Leaderboard

Popular Content

Showing content with the highest reputation on 10/13/2024 in all areas

-

4 points

-

Hows' your dipstick tube? I've seen leaks at the bottom seal there before. If the dipstick is in too tight and the tube isn't lockwired properly, unscrewing the dipstick can actually loosen the tube a bit and cause a leak at the bottom. Can be fixed with a new O-ring and tightening the lockwire on the tube.3 points

-

@redbaron1982 did you happen look up the winds at the time of the incident? That worked out extremely well. i am guessing he had over 10kts of headwind on takeoff providing a good tailwind on return to pull this off with just over 600 agl. I’ve done the emergency turn back a number of times in different Mooney’s and wouldn’t attempt it at that altitude with calm winds but with winds over 20 kts you’d still be struggling to get it down in time without a long runway as apparently this pilot did. good job! Unfortunate it got some damage but in the end all we really care about is the occupants. Great to see such a good outcome. Just a couple days ago we lost 5 people in a Baron departing from Catalina in the dark Sent from my iPhone using Tapatalk3 points

-

2 points

-

1 point

-

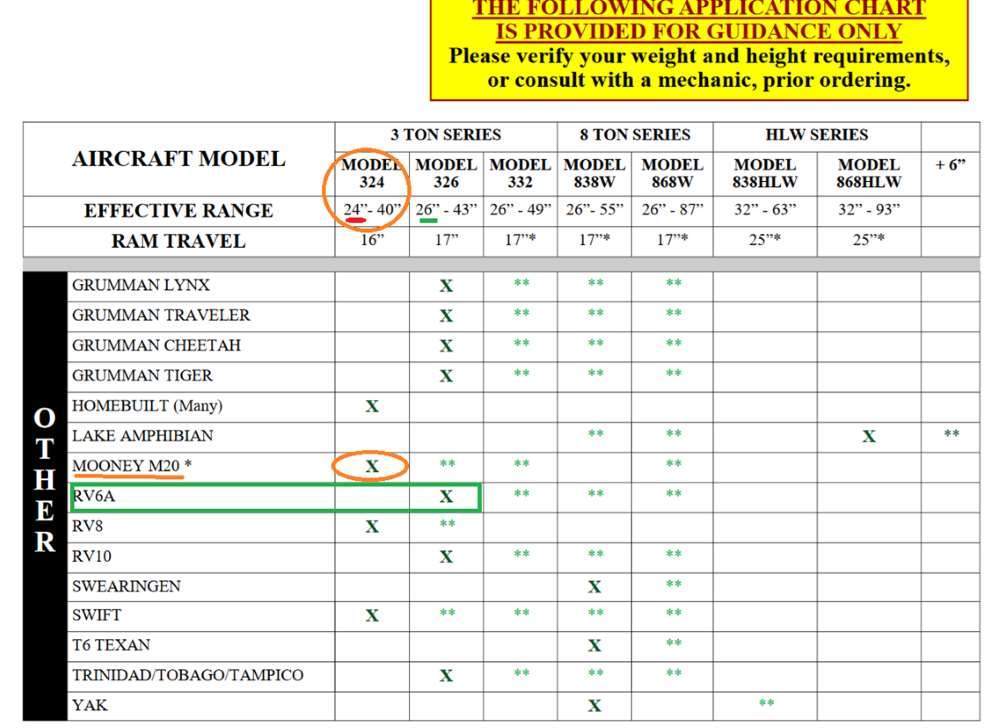

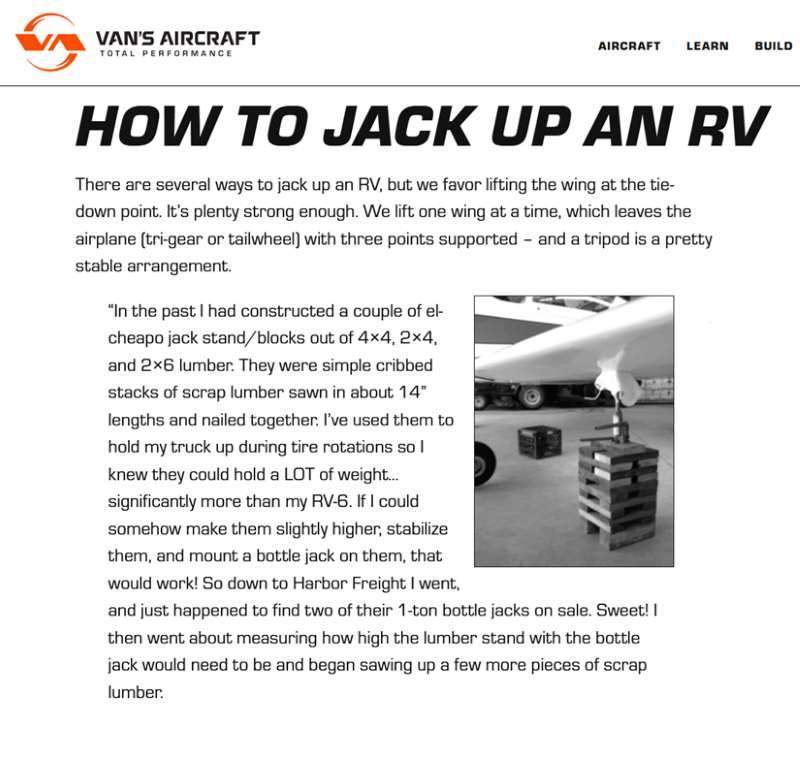

You didn't say if your friend with the RV-7 had proper jacks with a wide base or homemade ones to go with his "experimental". Some Vans builders/owners use nothing more than a stack of 2x4 with a bottle jack. Some have made something that looks proper, but I question the width of the base to prevent tipping. Someone on Vans Airforce measured the height from the floor to the bottom of the wingtip on an RV-7. He said it is about 25 inches. If your friend has 24 inch jacks they may work on your Mooney per @PT20J and @EricJ "RV-7 Wing Height May 4, 2008 - Does anyone have the distance from floor to the bottom of the aft tip of the wingtip for a -7? I'm just trying to figure out some hangar space. Just measured mine 24.75" inboard aft corner of wing tip 25.25" outermost aft corner" Also make sure that the jack pad/jack point adapter on the top of the jack actually fits your jackpoints. Don't be this guy. Mooney N2585W, a 1965 M20E, fell off the jacks back in 2017 and it wound up at a salvage auction after his insurance company scrapped it. The good news is that someone did repair the plane and it is still currently flying. Top of Wing......1 point

-

Freddy I just uploaded the M20R Service and Maintenance Manual P/N MAN161 Revision B: May 2014 into the "Downloads" section (1,175 pages complete). It is filed under "Airframe Manuals". Go to page 651.1 point

-

Be careful if you ordered one of the pre-packaged screw kits. I found that some of the screws were too long. In most places it doesn't matter, but there are a couple of inspection panels where screws longer than called out in the IPC can damage control push-pull tubes.1 point

-

1 point

-

That crush washer is not crushed by torque but by turning the bolt 135 degrees. If it leaks I would remove the screen check the mating surfaces and install a new washer and tighten it properly.1 point

-

+1 for Don's visors. They're significantly larger than factory but still able to be maneuvered into many positions. Price is amazing for the value.1 point

-

That crush washer is our first suspect. We’ve tighten it twice so far with another attempt to replace it with a new crush washer, and it still leaks. Either these mechanic I’m dealing with away from home is incompetent, or that’s not where the leak is from… My own mechanic is now telling me to check the vernathrm valve which is just below the oil filter, but I’ve gave up already. Flew the plane home on a three hour flight with a stop halfway yesterday and lost about hall a quart of oil. Whatever is leaking, isn't actually leaking a huge amount of oil. It just makes a huge mess. I’m going to call the engine shop that did an field overhaul on it only 80 hours ago and see what they think on Tuesday, when Canadian thanksgiving is over, and then decide if I want to fly the plane to Toronto or Montreal to get this leak fixed.1 point

-

Ross- Very cool! Thanks for sharing. There is quite a bit of space back there. My wife and I want to fly with our dogs and it makes sense for us and our mission to convert the rear seats into a cargo area. I appreciate your efforts with the photos. Norm1 point

-

Remove your old visor, trace it onto new plexiglass sheet, saw it out and sand the edges smooth. It will now look much better withiut the crazing; use smoked plexi and apply decal if desired.1 point

-

They're good on mine as well, and the pucks are far from new. However, we had to use a pipe through the knuckle and floor jack to raise a C model wing high enough to get it up to change a flat tire. Then we could get the 24" Alpha jack under the wing and lift it further for sufficient clearance with the new tire. So if a tire is flat it may not fit.1 point

-

Wow and i thought Rosen visors were stupid expensive i can’t imagine what original visors cost. Having said that, Don’s visors are a great set of visors that he makes at CB prices what’s not to like?1 point

-

It’s only 45 minutes away from me. Maybe I need to go take some pictures and post them here about 1 per week, just to mess with y’all.1 point

-

1 point

-

1 point

-

The stock Prestolite is a ginormous boat anchor compared to the 149-NL. An EC would have to be similarly huge to create a problem. Whatever he has in the pics, it doesn't look that big. Edit: BTW, my 149-NL was removed from a TIO-540 that had been installed on a Malibu, which is apparently why it has a Lycoming part number sticker on it.1 point

-

1 point

-

One procedure is laid out in excruciating detail starting on page 17 of the Cirrus SR22 and SR22T Airplane Maintenance Manual. Blow Out Cirrus AMM 30-00.pdf1 point

-

I live literally 2 minutes from the airport. By the picture of airplane I'm he landed south of the airport. So for me it makes sense that he overran the runway. Also, ADSBExchange shows 350ft over the Walmart, which is way to high to land 17. I always think "hey, this airport should move somewhere" but then I remember that the airpor was here before all the urbanization around it. Anyway, the airport property is too small around the runway. The threshold of 17 is literally on the perimeter of the airport. The airplanes landing 17 fly over the Westpark tollway at around 25ft. The powerlines (the regular, small ones) that are on the other side of the westpark tollway (1093) need to go underground to clear the path of landing aircrafts. To the north there is literally nowhere to go if you have an engine failure at say 200ft.1 point

-

1 point

-

1 point

-

Following Mike Patey’s turbine Lancair conversion on YouTube, I learned that people can/will buy a timed-out engine from a charter aircraft (his came from a King Air) and just maintain it on condition. I think he paid a small fraction of what it would have cost for a PT-6 that wasn’t timed out for Part 135 purposes. The engine ended up exploding on him and he had to buy a new one, so you know - not a great deal in the end, but gave me a picture of how this kind of thing is possible without spending a fortune to source an engine.1 point

-

non turbo, so probably not relevant. I've had birdy up to 15000 without issue, one day i'll get her to 18k1 point

-

Thank you Kevin! You were exactly right. All - My A&P spoke to Mr. Westbrook. The hoses were re-installed incorrectly by the avionics shop. My A&P re-installed it according to the schematic and it works normally now. The PC system passed a ground run test. After it's out of annual we'll verify with a flight test, but we should be good. If anyone else has an issue with the PC being stuck "on" and you rule out a problem with the cutoff switch, check the hose routing. Thank you very much again to Kevin Westbrook. I owe you one.1 point

-

Closure on the topic: sent the kx165 to Bevan and they fixed it replacing about 200 (ballpark estimate) capacitors. Flew it today and all works. Many thanks to Jake@BevanAviation and other wonderful people at Bevan who answered my questions.1 point

-

The final product from Hawk. I am satisfied with the results, extremely pleased that Joe worked me in almost at the last minute. Stoped by his shop in Feb, dropped of the airplane in May and picked it up end of August. It helped we were out of the country during that time. I received pictures of the stripping, masking and some towards the finishing. Much appreciated. During the inspection I did see a small run or two that were worked on, mostly gone. When I got it home a did a much more detailed inspection I have notice some spots of not enough paint as explained by previous posts. Joe stated that he stands by his work and any issue that I have he will take care of. I’m planning on having him “touch up” a few places when I return the airplane next summer for a windshield replacement that was forgotten this year, which he said he would do at cost.1 point

-

When I broke in my steel cylinders, we did an oil change at just over 5hrs. Oil consumption was normal after that. Something weird is going on and it does not necessarily have anything to do with your break in procedure.1 point

-

I love mine. I no longer have to be concerned with melting lenses. Pictures don’t do them justice. They’re much brighter than what comes across in photos. Well worth the expense. Chuck1 point

-

No greater compliment than a professional's confidence. I took a shorted mag to a local shop for repair. The mechanic who I knew and had worked with before told me to take it back to the parts washer and start breaking it down. We had it completely IRAN'd in about an hour. He then asked if I needed him to swing by my hangar later to inspect the installation and sign it off. I already had another IA lined up but the offer in and of itself meant a lot.1 point