-

Posts

786 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Z W

-

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Depends on what you mean by the "stop in the governor". The control arm swings up and stops against the RPM adjusting screw. Better picture here: We wondered if there's some internal stop inside the governor, because the arm rotating does not seem to bottom out. It's stopped by the screw, which is now all the way out. However, this is how the governor came back from the repair station, approved as in limits and supposedly making 2700 RPM on their test bed. So it doesn't seem likely that it's incorrectly set. The arm swings smoothly and firmly to the stop, with 1/8" of travel still left. Firmly pressing in the prop cable does not give any more RPM. I do still suspect the governor. I don't understand how giving it more travel did not increase the RPMs at all. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

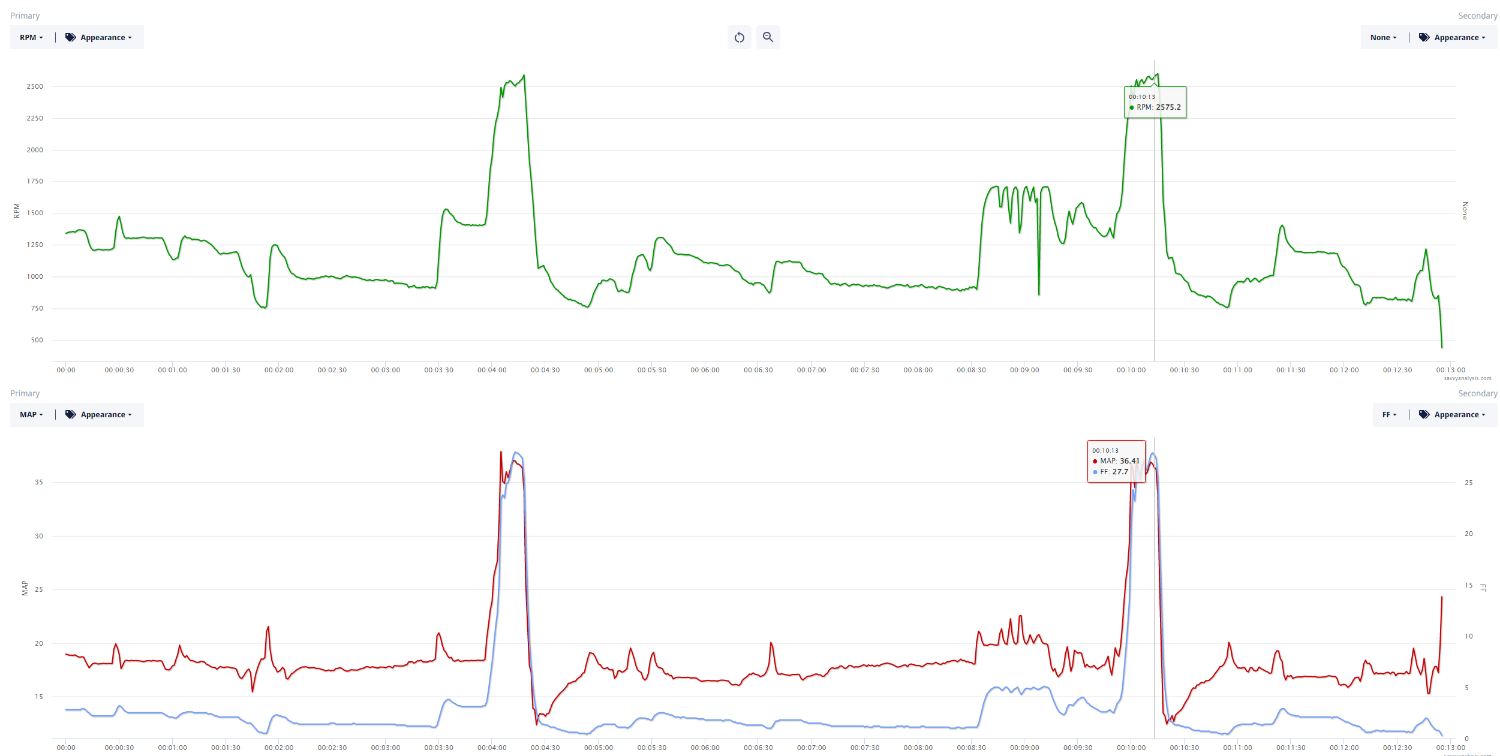

What seems odd about the EGTs? Some of those runups look strange I believe because when they were done with the cowl off, the air intake boot collapses, blocking off the air intake completely and the engine starts running off alt air. It won't idle correctly like that, by the way, and will only make 33-34" of MAP. It was doing the same thing with the cowl on, intermittently, depending on how good of a job you did cramming the extra intake boot material up onto the inlet on the lower cowl during install. I was the first person to realize this yesterday after several months of attempted troubleshooting when I noticed the alt air light was on during runup. Verified it by having someone watch from outside the plane. The engine will absolutely suck that boot flat against the air filter and choke itself onto alt air. Also in the latest data we were cycling the prop a lot, both at low and high power settings, trying to see if flushing some oil through the prop / governor would make any difference. It did not. Lots of high and low power prop pulls. May make for odd engine data graphs. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Not to my knowledge. How would those get changed? The prop has not be reinstalled. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Spent all day working on this today. Finally solved the original low manifold pressure problem. During last annual, they repaired/rebuilt the air filter intake housing. New/replacement not available. Someone repaired the cloth boot by adding about 3" of rubber extension: When the lower cowl was installed, this extended boot bunched and shoved down into the air filter housing, completely blocking off the intake, causing the alt air to come on. Trimming this rubber boot down to remove the excess material fixed the intake problem. After that, the engine was making full MAP (38", then settling to 35.5" which is perfect) and running great. Turns out we probably did not need to spend months replacing the fuel pump and getting it calibrated. But at least now we have a new fuel pump. Still have a problem though. RPM will not go above 2520 or so during static runup, or 2600 at 60 knots during high speed taxi: Fuel flows are 24-26 GPH which is good, maybe a little high even. MAP is 36" or even a little more, which is great. RPM just won't go any higher. Prop governor was previously sent out for IRAN, came back from the repair shop as in-spec. Today the governor limit screw was adjusted all the way out, and the brand new prop cable was properly adjusted and reset for maximum travel. Resulted in no change to engine performance. Photo proof: Still no more than 2500ish static RPM, and 2600 down the runway with takeoff power. This is displayed on the G500Txi that is 2 years old. The analog factory RPM gauge shows about 100 RPM lower at any given time, e.g. it was reading 2400 during runups and 2500 down the runway. That's normal for it to read lower than the Garmin. The engine runs, sounds, and feels great, as normal, now that the air intake problem is fixed. Plane seems to have the usual amount of power. Everything seems fine except for the RPM readout. Any suggestions? Running out of ideas. The service manual's "Propeller Governor Trouble Shooting" section's remaining suggestions are "Low engine power - Consult engine manual" and "Sticky pilot valve - Remove head and clean pilot valve..." which would appear to be a part inside the prop governor. Another data point - discovered the shop changed the oil with 100W, instead of the 15w50 we've been running for years. Asked them to change it which they say they did. No idea if that would explain some of the trouble. We plan to change it again ourselves here shortly. Filters arrived this afternoon. If anyone wants to review the full Savvy logs for more info, they are here: https://apps.savvyaviation.com/public_account/da323253-5fc0-4292-8b9c-75ae9ddd8305 Had a great day working on the plane and learned a lot about it. Thanks in advance for any suggestions anyone can give that we can either do or provide to a shop. -

New post yesterday from Garmin on Beechtalk: Hi everyone, I hope your holidays are going well. We're here and the team is making progress on the resolution. We received FAA Type Inspection Authorization (TIA) on the aircraft this morning that allows us to proceed to flight testing, which also occurred later this afternoon. We'll be analyzing the data over the next couple of business days. Once our team has all of the data together, they can sign the Supplemental Type Certificate (STC) authorizing the software that resolves this issue. Once STC is received, we'll publish a Service Bulletin with the instructions for the update. Expect our next update to confirm the availability of the Service Bulletin either the first or second week of January. I appreciate your patience, more soon. The Garmin team wishes you and yours a Happy New Year. -Joey Ferreyra Garmin Sales & Customer Experience Manager

-

Someone from the Garmin support team posted on Beechtalk that the FAA had the software fix data and were going through an expedited process of approval. It's already available for the experimental autopilots. I seem to remember them saying they were hoping to get approval before the end of the year. Although that's coming up in just a couple days at this point.

-

I got pretty far into a hangar design last year. First question I have not seen you answer - Steel or wood construction? For a 60x60 hangar you can do either, but most contractors will either do one or the other. Depending on materials prices and the size of the building, it can actually be cheaper to do steel. The wood frame option will likely be what they now call "post framed" construction which is using posts made of 3 laminated 2x6's. Then you have engineered trusses across the top. Again, either wood or steel. It honestly may be more of a preference than a monetary or design decision, as both can be done in a code-compliant manner. Do you want a red iron look, or a wood framed look? Wood can be easier to insulate with the traditional pink rolls. Speaking of hangar size - Scale out a drawing of your 60x60, and then of a Mooney, plus whatever other guest planes you envision you might one day host, RV's you may want to park inside, trucks, cars, etc. Print them out on scaled paper, or do it in CAD. You can then spend as many hours as you want moving hypothetical objects in and out and around in the hangar. Draw in the lines for your living space in the back, posts, etc. where you can't park stuff. It will help you understand how large the door needs to be for what you want. Remember that 4' of clearance on a door is only 2' on each side, which doesn't feel like much when you're pushing on the nose of a plane trying not to clip the wings. In reality, hangars are designed structurally around the door. Each has different requirements and I'm told it all affects the wind load. Choose your door size before sending the plans off for bids on the building package. Bi-fold doors hang from the building and require a very heavy (expensive) steel header to support their weight, with lots of cross-bracing to take the side load of the door. Hydraulic doors instead put the weight down the posts at the side where the hydraulic arms attach, putting far less stress on the building, but at the requirement of some concrete piers in the foundation. The hydraulic is less overall cost for this reason, but again, you need to choose the door before you spec and price the building and the concrete. Looks like you've already started this, but I found bi-fold quotes came in "cheaper" because the door company was not supplying the header. Once you added in the additional building material cost it was not any less money. They also require the building to be taller for the same door clear span, which adds a lot of material costs. Just raising the overall height by 2' can be tens of thousands of dollars. Even if you don't plan to heat the hangar, you still should consider pouring the slab on insulating foam and putting pex pipes in it for future heating. Impossible to do once it's poured. Many are heated with residential water heaters that are very inexpensive to run and maintain. Some codes may prohibit this. Leave room in the floor plan for a boiler room where the pipes come up. Don't forget floor drains in the hangar, and maybe a power, water, and/or compressed air box or two set in the concrete in the middle of the building. It will take a 30' cord or hose just to reach the middle of the floor from any wall. 60' if you're trying to reach something parked against the other wall.

-

Looks very similar to the one on our 262 conversion, which is a "600150-001-VF Air filter can back plate", made for Mooney by Globe Engineering at one point, but no longer. It appears to be a common failure point there where it attaches to the hot turbo. Ours has been repaired and re-welded multiple times. Last time we did it, during annual in May of this year, we sent an email to the Mooney factory asking them to either 1) make us one, or 2) release the shop drawings and material call out for the part number so that we could have an owner-produced part made that would be more durable and last longer. They replied that their engineering / production staff were looking into production of a replacement unit from the factory. Never heard back again. Hope you have better luck. If you want to PM me, I can share the contact info for the Mooney employees we were in contact with.

-

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

I would have no problem doing a regular takeoff limited to 2600 RPM, solo and light and with plenty of runway. The plane was flying just fine at 60 KIAS doing my high speed taxis and was up to that speed before using 1/3 of the 5000 foot runway. There's plenty of power. My concern comes from not knowing why it's suddenly only making 2600 RPM. A replacement cable and lack of adjustment of the governor screw stop is starting to sound likely. If that's it, I would have no concerns flying the plane, but would rather just get the screw set properly. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

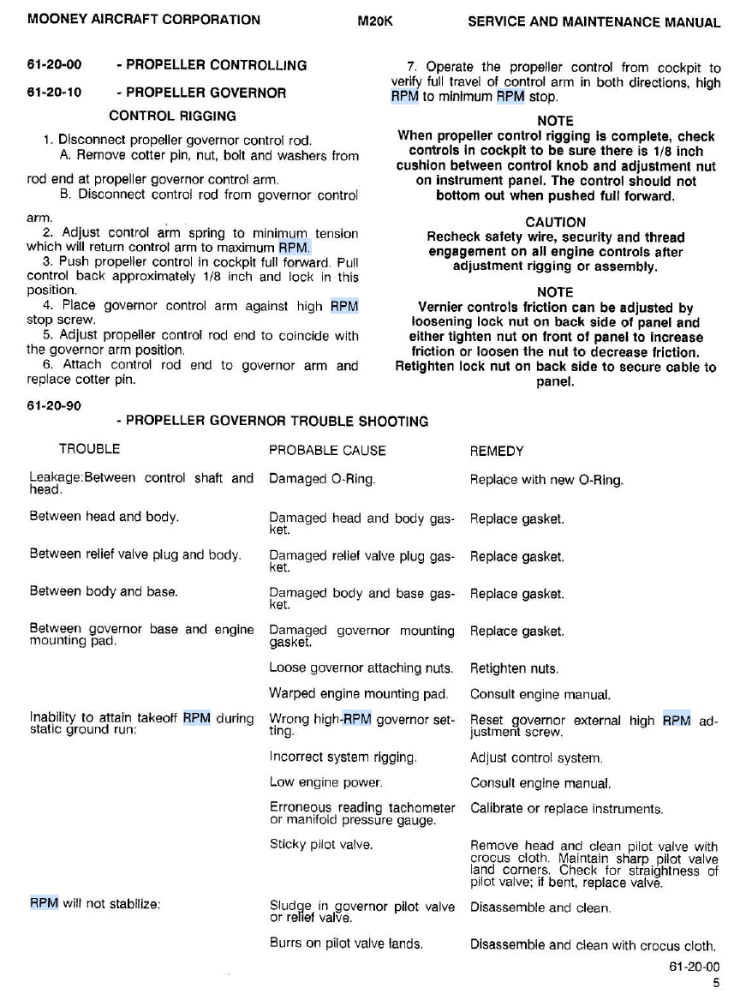

I'll grab the engine log SD card out of the plane hopefully today and post some logs of fuel flow, fuel PSI, MP, and RPM. I was expecting to leave the plane in the shop for them to continue troubleshooting, so I did not remove the log card. Instead they basically threw their hands up and said they can't continue to diagnose until someone flies the plane to confirm there's a problem, since they believe it is fixed and will make 2700 RPM in the air. Last night I sent the factory service manual instructions for adjusting the RPM to the shop manager and asked for confirmation that process was followed. Got this in response: "I can confirm that we followed the service manual as listed in your previous email. The prop governor was bench tested by Aircraft Accessories of Oklahoma. Their technician said it was running at 2800 rpm which we had adjusted it too before removing it. When I contacted them about the bench test, they requested we leave the adjustments where we have them for the bench test. Once they perform the test they would let us know the findings. At that point they contacted me with information that it was adjusted to 2800 rpm. They stated it was operating properly. They adjusted it down to the 2700 rpm where it was supposed to be. The adjustment screw was safetied when we received it. No adjustments from the 2700 rpm were made." To me, leaving the governor stop screw set and safety wired at a pre-determined setting sounds inconsistent with the service manual instructions for prop governor rigging, which says the screw should be adjusted until the plane makes the proper RPM. Am I misunderstanding that? -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

No, I am not absolutely certain. I located the engine set-up procedures in the factory service manual, highlighted the fuel pump calibration instructions, and provided them to the shop, with the help of Mooneyspace. A little while later, we got the plane back making full MP, but not full RPM. So I guess I'm assuming it was set up correctly. Without an A&P license, and with no other shop on the field, I'm working with what I have. Which makes all of your input that much more valuable. Thank you. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Good question. It's displayed on a G500TXi installed in 2020 that has been trouble-free. The old factory analog gauge is still installed on the far right side of the panel, but I did not think to observe it doing the high-speed taxi. I will do that next time. Thank you. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

I don't know about the stop screw. This seems to be the page from the service manual, unfortunately without pictures: -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Update to this. New fuel pump was properly set up. Plane now makes the proper MP. However, the RPM problem kept getting worse, and it would only make 2400 RPM. Some of you spotted this earlier which is impressive. They sent the prop governor off for inspection and it was returned as in-spec. It was overhauled not too long ago. They then found a broken prop control cable (photo below). After the cable was replaced, they reported RPM would only reach 2512 RPM on a static run, and requested that I come test fly it. I went out today and saw about 2520 RPM on a full-power static run up. I did two high-speed taxis down the runway up to 60 knots. The RPM reached a maximum of 2600 RPM on the first run, and 2580 on the second. 2700 RPM is max and takeoff power. This is not normal behavior for the plane. Verifying 2700 RPM at the start of the takeoff roll is standard procedure and I've never seen the engine do this. I did not take off. The new shop manager is insisting the plane "needs to be flown" and that the RPM may not come up until it's in the pattern. Supposedly they have talked to various other shops and mechanics familiar with Mooneys and they agree. Questions: 1. What would cause low RPM other than a failing prop governor that could or should be checked? 2. Would you fly the plane in this condition, or allow someone else to fly it? If I fly it, it will be to the nearest airport with another shop on the field, about a 15 minute flight away. Any thoughts or suggestions would be appreciated. Thank you. -

Well, I don't know who you are either, other then it sounds like you are new to running the TSIO-360 and maybe to flying. I'm just a stranger on the internet trying to help, for some reason. I did not say an engine will foul a plug by being lean. In fact I said the opposite. I suggest re-reading what I wrote. Good luck.

-

Some basic info nobody has really posted yet - Many (most?) piston aircraft engines will foul a plug if they are not leaned out on the ground immediately after starting. Standard operating procedure after engine start is 1) verify oil pressure, and 2) lean the mixture. You want it leaned aggressively to the point where you can taxi, but if you put in any more throttle than required for taxi, the engine will die. Keep it there for the run-up. Sometimes you have to add a little mixture to make run-up power if you're doing it right. This accomplishes at least three goals: 1) you will not foul a plug, 2) the engine warms up to operating temperatures faster, and 3) you can't forget to go full rich for takeoff, because your engine will die if you try to push in the throttle. I was taught this as best practice in anything, from a 172 trainer to a high power Mooney. It also makes you teach yourself to always go full prop and mixture before full throttle, which is important for your engine. Note that naturally aspirated engines are sometimes leaned for takeoff, but never a turbocharged engine. If you ever forget to lean for taxi and foul a plug, you'll discover it during the mag check on your run up. The engine will run rough, sound awful, and scare your non-pilot passengers. The fix is to do a higher power run-up (something like 2200 RPM), then lean the mixture until the RPM starts to drop, and hold it there for 1 minute or so. This burns off the fouling you've created on the plug. Repeat until you get a good mag check and you're good to go. If you were starting the engine, taxiing, doing run ups, and doing pattern work with a full rich mixture, I'm surprised you made it 10 hours before your engine started acting up. I believe this is just a symptom of the fact that aircraft engines have to be set rich enough to stay cool on climb, which is too rich for taxi operations. If it's a design flaw, it's not unique to the TSIO360.

-

Lots of speculation in this thread. Florida maintains an online registry of active judgment liens on personal property: http://dos.sunbiz.org/scripts/jlilist.exe Only one is active on Mod Works, Inc., it's not for that much money ($36k), and it might not even apply to a sale of the STC's. Would have to consult a Florida lawyer about that. The bankruptcy courts also maintain an online records search system. The company never filed for bankruptcy and is not in active bankruptcy. The most recent federal litigation about the Porsche Mooneys got settled and dismissed in 2014. Also the statute of limitations has likely long passed for all of the events people are worried about here, meaning any creditors who wanted to collect have likely waited too long. All of that to say, it looks like someone could buy the STC's if a deal could be struck with the owners. I'm not in the market but would like to see them go to a good home for the fleet.

-

Our plane's gear warning was set to come on at 20" MP when we got it. It's an adjustable sensor on the throttle but I wouldn't want it any lower. Previous owners managed to gear up land it at least once, which you could do without ever hearing the warning if it were set to 14". Keeping it 20" or more until gear down also avoids the low CHT problem Geoffb was worried about. An extended descent from 15,000 feet at 14-15" MP will give you a very cold engine by the time you get to the ground, maybe one that wouldn't make rated power on a go-around.

-

For instrument approaches, I set power at the top of descent to 20" MP (below this is where my gear warning comes on), 2500 RPM. This allows descent into the approach without picking up too much speed. I leave the power set there, sometimes reducing it back down to 20 if required, until the final approach fix. You should stabilize in level flight around 120 KIAS at this setting in a clean configuration, and the plane flies holds and turns very crisply. I leave the gear and flaps up until the final approach fix / glideslope intercept. Gear comes down at one dot below glideslope, which will naturally slow you to about 100 KIAS without changing your pitch much. Reduce power to 16-18" MP, depending on the amount of your headwind, which will give you about a 500 FPM descent. Once the speed drops into the white arc, I like to add takeoff flaps too. Trim to maintain 100 KIAS hands-off, adjust throttle to hold glideslope. Or, if you're flying a coupled approach, let the autopilot control the pitch for the glideslope, and you adjust the throttle for 100 KIAS. The plane is very happy at 100 KIAS down the ILS/LPV glideslope and it's easy to hold the needles. If you're ready to rapidly reduce power when you break out, it's not a problem to land, although to be honest, I don't fly actual low approaches on purpose. You can fly the glideslope slower, say 90 or even 85, but I don't like it as much due to reduced control authority, especially if it's gusty, and it leaves you banging around in the soup at a high angle of attack. For a very low approach to a short runway, though, you might want to do that to make it easier to land. You can fly the ILS faster, at 120 KIAS+ with the gear and flaps up, and once you break out, pop the speed brakes (if equipped), drop the gear, chop the throttle, and land, as Don Kaye likes to describe in his Bravo, but I don't often go to airports where that is required. The plane is very versatile and and can do a wide range of speeds with practice. With cowl flaps set for mostly closed at the top of descent, I do not have CHT problems.

-

Just started flying a k model… Is the juice worth the squeeze??

Z W replied to Alan Fox's topic in Modern Mooney Discussion

Full power, full rich, cowl flaps open in the climb to final cruising altitude will get you lowest temps, best speed, and best overall economy. If you're going high and the air is warm outside, sometimes you do have to level off in the teens for a couple minutes to cool the engine down before continuing your climb. Balancing RPM, MAP, CHT's, TIT, fuel flow, and cowl flaps is an art once you're in cruise. Some days you can do better than others. There is a wide range of settings available to optimize speed, efficiency, and temperatures, each of which is a tradeoff against the others. Most here seem to agree that keeping the CHTs under 380 and the TIT under 1625 (some say 1600) will result in longer engine life. The POH says as long as you're under redlines you're fine. -

Nice improvement with the LED, I should do that too. The 1982-vintage plastic covering our gear indicator light had gotten cloudy, scratched up, and faded, like yours is a bit. It was getting hard to read the indicator during the day, although you could tell if it was red or green under there. I spent 2 minutes polishing it with some polishing compound and a damp cloth and it cleared right up. Might help also.

-

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Thanks for the additional ideas. Plane is still down. New A&P has ordered and received the gauges required to perform the new fuel pump set up procedure. They did not come with the proper T's or some other parts required to perform the set up, so those are now on order and supposed to arrive this week. If getting it properly set up does not solve the problem, we will look at the injectors again, and the fuel spider. -

Part of my training was to avoid major configuration changes made blind. Dropping the gear and/or flaps would seem like a good plan, especially to keep you from overspeeding the aircraft, but it's hard to imagine a faster way to disorient yourself and maybe put the plane into an unusual attitude. It might take a lot of discipline not to grab the controls while the plane settles into a descent after doing all that, even though I think it should eventually. Maybe I should go try it that way under the hood sometime and see. I also heard that when spins were a mandatory part of the curriculum, they were taught as a method to descend through a cloud layer in a stable maneuver. Initiate and establish the spin above the deck, recover below it. Probably part of why they killed so many pilots in training. Definitely not a Mooney option.

-

My instrument CFI suggested that if you ever had a dual electric and vacuum failure in the clouds, assuming you were trimmed hands-off prior to that, to take your hands off the controls, reduce power for descent, adjust airspeed with the trim wheel only (some nose up will be required once it settles into the descent), and hold your compass heading +/- 10 degrees with light pressure on the rudders. Then ignore what your senses are telling you and hope you have enough room to maneuver when you come out of the clouds. The idea is that a properly rigged, certified aircraft is stable in flight. It will settle at a speed within the green arc and descend more or less wings-level. It will not stall itself even at max nose up trim, nor roll over inverted. A disoriented pilot yanking on the controls without instruments is more dangerous than an uncontrolled aircraft. It should exit IMC in a controllable attitude and airspeed and enable you to regain visual navigation. We demonstrated this a few times in VMC. It does appear to work, at least in smooth air. The plane will wander and hunt a bit, both in pitch and roll, but descend in a stable fashion on a heading. It works less well with an iPad or other device mounted on the yoke, which is part of the reason I no longer fly with anything mounted there. This was before battery-powered backup devices like the G5 existed. They are probably a far better plan. But I've always considered the above to be a final option. I suppose it would be harder now that we no longer have a separate altimeter or VSI in the panel.