1980Mooney

Basic Member-

Posts

3,142 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Blogs

Gallery

Downloads

Media Demo

Events

Everything posted by 1980Mooney

-

You are correct. Since 1979 they have used the same bearing on all Mooneys. I use LP2 which doesn't seem to attract as much dust but I have it in a hangar - might be worse tied down.

-

I replaced my eyeball sleeve bearing while everything was assembled a few years ago for the same reason as mentioned by the OP. The wires have to be cut, the yoke handle pulled, the wires pulled out of the shaft with a string in place to pull them back in, the linkage disconnected at the firewall and the shaft then pulled towards the firewall to clear it from the instrument panel frame (either out of the bearing or unscrew the bearing cap and pull it all out together). The yoke shaft (control shaft) has a welded bracket on the firewall side which necessitates pulling it out towards the firewall. (see pic) Reassembly is the reverse. It is easiest if your remove the pilot seat. It is tedious but not difficult. While under there lubricate all the linkage points and check for play.

-

You just made the point that they should have widened the fuselage while they were at it. They had to go through all the structural substantiation of the "cage" regardless. They probably did 60%-70% of the work. They drained their finances on the failed trainer M10T - what they did with the Ultra was "penny wise and dollar foolish". A small incremental investment of time and money in the Ultra would have yielded a bigger return. Instead, we have the remnants of a company that will likely never build another plane.

-

262 was from Mod Works 261 was from Mod Squad https://books.google.com/books?id=eK-0kCuwKz8C&pg=PA90&dq=mooney+m20k+Flying+Magazine+252+modworks+conversion&hl=en&sa=X&ved=2ahUKEwj6hZi7nJH2AhXzm2oFHQiRDqkQ6AF6BAgCEAI#v=onepage&q=mooney m20k Flying Magazine 252 modworks conversion&f=false

-

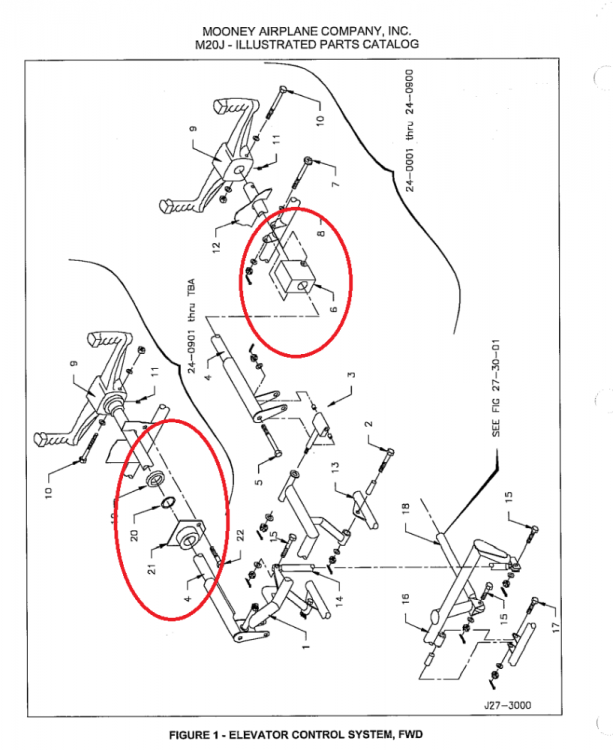

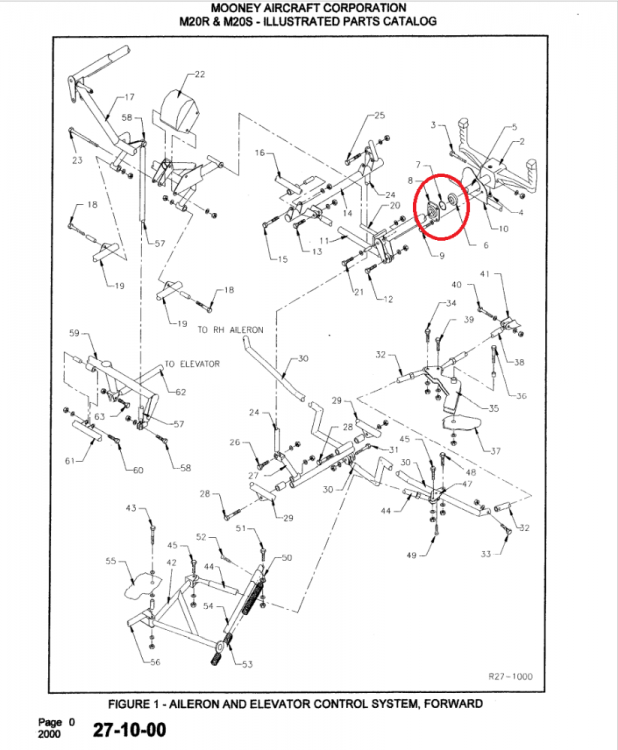

@Danb Mooney has been using the same "eyeball" or "donut" bearing on the same yoke shaft since 1977 on J through Ultra. Parts diagram is from an Ovation. (see pic below of Ultra assembly) I think it is a sintered bronze Oilite sleeve bearing. Make sure that your yoke shaft is smooth - no imperfections or corrosion. To replace the sleeve bearing you have to remove control handle, disconnect the shaft and carefully remove the wiring on one end.(radio tap to talk switch, pitch controls, etc) in order to get the old bearing off and the new one on.

-

All that engineering and they didn't bother to widen the cabin a couple inches. What a waste. So what if they sacrificed one or two knots. They truly did not understand marketing or what the paying market wants (in addition to Useful Load)

-

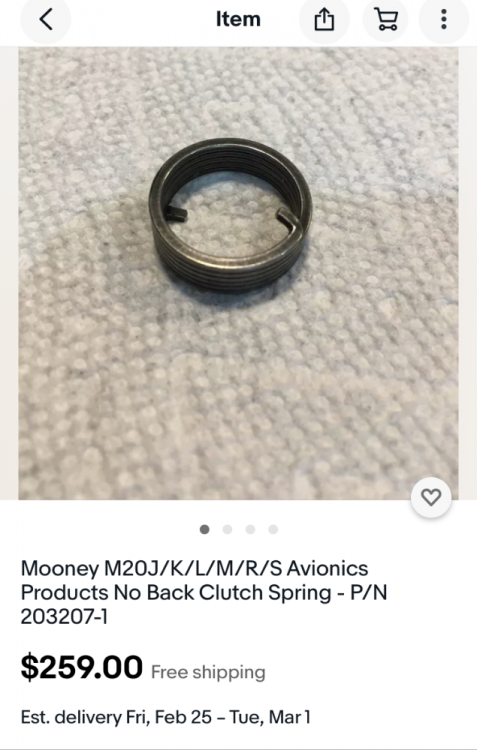

Anyone have a used out of spec no back spring I can buy?

1980Mooney replied to philip_g's topic in Modern Mooney Discussion

Exactly - it is in fact used and advertised in such condition (either salvaged or a replaced spring). At the beginning of this topic the OP said he just wants an old used one to get the dimensions and reverse engineer it by a supplier in Japan. As said above, an owner might be able to make a replacement spring that looks like it fits and actually works.....for a while! Without testing no-one will know the actual life of the "new" OPP spring. For all anyone knows, the new OPP spring might have a shorter life than the original. The irony is that the owner might go to all this work only to have the spring fail sooner than if he had never touched the original at all. -

Anyone have a used out of spec no back spring I can buy?

1980Mooney replied to philip_g's topic in Modern Mooney Discussion

There has been a used one for sale on eBay for a while. Mooney M20J/K/L/M/R/S Avionics Products No Back Clutch Spring - P/N 203207-1 $259. It’s Avionics Products - isn’t that what you want? If so surprised you haven’t started there -

We need to add a few more wide bodies Pipistrel Panthera 47 inches Diamond DA50RG 53 inches And narrow Narrow Piper Comanche 45 inches Diamond DA40 44 inches I doubt anyone is going to bring a clean sheet new design to market that is less than 47 inches cabin width - preferably wider.

-

Anyone have a used out of spec no back spring I can buy?

1980Mooney replied to philip_g's topic in Modern Mooney Discussion

"still technically in business".... It is a company carrying the overhead cost and liability of an "airplane manufacturing company" that is only a "parts company". All the fancy titles and cost for the executives, the liability for everything manufactured in the last 18 years (regardless of past bankruptcies), the Engineering Dept that is working on what??- it is not sustainable with the few $millions from part sales. -

Anyone have a used out of spec no back spring I can buy?

1980Mooney replied to philip_g's topic in Modern Mooney Discussion

Oh so you have some deep seated hatred of Canadians? -

Anyone have a used out of spec no back spring I can buy?

1980Mooney replied to philip_g's topic in Modern Mooney Discussion

The one person in the world that has what you desperately need, literally the ONE PERSON IN THE WORLD, and you still belittle and insult him - again, as usual, continually... What did he do to you?....insult your plane?, kick your dog?, sleep with your wife? -

No Back Spring for GEC Plessey actuator in ‘85 M20J

1980Mooney replied to spayne59's topic in Modern Mooney Discussion

This may help. There were several manufacturers of electric https://www.knr-inc.com/25-shoptalk/30-200107-emergency-gear-extension-systems -

No Back Spring for GEC Plessey actuator in ‘85 M20J

1980Mooney replied to spayne59's topic in Modern Mooney Discussion

Another way to to describe it is it keeps the gear up once retracted. From MooneyFlyer: page 17 https://themooneyflyer.com/issues/2017-AugTMF.pdf ”The No-Back Clutch Spring These newer models have a common problem with the no-back clutch spring, which is recommended to be changed every 1,000 hours of aircraft time. A no-back clutch spring is what keeps the gear up when retracted. It keeps the gear from unwinding after the gear up switch shuts off the power. I have dealt with planes that have a broken no-back clutch spring. Most of these had Plessey actuators, which were used in the late 90s. These use a slightly different spring from all other actuators. The Plesseys are now obsolete and their no-back clutch springs are not available. A later problem we have found on the Eaton actuators is chipping of the jack screw. While difficult, I have been able to buy a new jack screw. I don't know current prices, but I do know that a new actuator is well over $10,000. If the no-back clutch spring breaks while retracting the gear, the gear will not go down for landing. If it breaks during extension, the gear will go down, and probably hold the gear down. You probably won't know that the no-back clutch spring is broken until the next flight when the gear won't retract. The main defect in this gear system is that the emergency extension depends on an intact no-back clutch spring. Another problem with the newer actuators is the wear on the emergency extension cable. It is Teflon coated and the Teflon can tear and peel loose and that loose Teflon can actually jam the actuator. It actually happened during a practice emergency landing gear extension.” -

Anyone have a used out of spec no back spring I can buy?

1980Mooney replied to philip_g's topic in Modern Mooney Discussion

Not surprising since they are still trying to peddle what is left of the company on the business broker of last recourse - BizQuest - the "Craigslist" of business sale sites. Legendary Aircraft Manufacturer | For Sale in Kerrville, Texas | BizQuest.com I think the items on the top of Jonny Pollack's priority list is his real full-time job at Elliott Management. -

And expensive. Only Mooney sells that. I had to replace one about 8 years ago due to corrosion. And even more if breaks…the gear will collapse.

-

Who locks their controls like this?

1980Mooney replied to Derrickearly's topic in Vintage Mooneys (pre-J models)

Same here. 23 years with the copilot belt around on side of the yoke. No problems. No way to forget. Keep it simple. -

Also affecting it is the flow through the cylinder head, how the burn front propagates, hot spots in the cylinder head, spots of higher pressure in the head due to air/fuel mass flow momentum, how and where detonation (knock) starts, how the detonation shock wave propagates etc. It is a dynamic process in which not everything happens uniformly - like watching a creek or river, the water does not flow evenly - eddy currents appear. And although it is a vapor, there is still a momentum influence as the air/fuel mixture flow is started and stopped violently with each valve closing and opening - this creates additional dynamics of pressure and temperature that may not be instantaneously uniform. Safe operating ranges/conditions and the point of detonation knock are not all predicable without testing.

-

Interestingly here is a parallel current discussion on pre-J Mooney's landing gear. The gear is basically the same.

-

I agree with @PT20J and @EricJ but I WOULD NOT FLY THE PLANE. THERE IS NO NORMAL WAY THAT THE RETRACTION TUBE SHOULD BE ABLE TO CONTACT THE MAIN GEAR ASSEMBLY. Something is seriously wrong. I would fear a main gear collapse which would be incredibly expensive. The geometric arc of the swing of the main landing gear assembly (2 below in yellow diamond) and the movement of the retraction tube truss holding the retraction tube (16 below in green box) is defined, fixed and should remain stable and repeatable through its operation and life. @1964-M20E is right - It does not vary with shock disk load or compression and has nothing to do with the shock dics. (see the first video below - no way should it contact). I would jack it up and conduct a retraction test carefully looking at the reason for contact.( Like in second video.) I am not an A&P but have worked on my plane a lot over 23 years. The main gear assembly (2 in yellow diamond) is a solid fixture. You are contacting at the point of the red circle. Compression of the shock disks has nothing to do with the geometry of the main gear assembly. The only way it could contact is if The main gear assembly (2 yellow diamond) is bent or flexing because of a broken weld or corrosion. The main gear assembly brackets (4, 6 and on the other end purple pentagon) are broken, loose or excessively worn allowing the main gear assembly to shift. The retraction truss (green box) is cracked or broken and flexing towards the landing gear as pressure is applied in the retracted position. The bushing in the hinge of the retraction truss is missing (on bolt 19 in blue star - part number 914020-143) allowing it to twist and flex toward the landing gear as pressure is applied in the retracted position. The bolt holding the retraction truss or threaded backer (19 in green box) is loose, cracked, or bent allowing it to flex toward the landing gear as pressure is applied in the retracted position. Do you have a parts manual and also a service manual? Also look at these 2 Mooney gear retraction videos. The first one clearly shows your gear retraction geometry. Also this video shows it but not as clearly. Mooney M20J 201 Gear Swing and Emergency Retraction Test - YouTube

-

It is absolutely the reason. https://www.theglobeandmail.com/canada/article-737-max-report-calls-for-overhaul-of-canadas-process-for-approving/ Technically and politically it gave credibility to all the the Canadian interests that have long said Canada should be more independent and rely less on the US in general and FAA in particular. It was an easy political win for those with nationalist sentiment. Yes it probably probably increases the workload at TC (and it increases regulation, cost, manpower, needed budget and delays)

-

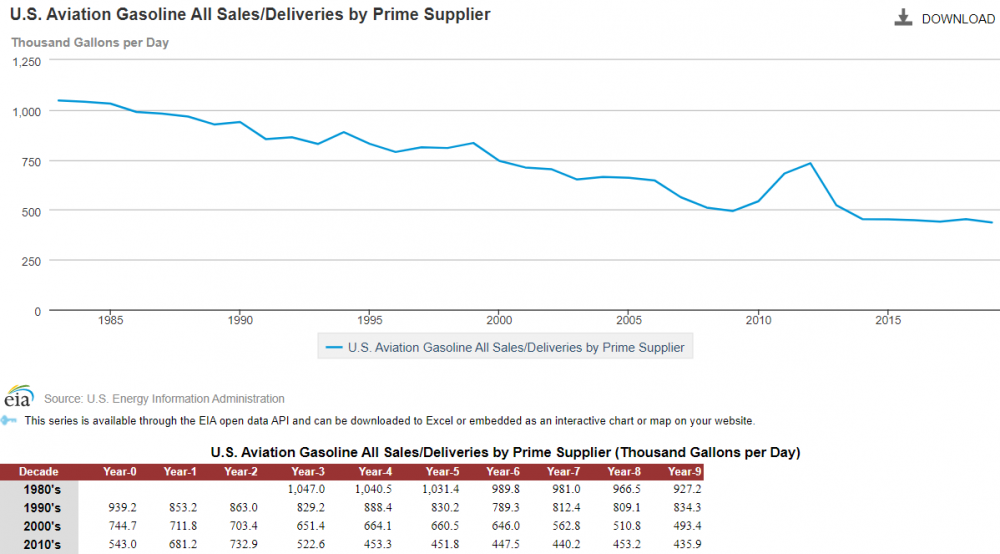

It is one thing to attract manufacturers/suppliers to a growing market. It is another to attract them to a declining/flat market. And just where is the competition? - most airports have one supplier - there is no option of pulling up to multiple pumps or having multiple trucks compete for your business. Look at the declining sales: Who wants to make an investment just to compete for declining sales? Before you think those look like big numbers, that is only about 9,000 gallons per day per state. That is about half the size of the average backyard in ground swimming pool. You can fill that with a garden hose over the course of a day. Volumes are so small that it will probably still have to be trucked around the country. A large tank truck holds 11,600 gallons - that would only be 37 truck loads per day. Automotive gasoline sales by contrast are about 900 times more than aviation gasoline sales. Said another way, in one day the amount of automotive gasoline sold is 2.5 times the amount of aviation gasoline sold in an entire year. We don't know the formulation of G100UL but the low volumes might not support more than one manufacturer in order to create some economies of scale. I think we are going to be in for sticker shock.

-

A few years ago an Aspen 1000 or 2000 was a natural recommendation. However a lot has changed. The Garmin offering has become broader and more capable as has Dynon Certified. Based on the majority of comments in this topic and elsewhere in MS as well as on Beechtalk and Pilots of America most seem to be recommending full Garmin (especially if a new autopilot is part of the install) and Dynon. Aspen was advanced for its time but in the ensuing 15 years has only added a faster processor and brighter screen. Here is a topic by a K owner discussing the same issue that you raise. He has Aspen and Century 41 AP. Everyone seems to be holding off on upgrading, adding a new or another Aspen - the Garmin GFC500 autopilot won't work with it. Replacement Autopilot - Modern Mooney Discussion - Mooneyspace.com - A community for Mooney aircraft owners and enthusiasts I think Garmin and Dynon will put Aspen out of business other than repair of existing units.

-

After cleaning the rollers you need to lubricate the bearing. I clean the roller with alcohol. I use LPS2 to lube the bearing.