gear actuators, or avionics/panel. They did relocate the battery and put 2 in the very back of the tail essentially for ballast to counter the forward CG of the new heavier motors and props. I have the last Missile they did in 2001 and it is 14 volt.

-

No - his serial number is 25-0872. 28 volt started with 25-1000

-

Per your model year and serial number I assume you have a 14 volt system. At 17.1 volts charging (if accurate) your twin batteries in tail per Rocket conversion are toast. Your regulator must be bad.

-

Similar discussion last year

-

Eventually like this. One day it looked like yours and then the next time I went to the hangar it looked like this.

-

No doubt many props have been either overserviced or poorly/improperly serviced during their life. No one said every leak is an AeroShell issue. But it is a serious enough issue that Hartzell publicized the formulation issue in letters to owners/shops and abandoned AeroShell completely - they surely have good reason. All I know is that during the 21 years of life of my Hartzell Scimitar, it has only been repaired by Texas Aircraft Propellor (formerly R&D Propellor) in Pearland, TX - a certified Hartzell Service Center. My Scimitar went 14 years without seal leaks before its first overhaul in 2015. The same A&P shop serviced my prop annually for 9 years before the 2015 overhaul and the 6 years after. Seal leaks developed the 6th year after the overhaul. They only known material thing that changed was the formulation of AeroShell 6 at the time of the overhaul.

-

This unfortunately is a quality issue with AeroShell 6. As Hartzell has highlighted in letters to shops and owners, for some reason Shell changed the formulation of AeroShell 6 sometime in the mid 2010's. It breaks down sooner than earlier formulations. I have a full feathering Scimitar that was overhauled and refilled with AeroShell 6 at a Hartzell Service Center in 2015. In 2021 I started seeing streaks on the blades. Then it got worse and started spattering a film on the windshield. The warm climate I am in probably makes it worse. Also the full feathering exercises the seals more on mine. As a result I had a reseal done early this year at a Hartzell Service Center using NYCO GN3058. In January 2020 Hartzell completely discontinued use of all AeroShell products and started shipping all new props exclusively with NYCO GN3058. It is synthetic and NOT COMPATIBLE with AeroShell. The props have a placard that warn your A&P - if they burp it with crap AeroShell they will be paying for a complete reseal.

-

I thought the appeal of a turboprop was 'it's insane reliability". Interesting.

-

Once again the introduction of G100LL and other unleaded fuels should lead to the use of modern synthetic engine oils. Synthetic lubricating oil is capable of carrying much higher-quality additives – friction modifiers, anti-wear additives, antioxidants, and more. Synthetics are able to withstand the high heat and high rpms of a turbocharger. Once that dinosaur mineral oil is gone your mental health will improve!

-

True - and when G100UL and any other unleaded fuel arrives all GA should move to 100 hour oil change intervals.

-

Oxygen refill - Tank size and filler adaptor help

1980Mooney replied to jrwilson's topic in General Mooney Talk

You can rig your own hoses, Y's, flow indicators and fittings up - easily purchased online. I bought this in line flow indicator online from Amazon. SP Bel-Art Roto-Flo Polystyrene Flow Indicator for ¼ to ⁵/₁₆ in. I.D. Tubing (H19937-0002): Enema Flow Indicator: Amazon.com: Industrial & Scientific -

Oxygen refill - Tank size and filler adaptor help

1980Mooney replied to jrwilson's topic in General Mooney Talk

I bought a used OxyGo NEXT (which is manufactured by Inogen and identical to the Inogen One G5) before Covid drove prices crazy. Works great. -

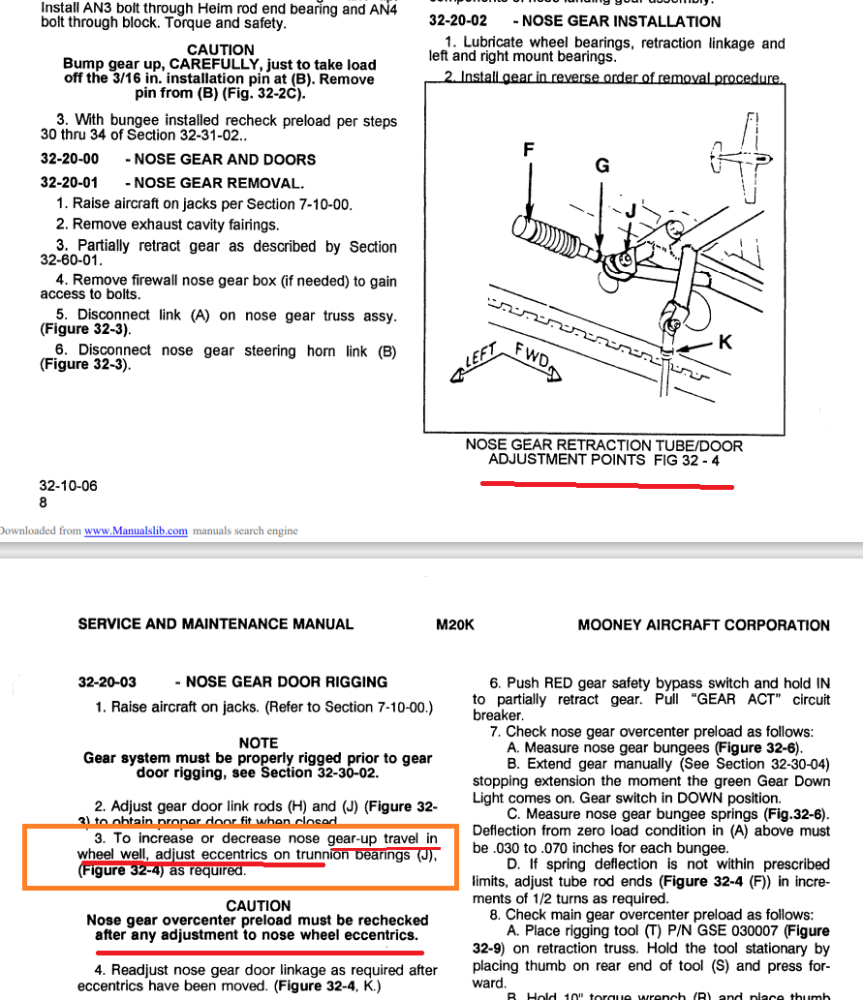

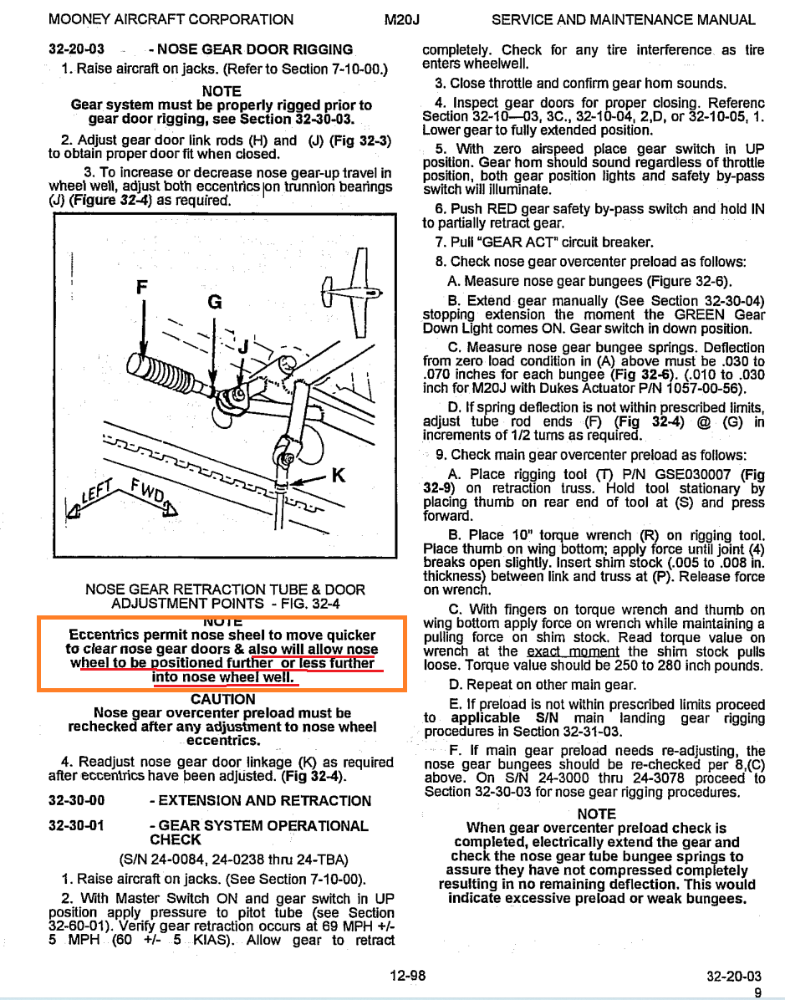

I hope you and your A&P have a copy of the M20K Maintenance and Service Manual are following the landing gear rigging instructions religiously. I see you have a "305" designation meaning a Rocket conversion which adds a lot more weight than the K nose gear was designed for. You should be able to adjust the nose wheel travel up into the wheel well. See the instructions for both K and J. They have the same body. The J instructions explain it a little better. Note that the nose gear overcenter preload has to be rechecked after adjusting travel.

-

Here is MooneyFlyer's (June 2020) advice on running LOP in a 231. See page 34. It is in response to the question from a 231 owner with Merlyn, Intercooler and GAMI injectores just like you. The article is by Brian Lloyd who flew an M20K around the world. Present Position (themooneyflyer.com) “In the last Mooney Flyer issue I read about Brian Lloyd flying around the world in a M20K. In his article he mentions that most of the time he flies LOP (Lean of Peak). “I also have a M20K for over 15 years also with intercooler, Merlin wastegate and Gami injectors -however I always fly it ROP because I hear so many stories about damaging the engine when flying LOP. Therefore, I would like to talk or write to somebody who really has the experience – like Brian –about him flying LOP on the TSIO 360 - and his experience, and which power settings, temperatures he is using.”

-

As @carusoam highlighed jlunseth has the same set-up as you (Merlyn and Intercooler) - his advice (and also on page 2):

-

This guy is a real shop pro when it comes to Mooneys. He has published some great articles. - look at his publication indext For you: 200001 Operational tips for the M20K (knr-inc.com) And your A&P: 199905 Adjusting the TSIO-360 (knr-inc.com)

-

Some history about the M20K 231 and 252. You said you have an intercooler and wastegate modification so you are similar to a 252 (but not exactly the same induction and cooling and other aerodynamic tweeks) Mooney 231/252 - Aviation Consumer

-

Cruising with 31" MP and 2300RPM. - the engine chart shows that would be about 155 HP or 70%. Those speeds look better. Was your fuel flow 11.0 - 11.5 gph (best economy)?

-

I believe Muller in the video highlighted that the alkylate in automobile gasoline is of much lower quality and lower octane than what GAMI is using. I think he said that GAMI sources it from a chemical supplier in Europe. Also auto gasoline is loaded with at least 10% Ethanol. GAMI will not have that "witches brew" of crap in auto gasoline. In any case they have been conducting tests now for years in Oklahoma where it is bloody hot. I have to believe that they have conducted shelf life and evaporation tests. Now you may be right that G100UL doesn't have the same 3-5 year shelf life of 100LL - but what does?!

-

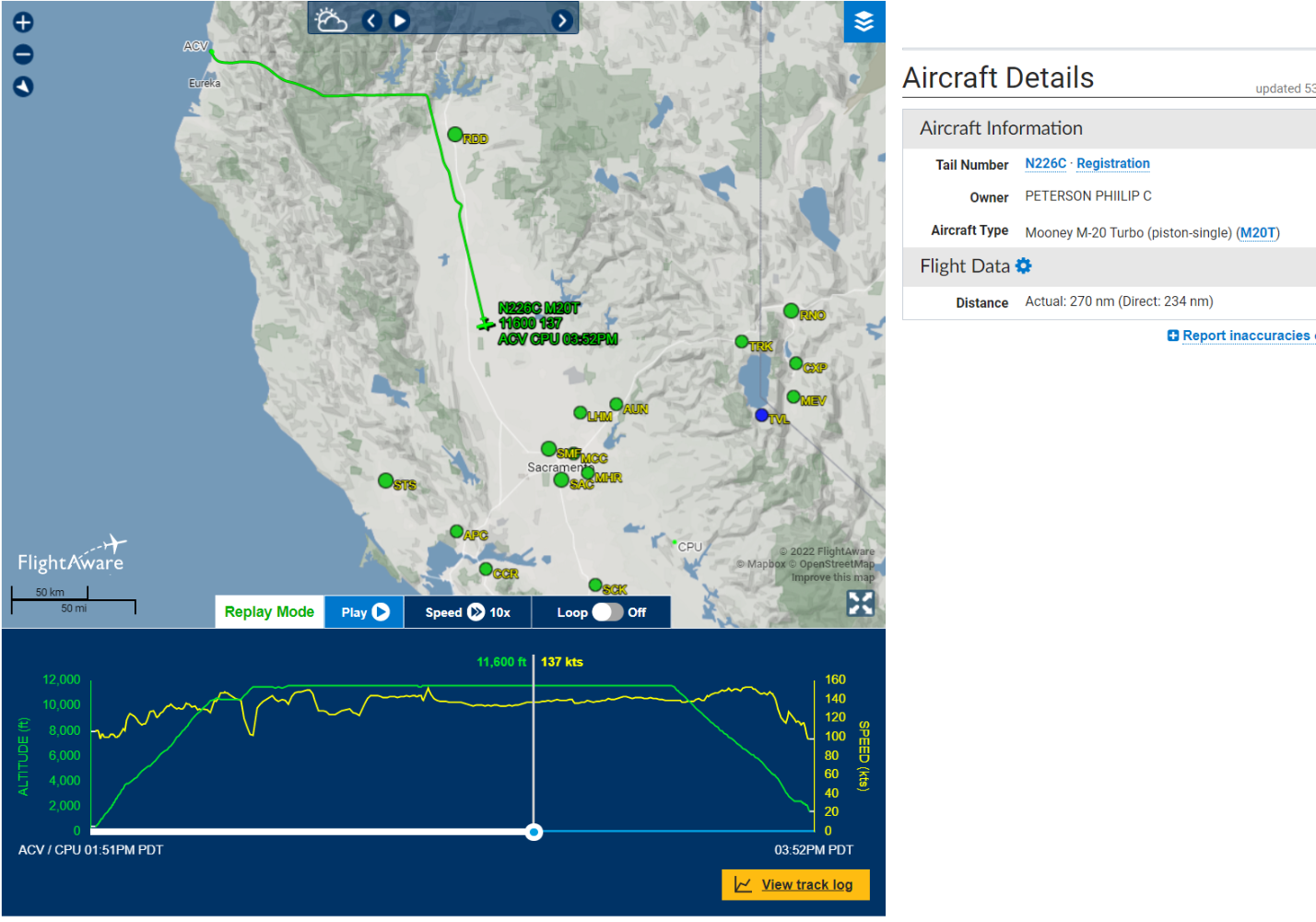

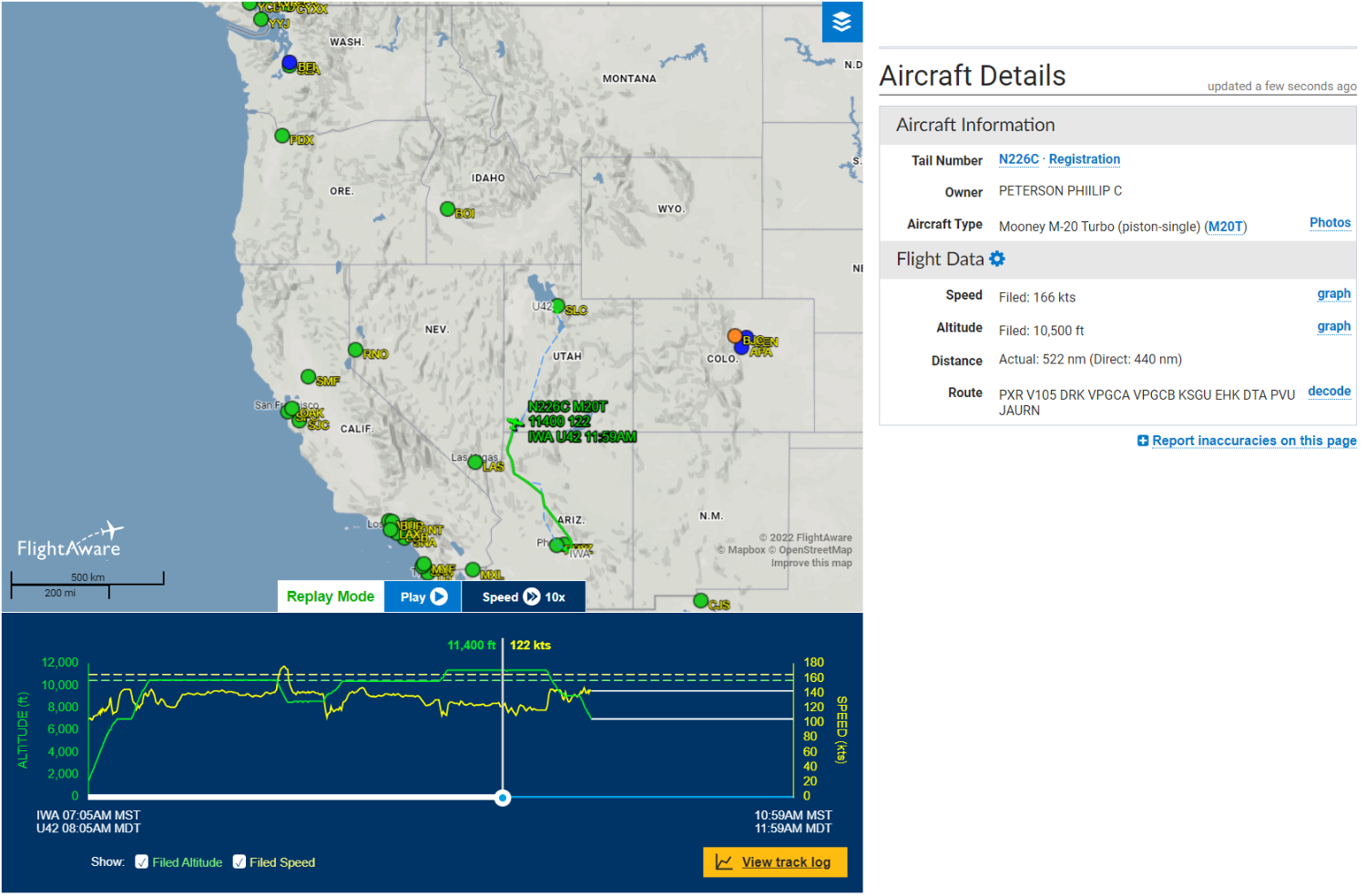

I don't fly a turbo but just looking at your flight history on long flights above 10,000 ft your plane seems slow for a K with waste gate and intercooler. And is there a typo in your N number in your profile? - are you N226C? Do you fly LOP? Are you sure your engine is making full power?

-

Departure Emergency - Challenger Oil Filter

1980Mooney replied to alextstone's topic in Mooney Safety & Accident Discussion

As stated previously the connecting rod bearings are downstream of the mains n the oil flow pathway. Upon loss of pressure the hydrodynamic pressure wedge is lost and there is more metal to metal contact. Depending on engine speed, engine load and smoothness of bearing surfaces friction induced heat will build. And as a result the connecting rod bearings seem to suffer more and sooner upon starvation. As you point out the engine will likely run just fine. But the question is what level of damage, what accelerated wear and reduction of engine life occurred? I am curious what a “one days worth of (engine) inspection” involves. What exactly do you inspect? Cylinder wall with boroscope? Do you pull a cylinder and rod to examine wall, rings and rod bearings? If any oil is left in the sump do you analyze for metal content? (Oil analysis and filter examination?) Thanks -

Departure Emergency - Challenger Oil Filter

1980Mooney replied to alextstone's topic in Mooney Safety & Accident Discussion

This sounds like the perfect candidate for an SDR and a broad PIREP on Challenger Aviation Products. It sounds like a poorly engineered product design with even poorer quality control. There is no way that that thick Quad Seal could be oozing out unless it is the wrong size or manufactured from the wrong elastomer compound which expanded in contact with hydrocarbons. The Quad Seal clearly does not fit the machined groove. It sounds like in spite of highly skilled personnel installing it with meticulous detail per Challenger instructions it still failed. The plane and lives could have been lost. Those on MS should consider this when contemplating buying anything from Challenger. And it should appear on the next to last page of Aviation Safety so all brand owners in the flying community can be aware. I would think that Challenger would be eager to make this right - both with you financially and by recalling the defective versions of this product before someone is killed. If you don't inform the FAA then Challenger can claim ignorance of the defective design and/or manufacturing. Once the FAA and Challenger are informed then future new installation failures will be negligence on the part of Challenger. -

I remember around 1995-2000 lots of additives for car engines were being heavily advertised…Slick50 original with PTFE “Teflon”, Microlon, Duralube etc. My then A&P had an engine in the shop torn down. The owner had been adding one of those additives without telling the A&P. The owner thought if one quart of additive was good then 2 quarts would be even better. Well all the valves stuck.