-

Posts

259 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Releew

-

So I just read all of the fatal M20F crash reports

Releew replied to FloridaMan's topic in General Mooney Talk

Really...Come on! Don't think so! You say.... "The Mooney's glide ratio is way better than the Skyhawks or Warriors, you don't need to be right on top of the runway on downwind to be able to glide in, in the event of an engine failure. And engine failures on landing are far less common than stall/spin accidents." I have had an engine out in a M20C. It was like going over a hump on a roller coaster. It took instantaneous back pressure and trimming at the same time to get to a comfortable glide speed. Got the engine to restart after about 60 seconds... which felt like an eternity. Don't kid yourself.... They drop like a freaking ROCK . Stay high....stay alive. Rick -

Son wants to become a professional pilot

Releew replied to Paul_Havelka's topic in General Mooney Talk

Consider an Associates Degree at a minimum in Aviation Management. I've seen enthusiastic kids make it all the way to the interview then get pushed aside for not having any higher education to their name. If it were my Son, I would encourage both schools....Flight and College. Rick -

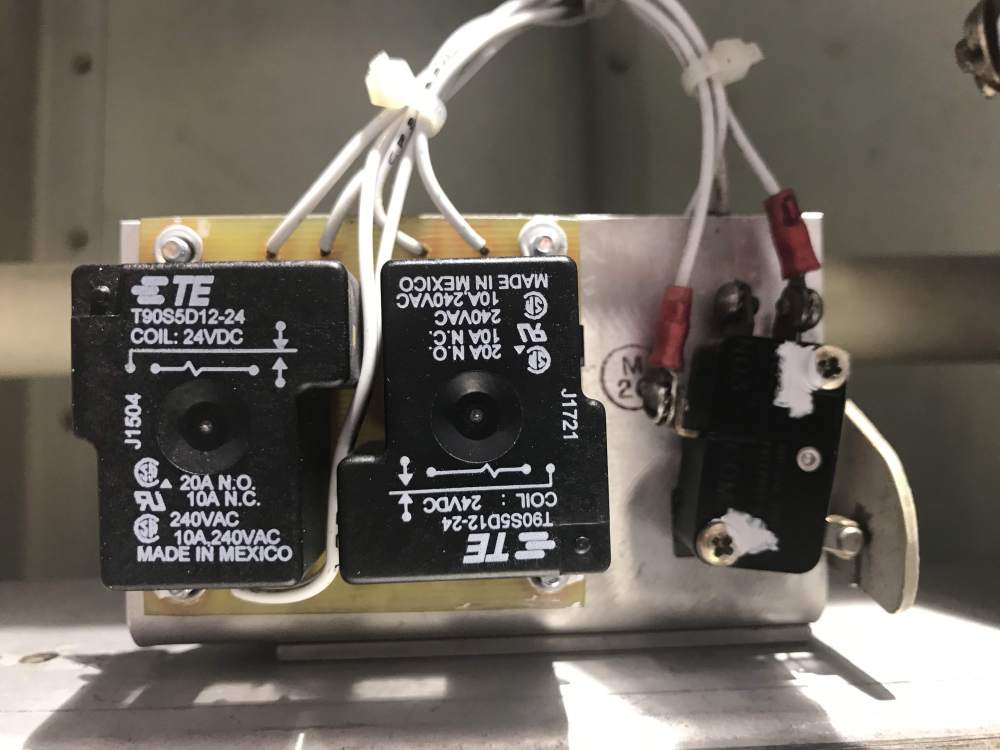

Agree..... electrically this can be done with Four Switches and no relays. Without a schematic its hard to tell what they are utilize for, but if I had to guess, its to latch and provide a permissive path to the secondary relay or other switch in the circuit.

-

Correct..... The Potter Brumfield relays were $11.00 each. You need to know how to remove and replace as they are soldered in position. No Biggie..... I was just happy to find a Root Cause..... Mine chattered under a load, meaning when "in air." Rick

-

A while ago, I published that my flaps would deploy and would not retract. After some extensive troubleshooting, it was linked to two sealed relays. Each micro switch in the circuit was methodically checked and found OK. The relays are hard soldered to a circuit board. Mouser electronics helped cross match the relays from the currently installed part. I looked in my service manual, but could not find any information on the relays. The new relays were installed and worked flawlessly until last week. Same problem occurred! I never found a "Smoking Gun" on the first replacement, so although the problem was solved, I could not conclude how these relays got their contacts fired. We use hundreds of relays in control panels at work and I have very seldom had relay failures. So why? It turns out the Flap Target was too close the the contact wheel of the micro switches. With the aircraft on the ground, and flaps at takeoff position (and Gravity doing its thing) the separation of the target and the switch contact was enough to drop the circuit. BUT...... when the flap were generating lift, it moved the target fractions closer to the switch contact and created relay chatter. Ill admit, this was discovered by accident when a friend in the hangar happen to lift up on the flap when I was staring up at the flap motor. Sure enough, the relays started humming and the motor started pulsing. Its a wonder they lasted as long as they did!!! Just wanted to pass this along. This site should be all about passing on information to solve problems! Rick

-

Thanks..... Steve has helped me in the past! Great advice...

-

If you see visible cracking, cuts and or deterioration, OR if the plane is on Jacks with the wheels OFF the Ground and you can move the gear in a vertical position. If you have rear door fairings you mas see some rubbing (marks) too. Rent the tool to replace the donuts or have it done by someone who has a clue. The compression tool makes it effortless! Rick

-

My HSI suddenly stopped movement. Upon landing, I reset to the correct compass heading and locked to the caged position. The gyro is running in the avionics bay, but the Autopilot is not following the heading bug or NAV. Pressing the NAV button put the aircraft in a continuous 360 SRT. It will hold altitude. The HSI does follow the compass and seems to be accurate to magnetic heading after I reset it. Any input would be appreciated. Rick

-

Look at the Mooney factory tour video. If you have any Engineering experience and or production manufacturing time, you can easily see there are simply too many manual complex operations that require more basic than off the street talent. That equals dollars. More dollars spent on complex building, eliminates margin for the investors. Reduced margin eventually leads to an operation, operating on a shoestring. Never a good outcome which we've seen happen this great product time after time. We all want to see this company successful, but from a business model point of view, I just do not see it happening. I cannot see how they could ever get the numbers to work even in a strong economy. Are their sales figures published anywhere? Rick

-

If your speed is in the White Arc you're fine. Little Flap, Lots of Lift. A Lot of Flap, Lots of Drag....... With full Flaps, Mooney's do very well on a steep approach. If the approach is flat it will take 15in of MP Plus depending on Load to maintain Level Flight. As a common practice, I to land with the first flap (take off) position in case I need to exercise a go around. There are so may factors to consider.... Clearing and obstacle on a short strip is one..... If there is plenty of runway and the approach is unobstructed the first flap position is all that needed. If you have to execute that go around, with a load, you will be glad that's all the flap you had dialed in....

-

Considering purchasing a Mooney - transitioning from a C182

Releew replied to David Klasing's topic in General Mooney Talk

You should not hesitate to make the transition to a Mooney. Personally I, as well as several others consider this aircraft to be one of the safest around. Based on the wing design you must respect the numbers in the POH. My belief is, if you can fly an airplane at controlled airspeeds the Mooney will land just like your land that 182. Obviously there is much more to manage in the Mooney and you need to learn to stay ahead of the aircraft but that comes with training and time in type. I have heard so many people speak about the Mooney as a Hard to Fly airplane...that's nonsense. As I suggest in the past, find an instructor that has a minimal of 100 hours in the Mooney. Use them to get past the insurance company then find a seasoned Mooney pilot that will fly with you as often as possible. There are several bits of information you can learn from a mentor with a lot of Mooney time! Good Luck and Welcome. You will find this site to be very helpful as there is a wealth of information on it by folks who are very fond of this aircraft!! Rick -

Nothing at all against CFI's so please do not take this negatively. I respect their level of training and what it took to get to that position. Personally I've found some of them, not all qualified to teach, but in all honesty not having the knowledge or the precision to dive into the Mooney's details. I suggest you look for a person with some significant Mooney PIC time to mentor you on the nuances, most likely not known by a CFI with a 100 or so hours in type. So..... just saying this person (your CFI) can teach maybe a long-shot. He can get you comfortable and hopefully and past the insurance company! Although I do not find the Mooney to be a difficult to fly airplane it is a Numbers machine. Respect the numbers!

-

Speed brakes work great to descend with MP.... Other than that, they're an expensive novelty..... Pull the nose back.... It will slow down! Rick

-

In my neck of the woods, premium goes for $2.75/gallon. We have been running $4.25-$4.50 for 100LL Rick

-

I can remember 100LL was generally speaking about $1.00 more than 93 Octane Premium in the 80's and 90's. Is it fair to say there is less general aviation interest, lowering the usage, thus changing the refining priority? I see such a decrease in South Louisiana in GA its concerning. Airports that had several aircraft on the ramp are now down to few. Hope GA picks up in this area...... Rick

-

I have painted a few aircraft over my time.... Do not kid yourself, a quality job on a small plane, single engine aircraft is 15K. If its not, question the shop on what products they will use and exactly what steps they will follow before topcoat. If your preference is red, hold on tight as its the most expensive on the color chart. If you want a modern polyurethane, with a brand name like Imron brace yourself. If would want an elaborate paint scheme, sit down before you see the estimate. I am responding to this because so many people ask me to paint or to do blend work who do not understand how time consuming and labor intensive it is to do a complete paint job on an aircraft. Just try getting the paint off yourself and the 15K will seem cheap! This is not like wet sanding a car with a color coat clear coat! Rick

-

Very nice! I would love to see a step by step process on how the film is applied. Rick

-

I feel your pain!!!! I caused a Flap Rash and couldn't sleep for three days! It's as bad as you want it to be in your head. I replaced the entire flap..... needed to eventually sleep! Rick

-

Our 6th annual Wings and Wheels event is this Saturday, October 27th from 10:00AM to 4:00PM at (L31) St. Tammany Regional Airport. 3000' runway in good condition with plenty of parking. Great Southern Hospitality. Clean air condition rest rooms, great music, lots of door prizes and a 50/50 raffle. We are expecting a crowd! We have several Mooney's in the area and three on the field. If your flying over to KJKA to the AOPA event stop by and see us.

-

John Tune work for me on several hops. There is a lot of private jet traffic and be sure to review the approach procedures. Right downwind landing south. Really nice people at the FBO (under green tin roof) and Hertz will drop of a car there. Rick

-

For dime size leading edge opportunities I have successfully taped the surrounding area and filled the void with multiple coats of paint. When you have enough build up (chip filled) remove the tape, wet sand with 800 Grit then cut and buff. This ONLY works with solid colors, NO Metallics! A little trick I learned was to activate the paint and allow it to start to thicken. If you wait long enough you can use a plastic or rubber squeegee and literally spread it on. Remember you are trying to get the surfaces even. Don't worry too much about what it looks like because you are going to sand, cut and buff it...... Like I mentioned earlier, before making the decision to fill a lot of Dime Size chips it may be a good idea to paint to a panel. On my Mooney I had a lot of paint splintering. Too much flying in the rain!!! I taped a hard line to the second row of rivets and painted the entire leading edge. This worked very well. Almost looks like protective wing tape. I will look for some pictures.... Rick

-

Use a Harbor Freight HVLP feed. OK for a few jobs. By far not a good solution for multiple uses or to paint an entire plane Set for 40 PSI at the tip Use a filter at the gun Quarter size chip can be feathered and blended Removing the paint completely from the belly takes care, as it is fiberglass. Solvent stripping is not recommended. Remember painting on aluminum takes additional prep steps as in an etching primer on the raw aluminum then followed by a build primer for filling. Rick

-

I've been painting for a while.... Lacquers, Acrylics, Epoxy, Poly.....Color Coat/Clear Coat so you can take my advise or go to the next guy. First determine what is a touch up and what is a panel spray out. Sometime enough of the dings = painting the panel! For a novice you will be more successful painting a panel with a hard stop (a panel line or a separate part like a cowl. Remember a control surface requires balancing on a full spray out. I do not recommend color coating a control surface. Too heavy! On a chip, the paint needs to be feather edged. Meaning there is no HARD STOP to the edge of the paint. The can be done by water sanding with 320 Grit paper in a circular motion using a rubber sanding block. Once feathered, spray some primer to build the surface back and lightly sand again. If you do not see a dimple, chances are you did it correctly. With the chip feathered and filled with primer, wet sand the entire area with 600 Grit paper. Wipe the are clean with PrepSol to eliminate painting atop of any oil residue. Apply one light tack coat , wait 5 minutes followed but two additional consecutive coats sprayed in different directions. Why still tacky, lightly spray a chemical called Blend or FADE. This is a HIGH level reducer that will melt the edge of the new paint and the old paint together. Try to apply this product on the spray line between the wet and dry paint. If you apply too much too fast your new paint will run off the surface. When dry for 24 hours, wet sand again with 800 Grit paper then use a cutting compound and buffer to polish the entire surface. I recommend you use a polypropylene based two part paint. If you screw up it will be hard enough to sand smooth in 24 hours. If you need a verbal explanation you can email me and I will give you my contact information. Rick

-

Thanks..... Each time in the air, a manual deployment was done to get the gear down. On jacks, the gear cycles perfect with the BYPASS switch depressed..... We just put a blower on the pitot tube to replicate airspeed and the problem was duplicated.....tripped the gear relay breaker when deploying the gear to down. Could be the switch is bleeding to ground when it sees airspeed and the gear down switch is triggered. Will focus on that in the morning.