-

Posts

259 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Releew

-

Hello all..... Got a Mooney buddy who has a 1985 J model with a gear actuation problem. Gear goes up normally. In the air, when switching gear to the down position the Gear Relay breaker trips On the ground, on stands the gear cycles perfectly. Has anyone heard of the permissive Airspeed switch shorting? Appreciate any input..... Thanks, Rick

-

This is our 6th year for the Wings and Wheels venue and it is growing into a very well attended gathering of cars, motorcycles and aircraft. There is plenty of parking available to provide separation of the aircraft and cars. The event is free of charge, no entry fee of any sort. There are multiple door prizes available including a free Sky Dive, City Flight Sunset Tour and even a Flying Lesson. Airplane rides are available for $25.00/ person. Great BBQ with Sides and Soda are reasonably priced. The event is well organized with EMT and Fire Department on site. All we ask is no glass bottles, as we are on a taxiway. St. Tammany Regional, L31 (Located North of Lake Pontchartrain or ~30m North of KNEW) If you have any questions please do not hesitate to email me at.... eleew@charter.net Hope to see you there! Rick

-

- 1

-

-

Just curious...... Why would anyone, even a non-pilot with no interest in aviation let an aircraft sit on the ramp to rot away. Too bad! There are lots of interested "want to be"... and existing pilots who would have really appreciated that gift as an inheritance! What a pitty! Rick

-

Could be the End Travel Switch on the down position is bad and not seeing the travel limit. If this happens, there is nothing to stop the motor from an over-current situation and pop the breaker. Rick

-

I get the engine warm and use the Foamy Gunk as a grease remover. Let it sit till the foam is gone.... Wash with a regular hose with normal pressure.... Has worked well for years! Rick

-

durable rattle can paint for leading edge touch up

Releew replied to Browncbr1's topic in General Mooney Talk

I didn't use a rattle can but went with the tried and true Nason Polyurthene and it looks great! I taped and sprayed all my leading edge surfaces with about a 3" cut back. Holding up very well. Rick -

Has anyone offered LED wingtip recognition lights yet? Something Plug and Fly.....at a reasonable price..... Rick

-

Thanks! Do you have a part #

-

Down for the Annual and the APIA spotted two cracks in the bolt hole of the alternator at the Pivot Bracket. This is a Kelly Alt. 70Amp. Does anyone prefer one brand over another? Is it best to replace with a higher output (90Amp) unit? Thanks, Rick

-

I sincerely hope they are selling airplanes. Has there been anyone to sign up on this site indicating they just purchased a new Mooney? Has anyone been on a tour of the facility and seen planes lined up in assembly? I also hope their sales is better than their service. Has anyone at Mooney ever picked up or returned your calls.......? If so, good for you because I've never received a return call or had anyone pick up the technical support line.

-

I have a damaged flap for sale. (Right Side) Definitely skin-able. I decided to go new for a replacement and I am trying to recoup some of the costs. 1992 M-20J Contact me at eleew@charter.net Wooden crate is ready to repack and send out or pick it up! Thanks, Rick

-

Gulf Coast Mooniacs - new club seeks members

Releew replied to 0TreeLemur's topic in General Mooney Talk

I'm in! Rick -

That is a topical wax.....meaning it has no cleaning agent (pumas) to cut. It sits on the surface. If it beads water it worked..... For a cutting wax look a the label for Wax/Cleaner. The logic is that it cuts the surface of the paint, removes grime/oxidation and fills the pores with wax. Kind a like buffing and polishing in one step. For the best possible result to restore a finish is to use a Dual Action Buffer with a light duty compound then come back with a good wax, like you just used. Keep in mind when you are cutting, (buffing with compound) you are actually removing a microscopic layer of paint, so don't get carried away or its going to get too shiny as in aluminum shiny...... If you are experienced with a buffer they now have circular buffers with an offset shank that rotates and oscillates. Like a Dual Action but more in a circular mode. If you use one of these, STAY OFF the PROTRUDING RIVETS..... Paint will come right off! Rick

-

Do yourself a favor..... If you purchase the Soda Blaster, also purchase the BEST air filter available. I personally like the Paper Filters to completely eliminate water in the line and mixing with the Soda. When it does, its a PITA to clear out. These blasters utilize a pressurized tank so the air pushes the blast media out. Its not like the old hopper sand blasters that pull the blast media through a venturie. Another trick I found is to take a garden hose and adjust it to a cone spray. Place the Blaster Nozzle in the middle of the cone and the residual atomized soda will dissolve eliminating the dust storm. Works really well and your hangar neighbors will be thankful...! It takes ~90psi at 15CFM to get a good cut at the tip of the blaster. You can do it in less but it will be in short spurts. Rick

-

Had a mishap in the hangar today. To make it short, I need a Right Side Flap. (passenger) I would appropriate any contacts to either refurbish or supply a used one that has been parted out. 1992 M20J MSE Thanks in Advance!!! Rick

-

Yep..... But you can get it in an aerosol can too. One can will last a LONG time!!!

-

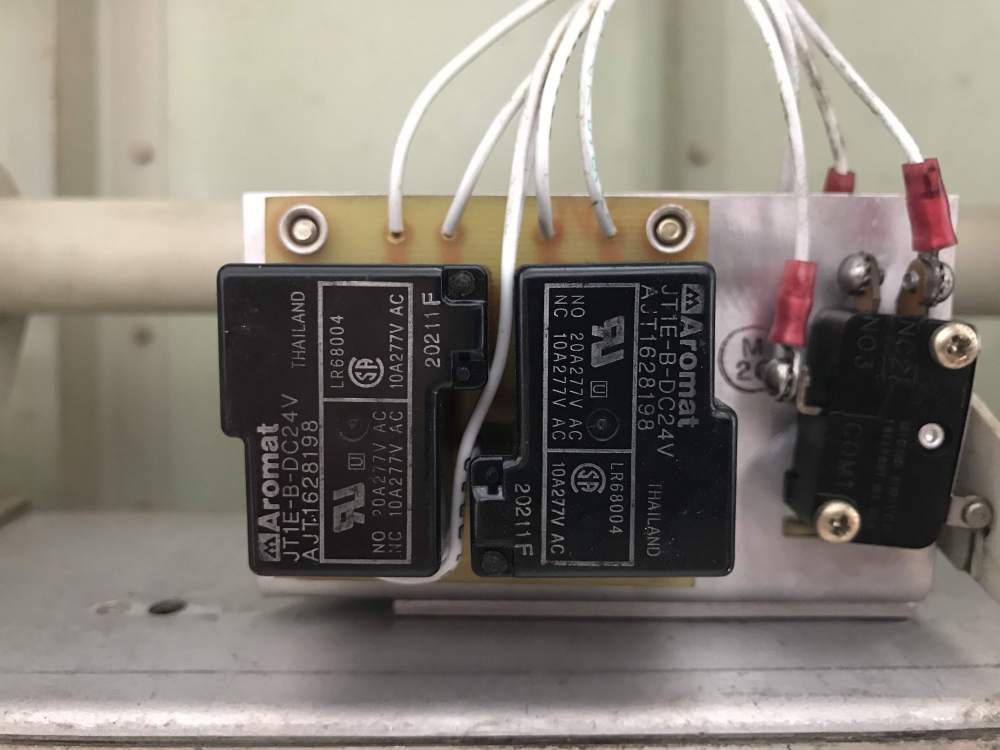

See below. It is not attached to the flap motor. The relays are on a circuit board. They are sealed relays....electronic cleaner will do you no good on this...... A relay contact can hang up/stick after so many cycles. This is an interment problem. Don is a fair guy. I'm sure he would be reasonable, to remove and replace the relays. You first need to run a continuity test on each switch and make sure it is activated at each travel limit. If you see continuity on each switch at the travel stop position it can only be the relays. The panel switch is very robust... not saying it cannot go bad but I see it as unlikely.

-

Since this site is about sharing knowledge I just got a "T" shirt in Flap Troubleshooting. About 2 months ago my flaps would not retract from landing position. I removed the belly pan and did all the normal stuff as in making sure the switches were tight and the contacts were actually depressing. This along with Electronic Cleaner and magically they started working again. until last Saturday.... Same situation. They would not retract from the Landing Position. We dropped the belly cover again this time with the plane on jacks and a comfortable creeper. I wanted to painstakingly go through every switch. I checked each switch for continuity and alignment, all good. Still the flaps would not retract. So what creates an intermittent problem.... Hmmm a relay! Yes... there are two permissive relays on a circuit board. With the flaps still stuck in the down position I taped on the relays with a screwdriver and up the flaps went! I could not find the exact brand but I was able to cross match it to a potter-brumfield part which I use a lot for control panels. There are six solder locations per relay and dropping the board is a PITA. But..... knowing the flaps will retract at a destination away from hope was worth every minute to get it corrected. Rick

-

Any automotive paint store. I think its a DuPont product. Great product! Be careful....its tempting to put it on heavy and it will RUN the paint off the plane!!! It's called Fade or Blend....depending on the supplier. Rick

-

With deep corrosion your best bet is a cheap soda blaster from Harbor Freight. Its really the only way to truly get all the embedded corrosion. Blast Feather edge surrounding paint Wipe with MEK Tape up Alidine Use Etching Primer...a couple coats (Rattle Can) Regular primer...a couple coats (Rattle Can) Sand with 400G wet paper Use a scotch pad pad to scuff around the area Light coat of paint until tacky followed by two cover coats Let become tacky once completely covered Use a rattle can product called FADE to blend the dry edges of the new paint. USE SPARINGLY. This is a HOT RETARDER Let dry for a week if rattle can, a day if polyurethane or an activated cover coat Buff with compound It will look like nothing was ever there! Rick

-

Call Steve at Autopilot Central....... Rick

-

Thanks everyone..... Regarding the EDM 350..... I was told if I kept the primary gauges installed and operational this was an acceptable unit to install. Rick

-

Rent or borrow the tool. I changed my mains and with the correct tool made the job simply a matter of turning wrenches. Not a big deal at all. Would it be possible to use the weight of the aircraft....yes it is, but you are also increasing your risks of damage as you will need to completely remove the jack to get enough compression on the shock to align the retainer screw at the top of the assembly. BTW, once you have compression you cannot easily twist the shaft into position so you will need to be certain the holes are lined up before compressing which is very difficult. If not you will be jacking the plane up and down! The tool is worth the trouble and expense of locating..... It provides full control over the disks compression with the aircraft remaining on jacks. Rick

-

Looking for opinions on Engine Monitors with multi-input options. Currently researching the JPI EDM 350 Deluxe and the Electronics Instruments CGR-30P. If any of you have experience with either of these or can recommend an alternative, I would be very interested in your opinion. Thanks, Rick