-

Posts

259 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Releew

-

Although my bird has speed brakes I try never to use them if not necessary. I believe they are a great addition when descending from altitude with the MP at a higher than normal setting when making a decent. At a 2 mile final, I want a Manageable Balance Aircraft....meaning Trimmed and at Gear Extension Speed. From 2 to 1 miles, gear extension and first position flaps. less than a mile, full flaps if desired. I don't think there is a magic number (distance from touchdown) it's all a personal preference. I personally do not want to slow down AT ALL..... until needed. They sequence in how you setup to land is the most important, not the distance from landing. The more experience you gain the tighter the sequence. Just my thoughts... Rick

-

I think If Mooney would design a Composite Aircraft (J Model) wrapped around a tube steel cage they would have one hell of an offering. I also believe it would bring the labor hours down, allowing for a better price point in category. Obviously, they need to KEEP what works, i.e. the profile, the articulating tail...etc. Throw a BRS in the offering as an option and just maybe they could compete with the outfit up north! Just think of the speed they could get with a smooth skin and Mooney aerodynamics. Get that price under 500K with a 220 Knot cruise and that would be an offering!!! I know......Dreaming! Rick

-

Remove the rear fuselage inspection hatch and look for play in the Elevator bell-crank linkage that takes the single push/pull tube to a double output. I personally would not attempt to "bend" aluminum to find a sweet spot. Something else is wrong. I recently replaced a worn out bell-crank which included a new bushing. The plane has NEVER held pitch so well since the change........ Rick

-

Mooney down in American Falls, ID

Releew replied to jwilcoxon78's topic in Mooney Safety & Accident Discussion

Rick Eleew is fine....flew today! Thanks for asking. Sorry to hear about this! -

I think you are 100% correct. You maybe too conservative in your numbers but not by much. Bottom line is Mooney is simply to expensive in today's competitive marketplace. If they do not change their business model its just a matter of time. To turn this company around they need to.... Seek used and create a refurbishment program (this creates shop hours and provides good aircraft at reasonable hours). Lower their margins on parts (keeps the doors open and talent in-house). Become innovative... Bring back the M10 program. Look at the possibility of a 6 place large reciprocating and turboprop market. Sorry to say this was predicted. Just not going to work the way it is Rick

-

We've been hosting this venue for the last 8 years. Started small and turned into a very well attended venue. If you need and excuse to fly, this is a great one. Cars, Bikes, General Aviation, Experimental and War-birds. Great mixture of Classic Cars and Street Machines. South Louisiana BBQ, along with lots of prizes sponsored by several auto stores.

-

OK..... I can only provide feedback to what I validated myself.

-

Off the web... The reason your stainless bolts are binding up is because of the composition of the steel. it is very strong due to the way the particles are arranged. when you tighten stainless steel bolts and nuts the stainless sometimes grabs and creates burrs inside the thread. Note the receiver end (not plate) is steel, so by using a SS machine screws we are creating three metals. I'll look for a chart on the shaft diameters but I can tell you from experience if you do not tap the holes the SS screws will gall and bind. SS replacement screws kits for aircraft have been available for years. Try running a 8-32 SS screw in a steel nut plate and remove the screw instantly. Feel the heat.... Now tap it and do the same test. Really makes a difference... I'm offering advice....not a mechanic. I work with very good experienced licensed mechanics who turned me on to these tid bits. I only offer up what I've proven myself. Rick

-

Do you or have you named your plane?

Releew replied to Mufflerbearing's topic in General Mooney Talk

Foxey....... Name fits the plane! -

If you are going to switch from "Steel" to "Stainless Steel" there are a few things you need to do..... Re-tap with the appropriate thread size 8-32 on most (NOTE there is a slight difference between the diameter of the Steel and SS machine screw). Failure to do this will increase your chances of binding the SS screw. If you don't do this step you will understand what I mean on the next inspection! Use corrosion X to blow out the hole and coat with a lubricant Use plastic washers to eliminate galvanic action where the face of the machine screw can contact the aluminum sheet metal Rick

-

New root cause theory for flap relay failures

Releew replied to larryb's topic in General Mooney Talk

Any relay will fail and fail quickly if subjected to chatter. Its not like a switch contact. If you have any of the switches in the circuit working when the flaps are static, in the take off position simply pull up on the flap to verify the switch position by inducing aerodynamic loading. in the plane and in the air you can't hear it or feel it, but if your switch is slightly out of position you WILL fry the contacts in the relay and will not be able to retract the flaps. That SUCKS..... because the only way to get back to neutral is to remove the belly and turn that flap coupling by hand about a thousand times!!!!! All that just to get home!!!! Rick -

Issue was resolved today. Problem was reproduced on Jacks! Problem source was with the lower terminals on the panel switch(LG) grounding out on the Bypass Switch cover. (located just left) Like everything on a Mooney, the gear switch fits into a cavity. If the switch rotates just a few degrees right (looking at the front) of the switch its very possible/probably for the LOWER terminal of the Gear switch to touch the side plate of the LG Bypass Switch as it did to me. Pop goes the Gear Relay circuit! The LG switch was removed and the terminals re-positioned to eliminate the possibility of this instance again. In addition, some chafe tape was adhered to the plate cover and rubber tape applied around the switch contacts for additional protection. Bottom line is.... the barrel of this switch has NO INDEX position to eliminate rotation. Yes, its got a Star Washer on both sides but its not enough! Bad design Mooney! Check the position and security of your LG switch as alignment is critical. Thanks for everyone input! Rick

-

Thanks Everyone!!

-

All gear components were recently lubed. I am leaning towards the switch on the panel. Going to pull the glare shield ASAP. I did check the top hat latch cover and it was secure. This was the second flight of the day when this occurred. I am certain it was secure because I had to disengage it to manually extend the gear to the safe position. Thanks! Rick

-

Just inspected all mechanical linkages and could not find anything obviously wrong. In the belly, there are two relays and two limit switches. I am assuming the relays are for Up and Down and the limits are definitely for gear down and fully retracted. Anywhere in between shows Gear Unsafe. All wires are tight to the terminals and there is nothing loose. The only other switch in the system I think is the gear up/down on the panel. I know there is the gear bypass switch and I think a flow switch that senses airspeed above 60 knots as a permissive to raise the gear. If anyone had a schematic I would appreciate it very much. 92 M20J MSE Thanks! Rick

-

While taking off the gear relay circuit breaker tripped and gear light remained in the Unsafe Position. The Red light (Gear Unsafe)was illuminated and the view port was crosshatched. Tried to reset the breaker and it popped twice. Leveled off and kept the aircraft in the white arc. I manually extended the gear until the Gear Safe light was illuminated. It took six pulls which indicates the gear was most likely about half way in its retract cycle. Going back to place the airplane on jacks and drop the belly to stat to look. Does anyone have any suggestions on troubleshooting? Any guidance would be appropriated. Thanks! Rick

-

For a few days I have been trying to get a call back from Mooney technical support. Was just trying to make sure I have the correct part identified. I understand they want us to utilize approved service centers, but one would think... the term, "Mooney Technical Support" would have some meaning and there would at least be the courtesy of a return call! One call to Don Maxwell's and their support person helped track the part, Don specified the required hardware and gave me hints on the best method to change it out. The follow up was amazing! I see positives and negatives on this site regarding this outfit. From my experience, I would not even think about going elsewhere for parts and or support. Even thinking about using Don for my next annual. What a breath of fresh air for customer service! Nice Job! Rick

-

It is part #18 in the parts book. It transfers motion from the singe tube to dual tubes to each elevator. Rick

-

That time of year again...... Found two opportunities with the aircraft. She needs a new muffler.... Inside is gone, like it never existed! I see special orders from Spruce for $805.00. Anyone suggest a different source, better price and availability? Even if a little more I would pay to get the part ASAP. Second item I think EVERYONE should do a check... check... double check. A new to the plane APIA did the inspection this year. Old friend who has been in the aviation world for 50+ years and is dam good at the profession. This was his first time looking at my aircraft, I know he was his extra critical, which I like!. Much to my surprise was the Elevator Bell crank was worn at the pivot point. Not to the point of a wobble, but enough, if you held it steady and moved the elevator you could see the twist on the shaft. He said this is the first time he has ever seen this on any Mooney he's worked on. I wanted to share this with the group. Make sure whomever inspects your plane does the tug and twist test on this section of your aircraft. Just looking at this control assembly with the mirror and flashlight is not enough! Rick

-

Thanks ! Rick

-

Does anyone have a copy of an Annual Inspection Checklist for the M20J. Thanks in advance! Rick

-

I like to run at 6 quarts. For flights longer than 2 hours I start with 7 quarts but believe it drops to 6 very quickly. I would love to see a level sensor that could show actual (proportional) level in 0-100% increments so you could see in real time what engine settings and conditions effect level consumption. Rick

-

Thanks everyone! I have located one provided from this Site!! Great to have this network! Rick

-

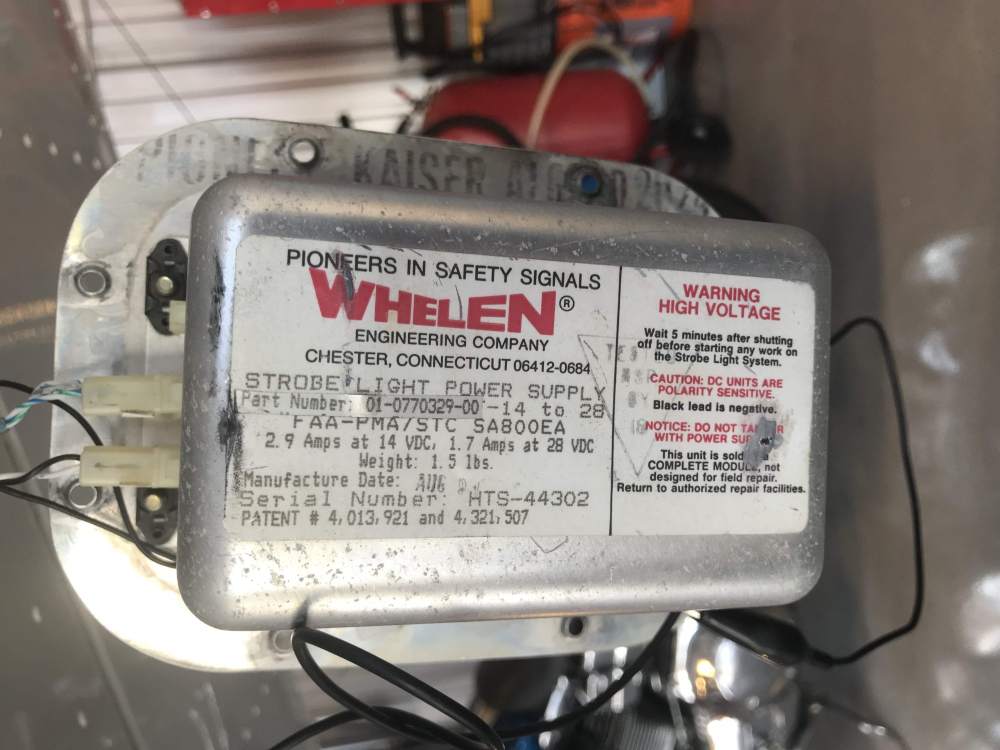

Looking for a used (working) Whelen power supply...... If anyone has one available please email me a eleew@charter.net. Thanks, Rick

-

So I just read all of the fatal M20F crash reports

Releew replied to FloridaMan's topic in General Mooney Talk

I was ferrying the aircraft back that has sat outside for a while. Although Every attempt was made to sump the tanks it was not enough. I'll admit, I have never pulled the throttle back to null in a FLAT Position in the pattern, so what the aircraft does at a lower speed with complete loss of power is debatable at best. Basic aerodynamics tells me that Mooney wing will not like complete loss of power unless the nose is already pointed down when it happens..... Remain level on downwind, pull the power to Idle and see what happens. Any Cessna, Piper will pitch down but no where near a Mooney Laminar Flow wing. Not looking for a debate.... Everyone has their own opinion. Just had to say something when I read that comment. Not an Instructor but I have a few hours. Flying a wider than normal pattern to eliminate pulling back too hard in your pattern turns and maintaining a safe altitude and airspeed has worked well for me in the Mooney. Just an opinion, but its an aircraft you do not want to force into a position in the pattern. Take Care..... Rick