-

Posts

1,205 -

Joined

-

Last visited

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Events

Store

Everything posted by Igor_U

-

I know that Regal aviation at KPAE is maintaining few Mooneys of various vintage, from classics to newer J and K. You want to speak with Brian...

-

Over the years few MSCs in WA closed. Command aviation at KNLI is now MSC but I have no experience with them. Where is the plane located and who is doing the annual? Good luck.

-

Summmer Leaning on Approach

Igor_U replied to Boilermonkey's topic in Vintage Mooneys (pre-J models)

We can always study this graph: -

I agree removing the old gages is a way to go. However, it took me as much time to remove the old stuff as to install a CGR-30 (primary) in my '67F with 201 windshield. There's just not much access there and many people underestimate labor needed to do that. BTW, you have very nice panel. Is that Garmin Avia 660 on top?

-

I agree with comments above but it might be difficult to convince your A&P... When I bought my M20F, it already had EI E4 installed in it in lieu of Alcor EGT.

-

Impressive! I've timed it 8 sec per 1000 giving 7500 fpm. I wish my plane can do that! It's true about twin design being overpowered. However I didn't have that feeling from 25C on AA's A321 on a my SEA-CLT commute run the other night. It took us (what it felt) a full runway to take off. Plane was full as always of self loading cargo...

-

Wow, Congrats! Engine sounds great and you cleaned it up well. Even your step retracts! Good luck with restoration.

-

No doubt MVP50 is better unit, with more features but price is higher then CGR30 and would require custom panel to fit it. I love my CGR30P but you'd need two for twin while I'm not sure about MVP as I looked only for my Mooney install. Keep in mind installing CGR30 would open many holes in your panel as it replaces primary instruments, so think about what to do with those.

-

Interesting list of upgrades! I’ve been there, in a past and I still have upgrades I need to do (panel, avionics) so I constantly make my own list… I’d be interested to know if everything will be done by a shop or you do owner assisted maintenance and annuals; that would reduce the cost help to do few things you might want to do. Here are my thoughts on upgrades and (maybe) the order you should do it: Headsets: my wife loves Quiet Halo’s; it doesn’t mess her hear, light weight and they have great noise reduction. Engine monitor: If you can do work yourself (I’ve installed mine), I would go with Primary instrument replacement like EI CGR30P (you’ll need fuel gages like Aerospace Logic) or JDP that many people love here. I chose EI as it fits into the 3-1/8” instrument hole, great support and price. This would delete bunch of old engine instruments out of the panel, the rotten oil and fuel pressure lines out of the cockpit etc; not to mention ability to monitor your engine health, fly LOP and so on. Go with one you like or has a rebate at the moment. Puck and tires: don’t do that before annual time. You can save money and do it when plane is already on jacks and would reduce downtime. I installed pucks myself during annual while I was practicing using neat hydraulic tool I’ve rented before my IA showed in my hangar. He was surprised how easy it was to use and so it once the plane is on the jacks and trailing links are off. Tool was rented from Hangar Tool box (or something) but I understand he’s out of business now. Door seal is easy and I believe can be done by owner. ADSB: Startus is a good choice. Is the price quoted ($3000 installed) correct? I see them for sale for $3000 and then there should be at least 10h of install labor. Interior: Not difficult to do using plastic paint system like SEM after you repair cracks in panels or replace some (Plane Plastic has them). I’ve wrapped mine in Ultraleather and replaced headliner as well. Everything really started with getting 201 side windows before the paint job… long story $$$. You could replace Aluminum panel with new one if you go with primary engine monitor. It is a lot of labor but could be done. Another option is to remove the existing panel(s) and refinish it if you are not changing arrangement and instruments. I would classify above upgrades as less expensive ones and something that could be done over a year or two especially if you’d do some work yourself. Paint job and new avionics would be much more expensive then list above. Do your research. Depending where you live, flying few states out can reduce the cost significantly. At the time I’ve done mine (11y ago!) great shop at my field wanted stupid money as they were busy with FedEx Caravans and new Kodiaks. I found a great shop in NV and saved 35-40%. Good luck.

-

Joe, Galvin flying at KBFI had a Mooney instructor years ago who owned a M20E. These days they have M20J for rent so must have instructors as well.

-

I plan to fly there.

-

Yes, I saw that: Article is saying "whether your ASI in in knots or mph, it's a good bet that your best speed ins 80 on final, at least until you get over fence" Definitely, oversimplification in my book but good rule of thumb for my F model (ASI in mph and 80 mph = 70kt ) and long body that ASI is in kt. You're doing it successfully for 40 years so I wouldn't change that!

-

12-13 years ago I had the same dilemma, living downtown and looking for hangar for my M20F. Nothing much changed except the prices want up; so are the waiting lists. I was based at KBFI (tie down by museum) and you could not find hangars there; those are just not available. KRTN: I was put on a waiting list and was number 50. after 3-4 years, I called them just for laughs and was #48. After 12 years, I'm still waiting! S43: I see you fly Acclaim; you don't want to be based there. Short, narrow runway with no approaches. They have open hangars and closed ones but it took then 1 year to return my call and offer open hangar. I'm not kidding! S50: If you live downtown, it's long commute but I believe hangars could be found. I remember, at that time, new Mooney salesmen rented a large box hangar (50x50) with not much waiting time. KPLU: in order to get there, I fly my Mooney. No-go if you live downtown/South LU. KPAE is where I'm based since 2006 with moving into hangar at 2009. Great airport with approaches and service and for 12 years I worked across the street (BA), and would fly to Jeffco for lunch. All T hangars are enclosed. I pay $310 for older one and newer are $480 ( $715 above is not correct). New hangars allow for more advanced repairs and maintenance. These units also have approximately 20-amps of individually metered power Waiting list is longer for older hangars (3y for me) and at one point newer hangars almost had no waiting list. Now? who knows! At this point a new terminal building is getting built and commercial traffic will be flying in mid 2019 (Alaska and Allegiant airlines). What will that do to prices and ramp access is your guess. Traffic got progressively worse in last 13 years but leaving downtown in the morning you are driving against the traffic - I never had issue with that working at KPAE. Coming back in the evenings can be pain even on weekends. And finally South Lake Union: in last few years there were number of high rise rentals built there and I've read that for the first time in years rental prices are going down this year. Number of those buildings close to Amazon and MS offices are empty so companies give incentives. It's still expensive, though. You are moving up at the right time of the year with great weather and scenery to boot but come October you'll have a lot of opportunity to practice your instrument approaches for real. Welcome!

-

I was looking at it but replacing all the lights with LEDs can add up to significant amount. I see some people did it but a lot with older vintage Mooneys still have incandescent lights as owners can’t justify expense on older airframes. When I bought it, my 67F had two landing 100W lights as a result of oil cooler relocation and after a couple of failed landing lights I installed a pair of automotive H3 lights (100W each). I wonder if anyone has this installed on their plane? Is it still available? I have this Stan Prodigal (sp?) STC installed for over 10 years now with no light bulb failure and I’m quite happy with it; however current draw is still the same as before hence my interest in LED landing light installation. Regards,

-

This looks like you replaced LED light bulb only, correct?

-

Starboard is Right side and Port is left. Remember this: Sailor left red port wine on the deck.

-

Manually retracting electric gear

Igor_U replied to Dream to fly's topic in Vintage Mooneys (pre-J models)

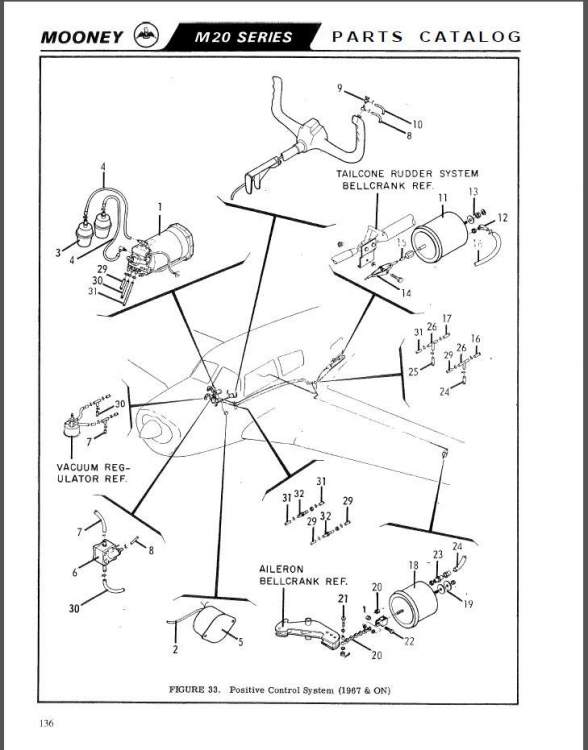

Robert, I agree wit this. What the picture shows (and what designer intention was) is to use AN960-616 washers as a "shim remaining space" on both sides of the spherical ball bearing. Note on picture, by design, calls for centering the ball joint to allow maximum rotation as you mentioned. Using washers is simple way to prevent bending of the clevis (sides of the bellcrank) when you torque the bolt to the spec. There are other ways to do that, notably with shoulder bushings in the clevis and sliding bushing that clamps the rod end with ball joint to one side but doesn't lad the clevis sides; these are more expensive and bulkier (heavier) and used on bigger Part 25 planes. -

I don't know. But question I have is: How much speed gain did you get?

-

Speeds quoted for M20E/F seem inflated. I believe I've seen lower numbers quoted by the owners on Mooney list or here. I hope will see some PIREPS soon.

- 27 replies

-

- mooney

- mooney m20c turbo

-

(and 1 more)

Tagged with:

-

your '67F does not have gyro system under the panel like older models. It should have Brittain TC100 Turn Coordinator in the panel. No. 1 in picture below. Are you talking about Main Landing Gear? Both gears should be perpendicular to the ground but due to wing dihedral, it looks like those are canted in.

-

fix my PC system and upgrade to auto pilot?

Igor_U replied to bavareze's topic in Vintage Mooneys (pre-J models)

System is very simple and easy to understand if you have schematics and service manual. Problem is parts, now that Brittain is out of business but I was told they are still looking at providing some service in a future. We'll see. I've contacted them a month or so ago to buy spare rubber kits for servo and then was told all parts are in the warehouse after the liquidation of the company. One issue you might have is non functioning gyro and that could be sent out for rebuild. Also you could have a simple leak in the tubing which is easy to replace. You might want to contact LASAR to see if they have any parts for servos or other replacement parts. Cost of repairing PC system could be minimal and well worth it as system runs well, at leas in my plane. Good luck. -

Yeah, I was looking at that as well. $115each is stupid for a light bulb but in a grand scheme of things drop in a bucket. I should be replacing them at my next annual.

-

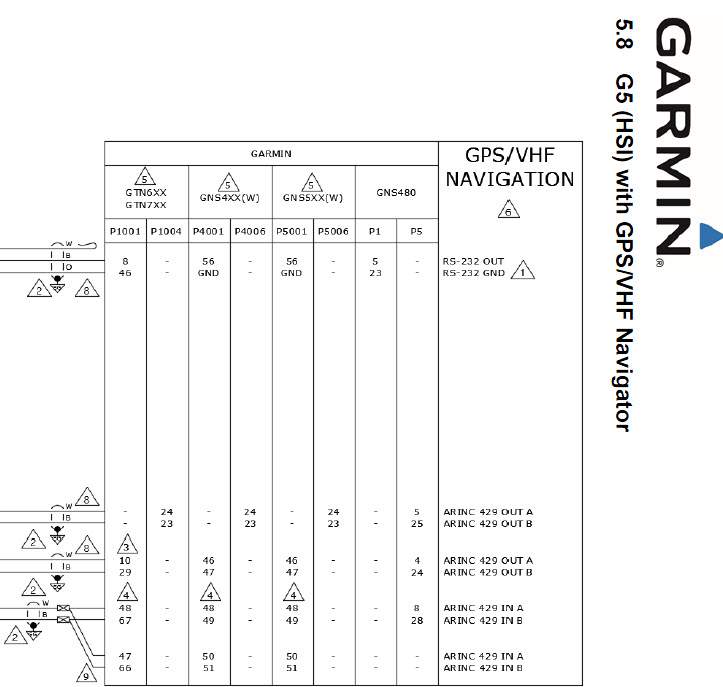

No, you are OK. above statement is not true. As per G5 Install manual, all Garmin GTN and GPS Navigators are capable connecting to G5 HSI.

-

Paul, does your IPC call for position light bulbs? Mine doesn't ('67F). It calls for Position, Light p/n 800223 and -501 (Green) with not mentioning light bulbs at all. How would you all proceed in this case? Thank you.

-

Anyone work with aluminum round rod?

Igor_U replied to Dream to fly's topic in Miscellaneous Aviation Talk

AL alloy 6061 is used for welding assemblies. Mainly heat treated to condition T46 or T62. You can find it easy as sheet metal but I see them in bars or extrusions. Not sure if that's easy to get on open market, though. I admire your intentions but I'd find a replacement, if possible. never had issue on my '67F ... Good luck