-

Posts

791 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Z W

-

The new valves I've put in are much stiffer harder to sump than the old ones. I suspect it's a new design with a stronger spring that makes them less likely to leak. The downside being it takes longer, with a harder push, to get a good sump.

-

When I went through this to replace a leaking Monroy tank valve, I read on here (possibly from this thread) that the Monroy tanks would take a different valve than the inboard tanks. I ordered a CCA-2800 which corresponds to the F391-72 or SA-72. It did not match the one I removed. I ended up replacing it with a SA53S which matched the existing valve, and which matches the valves in the inboard tanks. I carry a spare one of those in the plane now. Fuel lube and a 1/4" drive torque wrench that does inch/lbs are recommended for the swap. I also needed an adapter to go from 1/4" to 3/8" drive for the large socket that fits the drain valve. After the swap, despite me trying to be gentle, one of the rivets that holds in the drain valve threads inside the wing started to seep. Rubbing on a little Oil-Tite stopped the leak and it has been stable for over two years now.

-

Glad you got it safely on the ground. Thank you for posting this. I was not aware of it and the Service Instruction has not been completed on my plane. Until I can get it done, I think I'll run the trim all the way nose up with the electric trim on the ground and see if it jams. I've never experienced it, but I make it a point to never run full nose up trim on landing to avoid excessive forces during a go-around, so I'm not sure I've ever done it. I'd hate to find out it happens for the first time in the air like you and your student did. I'm confident I could maneuver and land at 80-90 knots or so with flaps down and full up trim. The plane likes to fly like that just fine, though not at full power. But it could certainly catch one by surprise at high power settings. I also have a G5 and GFC500, and for stalls, steep turns, and unusual attitude recoveries, I have been holding down the autopilot disconnect button to disable ESP. That is what is recommended in Garmin's manual for the autopilot (below). I don't think I would like having the circuit breaker pulled, and electric trim disabled, during ordinary training, though practicing with it pulled might be a good exercise as well. A question - how could an owner get notified of these service instructions and any new ADs or SBs? I have been reading Mooneyspace every morning since before 2016. If it was discussed here I missed it. I've tried hard to be involved and pro-active in maintenance. I've taken it to Mooney specialized shops who have not said anything about it. If there's a better way I'd like to know.

-

C models are great aircraft. Had one for a few years. Planned 135-145 KTAS on a little less than 10 GPH. Never felt underpowered on takeoff near sea level, even at max gross. It would run out of steam at about 10,000 feet. You could eventually get up to 12,000 if you were patient, climbing 100-200 FPM or doing step-climbs. I flew it to Denver and Sante Fe a few times and it really felt underpowered there. I've never flown an E but have seen videos of them flying up at 20,000 feet. I've heard they do a lot better at higher altitudes with their fuel injection instead of the carburetor in the C. Depending on where you plan to fly, that might be a factor.

-

Add in - talk to ATC, watch for traffic, arrange routing around thunderstorms/build ups, climb and descend to stay visual or avoid ice, get re-routed around MOAs and restricted areas, and be ready to land in a 15g25 crosswind after your instrument approach, which wasn't forecasted when you took off 7 hours ago. On the right day it can work out, but I personally just plan a stop at 3-3.5 hours. If I am thinking about a longer flight, I take plenty of gas and keep the mindset that if I get fatigued, the weather changes, or I just need a break, I'll find somewhere along the route to stop short.

-

I try not to fly as low as 6,000, but the OP asked for speed there. My preferred altitudes are 15-17k. If I'm lower, it's for weather, headwinds, or short distances. After getting used to being up there, I find it hard to consider going back to a naturally aspirated engine, even after paying for a turbo overhaul this year. Smooth air, good radio reception, plenty of glide range, direct routing, and very little traffic make it all very enjoyable. It still surprises me sometimes how much weather you can top at 15k, visual and in the clear. The speed is a bonus when you happen to get it, but is not the point. I plan 3-3.5 hour legs and pretty much never use the extended range tanks. I'll do two legs of that length in a day which lets me do about 1,000 NM comfortably, but not in one leg.

-

In a 262 - At 6,000, I plan 150 KTAS. At 10,000, 160 KTAS. At 14,000, 165 KTAS. All on 12.5 GPH. Some run LOP and do more like 10.5 or 11 GPH but my engine doesn't run well there. I've done a few 1,000 NM flights non-stop but don't like it and you shouldn't count on doing it reliably. The plane will do it with extended tanks but that's almost 6 hours in the air at 170 KTAS, no wind. I've only done it with a tailwind. A headwind can easily require a fuel stop. More importantly, when you go 1,000 NM, you will almost always encounter weather along the way, requiring detours or even sometimes that you stop and wait for it to clear. I believe a rocket may actually have worse endurance (range) due to it's higher fuel burn not being offset by its faster cruise speed. 1,000+ NM flights non-stop on a schedule is not a piston airplane mission. You need a jet.

-

I wouldn't do that. The guard is there because if you accidentally turn on the high boost pump when the engine-driven pump is functioning, it will flood the engine and the motor will stop. That's actually how you test to make sure the high boost function is working - you turn it on while the engine is running and the engine shuts off. Preferably on the ground.

-

This is how mine sits. It actually performs its function just fine, and you can still twist it out of the way if necessary to operate the switch. But it looks odd. Been thinking about going after it for a while. Concerned I'll break something without available replacement parts. If anyone has done the job before I'd be interested to know.

-

This poll needs an option for leaving the oil cap off after adding a quart.

-

Following. Mine looks just like that...

-

Minimum Cloud Ceiling to Launch VFR for Aerial IFR Pick Up (poll)

Z W replied to 201er's topic in General Mooney Talk

A tip that I didn't realize until I'd been flying IFR for a while - You can file IFR off any fix, not just an airport. So your flight plan can begin at a VOR, or anywhere else, and you pick it up from the nearest ARTCC frequency when you get there. Some possible use cases: Leaving Oshkosh this is recommended as you can't pick up IFR at the field. They give several recommended fixes to file from depending on your direction of travel. I should have done that this year and didn't, ended up having to call and get a pop-up clearance to get home when there were clouds where they weren't forecasted to be. Leaving a busy airport in VFR conditions, but headed into IFR conditions later in the flight. You can skip the "hold for release" delays and mandatory obstacle departure procedures you may not want to fly in clear weather. If you haven't experienced these, you will if you ever fly in Bravos, especially on the east coast, or in the mountains. Controllers seem to like it and will often let you skip the line and depart quickly VFR. Taking off somewhere where you want to do a scenic tour or circle around a bit, then head to your destination. Now with Starlink you can even file mid-flight off a fix somewhere along your route and pick it up when you get there. To answer the main question, I don't do much taking off in near-IMC conditions expecting to get a clearance. I'd much rather call ATC on my cell phone if I can't reach them on the radio and sit tight on the ground until cleared. Not much fun bouncing around below the clouds, staring at the ground not very far below you, looking for towers, and waiting for them to give you a clearance, while hoping no traffic comes along that you're supposed to see and avoid. -

When we updated from a JPI EDM 930 to a G500Txi for engine monitoring, pretty much all the CHTs, EGTs, and especially TIT readings changed significantly. Of note, the TITs read significantly higher at the same power settings, I think, anyways. Fuel flow changed from being displayed on a Shaden digital fuel flow display to also being shown on the G500Txi, and we kept the factory manifold pressure and RPM gauges, and they always read slightly different than the new digital display. So the power settings are likely not exactly the same. My take away is that we're trying to measure with a level of precision never available nor intended by the designers of our 40+ year old engines. I think the probes in each customized installation may be in a slightly different spot and may come from different manufacturers. I keep this in mind when comparing my engine's performance to photos posted on the internet by others. Useful to compare but your mileage may vary (literally).

-

KCPS is good but KSUS is pretty much the same distance/time to most of downtown, depending on where you're going, and factoring in traffic. Million air at KSUS is my usual pick. I'm usually coming from the west/southwest, so that's a factor. If you're coming from the east or southeast, KCPS might be overall quicker and easier.

-

First real annual / inspection post acquisition

Z W replied to SilentT's topic in Modern Mooney Discussion

I've had several large annuals. These are 40+ year old airplanes and things are in a constant state of wearing out and disassembling themselves. They take a lot of work to keep flying. Your estimate does not look unusual to me, but the good news is, it shouldn't be like that every year, hopefully. If the plane needs an upgrade I try to do it in years where the annual came back on the low side. If you find a shop that will actually list the squawks and offer to fix them for a reasonable shop rate, don't let that shop go, and don't nickel and dime them down on their bill. Too many shops don't do a thorough list, trying to keep costs down, and a few years later, you have airworthiness issues that put you out of service or put your safety at issue. Or you end up with a plane that needs so many things fixed it should be scrapped for salvage value. Finding a good A&P to work on the plane has become the biggest challenge in ownership for me. Nobody wants to work on Mooneys and they say the owners are all "cheap". This is a problem that starts with us. -

I've found Rustoleum high-gloss white paint, available at any hardware store, matches the white paint on my gear very well for touch-up purposes. I'd use a spray can for a larger surface like that. Multiple light coats. I wouldn't bother with more primer but maybe just a light scuff sanding on the green. Or, consider getting some paint stripper and removing the green primer, assuming the piece is aluminum and won't rust. You could use a magnet to check if you can't tell by its weight. A little polish would have a shiny wheel cover like you see on most Mooneys, if you don't want it white, or don't want paint that will get scratched and chipped. Those covers should come off pretty frequently to air up the tires and inspect the wheel bearings. A lot of wear and tear on a painted part.

-

Upper cowl machine screw issue on '83 J

Z W replied to 0TreeLemur's topic in Modern Mooney Discussion

I do the same but with Corrosion-X on most fasteners before they get re-installed somewhere exposed to the environment. Seems to give you a few more years before anything rusts or seizes in place. -

I believe removing the copilot seats, front and rear, might be easier than removing the right radio rack, depending on your panel setup. Makes it easy to lay on your back on the floor and reach the starter relay. Your legs can lay up into the rear of the plane where the rear seat goes. Not too bad under there that way.

-

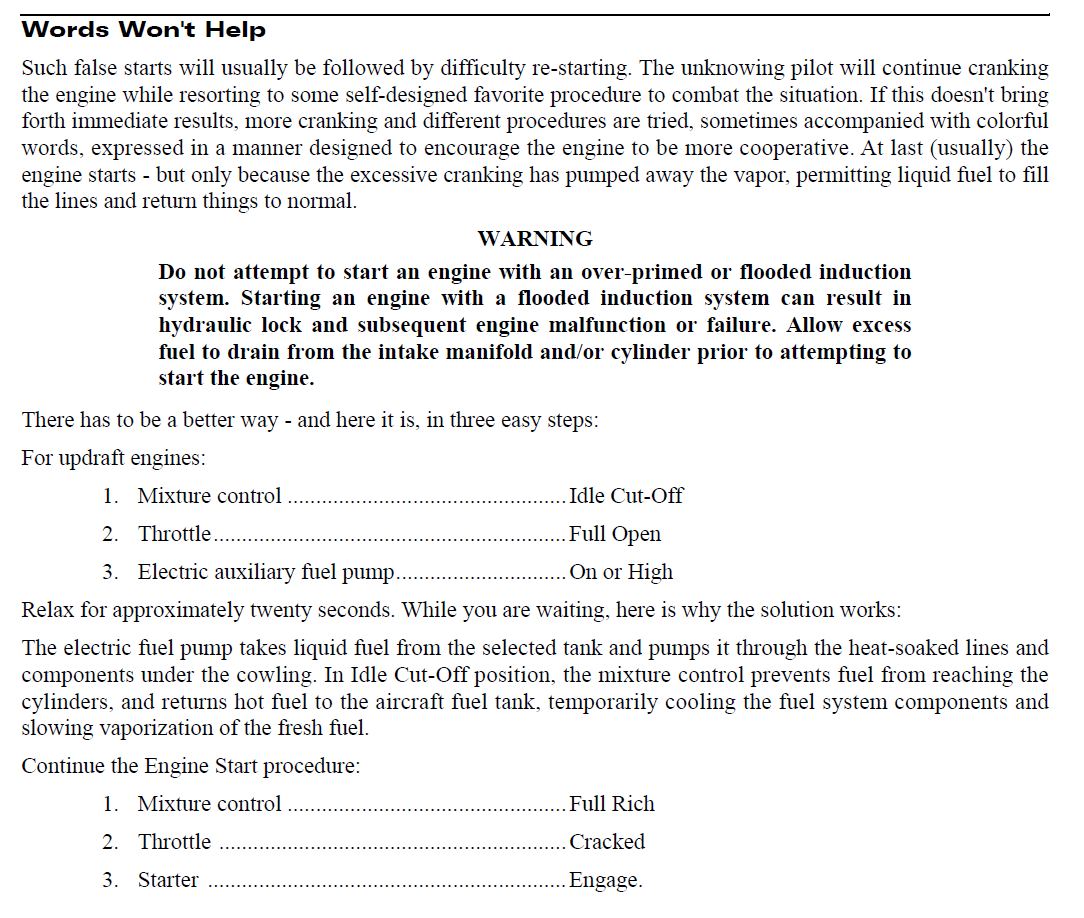

Here's how Continental says to do it, from their "Tips on Engine Care" publication. Works every time. Full documentation attached and worth the read. Lycoming people may have a different experience. Hot Start Procedures - Continental.pdf

-

In factory configuration, the avionics master is "on" by default meaning if its relay fails, the avionics stay on and won't turn off until the master goes off. When you flip the avionics master switch to off, the relay triggers and severs the connection to the avionics bus. You know the relay has failed when you try to power off the panel but it stays on until you turn the master off. If your avionics master relay in the tail fails, do your radios, flaps, lights, and gear continue to work? Or does your entire panel go dark? Where would you look to find the answer to the question, if you don't know?

-

If it were my plane, I would want that extra relay and 3-way avionics master switch removed and everything returned to stock configuration. There are reasons and failure mode considerations it's done the way it is, and what you are experiencing may be one of the reasons the factory didn't include the option to turn on the avionics with the master off in the first place.

-

Sounds like if your 3-way avionics master switch were to fail or have an internal short, it could be back-feeding power into your master relay or your panel, depending on how they wired it. You know something is back feeding power, and it would have to be either the fused line you sent a picture of, or your non-stock avionics master relay.

-

I have a similar inline fuse. In my plane, it connects directly to the main power line coming off the battery at the master relay, so it is always hot, and runs forward into the cabin. It therefore provides always-hot power to something in the cabin, though I never figured out exactly what, or if it's even still connected to anything. I would expect it to be something like a clock or cabin light that you would want powered with the master off. For what you describe, I am still suspicious of the mystery 3rd not-stock relay mounted to the aft of your battery without any terminal covers. Someone has done something non-standard with your wiring. Does that relay send any power thorough wires forward into the cockpit?

-

Every 10 minute job is one stripped screw or broken bolt away from becoming a 2-hour project.

-

My plane is sitting at KMKC right now. It's a great airport, easy access to downtown, Lyft and Uber work great. Easy to fly in under the Class B while VFR. The free transient parking is good as long as you have the time/desire to use the self-service fuel. You need the fuel receipt to get in and out of the city-owned terminal building and access the ramp. You have to self-fuel upon landing or you won't have the receipt to get back in, so leave extra time on your arrival. I've heard you can call the airport manager from a gate and get buzzed in, maybe, if you don't have the code, but I've never done that. Atlantic is very nice and accommodating next to the self-serve fuel, but they don't sell 100LL. They've let me walk through their lobby before and even arranged a rental car for me once. If you're short on time or prefer full service fuel, Signature is the only option. Their prices are usually high but the service is good and the people are nice.