All Activity

- Past hour

-

Unable to make maximum RPM a few hours post overhaul...

Bolter replied to Tito22's topic in Modern Mooney Discussion

Maybe I have it wrong, but on a hot or cold day, you should always get full RPM as the governor will pitch the blades until you reach full speed. Assuming you are not hitting the stops in the prop (not the governor limit), in which case he would have not reached full RPM in the past. -

The blades were red tagged. One was overcut 0.001" and the other 0.003". I don't know how many times it had been overhauled. The A/C was a '67 model and prop was installed in 1977, don't know if it was new or used. Probably used. It had the "A" hub. I didn't want an "A" hub- PITA. Rather than hunt around for a B-hub prop, I decided to go for the new Top Prop. All I'm saying is that a good B hub prop works great if you can find one. There is little to gain by going with a new Top Prop, unless your wallet is just too darn heavy from all that extra money in it. The challenge of course is finding a used prop that is in good shape and will take another O/H if necessary.

- Today

-

Unable to make maximum RPM a few hours post overhaul...

Shadrach replied to Tito22's topic in Modern Mooney Discussion

Was this a particularly high DA day? I’ve never checked to see what static RPM looks like at 24 inches of manifold pressure. Is that the best you could do? -

Replying to RagsfF15E No I did not locate another switch. I am not sure what it is. I have the S/N correct service and parts manual and I can't figure out what it really is. If it is one with a standard microswitch, I would just change that out, assuming I was smart enough to figure out the removal process. I'll cross that bridge if need be. I did however buy an extra sonalert in case the project pointed that way. Not here yet. amazon $35, 3 or 4 day delivery. I guess it will just be one more piece of hardware for my son to throw out after I'm gone. Please pardon the cynicism. Jer

-

Jer changed their profile photo

-

Unable to make maximum RPM a few hours post overhaul...

Andy95W replied to Tito22's topic in Modern Mooney Discussion

@Cody Stallings is our resident propeller expert. -

Ragsf15e started following Removing stall warning switch mystery

-

Excellent documentation for the rest of us for the future, thanks. Did you try looking for a new switch in case you needed it?

-

Lax291 started following Starlink Mini in a J

-

I haven't bit on Starlink yet, but I am sold on Internet in the cockpit. However, I'm waiting for Amazon's project Kuiper to hit the market. Not sure if it will be superior or less expensive, but I believe competition will drive prices down to something more reasonable from a hardware and plan standpoint. https://www.aboutamazon.com/what-we-do/devices-services/project-kuiper

-

Precise Flight charges a lot for overhaul so it is worth checking a few things before sending them in. These work pretty simply. There is a motor geared to one blade through a clutch. The motor drives the blade up and down. The other blade follows because there is a linkage that connects it to the driven blade. There are two microswitches operated by cams on the slave blade. One stops the motor when the blades are fully extended and the other stops the motor when the blades are fully retracted. The clutch is electrically energized to connect the motor to the driven blade when electrically extending or retracting the blades. When you pull the breaker, power is removed from the motor and the clutch and a spring causes the blades to retract. So, if they retract fully when power is removed, the spring is good. I would take the unit out of the airplane and look it over. See if anything is loose or binding. Without power, you should be able to move the blades freely without any binding. You can check the microswitches with an ohm meter to make sure that they operate at the appropriate blade positions.

-

Folks: Here is the report on today's effort. I went out with the intent to complete the circuit by taping the switch vane in place up. Then turning master on and testing voltage at various points on the circuit, to see if there was a large voltage drop across the switch, indicating excess resistance. You can understand my disappointment when I turned on the master and the sonalert sounded. I only did two voltage tests. Checked 22,7 volts to ground on the plus side of the sonalert and 22.7 acrosss the sonalert. I de-taped the vane, and hand triggered it a number of times to get it to fail, but it did not. I reinstalled the sonalert into a little panel that held two other sonalerts, screwed it up, put on the fabric cover. I kept running out to the vane switch each step of the way, expecting a failure and not wishing to discover that when fully assembled. So now it works. Very un-satisfying solution to this. I went and test flew it into a stall, and it didn't give me but 3 or 4 kts warning prior to stall (clean), but I'm going to let that dog lie. Regarding all the advice and help you have all offered, thank you very much. You have been very supportive. Regarding the advice from PT20J and M201MKTurbo. those issues are somewhat moot now, but lacking any advice at the time, several days ago, somewhat of a Hail Mary, I sprayed some contact cleaner into around the vane from the leading edge and by feel only, tried to spray the switch up through the access hole reaching in as deep as I could. Well, what's done is done on that score. I was intending to finish this note with, "Last call, leaving the pattern", but without a clear cause and corrective action, I am likely to be back. Thanks all, stay safe. Jer

-

is there any way to get a mite assembly manual? I tried to get one through the Mooney Mite sight however I cannot seem to make a purchase.

-

This is wonderful to hear, and I am still hugely excited about this path for my 68C. It's my forever plane, and I have squeezed extra speed out of it by various means, making it a solid 150kt cruiser. I flew out to KOSH this year in loose formation with some Bonanza driver friends, who have been ribbing me ever since for having to slow down by 10kt on my behalf. I'm pretty sure this mod will be cheaper and healthier way of medicating my hurt feelings than drugs, or buying an A36

-

What's it worth to upgrade to a Hartzell Scimitar prop?

Echo replied to AndreiC's topic in Vintage Mooneys (pre-J models)

Andre, if the prop is a search for speed, the issue may be that your plane is post 1968 "clean wing" Mooney production and is consisered a "dirty wing" due to non flush rivets done by Butler and Republic in a cost savings venture. Per Coy Jacobs in his book backward tails The later Butler and Republic aircraft with dirty wings can be several knots slower than earlier flush rivet retractable step clean wing Mooney aircraft. This speed deficit can easily be remediated with cowl, windshield and other 201 type mods per Jacobs. -

Removing stall warning switch mystery

bluehighwayflyer replied to Jer's topic in General Mooney Talk

That thread is for the Safe Flight lift detectors that were used in older Mooneys. They are a proprietary design and are very expensive to replace, so I can see the appeal. The OP’s Mooney uses a Mooney lift detector assembly that incorporates a generic switch, though, of a completely different design that at least just a couple years ago was cheaply replaceable. It sounds like his problem lies elsewhere, though, regardless. -

What's it worth to upgrade to a Hartzell Scimitar prop?

Echo replied to AndreiC's topic in Vintage Mooneys (pre-J models)

At 6500' and above at 2500 rpm and 9-10gph I don't make 24"mp so NOT a problem for me. I am reducing MP on decent so NOT above 24"mp. In climb I am max rpm so again, outside of 24". If down low say 3000' on a short hop I just set mp at 23. -

Thanks @Rick Junkin. I too suspect a connection issue. Looking back through the EDM data collected during the past year, this problem has been intermittent, but increasing if frequency and severity of late. The transducers included with my JPI use MetriPak connectors, which are "supposed" to be weather resistant. I'll go ahead and remove the cowl and give them a look see.

-

Ragsf15e started following What power setting do you use?

-

It will be important to clearly describe your engine for this, but it might be nice (and informative) to have a specific thread on power settings we all use and why. Obviously there’s going to be a lot of differences based on the different TSIO-360 models and aftermarket intercoolers or wastegates. I actually think there’s quite a wide variety of different ways we each look at this, even though my POH shows only 10 knots (and ~1.4gph) between 65% and 75% power which is noted as max recommended. Ive been happily flying my 252 (SB engine) at 65% LOP for about 6 months, but I want to be aware of what else I might try and why? @shawnd mentioned that he only flies ROP just to keep his CHTs high enough in the winter. I hadn’t thought of that. So last week I decided to try some settings out of the POH, except I’m not a fan of “peak TIT” , so I thought I’d add 1gph to them as a start to make sure I was really ROP. I was cruising along at 15,500’, 65% LOP and decreased mp to 28, increased rpm to 2500 and mixture up to 13.7. Should be 75% except 1gph richer than peak. Well my speed increased a little, but my CHTs started up and I gave up at 396f (and rising) on #3. Maybe I needed more ff to be richer? Dunno. But it should have been at least as good as the POH setting of 12.7gph with the same rpm/mp, no? So for now, here’s what I like with my MBcSB engine (220hp)… 2350rpm, 29.5mp, 10.4gph. That gives me about 20f LOP. It’s smooth, efficient, and book speed or slightly better than 65% “peak tit” in the poh. I have also run 2350, 30.5, 11.2gph for 70%lop and it’s fine but only gains maybe 3 knots. The 65% setting has my CHTs between 315-350f at 15,500’ and -2C OAT which seems good to me. So what do others do? If you run ROP, how far rich are you from the poh? Why do you run rop? Maybe it doesn’t run smooth LOP? Anyone use the poh numbers (PO of mine used POH 70% numbers a lot).

-

Subtitle: The overhaul from hell... Just got my M20J back from overhaul. Mind you this was after two test flights. The first flight, oil leaking from governor, we pulled it and overhauled it. Put it back on, second test flight was leaking from gasket. Replaced that gasket, third time was the charm and no leaks and I brought the Mooney back home. Next weekend, I flew it about 8 hours, to and from Omaha and Oklahoma - performed great with no issues on the flight. After landing, taxi back, and shutdown was uneventful. Skip forward a week and I go fly again. Engine start, taxi, runup was uneventful. Mag check was good. On takeoff roll engine sounded weird and like it wasn't making full power. I look down and see ~2200-2300 RPM. I abort the takeoff. A Couple of more static runs and it seems to be governed just above 2000 RPM. I pull the cowl, check the cable and it seems to be making it to the low RPM stop just fine. I was sure it was the governor since it was having issues. I have the governor removed and sent to the place that did the overhaul. They said it bench tested good... Has anyone seen anything like this before? Looks like I'm pulling the prop to send it to the shop to see if there's something wrong with the prop. It seems that with enough RPM there is something leaking into the prop hub to increase the oil pressure to increase the pitch on the blades. Attached videos show the runup. When I took this video, it looks like #2 cylinder dropped off (not sure if that was due to over boosting it or something else) but fuel flow and manifold pressure all looked good. #2 seems to keep good ignition the rest of the runs. I didn't want to run it too much over square. I also haven't checked the accuracy of the tachometer but it seems to be sounding like the prop is digging in and causing rough running.

- Yesterday

-

I've got a Starlink Mini. I've used it in flight. My opinion.... Meh. Not worth it for me as a pilot. If you are wanting to provide in-flight entertainment for passengers, it's amazing. For thunderstorm dodging weather info? Are you freaking crazy? Do you really want to explain to the NTSB and FAA that's what your plan was after you've had an in-flight emergency or incident or accident? Filing flight plans? Either do it on the ground or talk on the radio to ATC. If you are filing a flight plan that means you are VMC, so you need to be looking outside for other traffic. This sounds like a a bad idea that some marketing shill that isn't a pilot might put in an advertisement, like "Creating your grocery list on the laptop while you drive to the grocery store." If you are just looking for personal entertainment and staying in communication with people in flight but you are just ashamed to say that's what you want it for, well... I don't know what to tell you. Long XCs with an autopilot are kind of boring. Listen to music that is already downloaded or an audiobook or a podcast or whatever.

-

The Backward Tales by Coy Jacobs

Fly Boomer replied to Trazz's topic in Avionics / Parts Classifieds

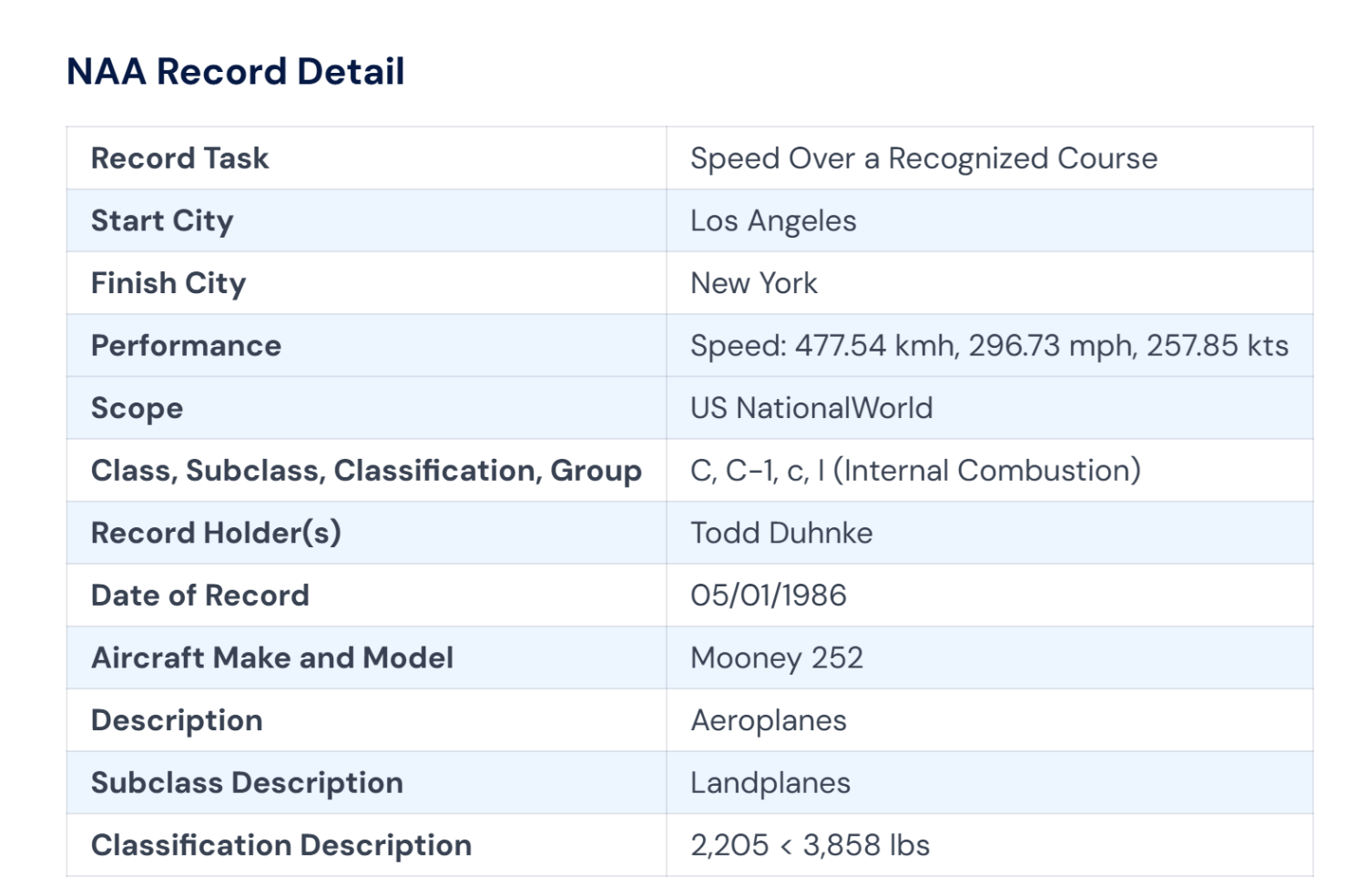

Just re-read (skimmed). Mooney began selling the 252 in 1986. May 1, a 252 set a non-stop record from Los Angeles to New York in 8:20. Previous record was held by a Bonanza in 11:56. Think about that: 3:36 faster than the best Bonanza. EDIT: Apparently, the 252 record still stands: -

Engine won't start when hot...

Matthew P replied to rwabdu's topic in Vintage Mooneys (pre-J models)

Thanks, I will forward to A&P to verify as the left magneto is a Surefly to make sure it can/was adjusted properly. -

Congratulations! You now own one of the finest traveling airplanes in general aviation. It is a high performance aircraft and it won’t tolerate low performance pilots well. You now have the ability to fly in the flight levels and travel long distances quickly while burning relatively little gas. Keep in mind that high performance turbocharged engine can be roasted in a couple of minutes if you aren’t paying attention. Personally, I wouldn’t want to fly a turbocharged engine without a good engine monitor. Three things I recommend - 1. Get plenty of Mooney specific training before you fly your plane…and especially get good instruction on how to properly use oxygen cannulas before flying on oxygen above 12,500’. 2. Get instrument rated as soon as possible. 3. Put the gear down before you land.

-

When you changed the timing, did you change the left magneto to one with a reduced lag angle. If not, it will be firing late during start. Here is the Lycoming SI. It's no longer on Lycoming's website (Lycoming only posts the most commonly requested service literature) but is still available from Lycoming if you ask tech support. SI 1325 Timing Change for IO-360 Series Engines.pdf

-

Awesome!

-

Rafael62 joined the community

-

I did it on the pressure transducer for a Saratoga landing gear. The connector was intermittent and unobtainable. Worked great afterward. They weren’t AMP CPC connectors.