-

Posts

704 -

Joined

-

Last visited

-

Days Won

5

Everything posted by Z W

-

I'd never heard of applying it to the exhaust slip joints. Will start doing that as well. Thanks Clarence.

-

-

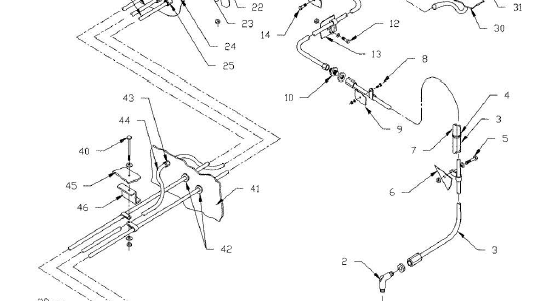

Replacing old, stiff, worn-out brake hoses on our M20K. Each one was strapped to the landing gear structure with two of these thin metal straps, wound several times around the tube and hose, with anti-chafe tape underneath. They are held in place with just a belt-buckle type mechanism. What are these called? Internet search did not identify them. They seem like a poor choice with sharp metal edges, and these are clearly worn out. Each one got replaced with a pair of padded Grip-Lock zip ties. But I'm curious what they're called and whether that's appropriate.

-

I like to think of it as a "zone of confusion" like flying over a VOR. With the Monroy tanks, your gauges are accurate at full, then they get confused for a while and stop moving, then they come back to their senses and start working again after the Monroy tanks are empty, which is when your main tank is down to about 20 gallons. It works fine, but makes it very difficult to know to the gallon how much fuel is on board at any given time unless you topped up to 105 gallons. It's rare I have the useful load available to do that, so more often, I top the mains which is 75 gallons (although I feel like a gallon or two probably flows up into the aux tanks while fueling) and use the fuel totalizer from there. Topping the mains, which is perfect for 1-3 people and most missions (maybe different for a Rocket), puts you right into the zone of confusion. You could use a dip stick on all four tanks and a spreadsheet and get pretty accurate numbers if it really mattered. Requires draining to empty, filling a few gallons at a time, and noting your data.

-

The steel tube side bracing on the Alpha jacks looks like thin wall conduit in photos, but is not. I would guess it's 1/8" wall galvanized pipe and is pretty stout. In case anyone was going to build their own, using thin wall conduit.

-

Just picked up a set of these and used them for the first time yesterday: https://www.aircraftspruce.com/catalog/topages/alphaJacks.php They worked great for the Mooney, the 324 model is the perfect size. This was my first time jacking up any aircraft, though I've done lots of work on cars and ground-based equipment. Looked at several threads and options to build or modify a set of jacks. Decided if I did that and managed to knock the plane off and put a jack up through the wing, I'd feel pretty bad about it. Having used the purpose-designed item, I would not hack something together for this, and I've been known to hack things together from time to time. The jack points on the wings are tiny. The plane is a little wonky and tipsy until you have it stabilized up in the air. Many tasks involve climbing in and out of the plane and swinging the gear. This is something that deserves an engineered solution, in my opinion. If you're going to do it, I'd spend some time on the engineering, and maybe get a set of real aircraft jacks to copy. I was impressed by the design and sturdiness of the ones linked above. Thought the price was steep until I got them, but now would do it again.

-

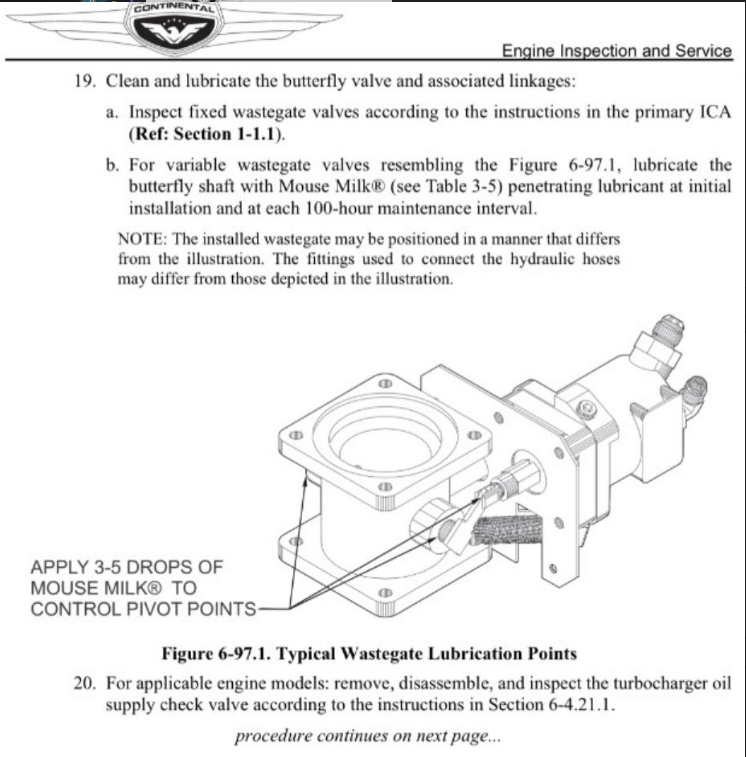

When ours did this, it was the wastegate sticking. Showed up like you described, slowly got worse, until MP maxed out around 28". Mousemilk lubrication was the answer. It's recommended in the service manual every 100 hours, and it's on Mooney's 100 hour/annual checklist, but seems to be commonly missed. Ours gets a few drops at every oil change now. Cheap and easy place to start. If yours is lubricated and/or this doesn't help, I'd suspect the wastegate itself, the turbo controller, and/or the turbocharger itself.

-

Our floor indicator was dirty, cloudy, and scratched to the point of being un-readable at one point. You could vaguely see a red or green blob through it. Spent a few minutes with a rag, some WD-40 for a degreaser, followed by a clean wet rag with some Meguier's polishing compound and it cleared right up. Can read it easily during the day now.

-

SWAPPING VACUUM-DRIVEN SPEED BRAKES FOR ELECTRIC ONES IN M20K

Z W replied to 231LV's topic in Modern Mooney Discussion

Don't forget the cost of some sheet metal work and paint to fit the new electric speed brakes. They are not the same size as the vacuum. Our vacuum pump now just runs the speed brakes and the retractable step. Would like to remove all that, but the cost is very high for the benefit while those systems are working. -

M20C wing replacement question

Z W replied to Urs_Wildermuth's topic in Vintage Mooneys (pre-J models)

Before this devolves into another lawyer bashing thread... Insurance companies spend millions of dollars every year on advertising and influencing campaigns to blame the cost of insurance on lawyers. Otherwise, who would you blame for your increased premiums? They have intentionally biased the jury pool in their favor before the case is ever called. They're very good at it. Bashing lawyers is a lot of fun, until you need a good one. Bashing the court system and advocating limiting access to it is a lot of fun, until you've been wronged and need your day in court. "It will never happen to me" is what most think. Some are wrong. You can be sued for anything, any time. Most of the time, the system gets it right. The alternatives of no system, or a system with limited access, don't help anyone. That's why some smart people a long time ago wrote equal access to the courts into the constitution. This lawyer would never chop up a perfectly good airplane. -

You could check the air filter inside the housing at the bottom of that boot. A clogged air filter is the designed reason for the alt air to come on. You could also check the alt air door and switch, located on top of the engine on the pilot's side. It's connected by a scat hose to the air filter housing we've been discussing. It's a very simple system - when that boot slips off or is closed off, the engine sucks air through the hose connected to the alt air housing. It pulls open a metal flap and then the engine gets air from the top left inside quarter of the cowling. There's a spring-loaded wire that controls the alt air light in the plane. A magnet and spring hold the alt air door closed under normal operation. You might make sure the alt air door and everything is properly clean and lubricated, if adjusting the boot and checking the filter doesn't solve the problem.

-

Yes, it looks correct. Don't tighten too hard or you can crack the fiberglass naca duct. A shop mysteriously had to repair ours once. Too loose and it can slip off and you'll see that alt air light come on as milotron says. You can also get the alt air light and decreased engine performance if the boot isn't pushed up high enough before tightening, which causes the crease you've spotted to get worse. Just received a new boot this week to install at annual in June. Old one is patched too many times. Mooney makes them in batches and they are not always available, order in advance if you ever do need one. Currently in stock, unless we got the last one. The intake filter housing it's riveted into is thin aluminum that vibrates around and is prone to cracking on the side nearest the turbo. Inspect carefully at annual time.

-

Thanks for posting this. My old whisky compass on the windshield post has started swinging 30 degrees off at most times. I had been wondering how that simple device could fail. A new cushion would be an easy fix to try.

-

I've only seen the low fuel light once. It was near the end of a trip, in the dark, about 10NM off shore over the Gulf of Mexico due to ATC routing. I switched to the other tank which had, supposedly, about 15 gallons left. In theory that, plus the 4 gallons in my low tank, was good for another 2 hours of flight at descent fuel flows with 1 hour remaining in the flight, giving me a 1 hour reserve, to land with about 10 gallons on board. That was planned, as I had 3 adults on board and was stretching for range. I landed short and bought some gas when that low fuel light came on. Didn't care for that feeling and don't plan to see that low fuel light again. I plan my fuel much more conservatively now, and don't really ever see less than 10 gallons on each side. Reliable amounts of usable fuel in both tanks is a redundancy I put a value on. I'm probably extra cautious in part because of the difficulty in being precise with the extended tank setup.

-

The fill port is a Scott part, part number 26875-76. Bought a new one in October 2021 from wbparts.com for $600.52 shipped. Had to wait two weeks for it to ship. I believe the -76 part may have only been used on the M20K. https://www.wbparts.com/commercial-rfq/26875-76.html We didn't have any luck getting ours repaired, our A&P called a couple places but told us he never got a call back. In retrospect, I'd call C&L myself first if I were doing it again.

-

I went through this exercise once. If you fill the mains to the cap, then fill the aux, on our plane anyways, the pressure will start pushing fuel out of the inspection plate on top of the wing nearest the fuselage. Good way to find out where your tanks might be leaky. Keeping track of all 4 tanks with a dipstick requires a lot of patience, waiting after fueling for the fuel to equalize, and a calculator, unless you're better than me at doing math in your head. 90% or more of the time, I fill the mains and go. Leaves you with 75 gallons, plenty of useful load for 1-3 people with bags, and the answer to "How much fuel do I have?" is 6+ hours and more than enough. The sight gauges become pretty accurate under 25 gallons or so. I also have found the tanks will hold more than the placarded 105 gallons if you're patient while filling. But again, it starts leaking out the top of the wings and sloshing out the vents, so not for long. Also, with 105 on board, there's not much useful load left for anything but the pilot, so not a lot of reason to do this on many flights. Good for flying to Alaska without stopping in Canada, heading out to the islands, or setting endurance records, I guess. It is cool to have a plane that's able to use essentially all of its useful load on fuel if you want though. Makes for an amazingly capable machine at 11.5 GPH and 175 knots.

-

I have sort of the same problem. Two boys ages 12 and 7 now pushing the useful load and cubic feet limits of the Mooney. Just booked a trip via United as a result, can't get all 4 of us plus ski gear in the plane. Could ship it ahead via UPS, or just buy a ticket and let the airlines handle all the hassle. Went with option 2 this time. Jumping backwards into a big older piston twin doesn't have a lot of appeal just to do those one or two trips per year. Jumping upwards into something burning Jet-A sounds great, but the costs are huge, especially for the small amount I get to fly. Work and life are very busy right now and we just aren't traveling much, even with a plane sitting there available. Time is the issue more than money, oddly enough. Oldest can't miss robotics tournaments, happening every weekend all fall and winter, which has had a big impact. Last year I was getting pretty serious about just adding a piston twin to the fleet for a few years while keeping the Mooney. Still might, and maybe that's an option for you. Plan would be to sell it after the oldest leaves the house, and still have the Mooney which is the perfect 2-3 person traveling machine. Or keep the twin, I guess, if it ends up being preferred. Requires another (or a larger) hangar. Should still be significantly less money than anything burning Jet-A. Main thing holding me back is actually the idea of how I would find the time to fly two planes and stay current in them.

-

Congrats. Just went through a similar situation related to the fuel system and engine setup procedures. They are complicated and it seems many A&Ps are not familiar and do not have the gauges to do it. Also, it requires cowling and de-cowling the aircraft to make each adjustment, a very tedious process. Once it's done and your TSIO-360-MB engine is dialed in, though, it sure is an amazing piece of machinery and engineering.

-

Probably. In many states the minimum required liability insurance limits are $25,000.00, an amount set 40+ years ago. That no longer covers the cost of an ambulance ride to the emergency room to get X-rays and confirm nothing is broken. Most policies sold are for the minimum amount (people call and ask for the cheapest monthly payment they can get). So the odds are, if someone hits you, they will have $25,000.00 of coverage available. To protect yourself, you can buy underinsured coverage on your policy, that pays you in that scenario. If you don't know how much your liability limits are, there's some chance they're only $25,000.00, and if you cause a crash, you're liable for any amounts over that. Getting a higher limit policy may be a good idea, and even better, an auto umbrella policy with a $1m or $2m limit is usually pretty cheap. The problem for airplanes is that getting an umbrella policy that covers flying is impossible. I've asked and been told nobody sells them. I've also asked about getting $1m smooth coverage on the plane and been told we can't get it (Avemco). Maybe a good broker could source it, I don't know. Insurance companies are good at selling you a product that doesn't help much when you need it. They make a lot more money that way.

-

I've wondered... are Acclaim owners just more likely to just say, "Top the engine"? That would explain why many of them listed for sale show a recent top overhaul, which many owners here then believe is a sign of a problem with the engine or its operation. Maybe it's not. Thinking being, the Acclaim owners represent those who paid the most for their Mooneys, and are likely the least concerned with costs of repair and maintenance. Bad compression reading at annual? Put all new cylinders on it. I want it ready to go and not down for more cylinders again at next annual. Only slightly more time down for a top overhaul than to do the one failed cylinder. We've put several new cylinders on our M20K over the years. Always due to low compressions at annual, and at the mechanic's recommendation, never due to abnormal temperatures or engine performance. I just read SB03-3 for the first time, and now feel misled. Never once were we asked to go fly it for 45 minutes so they could re-check the cylinder, or shown borescope photos of a problem inside the cylinder. I suspect many Acclaim owners, and other plane owners, have been treated the same.

-

Rocker Switch Cover Replacements - 3D Print your own

Z W replied to freff's topic in Modern Mooney Discussion

PLA prints very easily. It doesn't "mess up" as often and you don't have to spend a lot of trial-and-error adjusting temperatures and print speeds to avoid stringing, layer separation, and other problems. So, it's what most people get started with. The things you make out of it are surprisingly durable, in my experience, but it's not UV-stable. And supposedly it will melt in temperatures experienced inside a car or airplane on a hot day, though I've not tested that myself. I've printed some things in PET-G. Took quite a while to figure out the settings for my printer to put it out reliably, but after that, it worked pretty well. Supposed to be UV-stable. I have some things that have been outdoors in the elements for going on two years that are holding up fine. Much higher melting point, so unwanted melting not an issue. Not as toxic to print, and doesn't really require a heated enclosure. I've printed just a couple of things in ABS. I do have an enclosure. Even with that, I found it very difficult to print reliably. Probably user error. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Plane is fixed. Thanks so much to everyone here who chimed in. I don't think we'd have figured it out without Mooneyspace. Cheers. -

Never seen that before. I would suspect something binding / shorting out in the gear motor, since that's the system you were turning on when the problem started.

-

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

That makes sense, about the governor maybe not being the problem. Bringing in another mechanic is not really an option, that I'm aware of, we'll have to take the plane to them. I'm getting more comfortable with that option as we rule out causes. With the air intake issue resolved, it's running strong and reliably again, for the first time since it went in for annual in May. A lot of my concerns were caused by it running differently (and sometimes roughly) every time we fired it up. The shop ordered differential pressure gauges to set the fuel flows, and we had to wait a couple weeks for that, so I believe it was done per the engine setup instructions. I'm now wondering if it was done with the air intake blocked off and the engine running on alt air, though. I think it almost had to be. Maybe re-performing the engine setup with an unrestricted air intake would be warranted. Thanks to everyone for your thoughts. Your help means a lot. -

Help Diagnose Engine Problem - M20K TSIO-360-MB

Z W replied to Z W's topic in Modern Mooney Discussion

Hah, good point. To be fair to them, we knew they repaired the airbox due to metal fatigue cracks. We've been waiting for the Mooney factory to make us a new one since May. They declined to release the shop drawings to let us have it made. So it was re-welded by a local welding shop. I just did not know they'd also added the rubber to the intake boot. It's a McCauley prop. I'll put checking the blade angles on the list of possibilities. Thanks for your help.