All Activity

- Past hour

-

Annuals between 3-5k. Maintenance bills dependent on so any things - age of engine/ accessories (panel, TKS etc) and of course the way you fly the engine. This year my unscheduled maintenance costs have been around 12k - Less so last year.

-

IceM started following Avg Annual Costs on Ovation 2

-

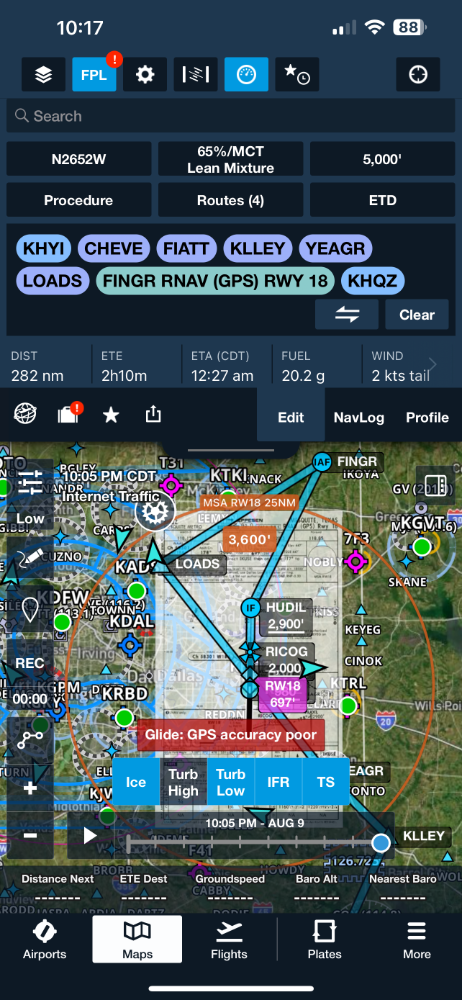

Ouch! if i setup an approach, i can see all the dynamic procedure info, IF i expand the approach - poof, dynamic procedure is gone!

-

Looking into buying an Ovation 2. Assuming there aren't any major squawks found... what does your average annual inspection cost? And then, assuming you do need some stuff addressed, what have your total bills run in those non-average years?

- Today

-

Is there a particular malfunction you are trying to manage? Or, is this just a fear you have? I’ve been flying for 6000 hours over 45 years and have not had a fuel problem yet. I could just be lucky…

-

Garmin is like a iPhone, their logic is pretty much the same throughout the line of products.

-

Uhh depends we talking in the 1st world? mo gas from the car gas station? avgas?

-

wiseng2 changed their profile photo

-

Thanks for posting! I closed on a 79 J a few months ago and am waiting eagerly to take her home from the shop. Yours looks like a nice plane and I'm sure you'll find a great buyer for that beauty.

-

1984 Mooney M20K TSIO-360-LB oil leak/loss of oil pressure

rklems replied to Logwes21's topic in General Mooney Talk

Loose oil filter, cracked oil cooler, and both turbo check valves and the hoses are also potential sources of high volume oil leaks in that area. -

@cliffy, you have a request for info! -Don

-

Oxygen is a dry gas. If you are using aviation oxygen there should not be any water involved. That is one of the reasons that during long transports or continuous use of oxygen they incorporate water downstream to moisturize it. It is also one of the reasons for the tank checks every five years. It checks for rust and moisture in the tank. As you’re coming down from altitude the heat inversion should melt any ice that is in the system.

-

Ragsf15e started following 1984 Mooney M20K TSIO-360-LB oil leak/loss of oil pressure

-

1984 Mooney M20K TSIO-360-LB oil leak/loss of oil pressure

Ragsf15e replied to Logwes21's topic in General Mooney Talk

I don’t have anything to add, but please let us know what you find! Ive got an SB engine with 230 hours on it, so im definitely interested. -

Cliff, how did your test flight go? I’ll be interested in the data you obtained -Matt

-

I'm sure of the hundreds of thousands of fuelings that happen each year that there are a few with water contamination. But, I'm not going to lose sleep over it. I remember when I was in Alaska I drove out to Lake Hood Strip to see the remains of an airplane that caught fire during a refueling from cans using a chamois. All that was left was aluminum ash on the ground in the shape of an airplane and a melted engine. I'm more afraid of fire than water. You cannot protect yourself against everything.

-

Adding a landing/pulsating light to the J and K wingtip

PeteMc replied to Steve Dawson's topic in Modern Mooney Discussion

Reach out to @OSUAV8TER. I have the original Whelen wingtip recognition lights and upgraded to the LED bulb through Gallagher Aviation. He should be able to tell you want the lates wingtip options are. And if you don't have a LED landing light, you might want to consider that too. I have the option to switch my pulsing lights to solid on if I need more light. But never have since I put in the LED landing light. Here's his contact info if he doesn't chime in: https://www.gallagheraviationllc.com gallagheraviationllc@gmail.com 1-833-425-5288 <-- Call/Text, please leave a voicemail if I do not answer 513-401-6495 <-- Call/Text/MMS, please leave a voicemail if I do not answer -

Mooney Aircraft Accident Nampa, ID

1980Mooney replied to 65MooneyPilot's topic in Mooney Safety & Accident Discussion

There doesn't appear to be a stiffener. It just appears to be a bracket welded to the tubular. Only a bracket is shown in the parts diagram - no separate stiffener is shown. Here is a J pilot seat shoulder attachment point. Here is a Long Body which would show any later model change. The Pilot and back seat shoulder harness attachment points are shown. You can see the simple bracket. And here is the parts diagram for the S and R. Only a bracket is shown - #63 Copilot and #71 Pilot shoulder harness attachment point. The Acclaim parts manual shows the same. Interestingly they don't even show the back seat shoulder harness welded on brackets; however, they clearly exist in the picture of the Long Body frame. -

Interested, if still for sale.

-

1984 Mooney M20K TSIO-360-LB oil leak/loss of oil pressure

rklems replied to Logwes21's topic in General Mooney Talk

Push rod tubes are drain back from the oil pushed up in to the top of the head from the hydraulic lifters, there is no real pressure there to have a significant volume leak out, especially in such a short flight. A blocked scavenge port or failed scavenge check valve would cause oil to flood the turbo bearing and be pumped out at fairly high velocity (I’ve seen a Rocket that did this twice and pumped 6qts in about 15m both times… there is actually a service bulletin on coking in the scavenge port on that conversion). But you would get a lot of smoke and of course the exhaust is on the right side, not left. The high pressure oil outlet that feeds the turbo is on the left side so perhaps check that for tightness, as well as the other end of that hose at the inlet check valve. I imagine a good wash down and engine run would probably show where the oil is shooting out pretty quickly I would of course be concerned with the low oil pressure condition, as well as if you went below the minimum oil level and potentially starved things for oil. -

Rick, can you send me the instructions too please Sent from my iPhone using Tapatalk Pro

- Yesterday

-

Yep. Crank the engine, then switch tanks.

-

New Changes To Memberships & New User Validation

Hank replied to mooniac58's topic in General Mooney Talk

Thank you, Craig! Just ran through the new process as a non-paypal-user. Fingers crossed, let's see how it goes. EDIT--it took effect before I could finish with the brief reply above! Well done! @mooniac58 Quick, easy and looking just like it did this morning, no ads. -

Mooney Aircraft Accident Nampa, ID

Schllc replied to 65MooneyPilot's topic in Mooney Safety & Accident Discussion

The later models do indeed have a bracket and a stiffener welded to the frame, but it is still a rather small thin wall tube… That being said, it’s a chromoly cage vs aluminum in most planes… -

mpess started following In the market for an E/F/J

-

I just posted my 78 J for sale It’s in the ballpark of what you are looking for if you would like to discuss. Matt

-

New Changes To Memberships & New User Validation

Mooney in Oz replied to mooniac58's topic in General Mooney Talk

A big thanks to you, Craig for creating and operating this site for the benefit and enjoyment of us Mooney owners. -

Asking $96,000 Unfortunately looking to part with my 1978 J as it’s getting to be a bit too small as the kids keep growing so we’re looking to move up to a 6 seater for the space and useful load. Mainly garmin stack GNS 430W, GTR 225, GTX345, PMA350b intercom with dual Bluetooth, original KNS80 for nav 2. Century 21 autopilot with S-Tec add on for 2 axis autopilot functionality. Shadin fuel flow meter and EDM-700 engine monitor. A3B6 motor, with two independent mags. 738 lbs useful load, 5830 airframe total time, 1810 smoh. The motor was torn down and rebuilt at 960 smoh due to a non-running prop strike and got a new crankshaft and upgrade to roller tappets. I bought the airplane in 2020 and replaced the full firewall forward hose kit, exhaust system, engine mounts, landing gear pucks, nose wheel, landing gear no back spring and the pilot inboard seat track (I also have the copilot side waiting to be installed), rebuilt the AI, and replaced both mags during the time I’ve had her. The plane has been rock solid reliable and burns less than a quart every 10 hours. Paint and interior are acceptable but not pristine. No rips or tears in the seats and the windows are like new. There is a small amount of fuel seepage in the left wing that will eventually need to be addressed, the tanks have not been resealed to my knowledge. Missing the logs pre 1988. The plane is based at KHFD and held in an LLC and I’m open to selling the whole LLC for the value of the engine reserve and remaining insurance policy if interested. 4775H prop strike repair.pdf 4775H airframe log 1.pdf

-

I take it the MP here is a calculated figure based on the Merlyn chart, temperature differential and indicated MP? I'd like to try this now that I'm intercooled!